Precision Wire EDM Machining Service

DEK provides first-class wire EDM machining services and is committed to providing customers with high quality complex-shaped machined parts. We excel in machining all conductive materials and easily cut a variety of hard special materials. We can generally achieve a machining accuracy of 0.005mm and a roughness of Ra 0.8 to produce parts with complex shapes, sharp corners and fine features. We have passed ISO 9001:2015, AS9100D and ISO 13485 certification.

introduction

High Quality Wire EDM Machining Services

DEK specializes in precision wire EDM machining, providing customized services for you who require complex, tight-tolerance parts. We can machine all electrically conductive materials such as tool steel, stainless steel, alloy steel, carbon steel, aluminum alloys, copper alloys, titanium alloys, nickel alloys, tungsten and more.

With state-of-the-art machining equipment and machinists with excellent programming skills, we can achieve tight tolerances of 0.005mm and roughness of Ra 0.18. Whether you need a single part, a prototype, or mass production, we are able to manufacture parts to meet the exact specifications and requirements of your project and ensure a high level of quality and accuracy.

Our team works in depth with companies in a wide range of industries, making us the ideal choice for manufacturers of parts commonly used in aerospace, medical devices, mold making, automotive, electronics and more. We can produce parts with high precision and complex geometries such as: turbine blades, implants, micro parts, die casting mold parts, stamping die parts, engine components, and connectors. Choose cost-effective, high-precision, repeatable on-demand machining services, contact us today!

- Get a quote within 6 hours

- All conductive materials can be machined

- Complex, low volume parts with very tight tolerances

- Machining accuracy of +/- 0.005 mm possible

- No cutting forces, virtually burr-free

- Highly repeatable, no distortion

Variety of Materials for Wire Cut EDM

Metals

Aluminum

Aluminum is a lightweight, highly thermally conductive,highly electrical conductivity, corrosion resistance and popular metal for Wire EDM machining.

At DEK, we specialize in machining all types of aluminum, including 6061, 7075 and 2024, you can get high-precision parts for mold, automotive and aerospace fields, such as injection mold parts, die casting mold parts, stamping die parts, engine parts, and aircraft components.

Alloy

AL6061, AL6063, AL5083, AL5052, etc.

Alloy Steel

Alloy steel is an alloy of iron (Fe) and other elements including carbon, chromium, nickel and molybdenum. It is a common metal used in wire EDM. It is widely used in automotive, aerospace and mold manufacturing due to its high strength, hardness, wear resistance and corrosion resistance.

At DEK, we specialize in machining all types of alloy steel, including 4130 and 4340. You can get high-precision parts such as: automotive engine parts, gears, bearings, turbine blades, stamping die parts, die casting mold parts.

Alloy

Alloy Steel 1215, 4130,4140,4340,8620,A514 etc.

Brass

Brass is mainly composed of copper and zinc and has a yellow metallic appearance. Brass is widely used in mechanical and electronic fields due to its excellent machinability, good electrical conductivity, thermal conductivity, corrosion resistance and excellent mechanical properties.

At DEK, we specialize in machining all types of brass, and you can get high-precision parts such as bearings, gears, valves and connectors.

Alloy

Brass 260, C360, Cz121,etc.

Bronze

Bronze is a copper-tin alloy with excellent corrosion resistance, electrical conductivity and castability.

At DEK, we specialize in machining all types of bronze, including 544 and 841, our high precision services ensure high quality parts for industries such as machining and artwork, ideal for bearings, gears, precision instrument parts, mold parts, decorative items.

Alloy

Bronze 544, 841, 932,954, etc.

Copper

Copper is a highly conductive metal and is widely used in electronics and machining due to its good thermal conductivity, ease of machining and corrosion resistance.

At DEK, we specialize in machining all types of copper, including 101 and 110, so you can get high-precision parts such as electronic components, heat sinks, various mechanical parts (bearings, gears, springs, valves), mold parts.

Alloy

Copper C101, C110, etc.

Inconel

Inconel is a nickel-based alloy composed of nickel, chromium and iron. It is often used as a workpiece material or electrode material in wire-cut spark discharge machining. It has excellent high-temperature strength, corrosion resistance and oxidation resistance, and meets the processing needs of various complex shapes.

At DEK, you can get high-precision parts for the aerospace and chemical industries, such as aircraft engine components, turbine blades, fuselage structural parts, and heat exchangers.

Alloy

Inconel 718, 625,620, etc.

Mild Steel

Mild Steel has a carbon content of 0.05% to 0.25%. Due to the low carbon content, mild steel has excellent machinability and ductility.

At DEK, we specialize in machining all types of mild steel, including 1018 and 1215, and you can get high-precision parts required for machining and automotive, such as various mechanical parts (gears, bearings, valves), mold parts, structural parts, automotive engine parts.

Alloy

Mild Steel 1018, 1045, A36, 1215, etc.

Stainless Steel

Stainless steel is an excellent material choice for wire EDM. This is because of its good mechanical properties, corrosion resistance, and high temperature resistance.

At DEK, we specialize in machining all types of stainless steel, including 304 and 316, so you can get high-quality parts for industries such as aerospace, chemical, and medical devices, perfect for turbine blades, turbine shafts, guide vanes, fasteners, flanges, valves, implants, and medical device housings.

Alloy

Stainless Steel 301, 303, 304, 304L, 316, 316L, 410,etc.

Titanium

Titanium is a lightweight, high-strength metal material that is popular for wire EDM machining. It has high temperature resistance, excellent corrosion resistance, and is biocompatible.

At DEK, we specialize in machining all types of titanium, including grades 2 and 5. Titanium is widely used in aerospace and medical applications, and you can get high-quality parts such as: aircraft engine blades, turbines, connectors, artificial joints, and medical device housings.

Alloy

Titanium Grade 1, Grade 2, Grade 5, etc.

Tool Steel

Tool steel is mainly composed of carbon, chromium, molybdenum, cobalt and other metal elements, it is a high-quality high-alloy steel with good hardness, wear resistance and heat treatment properties.

At DEK, we specialize in machining all types of tool steels, and you can get high-precision parts for aerospace, mold making, and machining, such as injection mold parts, stamping die parts, engine components, bearings, and gears.

Alloy

Tool Steel A2, A3, D2,S7, etc.

Tungsten Steel

Tungsten steel is an alloy composed of elements such as tungsten, cobalt and carbon, with high hardness, high wear resistance, good electrical conductivity and corrosion resistance, it is a commonly used electrode material for Wire EDM.

At DEK, we specialize in processing all types of tungsten steel, and you can get high-precision parts for mold manufacturing, automobiles and aerospace, such as injection mold parts, stamping mold parts, drawing mold parts, cutting tools, micro parts, engine parts, vortex blades.

Alloy

Tungsten Steel YG6, YG8, YG15, YL50, etc.

Diverse Surface Finishing Choices

Anodizing

Anodizing is an electrochemical process that enhances metals' corrosion resistance, durability, and appearance, particularly aluminum.

Black Oxide

Get functional and aesthetic benefits in one with Black Oxide surface finishing. It's a matte black finish that also adds protection to metals, reducing corrosion and wear over time.

Polishing

We enhance the visual appeal of components by providing a smooth and reflective finish with our polishing services. Polished surfaces can also serve as excellent bases for coatings, providing better […]

Electropolishing

Electropolishing enhances the corrosion resistance of metal by removing impurities and creating a clean, passive surface.

Heat Treatment

Improve the physical and mechanical properties of materials through heat treatment. Improve hardness, increase strength, enhance toughness, stress relief, and more.

Passivation

We form a thin, inert layer on the material's surface that protects it from environmental factors that could lead to corrosion. Passivation is commonly used in metals like stainless steel […]

Laser Marking

We provide high precision and accuracy, enabling intricate designs, fine details, and small text to be marked clearly on a wide range of materials, including metals, plastics, glass, ceramics, and […]

Electroless Nickel Plating

DEK offers electroless nickel plating’s adjustable hardness levels, can be engineered to be non-magnetic, adheres tightly to substrates, and the thickness is precisely controllable.

Nickel Plating

A uniform thickness and smooth finish contribute to an aesthetically pleasing appearance and consistent protective qualities. We ensure our process results in materials that can withstand friction and abrasion for […]

Zinc Plating

The compatibility of zinc plating with various materials adds to its appeal, while its ease of application and established use make it a readily available option.

DLC Coating

The low friction coefficient of DLC coatings reduces resistance between surfaces, providing durability to components like tools and mechanical parts.

PVD Coating

We offer a wide range of decorative finishes with PVD coating, including various colors and aesthetic effects. This process can also make materials more resistant to wear, abrasion, and scratching.

Powder Coating

Get a resilient finish that is resistant to chipping, scratching, and fading. Powder coating is your low-cost, eco-friendly finish that has long-term benefits, including reduced maintenance and enhanced longevity

Media Blasting

We commonly use media blasting in restoration projects to clean and rejuvenate surfaces without causing damage. We can effectively remove years of grime, corrosion, or coatings from historical or vintage […]

Instant & Accurate Quotes

We don't use online automated quotation tools, because it is very inaccurate. Online quote platforms rely solely on calculations based on cutting amounts and fixed coefficients, they fail to account for actual processing nuances, such as material deformation after heat treatment, tight tolerance requirements, grinding after heat treatment, etc. Consequently, automated price calculations can lead to inaccuracies, ultimately increasing your costs.

But you can rest assured at DEK!

Our quotations are both cost-effective and accurate because we have a team of professional mechanical engineers who meticulously review each drawing. These engineers boast over 10 years of experience and possess deep expertise in programming, machine operation, post-processing, material properties, and more. Ensure you will get accurate quotes within 6 hours.

PRODUCTION CAPACITY

Production Capacity Guarantee

With perfect production and quality process, you can place your order with confidence.

Advanced CNC Machine Shop

Quality Control

Professional Packaging

Global Shipping

Our Advantages

2300+ Engineers Love Work With Us

High Precision

DEK has been specializing in submerged EDM for many years, achieving tight tolerances of +/-0.005 mm and maintaining dimensional accuracy on tools and metal parts machined after heat treatment.

Complex And Thin Shapes

Wire EDM is ideally suited to producing parts with complex contours and designs. It is particularly good at producing narrow slots, fine holes and thin-walled sections that may be problematic for other machining methods.

Outstanding Surface Finish

The process provides an excellent surface finish, reducing or sometimes eliminating the need for secondary finishing processes. The burr-free and smooth surface is often superior to many other machining techniques.

Swift Delivery

DEK has established a long-term good relationship with UPS, FedEX, DHL and other courier companies, which can provide global transportation services for your project, guaranteeing the timely delivery of goods, and delivering the goods to you within 3 days at the earliest.

No Mechanical Stress

Since wire EDM is a non-contact process, this does not exert direct mechanical force on the workpiece, ensuring that parts are stressed or deformed during machining.

Ability To Cut Hardened Materials

Wire EDM makes it easy to machine hard, hardened metals, including those that have been heat-treated. This capability eliminates the need for post-machining heat treatment in many cases

24/7 Engineering Support

Our professional engineers are available online 24/7 to answer any questions you may have about your Wire EDM machining project. We are always available to provide technical support to ensure that your project is completed on time and within budget.

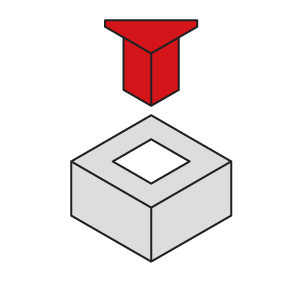

Our Ordering Process

Send RFQ

Send RFQ with 2D/3D drawings and detailed requirements via Email or online form.

Review & Quote

Our Engineer team will review every drawing carefully and provide an accurate quote within 6 hours.

Confirm Order

Confirm the quote, details and delivery schedule, then sign the contract.

Production

Arrange production process, start programming and machining.

Quality Control

Strict quality control during production and final inspection.

Packaging & Shipping

Pack the parts, attach part identification labels, and start shipping.

Send RFQ 222

Review & Quote

Confirm Order

Production

QC

Delivery

FAQ

Wire EDM Buying FAQs

Get An Accurate Quote For Your Next Projects

No matter your project is complicated or simple, no matter is metal or plastic, you will get an accurate quotation within 6 hours.

Get A Quote TodayGetting to Know Wire EDM

What is Wire EDM?

Wire Electrical Discharge Machining (Wire EDM) is a precision machining method primarily used for shaping conductive materials like metals. In this process, a thin, electrically conductive wire serves as the cutting tool and is threaded through the workpiece. The workpiece and wire are submerged in a dielectric fluid, often deionized water, which acts as an electrical insulator and coolant.

High-frequency electrical discharges, or sparks, occur by applying a voltage between the wire and the workpiece. These sparks generate intense heat, melting and vaporizing a small portion of the workpiece material. The dielectric fluid then flushes away the molten debris. The wire continuously advances, exposing new workpiece sections to the sparking process, allowing for intricate and precise shaping controlled by computer numerical control (CNC).

If you want to know the difference between wire EDM and Sinker EDM, don’t miss this blog.

What are the Pros of Wire EDM?

- High Precision

- Versatility with various conductive materials

- No contact cutting, minimal tool wear

- Capable of producing intricate shapes with tight tolerances

- Minimal material stress and heat-affected zones

- Can cut through hard materials like hardened steel and titanium

- Equipped with automation and CNC control for precision

- Low cutting forces, suitable for fragile or thin-walled components

- Efficient for small-batch or prototype production

- Excellent surface finish, reducing the need for additional finishing operations

When do you use Wire EDM?

Wire EDM is widely used in industries requiring intricate and highly accurate components. One notable use is creating molds for intricate plastic components, shaping tough materials like titanium for aerospace turbine blades, and crafting extrusion dies for aluminum profiles in construction and transportation.

Wire EDM ensures precision in manufacturing medical implants, electronic connectors, and Microelectromechanical Systems (MEMS) devices. In the automotive sector, it aids in prototyping engine components. Custom tooling benefits from Wire EDM's high precision, such as punches and dies for metal stamping.

Wire EDM excels in scenarios requiring intricate shapes and tight tolerances, offering versatility in various manufacturing applications.