Precision CNC Turning Services Company - Tightest Tolerances & Timely Delivery

- Tightest tolerances of ± 0.005mm are met during manufacturing

- On time delivery as soon as 3 days or less

- Saving more than 60% cost

- Over 60 kinds of materials can be turned, including metal and plastic

- Close tolerances, tight concentricities is our manufacturing standard

We supply precision CNC turning services, ability to meet precision tolerances as light as ±0.005mm (±0.0002 inch)

At DEK company, we offer a full of high precision CNC turning services to customers in a range of industries including aerospace, consumer products, automotive, medical, electronic, sports, and a myriad of other industrial clients.

Our CNC turning processes include cutting, facing, threading, forming, drilling, knurling, broaching, and boring. And a host of value-added services round out our turning abilities, including welding, tumbling, grinding, sandblasting, passivating, heat treating, plating, and assembly to name a few.

Different from other Chinese company, we are dedicated to high quality, DEK is equipped with highly skilled CNC programmers and machinists, as well as the most advanced CNC Turning technology, so no matter how complex the project is, we consistently exceed our clients’ precision, accuracy, and quality standards.

Typical lead times are 3 to 10 days, depending on part design, with expedited services are available upon request. We are ready for your next projects, contact us today!

Capabilities of Our CNC Lathe Services

According to your unique requirements, budget, and timeline, we will choose a best way for milling. For expert advice, please contact our professional sales team to find the right match for your needs.

Type of Turning Machines

- Engine Lathe x 6

- Turret Lathe x 4

- CNC Lathe x 12

Tightest Tolerance We Can Do

- Straightness : ±0.001mm / ± 0.00005 in

- Concentricity: ±0.001mm / ± 0.00005 in

- Diameter (outer/inner): ± 0.0005 in (± 0.0127 mm)

Available Turned Parts Specifications

- Part Diameter: φ5.0mm-380mm

- Part Length: From 2.0mm to 300.0mm

Available Operations of Our CNC Turning Services

A variety of other machining operations can be performed on a lathe in addition to turning; these include the following:

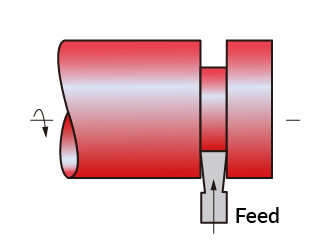

Facing

The tool is fed radially into the rotating work on one end to create a flat surface on the end

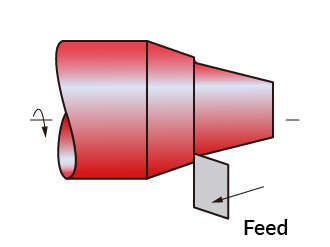

Taper Turning

Taper turning is a cylindrical turning procedure in which the diameter to be generated is constantly changing. This method is used to produce conical shafts.

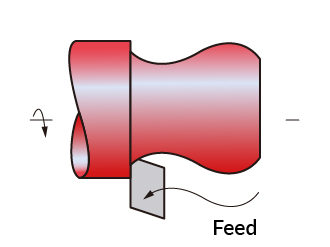

Contour Turning

Instead of feeding the tool along a straight line parallel to the axis of rotation as in turning, the tool follows a contour that is other than straight, thus creating a contoured form in the turned part.

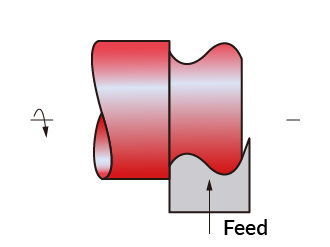

Form Turning

In this operation, sometimes called forming, the tool has a shape that is imparted to the work by plunging the tool radially into the work.

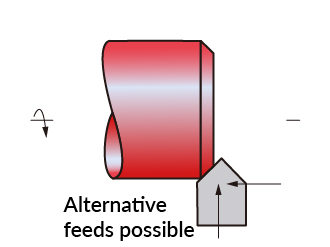

Chamfering

The cutting edge of the tool is used to cut an angle on the corner of the cylinder, forming what is called a “chamfer.”

Cutoff

The tool is fed radially into the rotating work at some location along its length to cut off the end of the part. This operation is sometimes referred to as parting.

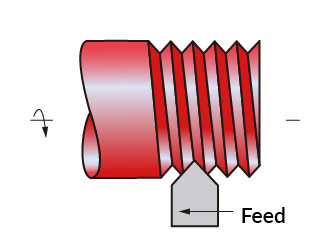

Threading

A pointed tool is fed linearly across the outside surface of the rotating work part in a direction parallel to the axis of rotation at a large effective feed rate, thus creating threads in the cylinder.

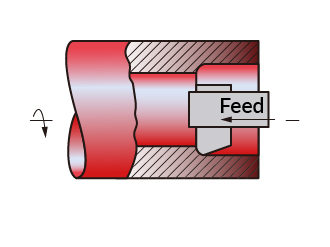

Boring

A single-point tool is fed linearly, parallel to the axis of rotation, on the inside diameter of an existing hole in the part.

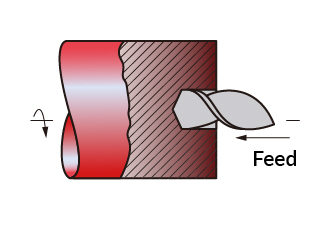

Drilling

Drilling can be performed on a lathe by feeding the drill into the rotating work along its axis. Reaming can be performed in a similar way.

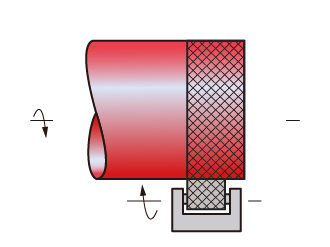

Knurling

This is not a machining operation because it does not involve cutting of material. Instead, it is a metal forming operation used to produce a regular crosshatched pattern on the work surface.

Materials We Work With CNC Turning

CNC Turning Metal

- Alloy Steels

- Aluminum

- Brass

- Bronze Alloys

- Carbon Steel

- Cobalt

- Copper

- IronLead

- Nickel

- Stainless Steel

- Stellite (Hardfacing)

- Tin

- Titanium

CNC Turning Plastic

- ABS (Acrylonitrile Butadiene Styrene)

- Acetal

- Acrylic

- Fiberglass Reinforced Plastics

- Nylon

- Phenolic

- Polyamide-Imide

- Polyetheretherketone (PEEK)Polyetherimide

- Polyethylene

- Polyethylene

- Polyphenylene Sulfide

- Polypropylene

- Polystyrene

- Polysulphone

- PTFE (PolyTetraFluoroEthylene)

- PVC (Polyvinyl Chloride)

- PVDF (Polyvinylidene Fluoride)

Available Surface Finishes After CNC Turning Services

Surface finishes are applied after turning and can change the appearance, surface roughness, hardness and chemical resistance of the produced parts. Below are the mainstream surface finish types from DEK:

As Machined

This is the standard choice, economical and rapid, the parts’ surface will leave visible machining marks. The surface finish is equivalent to 3.2RA μm (125 RA μin).

Polishing

Polishing is to make the surface smooth by physical friction processing, it is often used to prevent corrosion and remove oxidation. After polishing, the parts have a smoother and brighter finish.

Bead Blasted

Bead blasting is the process of spraying abrasive on the surface of parts under high pressure, after sandblasting, the metal parts have a satin texture or frosted surface, eliminating the processing marks.

Anodized

After anodizing, a hard non-conductive ceramic coating will be added on the surface of aluminum parts to improve the wear resistance and retain the metal texture and luster.

Electropolished

Electropolishing is the reverse process of electroplating, which simplifies the metal surface at the micro-level through chemical solution. After electropolishing, metal parts can be more bright and reduce surface roughness.

Black Oxide

The black oxide is a chemical conversion coating, it is produced by a chemical reaction between iron and oxide salt in black oxide solution. The corrosion resistance of parts can be improved after black oxidation.

Powder Coated

Powder coating can add a layer of solid and colorful polymer coating on the surface of parts, so as to improve the wear resistance and corrosion resistance.

Spray Painting

Spray painting is to spray paint on the surface of parts in the air. After painting, the parts have various colors, improve the aesthetic appearance, and make the parts unique, enhance brand awareness.

Other surface finishes are also available. Please click here to learn all surface finish knowledge. Or contact our sales team to get an instant quote.

Standard Tolerance Of Our Precision CNC Turning

The table below summarizes the standard tolerances of the parts produced. Tolerances up to 0.001mm are available upon request

Tightest tolerance: ±0.001 mm tightest tolerances are available to depend on your requirements.

DEK is A Professional CNC Turning Company That You Can Trust

Gapless Communication

You can communicate seamlessly with our English and Spanish sales team, and your requirements will be transferred to the engineering team clearly

Positive Services

Positive after-sales service and solutions. Never shirk responsibility, our team will take the initiative to deal with problems

Fast Response

You can get a quick quote within 4 hours. And we offer fast CNC turning service, you projects will be send out as fast as 5 days or less

Reduce Cost

We will reduce your 40%-60% purchase cost by investing in the finest CNC lathes, improving production efficiency, and purchasing raw materials in bulk

High Precision

By hiring true professionals and not just standard workers to operate our CNC lathes, to ensure you can get the high precision CNC turned parts

Multi Material

More than 60 kinds of material can be chosen, including metal and plastic

Surface Finish

After turning, we can handle several kinds of surface finish, for different requirements and use

On-demand Production

From 1 to 100k+, no matter prototype production, low volume manufacturing, or mass production, our CNC turning services can support you to achieve

Cilents & Feedbacks

As the Supply Chain Manager for a prototype design and supply service company, we are continually looking for vendors to partner with that can help us achieve our goals to provide our customers with the highest quality products. For many years now DEK has helped us to accomplish this by providing consistent quality, machining to the highest standards, on time and within budget. DEK has built its excellent reputation on the quality of our work, it is a company we enjoy doing business with.

Mr.Pozgay - Supply Chain Manager