Welcome to the ultimate guide of End of Arm Tooling. It will help you know about every detail related to the functioning and applications of the tool for robots. The use of arm tools for robots in certain industries and the components composed of this tooling will all be explained in this guide.

What is End of Arm Tooling (EOAT)?

End of arm tooling (EOAT) is a fundamental feature of robotic technology. It is the equipment linked with parts and components usually present at the end of a robotic arm—for example, the welding torch on a robotic welding system.

As the name indicates, this is a tool used at the end of a robotic arm. It is purposed for the safety of robots and humans as well. It is also named an end effector. Its prime importance is in its unleashing of automation potential in the robots.

What is the function of End of Arm Tooling (EOAT)?

The end of arm tooling is the structure that helps the robots perform certain chores efficiently. Its basic function is to improve the automation and speed of working of the robot. It functions to improve the accuracy of work. There are certain types of this tooling, and each one of them has different functions.

The end of arm tooling gives a specific but variable functionality to the robot. It helps the robot to perform different duties and fit in different applications. The EOAT has the special ability and improved technologies that enable the robot to perform several duties at a time. As the capabilities of the end of arm tooling improve, robotic technology improves.

Applications of End of Arm Tooling (EOAT)

End of arm tooling has found many applications in different fields. They include over-molding, bin picking, automation, clean room, and single or multi-cavity.

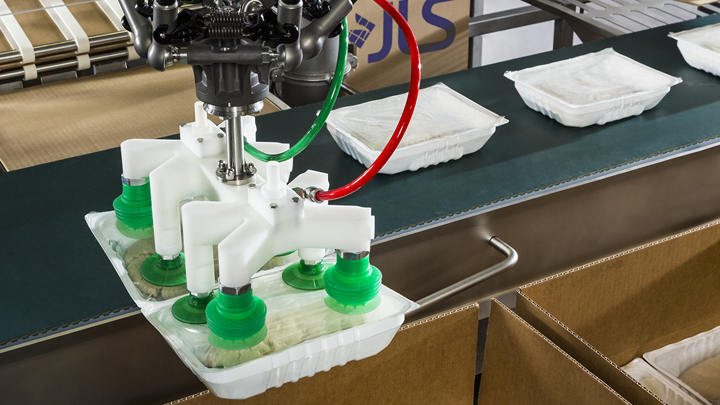

Random bin picking

The mainstream application of end of arm tooling in robots is a random bin picking service. The robots transfer different shapes and sizes from the required place to other. It is a computer vision and robotics-related core problem. The robots used for this picking are loaded with sensors and cameras.

Those robots pick up the objects from the bin with some random poses. Besides vision systems, the end of arm tooling plays the most crucial part in this. The objects are picked up by different types of arm end tooling like a suction gripper, parallel gripper, or any other type.

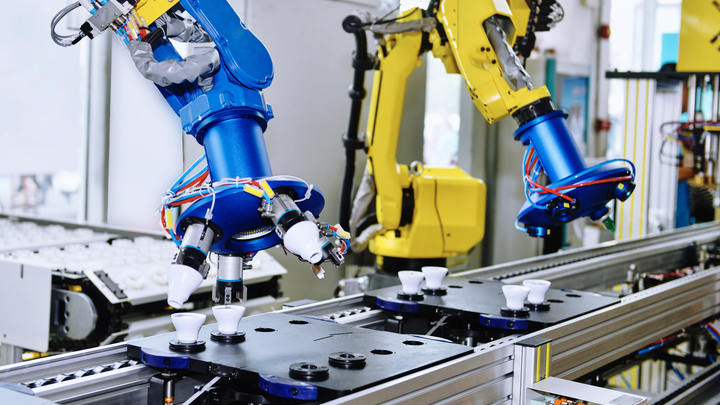

Automation in Robotics

The end of arm tooling provides automation to the robot. The end of arm tooling is a special type of light-weighted, conformal, and strong hand extension in the robots. It has seven metal segments that are joined together with the help of six joints.

The computer takes the power to control the robot by rotating the motors joined to each joint. These motors move in increments and allow the robot to move its hand easily. The end of arm tooling helps the robot sense and move in the right amount and direction. Hence, it helps the robot perform several industries, including manufacturing, packaging, food, agriculture, printed circuit boards (PCB) manufacturing, and so on.

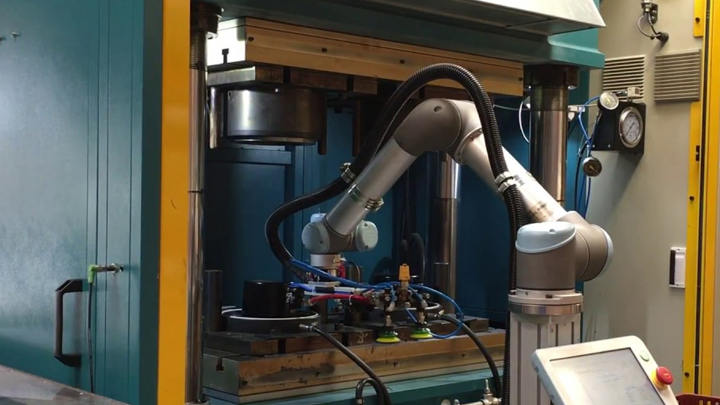

Injection molding

Robotic automation system that is enabled by the end of arm tooling has expertise in press-to-press transfer automation. The automation helps in the plastic injection molding of some specific operations. Automation systems in robots have a wide range of press-to-press transfer robots.

Different axes from the joints of arm tooling are used for this function. The most important ones are 3-Axis Robots and 6-Axis Robots. The 3-Axis Robots are top entry robots, while the 6-Axis Robots are articulating robots.

The top entry robots are used for the services that need high-speed options. Mostly they are used for top entry applications. The articulating robots are used for the services that need varied automation, which neither requires high speed nor much low. They are used for side entry applications.

What industry is the End of Arm Tooling (EOAT) suitable for?

We all know that robotic technology has been used as the most influential and time-saving technology. Many industries have replaced laborers with robots to improve their productivity. Robotics boosts efficiency and ease for both the consumers and the producers. I will explain some of the top industries that use arm tooling and robotics technology to improve their work.

Health care

You might be wondering about how can robotics take over the duty of health care professionals? Let me clear it to you that the technologies in robotics have not replaced the professionals, but they only make their work easier. End of arm tooling has been quite helpful in therapy, patient companionship, surgery, and other daily activities.

The end of arm tooling can help the nurses lift the immobile or elderly patients who cannot move independently. The arm movements are used in the surgery to hold certain tools in the patient’s body. The movements at the end of arm tooling allow the minimum invasion in surgeries.

Agricultural industry

One of the important uses of end of arm tooling in robotics is in the agricultural industry. Farmers have already been using machine technology in their fields. Now the robotic technology is helping them in irrigation. The sensor technology helps to eliminate pests from the crops.

Some processes in which the end of arm tooling has helped the farmers in the field include pruning, weed removal, mowing, spraying, and thinning. The automation in the arm tooling will help you in performing these activities easily.

Food preparation

We have wondered that robots might replace humans someday because the advancements they are making in today’s world are unmatched. End of arm tooling can be quite helpful in preparing and packaging food with the help of its automatic functioning.

We have now advanced so much in robotic technology that there are intelligent robots with arm tooling. The robotic chef is easily controlled with the help of a smartphone, and once you save the recipe, they start preparing food in a huge amount quite faster than the humans. Certain technologies are working on designing a smart robot that can perform other functions in the kitchen.

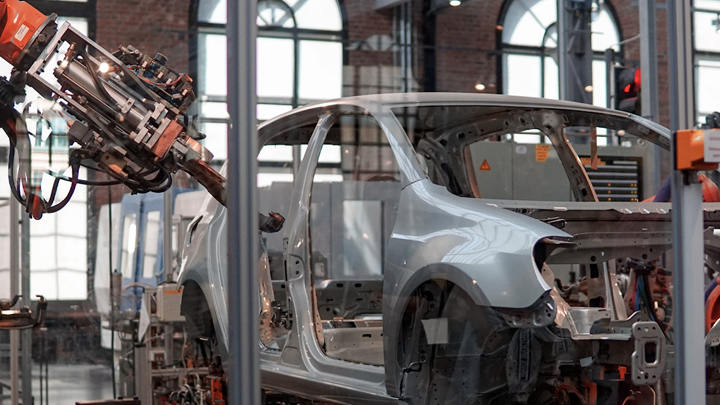

Manufacturing industry

The productivity and efficiency of many businesses have tremendously increased by using robotic technology.

The cost of these robot-made products is also quite reasonable. The automation and memory at the end of arm tooling have helped in many industries.

The robots help the workers in performing repetitive tasks quite efficiently. The workers also use arm tooling under their strict supervision to perform intricate tasks. The end of arm tooling has now become a safer and speedier option for manufacturing companies. The cameras, sensors, and automation enable the robot to work safely and stay clear from humans in the workplace.

Military

You might be surprised to know that robotic technology has found its use in military services. The armed forces have intelligent and smart robots that help them in their services. The automatic system at the end of arm tooling helps the robots release several fires in any foreign attack. The sensors and cameras in the arm tool can be beneficial in detecting any danger or enemy attack.

The end of arm tooling has many other applications in different industries. The human-less manufacturing of the items with increased efficiency and lower rates has increased its scope. We hope that shortly, this tooling technology will be helping us in many other fields as well.

What components is End of Arm Tooling (EOAT) composed of?

The end of arm tooling is composed of the following components

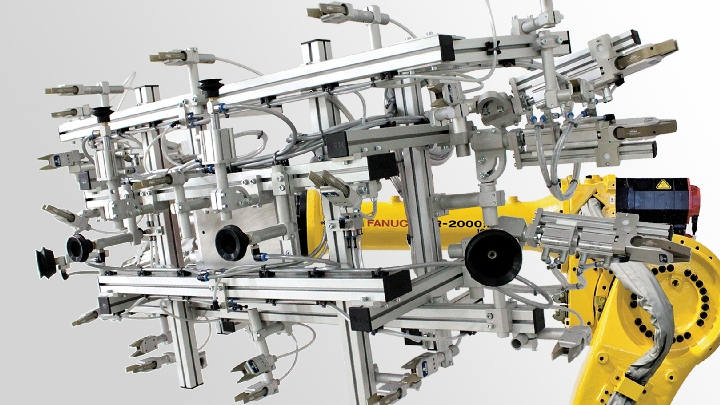

- Gripper systems; including the gripper arms, gripper fingers, and grippers

Grippers help in holding the object tightly or loosely as required. It enables holding, handling, tightening, and releasing of the object that needs to be manipulated.

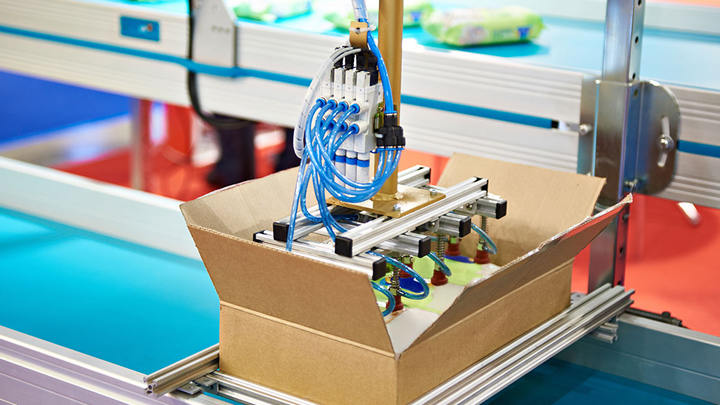

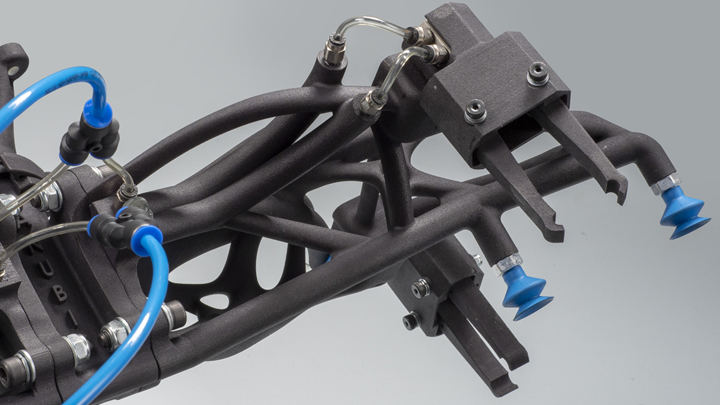

- Vacuum cup systems

They help in the transfer of certain heavy and large smooth objects. For example, glass panes and windscreens are transported easily to long-distance destinations. They are also helpful in affixing the objects that have nonporous vertical surfaces.

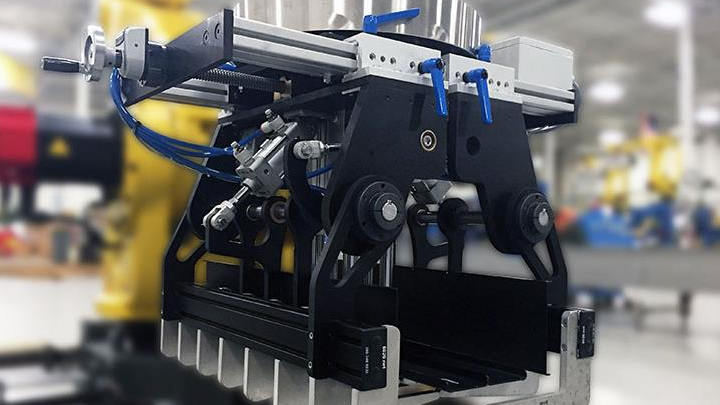

- Quick change devices

These are the parts of the robotic system that help in the adjustability of the arm tooling for performing various functions. They satisfy the industry’s needs with interchangeable parts.

- Profile-channel nut

They are used for tightening or losing the arm tooling in the robot according to the need.

- Clamps

The clamps in the EOAT have specialized tips that help in interchanging the parts of the end of arm tooling. They can be changed quickly and assist the robot to work in different applications.

- Nipper bodies and blades

They are used to reconfigure the arm tool whenever it is required. The end of arm tooling provides multiple axes to the attachment site. It provides variety and diversity in the functions and applications of robotic arm tooling.

- Pneumatics

Pneumatics are air-powered systems present in a robotic system that start with a compressor. The air moves to the reservoir, which stores the air. In a robotic system, the pneumatic system controls the flow of air. The air, in turn, controls the movement of a certain robotic part.

Some other components that have their role and function are named as follows:

- Cylinders and slides

- Microsystem

- Profile connectors

- Certain other accessories

Where do we attach the End of Arm Tooling (EOAT)?

The end of arm tooling is attached to the end of the wrists of the robots. It is also attached to the minor axes sometimes. Different components of the EOAT have different attachment sites. The tool changer helps in the attachment of the robot and its end of arm tooling.

A tool changer is present between the gripper and the robot. The tool changer exchanges the signals between the robot and the gripper to help the robot perform its function accurately. The tool changer at the end of arm tooling hence helps in improved productivity.

The trend of End of Arm Tooling (EOAT)

The improvements in customer demands and the revolution in robotic technology have brought some new trends at the end of arm tooling. I will help you learn about how these new trends have affected productivity.

Connected EOAT

Industrial automation system has found much connectivity in the industry. End of arm tooling can help in collecting useful objects from the stored data by using the internet. End of arm tooling can also help in communicating with other parts of the production line.

The typical application is easily made faster with this tooling. I will tell you how this happens. If we allow the arm tooling to position itself automatically, the robot programmers can make applications faster. It results in less downtime and indolent working hours.

Servo Grippers

The arm tooling helps in picking the material from anywhere in any possible orientation. It can tightly grasp a component or a product that helps the manufacturers in the labor challenges. The end product is moved speedily and undamaged with the help of servo grippers. The servo grippers have improved force-torque sensing and tactile sensing.

Modular Vacuum Grippers

Modular vacuum grippers are needed for the products that are dealt with gentle handling. The arm tooling can help in handling agricultural products and food processing. The soft grip of arm tooling is handled quite carefully without any damage. Different sizes and types of food are easily handled with the same gripper as the arm tooling.

The vacuum grippers are very compact. Small-sized robots can do the sorting and packing of food items. They are quite versatile, and they let food processors change the sorting and packaging with time. For this service, you do not even need to change the robotics and invest in EOAT. The arm tooling has vacuum bars that help to have a strong grip and replace the suction cups.

Conclusion

The end of arm tooling is an important part of robotic technology. It has diverse functions and applications. The variety in the performance and capabilities of the EOAT make it an integral part of many important industries. As time is advancing, arm tooling is gaining more and more popularity in various fields.