Ultra Precision Machining

When other machining shops are trying their best to reach tolerance ±0.01mm, we already have made ±0.001mm as our daily standard.

Why We Set Up Ultra Precision Machining Department?

In the past 20 years, some customers in high-quality mold, optical, medical, aerospace, and other fields were always disturbed by high-precision parts, because 99% of suppliers CAN NOT reach high-precision requests, only a few can make but the price is super expensive.

So we set up a high-precision machining department, use the precision grinders to produce close tolerance parts, and solve their problems.

Why Products Need Ultra Precision Machining?

Reduce friction, improve durability, and improve product quality. For example, the pursuit of higher precision for precision shafts can achieve more silent, higher speed and longer service life.

The tight tolerance cannot be seen with the naked eye, but it will affect your machine parts’ performance.

What We Can Do?

Our precision machining department is set up for high-end precision parts and meets most of the precision needs.

- External diameter tolerances as tight as +/- 0.00005" (±0.001mm)

- Internal diameter tolerances as tight as +/- 0.00005" (±0.001mm)

- Roundness to +/- 0.00005" (±0.001mm)

- Cylindricity to +/- 0.00005" (±0.001mm)

Types of Machining Processes We Use

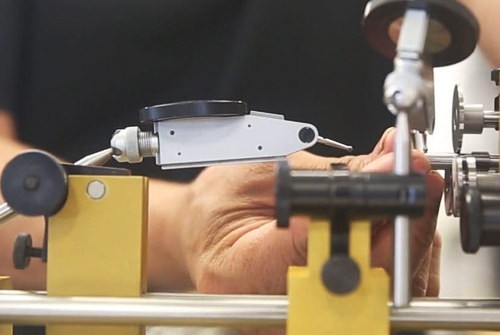

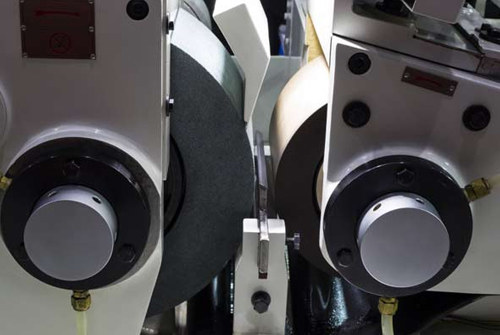

Mostly, after the parts are roughed on the lathe and grinder, we will move the parts to the centerless grinding and honing workshop for ultra precision grinding. Grinding is one of the best processing methods to ensure accuracy and the tightest tolerance.

- O.D. Centerless Grinding

- I.D. Honing

What Product Need Ultra Precision Machining?

- Precision Shaft

- Precision Rods

- Precision Mold Components

- Pin Gauge

- Precision Lead Screw

- Precision Screw

- Precision Medical Parts

- and more..

F.A.Q

We Make ±0.001mm As A Daily Standard

Have a precision project on hand? Send your drawings and requests to us today, then you will get an amazing price in a short time!