Premium die Sinker EDM Services (RAM EDM, Conventional EDM)

DEK’s sinker EDM services enable us to process complex profiles and machine any conductive material. We are capable of successfully machining your parts within 1-2 weeks and offer a very fast turnaround.

Specialize in Sinker EDM Service for A Full Range of Industries: Fully Customized & On-Demand

DEK offers the most precise and accurate sinker EDM services through its state-of-the-art sinker EDM equipment. We work within extremely tight tolerances and ensure accurate & fast results, top customer services, and cost-effective solutions for your sinker EDM needs.

Difficult and complex materials can be handled with extreme care and machined to achieve extreme accuracy and repeatability to within +/-0.001mm is what sinker EDM technology is known for.

Why Choose Our Precision Wire EDM Services?

Comprehensive Functionality

DEK's advanced sinker EDM services through technologically-enhanced functionality control the complexities involve in sinker EDM. Moreover, it enables our clients to understand everything involved in their part's manufacturing, from material selection to detailed inspection. Automatic detection of any flaw in your part's design in the early stages and convenient object-oriented electrode design help you get top-quality and high-performance parts.

Integrated Quality

DEK's integrated quality control of sinker EDM machined parts is a significant part of what makes our services superior to others. QC integration ensures the quality of manufactured parts at every step involves in the sinker EDM process. DEK's sinker EDM provides a fully integrated, intuitive platform through which we can monitor, inspect, and analyze the part's quality to improve productivity.

Fast and Easy Machining

Creating your part design using 2D or 3D CAD and uploading it on DEK's website to get a quick quote can help you get the precision, quality, and affordable sinker EDM services at any volume and high-quality manufactured parts within two weeks or less. DEK's state-of-the-art sinker EDM equipment can handle small and complex radius cuts and maintain a high level of quality. We take pride in manufacturing quality, custom, and low-cost parts.

Automated Processes

DEK's fully automated sinker EDM processes with flexible manufacturing skills are ideal for machining parts with complex designs with ease. Our automated sinker EDM processes accelerate the innovation in manufacturing machined parts efficiently and timely, which also helps to get your product(s) to market before your competitors. Moreover, our simplified processes mean lower costs for our customers without compromising on part's quality and performance.

Affordability

DEK's sinker EDM abilities to machine complex parts with chamfered edges, multi-radius curves, and tapped holes are few things that make your part's machining more workable for any projects. Our fully optimized machining process eliminates the unnecessary processes involved in the part's manufacturing process. Moreover, our advanced sinker EDM technology helps us eliminate the waste of material, energy, and other valuable resources that makes your parts machining cost-efficient.

One-stop Solution

DEK's machining services feature anything related to sinker EDM that can increase your part's manufacturing efficiency to achieve better results. DEK has one of the most extensive libraries of sinker EDM services in the industry. We provide complete one-stop sinker EDM services from your part's designing, manufacturing, sample testing, and production to surface finishing, detailed inspection, packaging, and delivery with our state-of-the-art sinker EDM machines.

On-demand Production

DEK's made-to-order sinker EDM services with complete manufacturing systems ensure that you get the cost-effective solutions for your sinker EDM needs. Whether you need low-volume manufacturing or mass production, we have hundreds of options from material selection to surface finishes. Our sinker EDM services are better from a financial, environmental, and operational perspective and the most prevalent way of top-quality manufacturing parts for customers all across the world.

Shorter Lead Times

Our advanced sinker EDM technology saves you valuable time in the production process. We believe that our success is your complete satisfaction, and we achieve that by giving you top-quality machined parts within very short time frames; having shorter lead times increase our ability to manufacture industrial-grade high-performance parts that meet your expectations successfully.

Common Metals for Sinker EDM Services

DEK’s sinker EDM technology is suitable for machining every soft/hard material that is electrically conductive. Below are the most common ones that sinker EDM can process better.

Aluminum

It is a soft and pliable metal with dozens of benefits that make it an excellent choice for sinker EDM. Aluminum is non-toxic and retains its original properties in every application and condition that also makes it extremely cost-effective.

Steel

It is one of the primary materials for sinker EDM and easy to machine as well as an economically perfect solution for your high-quality parts. It can increase the strength/performance of your parts based on its exceptional properties. The versatility of steel enables us to achieve even extremely complex shapes.

Stainless Steel

It offers many valuable properties that can significantly increase the part’s lifespan. Stainless steel machined parts can withstand the most difficult environmental conditions, and upgrading to it rewards both manufacturer and user.

Inconel

It is useful for multiple applications because of its being extremely robust and flexible. Inconel belongs to a family of superalloys based on nickel-chromium. Most interestingly, Inconel offers great resistance against corrosion and oxidation. It can withstand heat and pressure and is well suited for service in extreme environments.

Titanium

It has the highest strength-to-density ratio of any other electrically conductive material that also makes it extremely resistant to corrosion and rust. Titanium has relatively high melting points but low machinability. However, machining it through sinker EDM is an easy task.

Copper

It is a valuable material for sinker EDM because of its unique benefits and properties for a wide range of applications. Its excellent electrical conductivity, high corrosion resistance, and easy machinability is a reason behind its high quality.

Brass

Perfectly machined parts can be produced through sinker EDM rapidly and with a high level of precision and repeatability. We ensure that each machined part meets the strict requirements and specifications. DEK has the ability to produce high-quality brass parts and achieve tight tolerances of +/-0.001mm.

Tool Steel

Sinker EDM has the ability to machine this high-performance material rapidly, accurately, and with high repeatability. Tool steel can improve your parts’ performance and increase their lifespan. High-strength and wear-resisting properties make tool steel ideal for a range of technical applications.

Graphite

It is a common material for sinker EDM because of its high machinability. Graphite is extremely resistant to thermal shock, impact, and force. It has a low coefficient of thermal expansion (approx. x3 lower than copper), which guarantees the stability of the sinker EDM machined part’s geometry.

Our Wire EDM Services as a Perfect Solution for Your Challenging Parts

What makes DEK the leading wire EDM services provider is the quality control, top-grade material selection, and precision machining to achieve tighter tolerances of your parts to maintain exceptional quality and performance. Our primary focus is to surpass your expectations and give you exactly what you desire. DEK’s wire EDM services are cost-efficient and feature prices that are unbeatable in the whole market.

Contact us to learn more about wire-cut EDM services and request a quote today at the best price.

Guide To Sinker EDM & Buying F.A.Q

In the modern industrial world, sinker EDM is of extreme importance because of its ability to precision machining of complex parts.

In this sinker EDM FAQ guide, you will learn how it is the perfect solution for your complex parts machining needs.

Moreover, you will understand how DEK offers the best sinker EDM services in an extremely cost-efficient manner.

What is Sinker EDM?

It is a part machining process and features electrodes and workpiece submerged into an insulting liquid that can be either dielectric fluids or oil.

What defines a sinker EDM is its ability to machine complex shapes without including stresses into materials.

In general, Sinker EDM is a low-risk machining process for complex parts to achieve high-quality designs, unparallel accuracy, and reliability.

Moreover, it enables the manufacturers to achieve micron and standard tolerances from 0.001″ to 0.0005″.

Most importantly, Sinker EDM is known for its ability to achieve high precision tolerances as tight as 0.0001″ for an array of applications and industries.

Sinker EDM enables extreme machining efficiencies when machining multiple identical parts in the same machining cycle.

Additionally, state-of-the-art sinker EDM equipment and technologically-enhanced machining processes enable you to have repeatable quality parts from any conductive material.

Industries like medical, aerospace, power generation have the most use of sinker EDM.

What Are Advantages Of Sinker EDM?

The complex parts that would be difficult to produce with conventional cutting tools are sinker EDM’s responsibility to machined them perfectly.

Machining extremely hard materials to very close tolerances and achieving an exceptional surface finish defines a sinker EDM.

Graphite and copper tungsten is the primary material for sinker EDM electrodes.

CNC programming plays an important part in shaping the material.

The following are the primary advantages of using sinker EDM for your parts:

- Supports vast library of shapes and sizes

- Helps machining with great efficiency, repeatability, and consistency

- Eliminates the chance of size change caused by heat treating

- Handle complex shapes with extreme care

- Extremely hard materials machined to very close tolerances

- Remarkable accuracy

- Fine surface finishing with no compromise to quality or structural integrity

Moreover, sinker EDM requires less time to machine parts that means shorter lead times.

There is no direct contact between the tool and the workpiece in the sinker EDM process that means machining of weak and complex materials without perceivable distortion.

What is the Working Principle of Sinker EDM?

Sinker EDM features an electrically charged electrode as a tool for cutting workpieces and is configured geometrically.

It is most commonly used to machined dies and molds with exceptional detail and accuracy.

The metal parts submerged in a liquid insulating work as the source of current.

When the current flow is on, it creates an electric tension between the metal parts.

When both the electrodes and workpiece are brought closer to within a fraction of an inch, it discharges an electrical tension that creates a spark that jumps across.

When this spark strikes the surface of the material, it heats up and starts melting.

This melting process goes on and starts shaping the material into the desired form. The shape of electrodes defines the final shape of the workpiece.

This machining process is rapid; thousands of sparks fly per second that also known as EDM pulses, before erosion takes place.

However, the material needs to be flushed away. Hence, the spark gap is free of contamination to achieve perfect surface finish and accuracy.

What are the Capabilities of Sinker EDM?

Sinker EDM can burn any electrically conductive material to machine a part, whether soft/hard, without including the stresses into the material.

Sinker EDM is CNC-controlled and operates by following programmed instructions.

This computerized part machining is also considered ideal for low-risk machining solutions for dies, molds, or any other complex shaped part.

Sinker EDM is the advanced machining that is known to minimize park machining risks with reliability and accuracy.

The following are some primary capabilities of Sinker EDM:

- It can achieve typical and tighter dimensional tolerances of +/-0.0002″ but can vary due to the type of material.

- Its C-axis rotation (the rotation Z-axis) creates threaded holes in the workpiece.

- It mostly features an oil bath that submersed the materials to increase the erosion rate.

- With Sinker EDM, a slower feed rate means an increase in surface finishing and quality of parts. Still, a faster feed rate means cost-effectiveness and rapid machining. The standard feed rate of a Sinker EDM machine is 32 RMS or slightly higher.

- It can burn all the conductive materials, including soft or hard metals, including carbide.

- It can repair damaged holes, meaning that it can clean out damaged walls without affecting parts’ geometric position.

What is the Tightest Radius Sinker EDM can Produce?

The chief benefit of sinker EDM is its perfection and accuracy in machining complex parts.

Its capability of producing complex shapes into the materials without inducing stresses helps to produce high-quality and high-performance parts.

Thin walls, cross-sections, and cavities/keywords are some of the common applications of sinker EDM.

This versatility is what makes sinker EDM the more efficient machining technology for stamping dies and injection molds than any other.

The most interesting thing about sinker EDM that the more complex the required electrode, the more effective and precise the sinker EDM becomes without becoming extremely costly.

The tighter radius sinker EDM can produce 0.0005″.

However, with advanced machining technologies and state-of-the-art sinker EDM equipment, 0.0003″ is achievable.

How Many Electrodes Does Sinker EDM Require?

There are many factors that define the final electrodes required for machining a part successfully with sinker EDM.

Depending on the complexity of the shape and custom designing of your parts, they require custom electrodes customized through CNC milling/turnings.

However, the variables electrode wear can be affected by are the following:

- Material type

- On/Off times

- Sinker EDM machine settings

Moreover, it’s a fact that the involvement of more electrodes in the part machining helps to achieve a better surface finish.

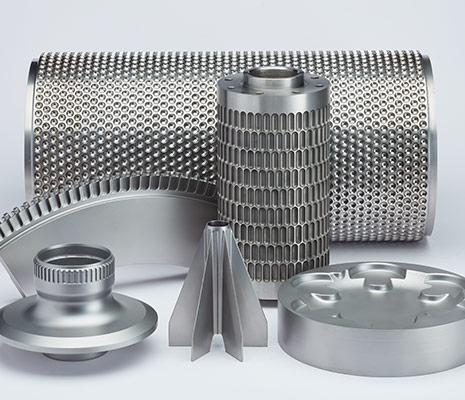

What are the Applications of Sinker EDM?

Sinker EDM is a technologically-enhanced machining technique that can manufacture molds, die sets, and other parts for many industries, mostly include:

- Power generation

- Medical

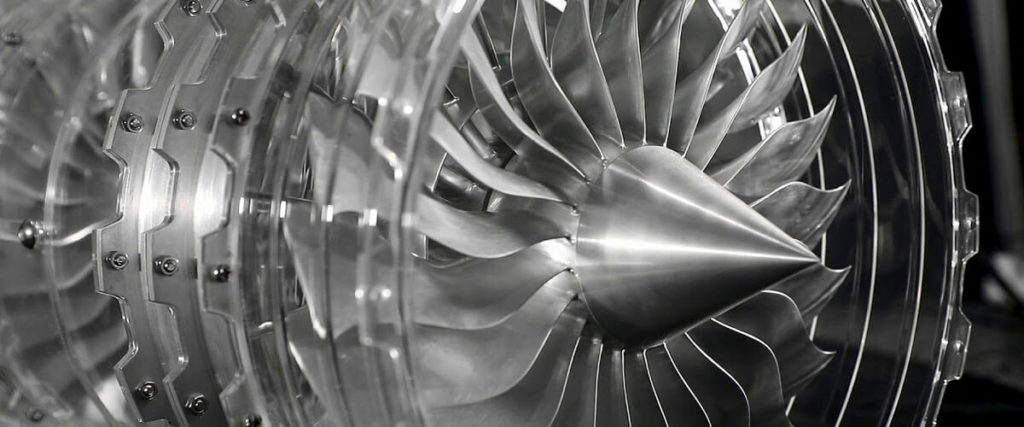

- Aerospace & Space

The precision and accuracy of sinker EDM-produced parts is exceptional and follows the standards even fit for airplane engine parts.

Moreover, the following are the common applications for sinker EDM:

- Micromachining components for medical and electronic industry

- Production of precision and small-scale components

- Tool and die components fit for precision molds, dies, and special machines

- High-precision components for automation and robotics

Sinker EDM is perfect to machine any soft or hard materials like aluminum, brass, carbide, copper, Hastelloy, Inconel, Kovar, stainless steel, tool steel, and titanium other than tungsten and exotic alloys.

Moreover, sinker EDM is an ideal option for a vast library of applications, including:

- Blind cavities

- Thin walls

- Fine Finishes (has the ability to 10 micro-inch surface finishing)

- Blind keyways

- Internal splines, squares, or hexes

- Sharp corners

- Machining threads into hardened parts

- Intricate details

Additionally, tolerances can be held to 0.0001″ with the use of state-of-the-art sinker EDM equipment.

Sinker EDM can produce great surface and edge finishes.

What is the Importance of Sinker EDM in the Manufacturing Industry?

Sinker electrical discharge machining (EDM) is known to be the primary source/standard of removing metal and shaping a part.

It is an electro thermal production process that facilitates injection molding.

Sinker EDM has the capability to produce workpieces in large volumes and features mass production processes.

There are times and circumstances where a certain geometrical shape requires the use of sinker EDM processes to represent itself as a perfectly manufactured part.

Industries that perform mold, tool, and die making for mass production mostly utilize sinker EDM.

Most importantly, sinker EDM is extremely productive in the manufacturing industry because of the following reasons:

- It’s fully optimized and cost-effective

- It focuses on precision and accuracy

- It has the ability to achieve extremely tighter tolerances

- It outputs parts with the perfect surface finish

- Parts can have a longer life-span, quality, and performance

Sinker EDM is highly useful when it comes to machining complex parts to achieve extremely tighter dimensional tolerances that are mostly part of aviation and power generation.

Moreover, sinker EDM is capable of machining prototypes and production parts in the aerospace and electronics industries.

Parts with oddly shaped angles, complex cavities, or intricate contours got perfectly handled by sinker EDM.

With high-tech manufacturing equipment, you can always count on sinker EDM to machine complex parts in cost-efficient manners to achieve your parts’ top-quality and performance.

High-functioning sinker EDM methods are the most organic and known to be perfect for creating shapes in very hard metals before placing them under heat treatment.

What is the Accuracy Enhancing Stability in Sinker EDM?

With sinker EDM, achieving extreme accuracy and uncompromising quality of parts is possible.

Forming exceptional accuracy, highest precision in your parts machining, and unparalleled productivity come together as the future-shaping solution with sinker EDM.

Most importantly, sinker EDM ensures the highest part accuracy and reproducibility as well as also delivers the perfect positioning accuracy along with the entire axis travel.

Customers in electronic component manufacturing now can easily meet their ICT and automotive customers’ quality requirements through the sinker EDM’s state-of-the-art design with:

- Breakthrough generator technology

- Accuracy-enhancing stability

- Thermostabilizing

- Productivity-boosting machining quality

Moreover, it helps to boost the accuracy of parts and your running time with efficiency.

Its high productivity supports and strengthens the end product and is proven to have the best value for your business.

Sinker EDM takes the parts manufacturing to a new level of respect for geometrical details and surface finishing while advancing the manufacturers’ cost efficiency and machining speed.

Additionally, sinker EDM:

- Offers superb accessibility

- Machines a wide range of materials

- Has automated dielectric management

- Extended automation capabilities

- Ever-evolving technological improvements

What Materials Can be Machined in the Sinker EDM Machine?

Sinker EDM features processes that enable it to machine parts with complex designs, shapes, hard to hold, and difficult to machine otherwise.

Sinker EDM is a slower process than traditional CNC milling/turning. Still, it is more cost-effective and can achieve tighter tolerances.

Technologically advanced sinker EDM machines feature electrodes that can fabricate any soft or hard electrically conductive material.

The following are some common materials that conduct electricity and can be perfectly machined through sinker EDM machines:

- Aluminum

- Brass

- Copper

- Graphite

- Inconel

- Steel

- Stainless Steel

- Titanium

- Tool Steels

Moreover, the interesting thing about sinker EDM that the material’s hardness or machinability has little to no effect on its cutting and machining capabilities.

Unlike the CNC turning/milling, where selecting a machining process based on the material’s machinability and hardness is a great consideration, the sinker EDM is virtually the most suitable.

However, sinker EDM is not suitable for machine materials, including tungsten and exotic alloys.

How DEK Offers High Accuracy Sinker EDM Services?

DEK offers high accuracy and precision sinker EDM services to its customers internationally in the most cost-effective manner.

Our 15+ years of experience in machining top-quality parts through sinker EDM is a guarantee that you can count on our expertise.

DEK always focuses on the most organic and fully optimized processes associated with sinker EDM to create a pollution-free and eco-friendly environment that helps to produce parts without wasting valuable resources, material, and energy.

Our sinker EDM technology and state-of-the-art equipment enable us to deliver precision and superb surface finishes at a low cost per part.

Our sinker EDM services feature industrial-leading precision that helps to produce parts with high-quality surface finishes.

Moreover, our services offer supreme reliability and lower manufacturing costs by optimizing the machining process that also minimizes the number of required electrodes.

DEK is an expert in minimizing and controlling the complexities involve in sinker EDM and supports the entire process for shorter lead times and greater process reliability.

Most importantly, DEK is able to produce parts of maximum performance and quality by supporting the whole process with integrated quality control.