- Home

- Aerospace Prototyping Services

Aerospace Prototyping Services

DEK has extensive experience in the aerospace industry and we offer reliable aerospace prototyping and manufacturing services. Whether it's a large, complex prototype or a small, precision metal part, we always maintain tight tolerances and meet industry quality standards, and we produce on-demand at competitive prices to bring products to market faster through rapid prototyping, bridging tooling, and low-volume production.

- Production-grade Products

- 24/7 Engineering Support

- ISO 9001:2015 Certification

- Design for Manufacturing (DFM) Analysis

Aerospace Component Manufacturing for Prototyping and Production

At DEK, our reliable rapid prototyping services have been serving numerous customers in various stages of the aerospace industry for over a decade. We can quickly create prototypes of aerospace parts and produce small or large quantities at high quality standards and affordable prices.

We can provide the materials or processes you need for manufacturing, including CNC machining, sheet metal fabrication, 3D printing and more. With our professional and experienced technical support, we can ensure high dimensional accuracy and consistency. No matter how complex the surface design, we can meet or exceed the expectations of our aerospace customers.

We are proud to work with industry leaders to help them launch new products faster. Some of our successes include: business class seat armrest, economy class seat table, aisle spreadbar, tray table assembly and support blocks. DEK has no minimum order quantities, offers a wide variety of surface finishes, and maintains strict quality control to provide a solution for projects of any scale or complexity.

Business Class Seat Armrest

Millimeter Wave Receiving Module

Radar Communication Module

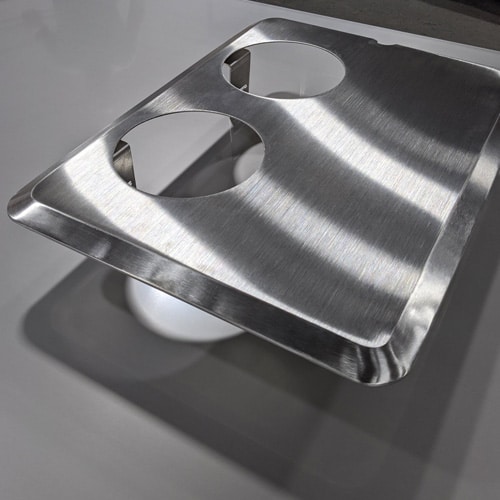

Tray Table Assembly

Aerospace Prototyping Capabilities

CNC Machining

DEK has state-of-the-art CNC machining centers with 3, 4, and 5 axes for a wide range of plastics and metals including aluminum, titanium, brass, alloy steels, POM, PTFE, PC,PDHE, and other product grade materials.

Our engineering and production teams have the experience and design flexibility in aerospace prototyping and part production to quickly produce physical prototypes of complex geometries and accelerate time to market. From aerospace prototypes to low volume quantity machining, DEK can provide you with cost-effective quotes based on market prices and fast delivery of high-quality, safe, durable parts.

Sheet Metal Fabrication

DEK offers reliable sheet metal prototyping and custom parts services ranging from sheet metal fabrication and precision molding of small, complex parts to a full range of cutting, forming and finishing to meet your diverse needs. Some of our success stories are business class seat armrests, safety switch brackets and enclosures.

We have a wide selection of metal materials including stainless steel, aluminum and steel. In addition, we can provide a variety of surface treatments such as blackening, painting, plating, anodizing and polishing to enhance the corrosion resistance and aesthetics of aerospace components. Meanwhile, we can also provide laser cutting and engraving services to improve the accuracy of the parts.

Injection Molding

At DEK, we specialize in manufacturing aerospace prototypes and custom parts through our proven injection molding capabilities. We utilize a variety of high quality plastics including POM, PTFE, PC, HDPE and more to ensure compliance with stringent safety and usability standards.

Our injection molding process is ideally suited for rapid prototyping and low-volume production to achieve the complex geometries and tight tolerances of aerospace prototypes, which can be functionally validated and tested prior to full-scale manufacturing. By integrating feedback at every stage, we can help you launch products faster, reduce risk and streamline production processes.

3D Printing

DEK's 3D printing services can help you quickly turn aerospace prototyping concepts into reality, shorten R&D cycles, and help aerospace designers and engineers to quickly iterate and test and make timely adjustments.

We can provide over 50 certified materials to meet different customer needs. We can realize complex geometries, reduce design constraints, and customize the aerospace precision components you need. We simplify the production process with flexible manufacturing that is cost-effective for aerospace prototyping and low-volume part production. Our talented engineering team provides fast, efficient and flexible solutions for aerospace industry applications.

Materials

Aerospace Prototype Material Options

Aluminum

At DEK, we specialize in machining various types of aluminum for the aerospace industry, mainly using Aluminum 6061 and Aluminum 7075.We produce aluminum aerospace prototypes and parts such as aisle spreader bar, tray table assembly, cartridge frame, support plate and others.

Stainless Steel

At DEK, we specialize in machining various types of stainless steel, which is an ideal material for aviation prototypes and components. Mainly including SUS304/304L, SUS316/316L, SUS17-4H. We produce high-quality components such as satellite frames, engine nozzles, tray table assembly and locating shaft.

Titanium

At DEK, we use grade 1 titanium, grade 2 titanium and grade 5 titanium as the primary materials for aerospace parts and prototypes. Our superb 5-axis machining produces high-precision structural frames, antenna mounts, turbine disks, landing gear and satellite mounts.

Inconel

Inconel is the material of choice for extremely high temperature applications in the aerospace industry, and at DEK, we primarily use Inconel 718 and Inconel 625 for machining aerospace components, including gas turbine rotors, blades, seals, flame holders and heat exchangers. .

Brass

Brass has unique engineering properties to meet the demands of aerospace applications. Its excellent corrosion resistance makes it the material of choice for bearings and bushings in landing gear and cargo doors, as well as wheels, brake components and millimeter wave receiving modules.

Copper

Copper alloys are used in aerospace for electrical systems and cooling components due to their excellent electrical and thermal conductivity. At DEK, we produce precision customized copper parts, including hard and soft copper platoon,structural members, landing gear parts and engine components.

PC

Due to its outstanding strength, durability, and lightweight, PC has a wide range of applications in aerospace prototypes and components. At DEK, we manufacture high-quality avionics housings, fuselage panels, airline seats and luggage racks to meet the exacting requirements of your project.

POM

The versatility and performance of POM plastics in the aerospace industry make them ideal for prototyping and parts manufacturing, and DEK's outstanding manufacturing capabilities produce high-precision, high-quality fuselage and wing assemblies, fasteners, connectors, bearings, and gears that are guaranteed to meet your specifications.

PTFE

PTFE has an excellent low coefficient of friction and chemical resistance and can be used in a variety of aerospace applications. At DEK, our success stories include seals, gaskets, engine shafts and heat shields that exceed our aerospace customers' expectations for size, precision and quality.

Why Choose Our Services

One-stop production of high-quality prototypes saves you time and money.

Engineering Capabilities

Rapid Production

Surface Finishes

Quality Control

Precision Assembly

Packaging and Shipping

Our Ordering Process

Send RFQ

Send RFQ with 2D/3D drawings and detailed requirements via Email or online form.

Review & Quote

Our Engineer team will review every drawing carefully and provide an accurate quote within 6 hours.

Confirm Order

Confirm the quote, details and delivery schedule, then sign the contract.

Production

Arrange production process, start programming and machining.

Quality Control

Strict quality control during production and final inspection.

Packaging & Shipping

Pack the parts, attach part identification labels, and start shipping.

Send RFQ 222

Review & Quote

Confirm Order

Production

QC

Delivery

Aerospace Prototyping Service Buying FAQs

Get An Accurate Quote For Your Next Projects

No matter your project is complicated or simple, no matter is metal or plastic, you will get an accurate quotation within 6 hours.

Get A Quote TodayKnowledge of Aerospace Prototyping

What is Aerospace Prototyping?

Aerospace prototyping is the process of testing and validating design concepts in aerospace engineering through the creation of physical models. The process generally involves rapid prototyping techniques, which are designed to transform a design concept into a tangible, testable model that can be evaluated and improved before final production.

The creation of prototypes is very important in the development of these aerospace systems. Designers and engineers can identify if problems persist and make improvements in a relevant way. These prototypes can even ensure that components created as prototype models meet aerospace industry standards.

Advantages of Aerospace Prototyping

Save Time and Cost: Due to the complexity and standards associated with aircraft and spacecraft development, prototyping allows design flaws to be identified and resolved as early as possible, resulting in faster iterations and shorter overall development time.

Reduce Risk: Two of the most important issues in the aerospace industry are reliability and safety, and prototyping allows engineers to test designs and ensure they are safe and reliable.

Design Approval: Aerospace components are complex, and these components must have structural integrity, aerodynamics and thermodynamics.

Process for Creating an Aerospace Prototype

Concept Development: Identify needs and feasibility.

Preliminary Design: Outline systems and select materials.

Detailed Design: Create CAD models and analyses.

Prototyping: Build the prototype.

Testing: Conduct ground and flight tests.

Evaluation: Gather feedback and iterate design.

Documentation: Compile technical and compliance data.

Final Review: Seek stakeholder approval.

Production Planning: Prepare for scaling and supply chain.

Post-Evaluation: Analyze the process for improvements.