Reliable CNC Machining Services in China, Rapid & Ultra Precision

With DEK’s CNC machining services, you can get high-precision parts quickly and cost-effectively. Our experienced team is committed to delivering quality parts that meet even the most demanding requirements.

ISO9001:2015

Certified

Get precision machining services, delivered on-time.

At DEK, we offer world-class CNC machining services for all types of clients. Our services are designed to meet the highest standards of precision, quality, and efficiency.

We use state-of-the-art technology and the latest machines to provide our customers with the best results. What’s more, we are proud to offer unparalleled speed and no minimum order quantity (MOQ) on all our services, making it easy to find the perfect solution for your needs. Our services are also much cheaper than the industry standard, making them highly cost-effective.

Whatever your CNC machining needs, DEK is here to help. With our cutting-edge technology and experienced professionals, we guarantee to deliver the perfect solution.

Get it done right the first time with DEK’s high precision and high quality CNC machining services. Let us take care of the details so you can focus on your project.

Get your projects done quickly and efficiently with DEK’s CNC machining services. With faster delivery, you can get back to focusing on what matters most—growing and scaling your business.

Get the same high-quality CNC machining services you need from a reliable partner, without breaking the bank. DEK offers cost-effective solutions to help you get the most for your money.

Our Capabilities

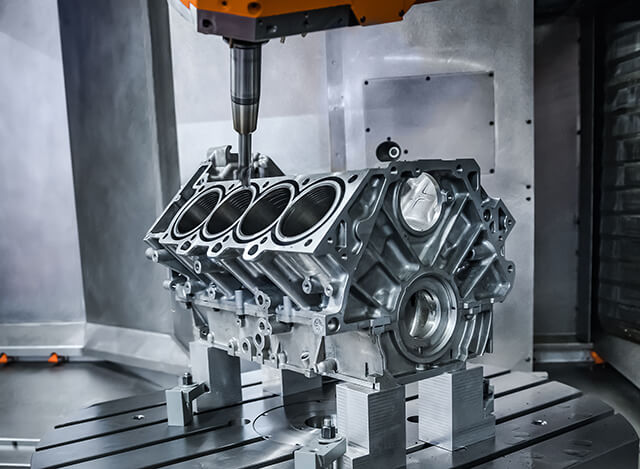

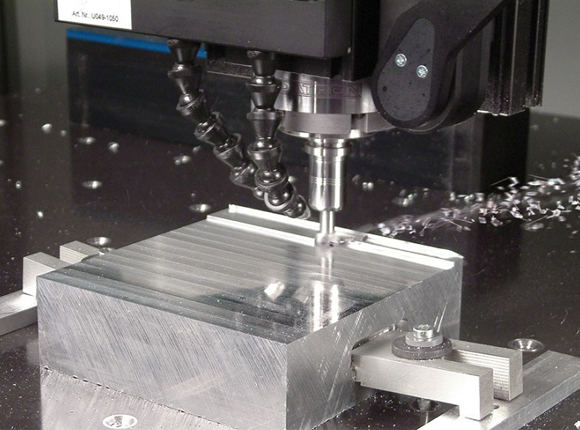

CNC Milling

CNC Turning

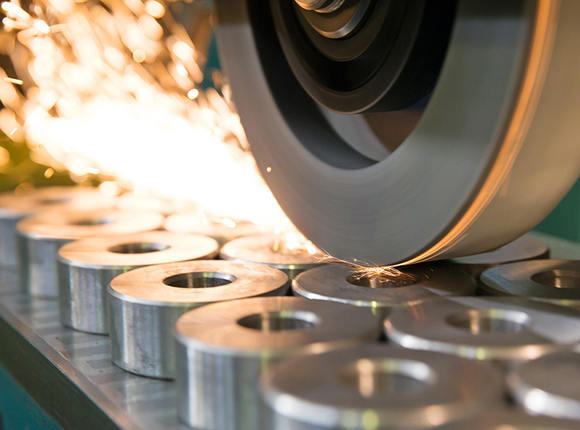

Precision Grinding

Swiss CNC Turning

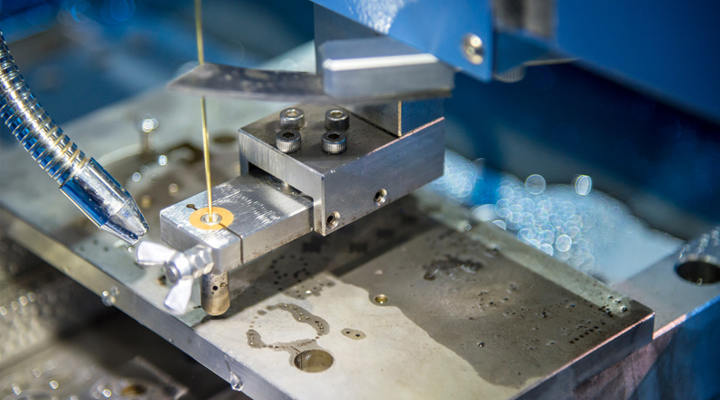

Wire Cut EDM

Sinker EDM

Materials

Metals

- Aluminum

- Stainless Steel

- Tool Steel

- Copper

- Brass

- Mild Steel

- Titanium Alloy

- Magnesium Alloy

- Invar

- Inconel

Plastics

- ABS

- POM

- Acaylic

- PEEK

- Nylon

- Polypropylene

- Polycarbonate

- Polyethylene

- PVC

- PET