Your Reliable Plastic Injection Molding Services Supplier - DEK

Custom injection molding is ideal for plastic parts where success relies on achieving specific mechanical or aesthetic features.

Custom Plastic Injection Molding Services - Premium Quality, Fast Delivery, Cost-Effective

DEK is a China leading plastic injection molding company, we take pride in manufacturing high-quality plastic products to global clients.

You can get full-services of injection molding here, no matter what materials and what colors. By using the finest injection molding machines, we can manufacturing plastic products from the very small to large size, our clamping force from 55 to 1,650 tons with up to 64 cavities, the shot sizes from 3 to 600 oz., finished part weights can range from 4 grams to 24 lbs. In addition, we also offer additional services including mold making, plastic surface finishing, assembly needs, etc.

Customer satisfaction is the goal for DEK, whatever the requirements and tolerances for your components are, we have the capabilities to meet your expectations.

Premium Injection Molded Parts We Did

On Demand Injection Molding Services

From prototype to mass production, by using our on-demand manufacturing services, you can get the most cost-effective solution at every stage.

Low-Volume Injection Molding

Short-Run (Low Volume) Injection Molding is a specialized service that provides a bridge between initial prototypes and high volume injection molding. Our Short run molding is ideal for small businesses or small-batch manufacturing, it can shorten your lead time, help you access new markets rapidly.

High-Volume Injection Molding

Injection molding is the best way for the mass production of plastic parts, because it can reduce unit costs and cycle time, it can ensure accurate and consistent parts. We offer specialized high volume injection molding service, can produce premium quality parts in volumes of up to millions of pieces a month.

Our Injection Molding Capabilities

Our various kinds of injection machines, experienced engineers team can support all your needs, from prototype to mass production.

Rapid Tooling

Rapid Prototype Tooling

Production Tooling

Production Tooling

Family Molds

Family Molds

Single Cavity Molds

Single Cavity Molds

Multi-cavity Molds

Multi-cavity Molds

Overmolding

Overmolding

Insert Molding

Insert Molding

Part IMD & IML

Part IMD & IML

Professional Injection Molding Services To Make You Worry-Free

Premium Quality

We specialize in injection molding high-quality parts and have rich experience in complex products. Your plastic parts will be led by an expert team of engineers.

Well-experienced Services

For each order, our engineers will carry out DfM and mold flow analysis to ensure the rationality of design and production.

One-stop Solution

From design, mold manufacturing, sample testing, formal production, surface finishing, assembly, packaging, and delivery. We provide a complete one-stop service, to help you reduce the process and risk.

Variety Materials

Whether rigid plastics, flexible plastics, or rubber plastics, all we can handle with our strong injection molding capabilities, to meet your unique needs.

On-demand Production

Whether you need rapid tooling, low volume manufacturing, or mass production, we have complete manufacturing systems that can ensure you will get a cost-effective solution at each stage.

Save Costing

Due to our strong injection molding capacities and various supply chain partners, you will save 58%-70% of the cost compared to purchase locally.

Powerful Capabilities

Our clamping force from 55 to 1,650 tons, which can meet the needs of various sizes of products. And we are very good at high precision injection molding.

Worry-free

From quotation, production to delivery, we will actively update the latest information for you to ensure that you can easily grasp the order status.

Available Material For Plastic Injection Molding

DEK’s plastic injection molding process is suitable for a wide range of plastics, including all thermoplastics and some thermosetting plastics and liquid silicone resins. Below are the most common options.

ABS

ABS (Acrylonitrile Butadiene Styrene) plastic is a thermoplastic polymer. Its outstanding performance and low price make it one of the most commonly used plastics in the injection molding process.

Benefits

- Excellent impact resistance

- Strong heat resistance

- Lightweight

- High tensile strength

- Great Scratch resistance

- Excellent processability and appearance

- Recycling available

- Low cost

- and more..

Polypropylene (PP)

Polypropylene (PP) is the second-most widely used plastic in the injection molding parts, it is suitable for multiple applications due to its tough and flexible consistency.

Benefits

- Inexpensive

- Heat Insulating

- Chemical resistant

- High heat and friction

- Excellent moisture resistance

- Food safe grades available

- High impact strength

- and more..

Polyoxymethylene (POM)

Polyoxymethylene (POM), also named Acetal plastic or polyacetal. It is very stiff, the good wear resistance and dimensional stability make POM polymer a highly versatile engineering material.

Benefits

- High strength, rigidity and toughness

- Good impact strength

- Small friction coefficient

- Good dimensional stability

- Low moisture absorption (at saturation 0.8%)

- Excellent machinabilityry elasticity

- and more..

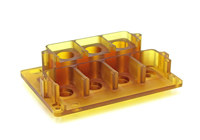

Polycarbonate (PC)

Polycarbonate (PC) plastic is a naturally transparent amorphous thermoplastic material, it is lightweight, very strong, and resilient.

Benefits

- Has a very high impact resistance

- Superior strength

- Dimensional stability

- Superior transparency

- High durability

- High machinability

- and more..

Polycarbonate / ABS

PC-ABS (polycarbonate-ABS) is a high-impact thermoplastic, it combines the strength and heat resistance of PC and the flexibility of ABS.

Benefits

- High impact strength

- Heat resistance

- High stiffness

- Easy processing

- Dimensional stability

- and more..

Polyvinyl Chloride (PVC)

Polyvinyl Chloride (PVC or Vinyl) is a high strength thermoplastic material, it is the world’s third-most widely produced synthetic plastic polymer.

Benefits

- Good abrasion resistance

- Lightweight

- Good mechanical strength and toughness

- Resistant to weathering, chemical rotting, corrosion

- Cost-effective

- and more..

Nylon (PA 6)

Nylon PA 6 is a synthetic thermoplastic polymer, it is versatile, durable, and flexible, commonly used in injection molding applications.

Benefits

- Temperature capability 600°-700° for short term

- Excellent chemical resistance

- High resistance to abrasion

- Tough and withstands repeated impact

- Excellent abrasion resistance

- Outstanding dimensional stability

- and more..

Polyurethane (PU)

Polyurethane (PUR, or PU) is an elastomer plastic, which made by combining organic compound units with carbamate (urethane).

Benefits

- Wide range of hardness

- High load bearing capacity

- Flexibility

- Abrasion & Impact Resistance

- Tear Resistance

- Resistance to Water, Oil & Grease

- Electrical Properties

- and more..

Acrylic (PMMA)

Acrylic Plastic, also known as plexiglass, is one of the clearest materials. Due to the low pricing, high transparency, and lightweight, it is an ideal replacement for glass in many applications.

Benefits

- Excellent optical clarity

- Highly Transparent

- Excellent weatherability and resistance to sunlight

- Rigid with good impact resistance

- Easy to Fabricate

- 30x as strong as glass

- 2x lighter than glass

- and more..

Polystyrene (PS)

Polystyrene (PS) is a clear, amorphous, nonpolar commodity thermoplastic that is easy to process. As a hard, solid plastic, it is widely used in the consumer products market.

Benefits

- Optical clarity

- High gloss

- FDA grades available

- Low cost

- Good dimensional stability

- Good rigidity

- and more..

Polyethylene (PE)

Polyethylene (or polythene) is a lightweight, durable thermoplastic with a variable crystalline structure. It is one of the most widely produced plastics in the world.

Benefits

- Resistance to bacterial growth

- Resistance to moisture

- Extremely Lightweight

- Provides insulation

- Durable

- Recyclable

- and more..

High Density Polyethylene (HDPE)

Benefits

- Lightweight

- Freeze-break resistance

- Low cost

- Impact resistant from -40℃ to 90℃

- Moisture resistance

- Good chemical resistance

- Food grades available

- and more..

Polyetherimide (PEI)

Polyetherimide (PEI) is an amorphous, amber-to-transparent thermoplastic with high mechanical strength and rigidity. PEI characteristics are similar to the related plastic PEEK.

Benefits

- High heat resistance

- Broad chemical resistance

- Excellent machinability and finishing characteristic

- High mechanical strength

- High rigidity

- High dimensional stability

- Good electrical insulation

- and more..

PEEK

Polyether ether ketone (PEEK) is an organic thermoplastic polymer that has a high-performance engineering plastic with outstanding resistance to chemicals, excellent mechanical strength.

Benefits

- Excellent chemical resistance

- Low moisture absorption

- Good wear and abrasion resistance

- High-temperature tenacity

- Long lifespan

- Excellent heat distortion properties

- Low coefficient of friction

- and more..

Available Surface Finishes Class

Smooth and glossy finish

If your plastic parts require the smoothest finish, SPI grades A1, A2 and A3 are recommended. The molds in these grades will use hardened tool steel, the surface of the mold is polished by grit diamond. The mirror gloss provides a smooth gloss almost like a mirror. Products such as sun visors, plastic mirrors and optical products are made using such finishes.

Semi-glossy finish

If your plastic parts require the Semi-glossy finish, SPI grades B1, B2, and B3 are recommended, the semi-glossy finish is a good way to remove the processing, tooling marks. In the mold with a semi-glossy finish, grit paper will be used for grinding.

Matte finish

For plastic products that need a matte finish, we recommend SPI grades C1, C2, C3. The mold used for the matte finish is polished with gritstone. Matte finish is widely used in industrial parts, consumer goods, and other fields.

Textured finish

SPI grades D1, D2, and D3 are recommended if the part requires a textured finish. Molds for textured finishes are first ground with the dry blast and then dry sprayed with alumina and sometimes glass beads. A textured surface provides a good grip quality, conceals deformations and traces, and sometimes even helps to mask fingerprint stains.

Additional Finishing and Coating Options

Finishing or coating is applied after machining and can change the appearance, surface roughness, hardness, and chemical resistance of the produced parts.

- Polishing

- Pad Printing

- Silk Screening

- Custom Color Painting

- Laser Marking

- Heat Staking

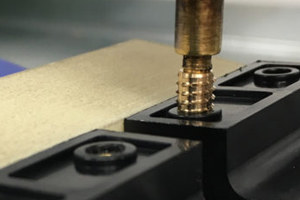

Additional Processing Services

In addition to injection molding and coating services, our one-stop solution can also provide assembly, packaging, and other services, to save your time and cost.

Threaded Inserts

Assembly

Packaging Service

How To Start?

Send Inquiry

Send your 2D/3D CAD drawings and requestions via the Online Form or email

Confirm Order

Receive our quotation within 24 hours, and then confirm the order to us.

Start Production

After confirming the order, we will arrange the production immediately.

We're Ready For Your Next Project

Looking for a reliable injection molding supplier? You are in the right place now, DEK has more than 18 years of experience in custom plastic injection molding, trusted by Huawei, DJI, etc.