Premium Rapid Prototyping Services

Through efficient production and extensive processing capabilities, we provide rapid prototyping services for many industries around the world. We make designers and engineers arrive in CAD to life within 2-3 days.

Rapid Prototyping Services, One-Stop & On-Demand

DEK is a leading prototype manufacturer in the world, since its establishment, we were committed to providing customers with high-quality, fast turn, and affordable prototypes.

From the initial manual model and machined model to the current 3D printing, we never stop developing and have been keeping up with the development of technology, so as to provide customers with more advantageous solutions. This is why we have been leading the China prototype industry.

Whether metal or plastic products, you will get an ideal solution through our diversified processing technology and comprehensive surface finishing technology, as fast as 2-3 days.

Diversified Rapid Prototyping Processes

We have a variety of equipment and corresponding technologies, these ensure we can offer the best solution for your unique prototype.

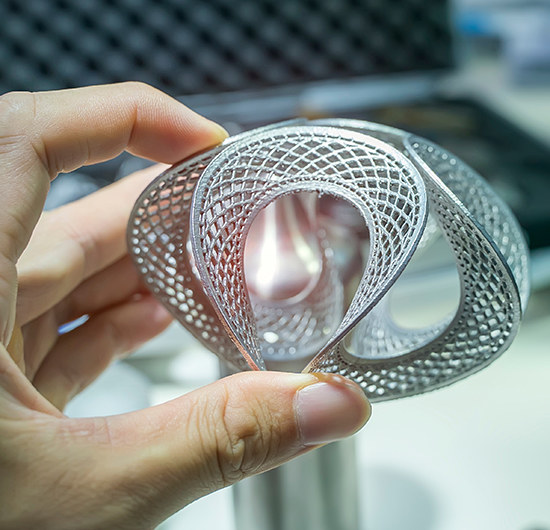

3D Printing

3D Printing

CNC Machining

CNC Machining

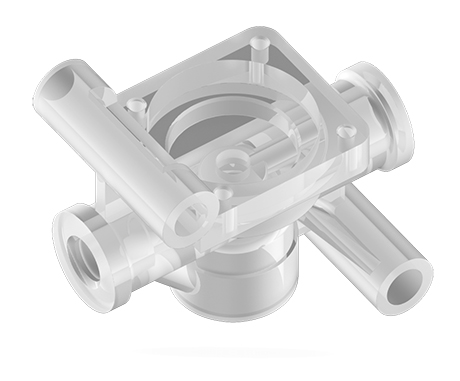

Vacuum Casting

Vacuum Casting

Freely Choose a Variety of Materials

We have a variety of equipment and corresponding technologies, these ensure we can offer the best solution for your unique prototype.

Plastic

Different plastic materials will bring different properties, you can choose various plastic here, whether it is common or unpopular used types, including: PP, ABS, PC, POM, acrylic, PVC, PTE, PEEK, etc.

Metal

Different metals have different colors, hardness, physical properties, and chemical properties. You can choose various metal materials here according to different application scenarios, including stainless steel, copper, brass, aluminum, Titanium, etc.

Why DEK is Your Best Rapid Prototyping Partner?

We have made more than 12M piece of prototype for global clients, below are the main reasons why they choose DEK’s rapid prototyping services.

Various Capabilities

We have strong and diverse processing capabilities, including 3D Printing, CNC machining, injection molding, die casting, vacuum casting, stamping, metal sheet fabrication, etc, which allow us can make an ideal production plan for you.

Various Materials

Whether it is plastic or metal, we have a variety of different materials for you to choose, to meet the needs of different projects. At the same time, we can also give material suggestions based on application scenarios.

Rich Experience

Design, sales, production, QC, packaging, we have hired experienced employees for each position, and each link is in place, which makes our technology always at the forefront of the Chinese rapid prototype industry.

One Stop Solution

In addition to a wide range of machining and manufacturing capabilities, we can handle more than 10 types of mainstream surface treatment. Through our one-stop service, you can save money, time, and energy.

Cost-effective

By improving production efficiency, reducing aimless work, combined with the preferential treatment of bulk purchase of raw materials, our overall price can save you 30% - 50% of the cost.

Faster Lead Time

DEK has a mature production process and a complete KPI production assessment system, which enables us to quick delivery. At the same time, we have a large amount of raw material inventory, which makes our delivery time 30% faster than other companies.

Unhindered Communication

We have eliminated language and cultural barriers. You can seamlessly communicate with our sales via email and telephone. At the same time, sales will clearly transfer your requests to the technology and production teams, ensuring that the final product fully meets your needs.

Worry-free

DEK has a complete customer service system and KPI system, and all work follows the principle of "Customer is King". Active pre-sales and after-sales, regular updates of production trends, we do everything to let you worry-free.

Recent Projects & Reviews

In February 2020, because most of the temperature guns were sold out, our company decided to develop a new type as quickly as possible and put it into mass production.

We found DEK to help us produce functional prototypes for testing. They only took 2 days to complete the production of all parts, which made our project lead time short 30%. The prototypes are very qualified, after the functional tests, we immediately let DEK team manufacturing the plastic mold and injection production.

– Mr.Liu, Engineer at Midea Group

This is our new PC keyboard with an aluminum keyboard case. Because it is a new design, we entrusted DEK company to help produce 20 prototypes for display at the exhibition.

DEK has very professional machining engineers who helped us optimize the design and successfully produced high-quality keyboards. A great cooperation experience!

– Mr.Huang, Owner of Shenzhen XM electronic co., ltd

We are a startup technology company. When we finished the design of this service robot, what we were most worried about was that the actual product produced could not meet expectations, so we found the most reliable prototype manufacturer to produce it.

Thanks to the DEK team for their efforts for us. Unlike other suppliers, they also made unique insights and recommendations on the materials of the robot. After 3 months of proofing and testing back and forth, the final prototype was finally successful. Happily, this robot was recognized by many well-known companies around the world, including SoftBank.

– Dr.Zhang, CEO of KS robot

F.A.Q

How To Order?

Send Inquiry

Send your 2D/3D CAD drawings and requestions via the Online Form or email

Confirm Order

Receive our quotation within 4 hours, and then confirm the order to us.

Start Production

After confirming the order, we will arrange the production immediately.

Looking For Premium Rapid Prototyping Services?

We have successfully provided high-quality prototypes to more than 2,300 customers worldwide, let’s make your great product!

Guide To Rapid Prototype & Buying F.A.Q

Although the rapid prototype has existed in many industries for countless years, most people still don’t understand what is it, classification, manufacturing process, etc.

So we have written a FAQ guide for you to understand more deeply.

1. What is a prototype?

After completing the design drawings, the one thing engineers and designers want to do most is what is the actual product of their design? Does the appearance match their design ideas? Is the structural design reasonable? and many more.

A prototype model can help engineers or designers to check the rationality of the appearance or structure. At this time, the rapid prototype is an ideal solution, because it saves time and costs. Commonly, it only takes 1-7 days to produce, and without making a mold.

2. What are the functions of the prototype?

Prototypes are usually needed in industrial design and manufacturing. Because the products that have just been developed or designed are generally not perfect or even unusable. Once they are directly produced, they will all be scrapped, which greatly wastes manpower, material resources, and time.

A Prototype is the first step to verify the feasibility of the product. It is the most direct and effective way to find out the defects, deficiencies, and drawbacks of the designed product, so as to improve the defects until you can’t find the deficiencies in the individual prototype.

A prototype is generally a small number of samples, the production cycle is short, the waste of manpower and material resources is small, and the shortcomings of the product design are quickly found and improved, which provides a sufficient basis for product finalization and mass production.

3. What are the advantages of the prototype?

Usually, 80% of the production cost is determined in the design stage, and prototype making is an important part of the design stage, which means that the prototype has a very important role and incomparable advantages.

The practice has proved that the production of prototype models not only plays a very important role in product design decisions, but is also a weapon for product information confidentiality and market promotion, which should not be underestimated.

Below are some key advantages:

Design inspection

The prototype is visible and touchable. It can intuitively reflect the designer’s creativity in the form of physical objects, avoiding the disadvantage of “drawing to look good but can not be manufactured”.

Check structure design

Because the prototype is assemblable, it can intuitively reflect the reasonableness of the structure and the ease of installation. It is convenient to find and solve problems early.

Functions testing

The prototype can simulate the final form of the product, including functional form, curved surface form, etc, so can be tested for certain functions.

For example:

Using materials with a certain strength (such as ABS, PC, etc.), a functional prototype with an internal structure can be manufactured. This can check whether the structure of the product is reasonable, whether the wall thickness meets the requirements, whether the moving parts are smooth, etc.

It can also be used for aerodynamic testing. When designing high-speed moving objects such as automobiles, high-speed trains or spacecraft, put a 1:1 prototype into the wind tunnel for intuitive aerodynamic research.

Reduce risks

Because making plastic mold is generally very high, the price of relatively large molds is from $5,000 to $3M. If the structure is unreasonable or other problems are found after the mold is developed, there will lose much money.

The rapid prototype can reduce these risks before making the plastic mold.

Small volume production and assembly can get market feedback rapidly, trial product is modified until it is finalized. This helps greatly reduce risks to you.

Quickly occupy the market

Because prototype production is fast, you can use prototypes for publicity and pre-sales before mass production, this is a proven way to occupy the market as soon as possible.

Reduce costs

A product has a design defect, if it is put into production, may cause hundreds of thousands or even millions of dollars in losses.

The steady progress of the design process is necessary. Therefore, it is very important to find the defects in the product design process, and correct them in time to avoid subsequent production problems.

How to find design defects? The simplest way is to make a prototype.

Through the prototypes, the final shape, size, structure, and color can be obtained at a relatively small cost, and important information such as product weight and quality can be predicted (This affects the packaging cost, transportation cost, and raw material cost). And from this estimate the sales price and sales profit of the product.

If the cost exceeds the initial design, it can be adjusted in time until the target range of the cost is reached.

Therefore, a prototype is an effective means of enterprise cost control.

4. How many types of prototypes?

According to usage scenarios and production processes, prototypes can be divided into several types.

4.1 Classified by manufacturing technologies

Hand-made prototypes

As the name suggests, the main workload is done by hand. It is suitable for some products with simple design, low precision requirements, small size, and lightweight. At present, there are few completely hand-made models because they are not suitable for the requirements of current industrial designs.

CNC machined prototypes

The main workload is completed by the CNC machines. CNC machining can produce the parts required for drawings very accurately. With its advantages of high precision, high efficiency, and adaptability to the processing of small batches of multiple types of complex parts, it is a very popular way to become a prototype model.

3D printed prototypes

The main workload is completed by a 3D printer. 3D printing is a very popular way to create products in recent years. When requesting small quantity parts which with complex shapes or inner shape, 3D printing will be more efficient and accurate than the CNC machining.

4.2 Classified by materials

Plastic prototypes

The raw material is plastic, such as ABS, PC, PPS, Acrylic, POM, PS, PE, etc. It is widely used in TVs, telephones, electric fans, refrigerators, etc., most of which refer to housings or assembly parts.

Silicone prototypes

The raw material is silica gel, which is mainly used as displays the product design shape, such as cars, mobile phones, toys, handicrafts, daily necessities, etc.

Metal prototypes

The raw materials are aluminum alloys, stainless steel, magnesium alloys, and other metal materials, mainly the prototypes of some electronic products, such as notebook computers, mobile phone accessories, MP3 players, CD players, etc.

4.3 Classified by use scenario

Appearance prototype

It is mainly used to observe the appearance of the prototype. The appearance prototype requires an exquisite surface, accurate color, but its low requirements for internal processing.

Structural prototype

The structural prototype is mainly used to verify the rationality of the product structure, the size of the structural prototype is more accurate. The structural prototype is assemblable, so it can intuitively reflect the rationality of the structure and the ease of installation. It is convenient to find and solve design problems early.

Function prototype

If the prototype is required to be realistic in appearance and functional, this type of prototype is called a functional prototype, or it can be said to be a finished product, which can be sold directly, and most of them will be taken to the exhibition and can be well displayed to customers.

5. How to make a prototype?

There are many ways to make prototypes, such as 3D printing, CNC machining, vacuum casting, rapid tooling, laser cutting, metal stamping, and so on.

The characteristics of each manufacturing method are different, and you need to choose one or more ways according to your product requirements, materials, design, and quantity.

Here, I briefly introduce the 3 commonly used manufacturing methods:

CNC Machining prototypes

CNC machining is the most commonly used method of machining prototypes. CNC machining has many advantages, such as high precision, stable quality, high production efficiency. A wide range of plastics and metals can be machined. For some parts with very tight tolerance requirements, CNC machining is an ideal choice.

3D printing prototypes

3D printing is currently a very popular manufacturing method. Some companies directly equate rapid prototypes with 3D printing.

3D printing is additive manufacturing, which is based on digital model files, using powdered metal or plastic and other bondable materials to print out prototypes through layer-by-layer printing.

3D printing is very fast, some prototypes can be produced within 1-2 days. and it is an ideal way for some models with complex internal structures. However, the range of materials it can choose is not as many as CNC machining.

Vacuum casting

Vacuum casting technology is to use the existing products to make a silicone mold, and then use materials such as PU, ABS and other materials for pouring in a vacuum state, thereby cloning a prototype copy of the product.

This method is mainly used for small volume production. The production cycle is short and the cost is low, but the quality is not as good as CNC machining.

6. What materials can be used to make prototypes?

Vacuum casting technology is to use the existing products to make a silicone mold, and then use materials such as PU, ABS and other materials for pouring in a vacuum state, thereby cloning a prototype copy of the product.

This method is mainly used for small volume production. The production cycle is short and the cost is low, but the quality is not as good as CNC machining.