Ultra Precision Grinding Services - Centerless Grinding, Surface Grinding, OD & ID Grinding

- External diameter tolerances as tight as +/- 0.00005" (±0.001mm)

- Internal diameter tolerances as tight as +/- 0.00005" (±0.001mm)

- Roundness to +/- 0.00005" (±0.001mm)

- Cylindricity to +/- 0.00005" (±0.001mm)

- Grinding surface finishes 0.6Ra~0.8Ra

- Diameter from 0.1mm to 300mm

We Supply Precision Grinding Services, Ability to Meet Precision Tolerances as Tight as ±0.001mm (+/-0.00005 inch)

DEK provides a wide array of precision grinding services to global clients in medical, mold, automotive, aerospace, marine, agricultural, and so on industries, and adhering to their specifications to manufacture quality components.

We specialize in I.D, O.D, surface, forming, and centerless grinding, apply our precision centerless grinder, cylindrical grinder, honing machine, form grinder, and surface grinder, allow we can handle any grinding requirements. And Our ability to work with a wide range of metals, such as stainless steel, Aluminum, tool steel, die steel, brass, copper, magnesium, platinum, tantalum, and cobalt, as well as ceramics, composites, ferrites, rubbers, and plastics, makes us truly versatile.

At DEK, we pride ourselves on ultra-precision technology and quality. Our capabilities in grinding start at 0.1mm up to 300mm in diameter, 2mm up to 1200mm in length with a tight tolerance as low as ±0.001mm (+/- 0.00005″), and a micro finish as low as 0.6ra.

Don’t hesitate, we are your best partner for precision grinding services, contact us today!

Full Series of Precision Grinding Solutions Ready For You

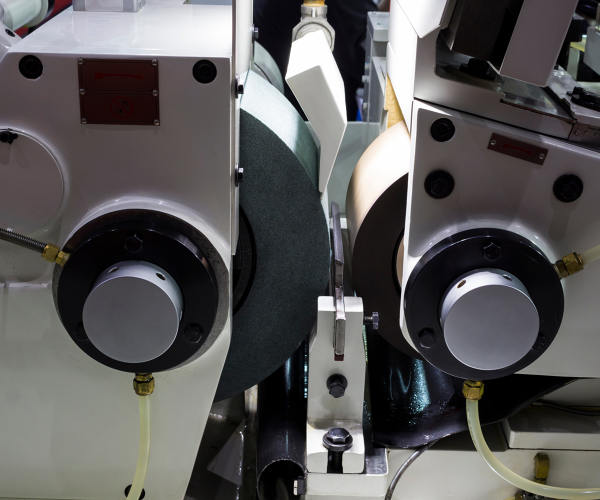

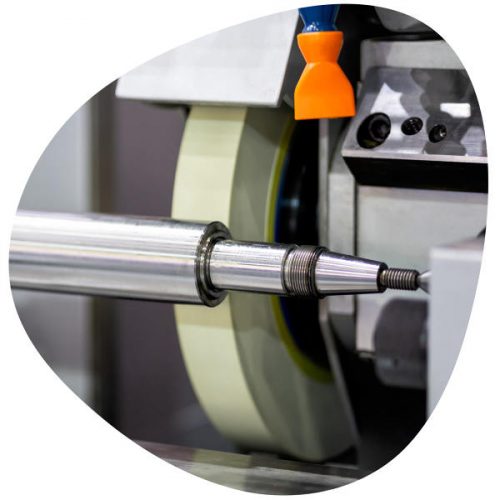

Centerless Grinding Services (OD)

Centerless grinding is an OD grinding process. It differs from other cylindrical processes in that the workpiece is not mechanically constrained.

We can perform Centerless Grinding services for the large number of metal parts you may want grinded within a short period of time. Centerless Grinding is definitely the way to go if you have a large number of parts and components that need to be shaped and grinded. We offer high precision Thrufeed and Infeed centerless grinding for workpieces. With Thrufeed centerless grinding, we are able to work with workpieces with consistent roundness in the length of the workpiece. In Infeed centerless grinding, DEK can grind cylindrical workpieces with complex shapes and or tapers to stringent tolerances.

Whatever the method we have over 18 years of experience, and can do the job right and on time!

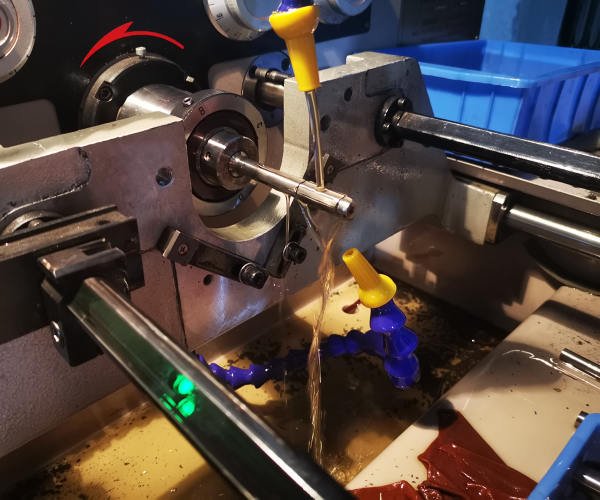

Cylindrical Grinding Services (OD & ID)

Some components having complex geometries or featural relationships that cannot be grinded by the centerless grinding process, but we will use our precision cylindrical grinders to handle.

DEK specializes in precision cylindrical grinding– that is, precision grinding inside diameters (IDs) and outside diameter (ODs) of cylindrical parts, excelling at those with multiple features, such as grooves, radii, and tapers. In some cases, form grinding may be utilized, where the component’s profile is formed directly into the grinding wheel.

Precision ID/OD grinding provides better part-to-part consistency over similar, alternative turning processes, especially for parts with size, roundness, concentricity, and surface finish requirements.

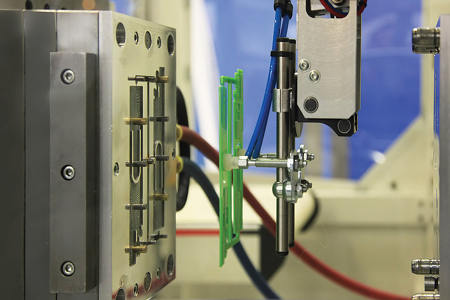

Honing Services (ID)

Honing is a finishing process used for workpieces that require the most accurate tolerance, and finish. Honing can improve the tolerances of workpieces when they are assembled in high precision systems such as internal mold cooling core pins. Honing also improves the geometric form of the surface and can perfect the surface finish of tubing or bores. The hone is turned in the bore while being moved in and out of the workpiece, removing stock and providing a high-quality finish.

DEK’s honing capabilities are extensive. We welcome a diverse range of applications and any production volume. From large machine components to intricate valves and gears, we pride ourselves on our ability to meet close tolerances as tight as +/- 0.0005″ (±0.001mm), so you’ll never have to worry about fit or functionality.

Surface Grinding Services

DEK surface grinding team has the experience and knowledge to assess the ideal ways to perform surface grinding operations and tailor every process to the needs of each part. We can accommodate large surface material. Dimensional tolerances to +/- 0.001mm can be accomplished. Surface grinding is ideal for material with a large surface and reducing cost by surface grinding multiple units at the same time. This can be achieved with stringent tolerances.

At DEK, we welcome all types of surface grinding jobs, from simple or flat surface grinding to the most complex parts. We look forward to meeting and exceeding your expectations every time.

Tightest Tolerance You Can Trust

The above table is the standard tolerance of our grinding process. If you need a more precise tolerance, such as diameter ±0.0005mm, also can be met. Please contact our technical team to get more info.

Available Material For Precision Grinding

Our CNC machine shop can machine virtually any engineering material, including plastics, metals, alloys, foam or tooling board. Here is a list of our standard grinding materials available, other materials are upon request.

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

- 6061-T6

- 5052

- 1060

- 3003

- 4130

- 4140

- 5083

- 6082

- 5A12

- 7075 T651

- 5052

- 2024

- 1100

- 3004

- 5754

- 6063

- 7050

- 5A02

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity, and has a golden (brass) appearance. It is commonly used in parts that need a large load.

- Brass C360

- Brass 260

- C932 M07 Bearing Bronze

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

- Copper

- Copper H62

- Copper H65

- Copper H70

- Copper H80

- Copper H90

- Copper alloy special

Stainless steel features a high-temperature resistant, with good oxidation resistance and corrosion resistance. It is widely used in machine parts, contruction industry parts, etc.

- 303

- 304

- 316L

- 2205 Duplex

- 17-4

- 15-5

- 416

- 420

- 430

- 440C

- 301

Plastic is one of the most commonly used materials in the world because of its strong corrosion resistance, durable, waterproof, light weight, low cost and easy processing.

- ABS

- Acetal [Delrin]

- Acrylic

- G-10 Garolite

- Nylon 6/6

- PEEK

- Polycarbonate

- PTFE [Teflon]

- Polypropylene

Titanium alloy is widely used in automobile industry because of its light weight, high strength and good corrosion resistance.

- Titanium Grade 2

- Titanium 6Al-4V

Special steel is a kind of steel with special composition, special production process, special structure and performance, which can meet special needs. Compared with ordinary steel, special steel has better strength and toughness, physical properties, chemical properties, biocompatibility and technological properties. It is widely used in machinery, automobile, military industry, chemical industry, home appliances, ships, transportation, railway and other fields.

- Tool Steel

- Bearing steel

- Die steel

- High speed steel

- Tungsten steel

- Manganese steel

- Molybdenum steel

- Tungsten chromium steel

Available Surface Finishes After Precision Grinding

Surface finishes are applied after precision grinding and can change the appearance, surface roughness, hardness and chemical resistance of the produced parts. Below are the mainstream surface finish types from DEK:

As Machined

This is the standard choice, economical and rapid, the parts’ surface will leave visible machining marks. The surface finish is equivalent to 3.2RA μm (125 RA μin).

Polishing

Polishing is to make the surface smooth by physical friction processing, it is often used to prevent corrosion and remove oxidation. After polishing, the parts have a smoother and brighter finish.

Bead Blasted

Bead blasting is the process of spraying abrasive on the surface of parts under high pressure, after sandblasting, the metal parts have a satin texture or frosted surface, eliminating the processing marks.

Anodized

After anodizing, a hard non-conductive ceramic coating will be added on the surface of aluminum parts to improve the wear resistance and retain the metal texture and luster.

Electropolished

Electropolishing is the reverse process of electroplating, which simplifies the metal surface at the micro-level through chemical solution. After electropolishing, metal parts can be more bright and reduce surface roughness.

Black Oxide

The black oxide is a chemical conversion coating, it is produced by a chemical reaction between iron and oxide salt in black oxide solution. The corrosion resistance of parts can be improved after black oxidation.

Powder Coated

Powder coating can add a layer of solid and colorful polymer coating on the surface of parts, so as to improve the wear resistance and corrosion resistance.

Spray Painting

Spray painting is to spray paint on the surface of parts in the air. After painting, the parts have various colors, improve the aesthetic appearance, and make the parts unique, enhance brand awareness.

Other surface finishes are also available. Please click here to learn all surface finish knowledge. Or contact our sales team to get an instant quote.

World-class Precision Grinding Services For Your Accuracy Metal & Plastic Parts

FREE Samples for testing are available, contact us today!

Accuracy Grinding For Industrial Applications

Many parts require conformity to exact specifications and standards to function and fit as intended. To meet these precision and accuracy requirements, DEK employs different grinding tools and techniques to achieve the desired size, shape, and surface texture with tight tolerances. Precision grinding finds application in the daily needs and operations of a wide range of industries, including but not limited:

Aerospace

Aerospace parts need to perform in extreme conditions with minimal risk of failure or malfunction. Precision grinding processes such as thread grinding produce rivets and bolts that match their original designs to the last detail. Grinding also produces exact dimensions and finishes for engines, control system parts, and hydraulic or pressurized components.

Automotive

Car parts have tight tolerance demands so that all moving parts operate in tandem. The slightest protrusion or rough surface can interfere with safe operation and degrade fuel efficiency. Precision grinding the surfaces of every part ensures each component is precisely sized and reduces the amount of friction experienced.

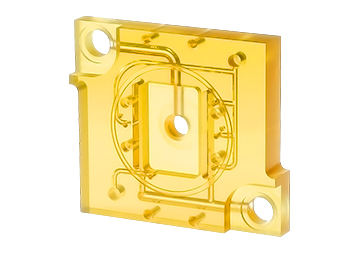

Injection Mold

The function of the ejector pin and core pin is very important for the plastic injection mold, if the tolerance of these mold components is not accurate, it may lead to too loose or too tight, which will directly lead to unqualified products or production paralysis. Precision grinding can make the diameter tolerance of the core pin reach ± 0.001mm, make the surface more smooth, reduce friction, increase durability, and ensure the normal operation of the injection molding.

Manufacturing

The machines and tools that perform manufacturing and machining processes are built to withstand the stress of operation, from time to time, maintenance, repair, and part replacement are required. Precision grinding is used to maintain the performance of machining and manufacturing equipment, including by repairing existing tooling or producing new ones based on OEM specifications. Newer grinding techniques, such as centerless grinding, have also impacted the manufacturing and machining industries by reducing the costs and material wastes required to achieve higher precision parts.

Medical

Medical devices and instruments, such as drills, scalpels, and dental tools, require high precision and accuracy. Precision grinding processes enable manufacturers to finish tools to exact specifications, sharpness, and finish requirements. The grinding process also produces smoother surfaces that reduce the risk of friction or infection

Printing

The printing industry uses a variety of machinery and tools to produce the finished products, including paper rollers and blades. Precision grinding services keep blades sharp and ensure that rollers can run smoothly without bumps or rough surface interactions.

Transportation

Despite the difference in size, components used in transportation equipment and heavy machinery require the same amount of precision as those used in smaller electronics and vehicles. Precision grinding machines ensure that parts are finished to exact dimensions and kept smooth to prevent frictional damage or overheating. Typical transportation parts that are precision ground include axles, engines, hydraulic components, transmissions, and valves.

3 Secrets Make Us The Best Grinding Services Company in China

One Stop Solution Make Your Purchase More Convenient & Fast

At DEK, we have precision grinding department which has one-stop manufacturing and machining services in-house. Different from some machining companies, they only have CNC services, not grinding services, This makes them impossible to process precision parts for you.

We have many years of mold components manufacturing experience, not only has dozens of centerless grinders, cylindrical grinders, and surface grinders, but also has skilled workers, this ensures we can support CNC turning, CNC milling, and precision grinding in our machining shop, and adhering to your specifications to manufacture quality components in a short time.

Quality Grinding Your Parts in 20℃ Dust Free Workshop

When parts require grinding with tolerances of up to ±0.001mm (+/-0.00005 inch), even small variations in the environment can alter the grinding process and measurements. Maintaining a temperature of 68° Fahrenheit (20° Celsius) ensures all grinding is consistent and that the measurements are accurate. Our precision grinding services and measurements are performed in the dust-free workshop which has a climate-controlled facility. Once the grinding is complete, our machinists measure and recheck the parts using a state of the art CMM inspection to ensure parts meet the customer’s precise specifications.

At DEK company, we never stop improving the quality of our product. This is how we differentiate ourselves from the competition and is also why we can remain on top of the game for so many years.

Reduce 80% of Your Worries to Make You Worry-Free

Through communicate seamlessly with our English and Spanish sales, your requirements will transfer to our engineer and production team clearly and will be grinded 100% according to the drawings and requirements.

We will push the work and never delay your lead time, the production progress and shipment information will update to you actively and regularly.

DEK has a strict service system, all inquiries and questions must be answered within 4 hours. After-sales problems must be actively handled to give professional and satisfactory answers to customers without shirking responsibility. DEK’s “Customer is King” service attitude, will reduce your troubles, let your work worry-free.

Cilents & Feedbacks

We are one of the top mold manufacturers in Japan since 1992, high quality is our company's mission, so we have been purchasing mold components locally until 2018 cooperate with DEK. Among many suppliers, DEK is the only one from China. We met at the INTERMOLD exhibition, and then they started to produce samples for testing and finally delivered qualified products. Their mold core pins quality can be compared with Japanese manufacturers, but the delivery time is fast, and the price is more than 70% cheaper. We will continue to cooperate with DEK and believe that we will all have a win-win future.

Y.Takashiku Purchasing Manager of HM Mold