From early prototypes to full production, DEK supports precision CNC machining programs that require stable processes, controlled quality, and reliable lead times for high-precision industries in Europe and North America.

Welcome to DEK Manufacturing, Your Trusted Partner in High Precision Machining

We serve aerospace, medical, and industrial OEMs across Europe and North America, helping customers meet tight tolerances, maintain supply stability, and manage production programs with confidence.

Engineering-Led Precision Machining Solutions

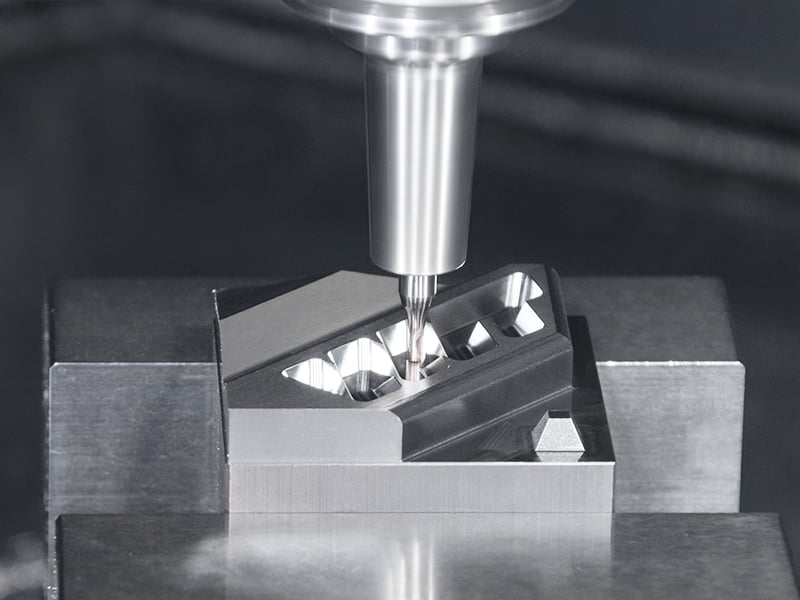

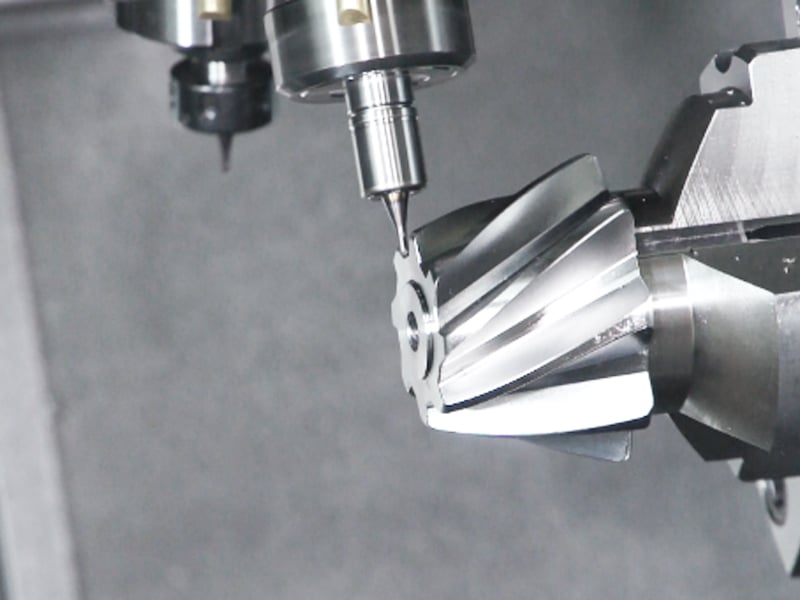

Complex Geometry Machining

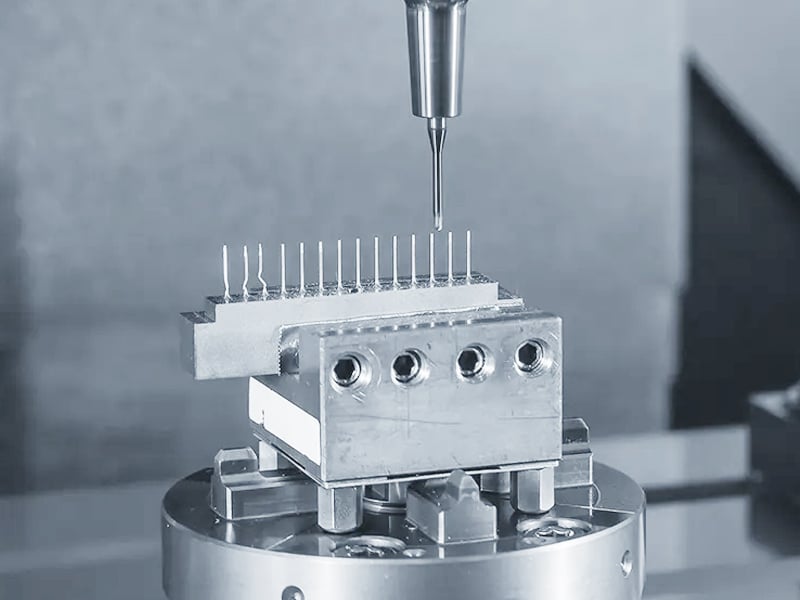

Micro Precision Components

Hard Material Machining

Large Structural Parts

Fit-Critical Assemblies

Production-Grade Consistency

Precision Machining Solutions for Demanding Industries

Every industry has its own set of challenges, standards, and critical requirements. We apply our engineering-first approach and precision machining expertise to meet these specific demands, delivering components that perform reliably where it matters most.

Aerospace

Medical Devices

Robotics

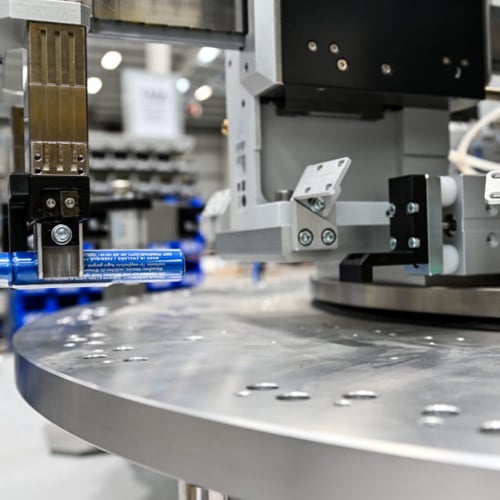

Semiconductor Equipments

Industrial Equipment

Energy

Quality System Built for Precision and Repeatability

DEK operates a documented quality management system covering IQC, IPQC, FAI, OQC, SPC, and CAPA, controlling dimensional accuracy, process stability, and inspection consistency across all production stages.

All machining programs are supported by defined inspection plans, calibrated measurement equipment, and full lot-level traceability to ensure parts conform to specification before shipment.

Our quality system is certified to ISO 9001, ISO 13485, and AS9100D, supporting regulated, high-precision manufacturing programs that require stable processes and repeatable results.

Engineering Support from Start to Finish

DEK provides integrated engineering support throughout quotation, manufacturing, and production execution.

Our engineers collaborate with customer teams on DFM feedback, material selection, and process definition to reduce manufacturing risk and align design intent with stable, repeatable processes.

Engineering, quality, and sales operate as a coordinated team to ensure clear communication and consistent execution across the full manufacturing lifecycle.