- Home

- Aerospace

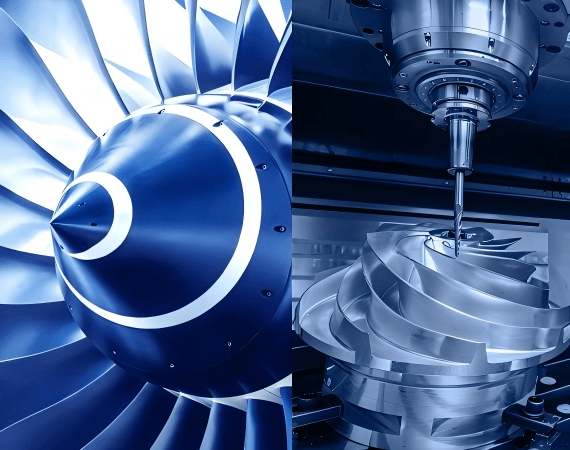

High Precision Aerospace Parts Manufacturing

DEK has specialized in precision manufacturing of aerospace parts for 20 years, you can get high quality custom aerospace precision parts here. We can quickly turn around complex parts with tight tolerances up to +/- 0.005mm, a wide range of production grade aerospace materials, and surface finishing options. ISO 9001:2015, AS9100D certified and ITAR Registered.

- Competitive Prices & DFM

- 24/7 Engineering Support

- Quick Turn, Short Lead Time, not MOQ

- 20+ Years Aerospace Parts Manufacturing Expertise

Specializing in Manufacturing Precision Aerospace Components

At DEK, we have strong manufacturing capabilities, including CNC machining, sheet metal fabrication, 3D printing, injection molding, etc.. With professional and rich experience in manufacturing aerospace components, we have provided excellent services to more than 20 European and American customers including JCB, and achieved 98% on-time delivery rate.

We offer a diverse range of aerospace materials, including aluminum, titanium, magnesium, stainless steel, Inconel etc. In addition, we offer post-processing options such as anodizing, passivization, electroplating, powder coating, black oxide and heat treatment to enhance the appearance of parts as well as corrosion, wear, and heat resistance in high-stress and harsh environments to meet the stringent requirements of high-performance aerospace components.

Examples of our success include: actuator components, panel components, aerospace fasteners, structural parts and aircraft seat components. DEK has no minimum order quantity, and our parts are rigorously inspected for quality through CMM, hardness tester, surface profiler, and other precision metrology to ensure that they meet industry standards. Our prices are favorable for small and large quantities, and you have the flexibility to purchase in batches, so contact us today for a quote!

Custom Aircraft Component

Actuator Components

Aerospace Components

Millimeter Wave Receiving Module

Aerospace Turned Parts

Tray Table Assembly

Aerospace Component Manufacturing Capabilities

Precision CNC Machining

DEK has an advanced CNC machine shop with 3-axis, 4-axis, 5-axis, turning, precision grinding, EDM machining and more. DEK offers a wide variety of metals and plastics including aluminum, titanium, stainless steel, Inconel, brass, PA, PEEK, PTFE, and other product grade materials.

DEK's production and engineering teams are experienced in handling difficult-to-machine materials such as titanium and high-temperature alloys, and specialize in machining aircraft components with complex geometries. We perform stringent quality control on aerospace components, including the use of CMM, optical measuring instruments, height gauges, hardness tester, roughness tester and other testing equipment, to ensure that the aviation parts or prototypes produced meet ISO standards.

Sheet Metal Fabrication

DEK provides reliable aerospace sheet metal prototyping and custom parts manufacturing services, focusing on the ability to deliver consistent and repeatable parts quickly. Some of our success stories include main rotor pylon parts, aircraft tail sections, panels, switch brackets, seats, drone parts and enclosures.

We have a wide selection of metal materials including stainless steel, aluminum, titanium and brass. In addition, we can provide a variety of surface treatments such as electroplating, anodizing, polishing, etc. to improve the corrosion resistance and aesthetics of aviation parts. Meanwhile, we can also provide laser cutting and engraving services to improve the accuracy of the parts.

Industrial 3D Printing

DEK's 3D printing services can create very strong, lightweight aerospace structural parts that help extend the life of aircraft components. We have flexible production lines to manufacture your aerospace 3D printed parts on demand for fast delivery.

We offer specialized materials for processing in the aerospace industry to meet the needs of different customers. Through advanced additive manufacturing technologies, we can achieve complex geometries, reduce costs, and customize the aerospace precision parts you need. We streamline production processes, manufacture flexibly, and offer price advantages in aerospace prototyping and low-volume part production. Our ability to manufacture more efficient engines, turbines and lightweight interior parts reduces aircraft fuel consumption and provides practical solutions for aerospace applications.

Injection Molding

At DEK, we specialize in manufacturing aerospace custom parts through our proven injection molding capabilities, including plastic injection molding, overmolding and insert molding. We use a variety of engineered plastics including PA, PC, PTFE, PEEK, PU, etc. to ensure compliance with stringent safety and usability standards.

Our injection molding process is ideally suited for both low- and high-volume production of aerospace parts, allowing for design flexibility and process repeatability for consistent production of high-quality injection molded parts. Additionally, our tolerance accuracy of +/-0.01mm allows us to offer a wide variety of surface finishes to produce parts with high strength and durability.

Die Casting

DEK specializes in the production of high-quality, low-cost die-cast components, and we are a top manufacturer of aerospace precision components. In recent years, we have continuously improved our die casting technology and have excellent machining capabilities especially in aluminum aircraft and spacecraft components.

Our die-cast parts have excellent surface finish and tight tolerance up to 0.005mm, which can satisfy the manufacturing of various sizes and complex parts, and meet the special requirements specified by customers. We have flexible production lines for rapid prototyping and cost-effective production.

Materials

Materials Options

Aluminum

At DEK, we specialize in machining aerospace-grade aluminum materials, mainly including Aluminum 2024, Aluminum 6061 and Aluminum 7075. We manufacture aluminum aerospace parts such as wing structure and support parts, landing gear parts, aircraft connecting parts, fuselage parts, interior parts and others.

Titanium

At DEK, we use grade 1 titanium, grade 2 titanium, grade 5 titanium and grade 23 titanium as the primary materials for aerospace parts. Our superb 5-axis machining produces high-precision aerospace structural components, turbine blades, turbine disks, landing gears, aircraft connectors and medical aerospace components.

Magnesium

At DEK, we offer a wide range of magnesium alloys, including AZ91D, AM60B, ZK60A and more. Our aerospace magnesium components offer excellent results in terms of high performance and weight reduction. Successful examples include seat structural parts,instrument display panels,jet engine fan frames and engine thrust reversers

Stainless Steel

Inconel

Inconel is the material of choice for extremely high temperature applications in the aerospace industry, and at DEK, we primarily use Inconel 718, Inconel 625 and Inconel 600 for machining aerospace components, including exhaust system parts, turbine blades, turbine disks, high-temperature fasteners, and high-pressure compressor parts.

Brass

Brass has unique engineering properties to meet the demands of aerospace applications.Its excellent corrosion and wear resistance makes it an excellent material for aerospace instrumentation parts, electrical connectors, interior parts and millimeter wave receiving modules.

Instant & Accurate Quotes

We don't use online automated quotation tools, because it is very inaccurate. Online quote platforms rely solely on calculations based on cutting amounts and fixed coefficients, they fail to account for actual processing nuances, such as material deformation after heat treatment, tight tolerance requirements, grinding after heat treatment, etc. Consequently, automated price calculations can lead to inaccuracies, ultimately increasing your costs.

But you can rest assured at DEK!

Our quotations are both cost-effective and accurate because we have a team of professional mechanical engineers who meticulously review each drawing. These engineers boast over 10 years of experience and possess deep expertise in programming, machine operation, post-processing, material properties, and more. Ensure you will get accurate quotes within 6 hours.

Why Choose Our Services

One-stop production of high-quality parts saves you time and money.

Engineering Capabilities

Fast Lead Time

Surface Finishes

Quality Control

Precision Assembly

Packaging and Shipping

Our Ordering Process

Send RFQ

Send RFQ with 2D/3D drawings and detailed requirements via Email or online form.

Review & Quote

Our Engineer team will review every drawing carefully and provide an accurate quote within 6 hours.

Confirm Order

Confirm the quote, details and delivery schedule, then sign the contract.

Production

Arrange production process, start programming and machining.

Quality Control

Strict quality control during production and final inspection.

Packaging & Shipping

Pack the parts, attach part identification labels, and start shipping.