The marine propeller shaft is a kind of low-speed marine propulsion and steering system for ships. The marine propeller shaft is widely used on vessels with low speed.

It is a specific part of the marine engine. With proper maintenance, they are pretty reliable but, just as any other part of the engine, it is essential to understand how it works and how to maintain it properly. This article explores the basics of marine propeller shafts on their types, components, and coupling.

What is a marine propeller shaft?

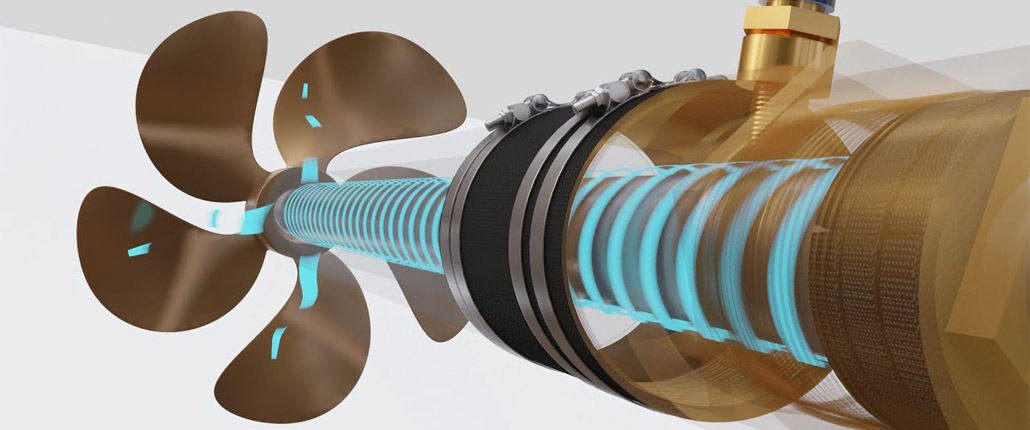

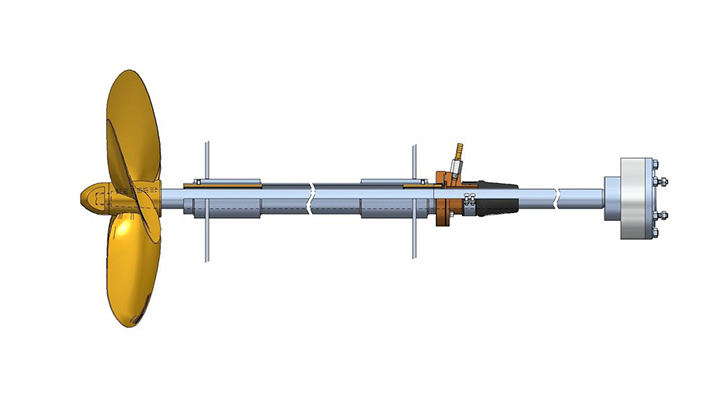

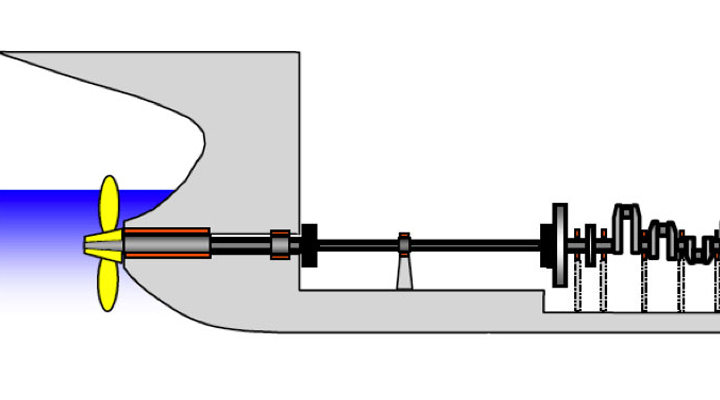

Marine propeller shaft, also referred to as marine shaft, is the center of the propeller propulsion system. It transmits the energy from the propulsion unit to the propeller. The marine axial thruster control unit controls the marine shaft to provide bidirectional movement. Screw propeller and acrylic strip propeller are other standard terms that you’ll hear used when talking about marine propellers.

The shaft comprises the most significant component of a marine engine. It is also referred to as the aircraft engine blade. On ships and aircraft, they simplify servicing a large area or general areas of an interceptor by simplifying the servicing and quickly replacing components of a large size.

How does a marine propeller shaft work?

The propeller shaft also forms an outer and an inner core. The outer core surrounds the main shaft, called the outer shaft. This outer shaft makes contact with the water and causes it to heat up. As this happens, the water pressure coming out of the air perforates the metal skin of the boat. By rapidly firing the blades, the boat can quickly move along at speed. They are also used to connect another related CNC machining for marine use.

A marine shaft works by engaging with another marine component, most commonly a propeller. The propeller can be a screw-blade type or a paddle type. A paddle-type often has ‘blades’ that are turned perpendicular to the shaft’s rotation. So, if the propeller rotates clockwise, the blades would rotate counterclockwise.

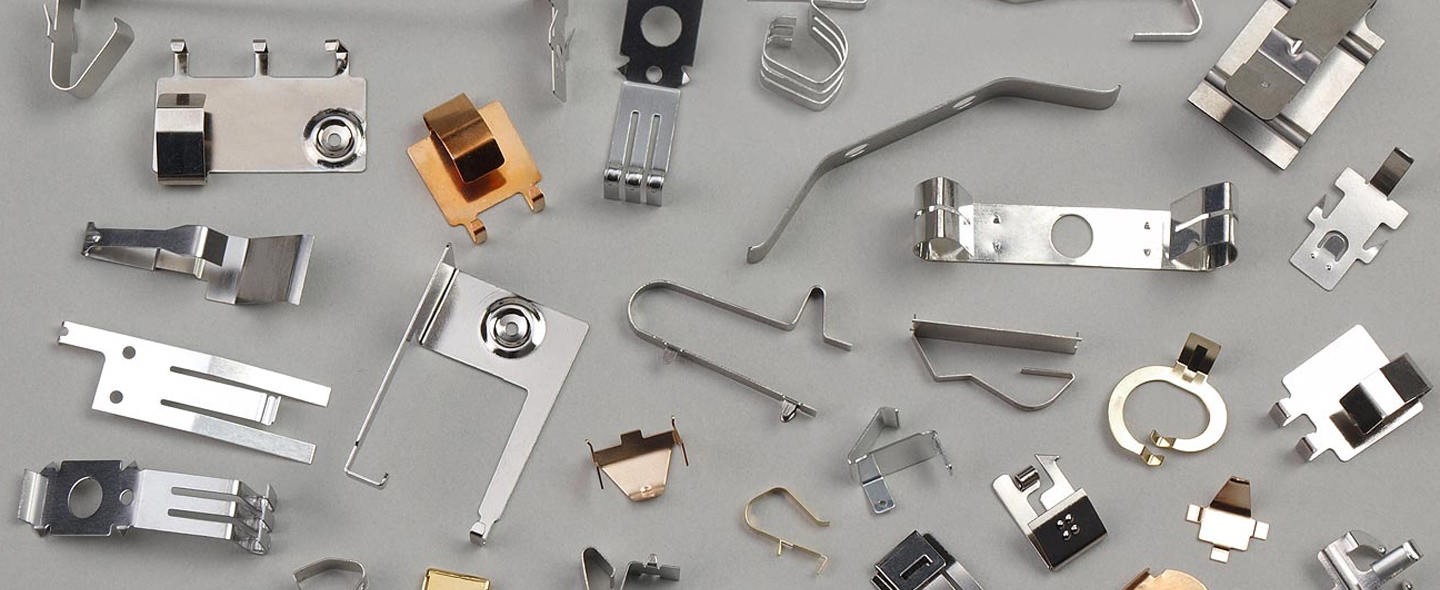

What are marine propeller shafts made of?

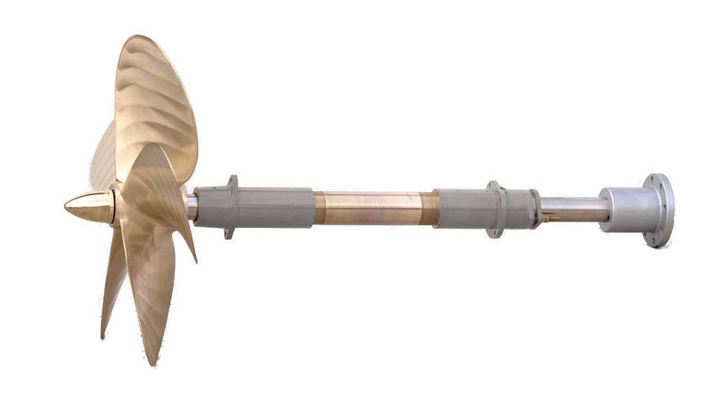

Marine propellers consist of two parts. One part is the main body of the engine or gearbox, while the other part is the upper shaft which may also be made of machining aluminum or copper.

The shafts, which are designed to have a specific diameter, vary in material composition. From the more expensive types, which come in various materials, including high-quality steel, alloys such as nickel and aluminum can be used where the performance is required.

A variety of alloying metals are used in marine, industrial, and construction products that make them valuable parts where strength, durability, and corrosion resistance are essential. Overall, propeller shafts are commonly used in the construction industry as they tend to be lightweight and inexpensive.

What are the significant types of propeller shafts?

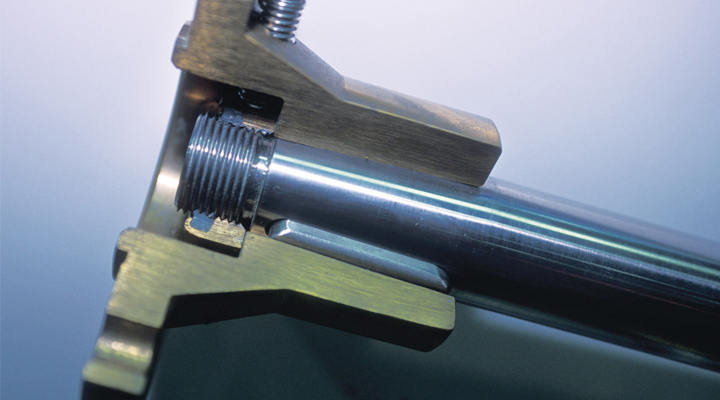

Tapered propeller shaft

A tapered propeller shaft is a wind-assemble structure or part of a tool fixed on a propeller shaft. More precisely, it is the adjustable part of a ship’s or boat’s propeller, allowing variability in pitch or angle. This shaft works by tapping into the universal engine design. The tapered propeller shaft is also the main connecting thread in a propeller hub. At its heart, TPLS is a coil spring of constant length with constant load force being applied.

Splined Propeller Shaft

These kinds of shafts are responsible for torque transfer. They are the teeth of the drive shaft. It is tasked with maintaining alignment. Splined propeller shafts are a great way to get the most out of your motor. They provide better air volume with a flatter path in the engine such that the air that is burned has more speed ductile. They also help reduce vibration and unwanted noise.

Flanged Propeller Shaft

This is an elongated cylindrical shaft with one or more flanges or flat circular faces at regular intervals to resist bending. This type of shaft is usually used in various manufacturing industries and has different purposes.

A flanged propeller shaft is the piece of equipment that connects the machine to the motor. The flanged propeller shaft has a longitudinal extrusion flange at both ends. The flange can be divided into two kinds: the positive flange and the opposing flange.

What are the materials used for the marine propeller shaft?

The materials for most propeller shafts of marine are of low carbon steel. Aluminum alloys are not a good fit for marine propellers because they possess a fatigue limit for rotors. When cyclic stress increases, your aluminium propellers will not be able to survive the magnitude.

Steels made of martensite are quite a good choice, given they perform excellently during cyclic stress. They enhance the more they are faced with that magnitude. Most commercial marine vessels and aerospace machining employ the Tobin bronze or monel for their propellers because they are primarily non-corrosive. This will ensure zero or minimal leakages over time.

How do I choose a marine propeller shaft?

Choosing the right marine propeller shaft for your boat can be confusing. There are many considerations, including width, pitch, length, and durability. First, you need to know the main parts of the marine propeller shaft. And you should comprehend various materials and their properties as well as the manufacturing process.

There are many ways to choose the best marine propeller shaft for your boat. First, you must get familiar with basic metrics like diameter and length before moving on to the next question. Whether you’re choosing a single or double blade, these factors form the backbone of proper comparison.

The most critical factor in choosing a quality design for your superior quality marine propeller shaft is first to understand what you want. One of the best ways to find the right shaft is to examine a boat’s design or hull.

What is marine propeller shaft coupling?

There are many reasons why we need to have marine propeller shaft coupling. One of the reasons is a convenience when it comes to moving. The propellers are mounted, and they can be moved very easily by just “unscrewing” them. When we unscrew the propeller, we can replace them with other products.

The marine propeller shaft coupling is one of the crucial parts of the marine engine. The underwater crankshaft connects with the underwater propeller blades by way of the marine propeller shaft. As usual, the crankshaft is the much more significant portion of an engine, measuring about 12 meters by 7 meters in length. In comparison, the underwater upper part is made of this material and measures 2.5 meters by 1.5 meters in diameter.

Marine propeller shaft couplings are designed to tie down two marine propellers and keep them in place. These marine propellers are typically 55-65 inches in diameter and 545 grams in weight.

Straight propeller shaft coupling

They rely on propeller shafts on a lighter base. They are also called the straight-bore coupling, which is of the same diameter on both sides. The straight propeller is being coupled with the shaft by using a mallet, a block of wood. Minor damage can cause a slight raise of misalignment on the face, leading to unnecessary vibrations during motion.

Split propeller shaft coupling

These couplings are known for their bifurcated ensemble. The shaft plates here are divided into two separate parts but maintains the required synergy needed for smooth motion. Both parts are fastened to the shaft by screws. One undeniable advantage of this coupling over others is that it is easy to detach. This can be achieved by driving in some wedges into the split gap.

Tapered propeller shaft coupling

This is the most commonly used amongst the three. They possess a cone-shaped bore that has a similar concept to a hub core. They engage the cone machine, which is located at the front of the propeller shaft. This ensemble is very reliable due to its flexible compactness. They are never too tight or never too loose to be detached.

Can you offer customized marine propeller shafts?

Yes, I would recommend custom-made propellers to a friend. There are numerous companies skilled in producing customized marine propeller shafts. The size and material of the shaft itself are irrelevant. What matters is the direction of the airflow in the shaft.

Most customized marine propellers are built to withstand tremendous forces and function reliably even under adverse weather conditions. They are constructed of lightweight alloy steel and are topped with high-strength polypropylene bearings coated with ceramic coating. The shaft and bearings are packaged together and high heat-resistant resins that help minimize heat buildup and corrosion. After heating, they then become solid cores which help retain shape and resist deformation.

Conclusion

We have been able to highlight everything that is needed to be said about Marine propellers. They have been hexagonal, conical, and square designs. Hexagonal is the most common and was used on small wooden bicycles; conical, also known as shotgun-style and invented in the mid-20th century; and square, more recently used.

All shafts have one common characteristic: they have an oval-shaped opening at the ends. The specifics about how they are used depends on the type of material they are made and manufactured. So, if you are wondering what kind of material it is made from, it comes down to the shape of the opening. By now, I’m sure you might have gotten a good idea of how a propeller works.