Rapid CNC Milling Services - Custom CNC Milling Metal, Aluminum, Plastic Parts

- 3-axis, 4-axis, 5-axis CNC Milling Services are available

- Rapid services, your parts can be shipped as fast as 3 days

- Competitive pricing

- CNC milling metal and plastic are available

- Tolerances of ±0.005mm are achievable

#1 Precision CNC Milling Services Supplier in China

DEK is a world-class CNC milling services supplier to customers in the aerospace, defense, medical, mold, and commercial markets. Our machining knowledgeable staff and the finest CNC milling machines make our services superior in the industry.

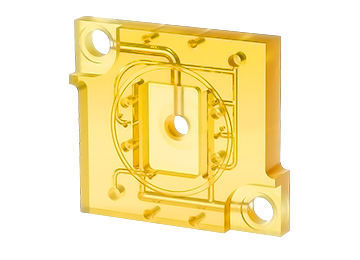

DEK can produce custom prototypes and end-use production parts. Using our 3-axis, 4-axis, and 5-axis milling machines, we can help you rapidly create designs from simple straight lines to complex geometric shapes. We are knowledgeable, lean, competitive, and deliver consistently high-quality products. We maintain an elevated standard of excellence in everything we manufacture.

Our precision CNC milling services provide you with cost advantages that help you maintain a competitive edge without the sacrifice of quality or the threat of missed delivery deadlines. The customer service team is ready to respond rapidly to your every requirement. Contact us today to learn how our precision CNC milling services can benefit your next project.

Precision 3 Axis and 5 Axis CNC Milling Services

According to your unique requirements, budget, and timeline, we will choose a best way for milling. For expert advice, please contact our professional sales team to find the right match for your needs.

3 Axis CNC Milling Service

3 axis CNC milling is one of the most widely used techniques to make mechanical parts. For many decades, it has been well known to manufacturers and other players in the industrial sector, as well as in many other domains like architecture, design, and art.

3 axis milling is a relatively simple process, using conventional machining tools like the milling machine, which allows the material to be worked on 3 axes (X,Y and Z). The machining tool then proceeds to remove shavings in three basic directions corresponding to the axis of a flat surface.

It is very suitable for parts with a simple design and no need for multi-surface machining. For these simple parts, we will use 3 axis CNC milling processing because it is fast and cost-effective.

5 Axis CNC Milling Service

5 axis milling involves all the axes of 4 axis milling, with an additional rotational axis. 5 axis milling machines are the best CNC milling machines available today, capable of creating precise and intricate parts for artificial bones, aerospace products, titanium pieces, oil and gas machine parts, car molds, medical, architectural, and military products.

For some complex internal design or models with multi irregular surface design, we will use 5 axis CNC milling machine to produce, to improve the overall accuracy and reduce the processing time and cost.

What Materials Can Use For CNC Milling?

Our CNC machine shop can machine virtually any engineering material, including plastics, metals, alloys, foam or tooling board. Here is a list of our standard CNC milling materials available, other materials are upon request.

Aluminum is a highly ductile metal, making it easy to machine. The material has a good strength-to-weight ratio and is available in many types for a range of applications.

- 6061-T6

- 5052

- 1060

- 3003

- 4130

- 4140

- 5083

- 6082

- 5A12

- 7075 T651

- 5052

- 2024

- 1100

- 3004

- 5754

- 6063

- 7050

- 5A02

Brass has desirable properties for a number of applications. It is low friction, has excellent electrical conductivity, and has a golden (brass) appearance. It is commonly used in parts that need a large load.

- Brass C360

- Brass 260

- C932 M07 Bearing Bronze

Copper displays excellent thermal conductivity, electrical conductivity and plasticity. It is also highly ductile, corrosion resistant and can be easily welded.

- Copper

- Copper H62

- Copper H65

- Copper H70

- Copper H80

- Copper H90

- Copper alloy special

Stainless steel features a high-temperature resistant, with good oxidation resistance and corrosion resistance. It is widely used in machine parts, contruction industry parts, etc.

- 303

- 304

- 316L

- 2205 Duplex

- 17-4

- 15-5

- 416

- 420

- 430

- 440C

- 301

Plastic is one of the most commonly used materials in the world because of its strong corrosion resistance, durable, waterproof, light weight, low cost and easy processing.

- ABS

- Acetal [Delrin]

- Acrylic

- G-10 Garolite

- Nylon 6/6

- PEEK

- Polycarbonate

- PTFE [Teflon]

- Polypropylene

Titanium alloy is widely used in automobile industry because of its light weight, high strength and good corrosion resistance.

- Titanium Grade 2

- Titanium 6Al-4V

Special steel is a kind of steel with special composition, special production process, special structure and performance, which can meet special needs. Compared with ordinary steel, special steel has better strength and toughness, physical properties, chemical properties, biocompatibility and technological properties. It is widely used in machinery, automobile, military industry, chemical industry, home appliances, ships, transportation, railway and other fields.

- Tool Steel

- Bearing steel

- Die steel

- High speed steel

- Tungsten steel

- Manganese steel

- Molybdenum steel

- Tungsten chromium steel

Available Surface Finishes of Our CNC Milling Services

Surface finishes are applied after milling and can change the appearance, surface roughness, hardness and chemical resistance of the produced parts. Below are the mainstream surface finish types from DEK:

As Machined

This is the standard choice, economical and rapid, the parts’ surface will leave visible machining marks. The surface finish is equivalent to 3.2RA μm (125 RA μin).

Polishing

Polishing is to make the surface smooth by physical friction processing, it is often used to prevent corrosion and remove oxidation. After polishing, the parts have a smoother and brighter finish.

Bead Blasted

Bead blasting is the process of spraying abrasive on the surface of parts under high pressure, after sandblasting, the metal parts have a satin texture or frosted surface, eliminating the processing marks.

Anodized

After anodizing, a hard non-conductive ceramic coating will be added on the surface of aluminum parts to improve the wear resistance and retain the metal texture and luster.

Electropolished

Electropolishing is the reverse process of electroplating, which simplifies the metal surface at the micro-level through chemical solution. After electropolishing, metal parts can be more bright and reduce surface roughness.

Black Oxide

The black oxide is a chemical conversion coating, it is produced by a chemical reaction between iron and oxide salt in black oxide solution. The corrosion resistance of parts can be improved after black oxidation.

Powder Coated

Powder coating can add a layer of solid and colorful polymer coating on the surface of parts, so as to improve the wear resistance and corrosion resistance.

Spray Painting

Spray painting is to spray paint on the surface of parts in the air. After painting, the parts have various colors, improve the aesthetic appearance, and make the parts unique, enhance brand awareness.

Other surface finishes are also available. Please click here to learn all surface finish knowledge. Or contact our sales team to get an instant quote.

Standard Tolerance Of Our CNC Precision Milling

The table below summarizes the standard tolerances of the parts produced. Tolerances up to 0.01mm are available upon request

Tightest tolerance: ±0.005 mm tight tolerances are available to depend on your requirements.

DEK is a Professional CNC Milling Company That You Can Trust

Gapless Communication

You can communicate seamlessly with our English and Spanish sales team, and your requirements will be transferred to the engineering team clearly

Positive Services

Positive after-sales service and solutions. Never shirk responsibility, our team will take the initiative to deal with problems

Fast Response

You can get a quick quote within 4 hours. And we offer fast CNC milling service, you projects will be send out as fast as 5 days or less

Save Cost

We will reduce your 40%-60% purchase cost by investing in the finest milling machines, improving production efficiency, and purchasing raw materials in bulk

High Precision

By hiring true professionals and not just standard workers to operate our CNC milling machines, to ensure you can get the high precision milled parts

Multi Material

More than 60 kinds of material can be chosen, including metal and plastic

Surface Finish

After milling, we can handle several kinds of surface finish, for different requirements and use

On-demand Production

From 1 to 100k+, no matter prototype production, low volume manufacturing, or mass production, our CNC milling services can support you to achieve

Cilents & Feedbacks

We are doing the machining business with DEK have over 12 years, it is a true partner, we both benefit in success by working together. Their high-quality services, on-time delivery, and willingness to work with us to reduce cost, it is why we will still do business with them is the years to come.

Martin S. - Business Owner