I am a computer enthusiast, the mechanical keyboard is one of my favorite hardware, especially using the cherry axis, I am very intoxicated when I type.

DIY keyboards have become part of our everyday lives, and design preference has become a big deal.

At times, you may find it daunting to select a suitable keyboard case. In this guide, I’ll show you why aluminum keyboard case or frame now exerts more dominance.

As soon as you’re done with this, you’ll understand fully well how to choose suitable cases. Not only would we cover all you need to know about aluminum cases, but DEK will also deliver the best quality to your doorstep.

At the end of this article, you’ll have a better understanding of the following:

- What is a keyboard case or keyboard frame?

- What advantages does the aluminum keyboard case have over other keyboard cases?

- What colors does the aluminum case have?

- What is the standard size of an aluminum keyboard case?

What is the keyboard case or keyboard frame?

A keyboard case is a customized physical casing built with keycaps on it. The keyboard case is what houses your keys. The keyboard is just a means of communicating with our computer. Suffice to say that your keyboard case is as essential as your keyboard itself.

Why use aluminum alloy to make a keyboard case?

Aluminum has evolved to become one of the most important metals used in electronics. Aluminum provides the convenience of use. It provides for a lighter and more innovative way of using keyboard cases. Let’s look at some reasons you should use Aluminum for your keyboard case.

Eco-friendliness

If you care about your environment, using Aluminum is your best choice. It is one of the most eco-friendly metals around.

Recycling

Aluminum provides ease of recycling. Thus, it would be best if you considered using Aluminum. Recycling means that you can also re-use it when the need arises.

Heat Control

Aluminum dissipates heat faster than other metals. It means that you can work with this type of keyboard case anywhere.

The advantages of aluminum keyboard case

Selecting an appropriate keyboard for use can be difficult for you. Therefore, considering the advantages of the aluminum keyboard case is just the right key. The benefits of the keyboard cases are but not limited to the following.

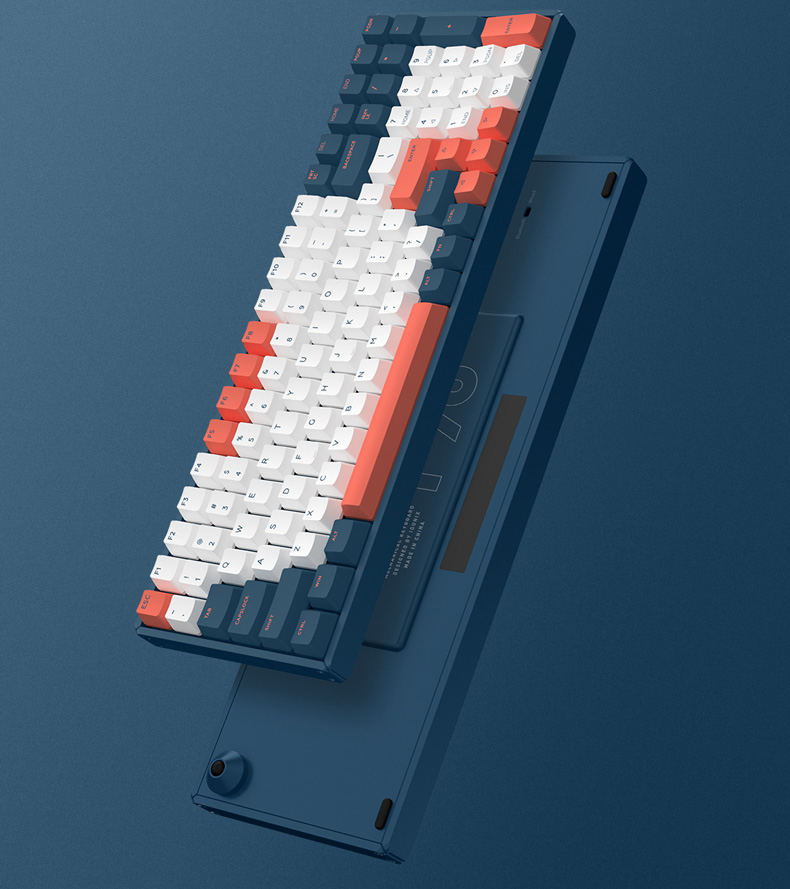

Colorful

After anodizing, the aluminum keyboard case not only has excellent scratch resistance, but also has a variety of colors, which enhances the beauty of the product.

Durability

Aluminum keyboard cases are far durable than their counterparts. The aluminum keyboard case has proved to stand the test of time while it remains sturdy.

Anti-rust

Naturally, Aluminum reacts with air to provide an anti-rust layer. It means that keyboard case rust is not an issue.

Weight

Aluminum is comparatively lighter compared to other metals. For instance, it is three times lighter than steel.

Reflection

An exciting part of using Aluminum for the keyboard case is that it reflects light. The light makes it look different from a conventional keyboard case.

Malleability

Aluminum is also a soft metal which makes it easier for design versatility. The essence of this property of Aluminum is to help you create different sizes of cases.

Heat Conductivity

Aluminum cases dissipate heat better from your keyboard frame.

Balance

Using an Aluminum keyboard case gives a sense of stability to your keyboard.

Which aluminum type is best for making a keyboard case?

Aluminum is a chemical element gotten from ingenious rocks. Aluminum also has alloys that make it endearing in the use of a keyboard case. It means that two or more metals are combined to form the material. For ease of understanding, let me classify the type of aluminum material by its physical properties. Some of the most widely-used types of Aluminum are:

6061 Aluminum

You can call the 6061 Aluminum a jack of all trades. 6061 aluminum is always in the market. It makes it a popular choice for producers. The 6061 aluminum is a better option for making keyboard cases. It has excellent strength, highly anti-corrosive, high weldability and machineability. 6061 aluminum is preferred where strength and corrosion resistance is a much-needed factor. Their good surface finishing also makes them a better option for consumers.

6063 Aluminum

This type is almost like the 6061 type. While this is almost like the 6061, it is more preferred for architectural uses. They are also for exterior and interior designs.

5052 Aluminum

The 5052 has an excellent quality too. Just like the 6061, it has better finishing and corrosion resistance. The drawback of this type of Aluminum is that it is difficult to machine. A heat process can not treat this type of Aluminum.

Other types of aluminum such as 5053, 7075, 6053, can be used to make a keyboard case also, but it is not common.

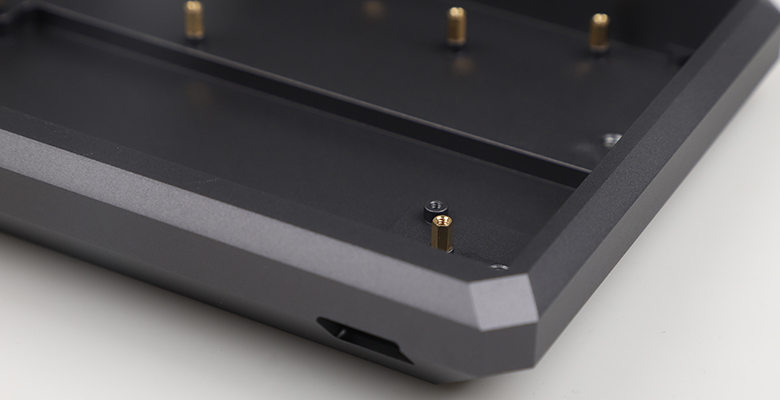

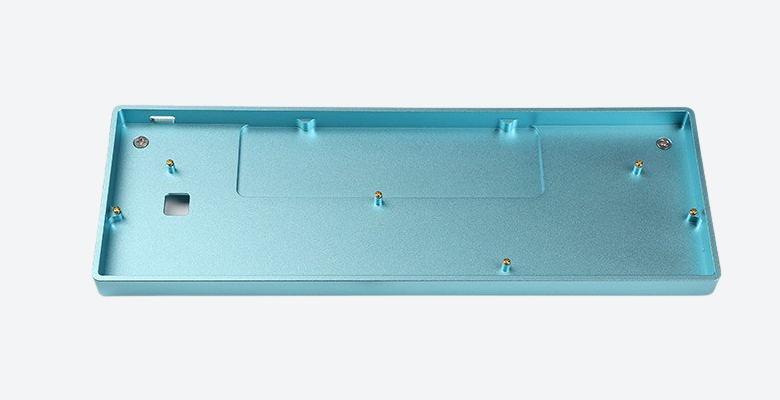

How to make an aluminum keyboard case?

After finishing the keyboard case design, one of the important things is producing it. Otherwise, you never know what your keyboard looks like, how cool it is to use, right?

So let me talk about the different ways of making aluminum keyboard cases. For different quantities, we will have a different production method.

For Prototypes or small volume production

For the keyboard case that has just been designed, has not been tested, and has not been accepted by the market. We recommend making prototypes to test first, such as check match with the keyboard PCB installation. This can reduce the production risks caused by design errors. Imagine if there are 1,000 failed keyboard cases in your warehouse, how much money and energy pressure will it bring you?

For small batches, we will use 3D printing and CNC machining methods to produce, this is the fastest and cheapest way.

3D printing is a very popular manufacturing process recently, and it is an ideal choice for parts with complex internal structures. However, CNC is still the most mainstream processing method for aluminum keyboard cases because it is fast, precise and stable.

According to our experience in machining more than 190 different kinds of aluminum keyboard cases, it will cost about $35-$68. Of course, it depends on your design.

For mass production

When your keyboard case has passed the test, and ready to hot sell in the market. So how to reduce costs becomes your next consideration.

Using die casting technology can greatly reduce your costs. Of course, this will require MOQ, because manufacturing a die-casting mold is also a big expense.

Die Casting can be produced in stable mass production, even if the internal space is more complicated. After die casting, CNC machining is needed for secondary processing, such as deburring, threaded hole drilling, and so on.

After that, anodizing or other surface treatments are carried out.

If you are not professional in production, it doesn’t matter, DEK can serve you one-stop. You design, we produce. We are a professional company to help you more worry-free.

Can the aluminum keyboard case be anodized?

Yes, your keyboard can be anodized. The process of anodization gives your keyboard case a better surface finishing. Anodizing is a method employed to transform your aluminum keyboard case. Anodizing your keyboard makes the outer surface stronger and protects it from peeling off. It also helps your keyboard fight oxidation, which protects it from rust.

What colors does the anodized keyboard case have?

The anodizing color ranges from brown to blue, red, purple, green, black, grey, gold, etc. Therefore, depending on your preference, you can have the color you desire. Note that your Anodized Aluminum case color is dependent on proper control of the process. Thus, depending on the control process, you can have pale yellow, orange, pink, lime green, dark green, etc.

For example:

Other ways to add colors to your aluminum keyboard case

There are possible ways to add color, but the colors aren’t very predictable. We have two broad ways to add color to an aluminum keyboard viz:

Electrolytic Coloring

In this method, you immerse the part you want to add color into the solution. The solution contains corresponding metallic salt. The essence of the salt is to fill the holes on the aluminum surface. After filling the gaps, they provide a strong coating. The coating fights ultra-violet fading of the bronze and black color.

The resulting color is not only a function of the color of the die. The color also depends on the depth of the pore. It depends on how much light shines off the surface of the Aluminum.

Conversely, it becomes difficult to predict the added color. The anodizing process is the least controlled when trying to add more colors. Also, in anodized Aluminum keyboard case, not stains can be reproduced.

Dip Coloring Method

This process involves placing the desired part in a die tank. In this process, the die is absorbed into the pores. As the die is absorbed, the surface goes through boiled de-ionized water. Putting the surface inside the de-ionized would stop further reactions.

The advantage of this process is that it gives a wide variety of colors. The colors appear almost as desired, but they fade over time. It is because they are not ultra-violet resistant.

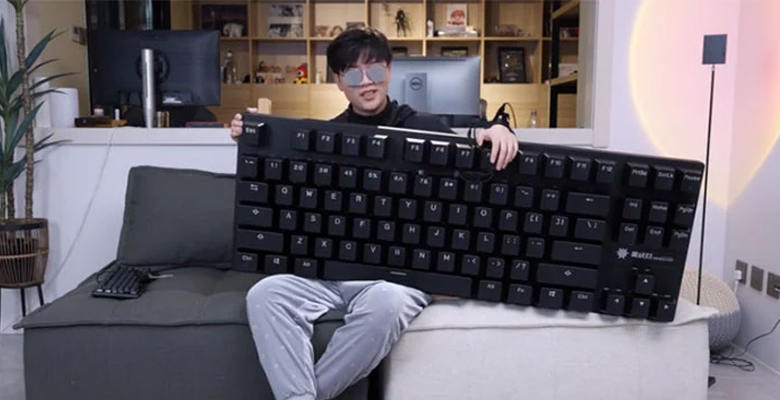

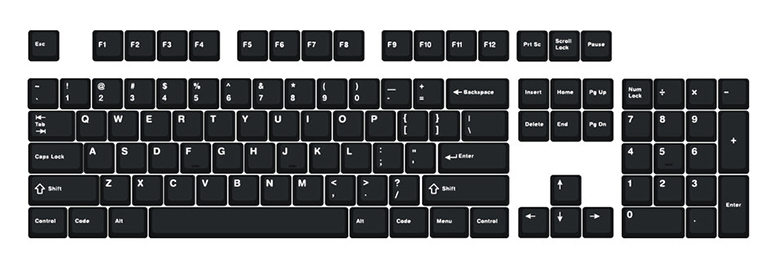

What is the standard size of an aluminum keyboard?

Keyboard cases come in different sizes. For instance, the aluminum keyboard comes in the following sizes:

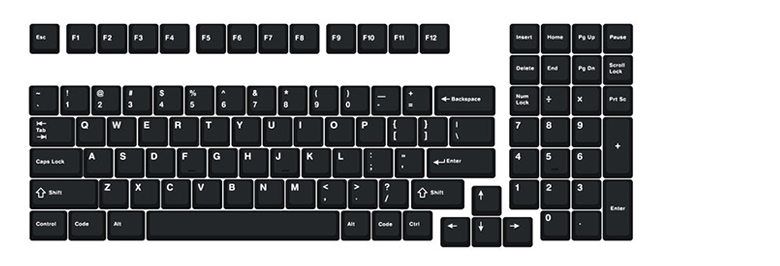

Full-Size or 100%

This type of keyboard case carries all the required keys. It is the standard size with all the keys on it. The standard-sized keyboard could have up to 108 tickets. As technology gained popularity, there was a need for smaller keyboards. Therefore, it gave rise to smaller sizes with lesser resolutions.

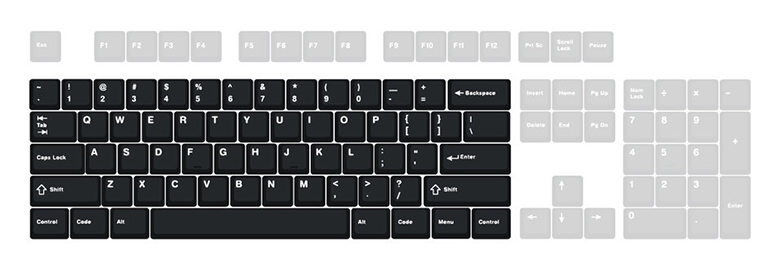

1800-Compact

The 1800-compact has duplicate keys as the standard. The difference is that the keys occupy lesser space.

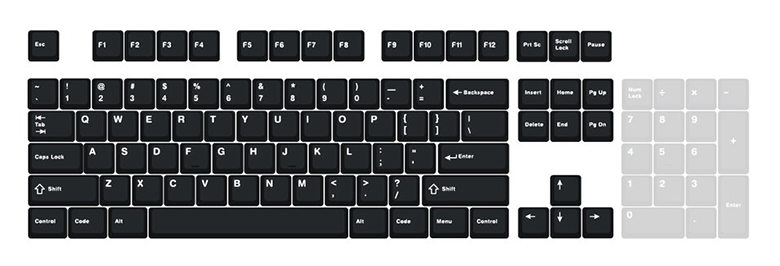

Tenkeyless (80%, 87%, TKL)

This type of aluminum keyboard carries the standard’s exact size. The difference lies in the omission of the number keypads. Without the number keypads, this type of keyboard would have about 87 or 88 keys.

75% Size

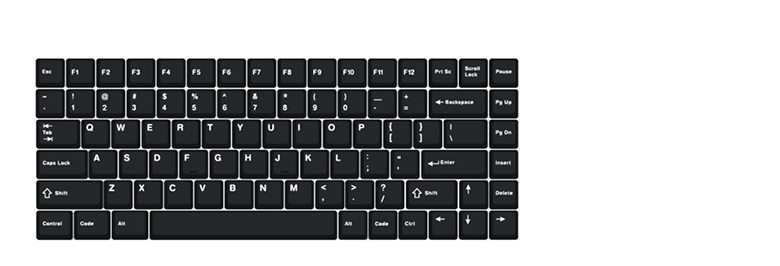

The 75%-sized keyboard carries all the necessary keys with the “F” keys at the top. The chief difference between this size and the TKL is space reduction.

60% Size

The 60% aluminum keyboard case is now typical. It is because it is more compact. It does not carry the number keypads and the “F” keys.

40% Size

It is a minor aluminum keyboard case. The 40%-sized keyboard only contains letters without the numbers.

Here is a comparison table you can know their features quickly:

Will the aluminum keyboard case affect the WIFI signal?

The Aluminum will interfere with wifi signals. Recall that Aluminum is a metal and conductor of electricity. However, the interference is minor. As with all metals, interference is inevitable. Nevertheless, you can improve the wifi signal considerably. Since the interference is petite, you can change the position of your router. Perhaps, you can use aluminum foil to enhance the wifi strength.

Keyboard case comparison: Aluminum VS other materials

Have you seen a comparison for this before?

It’s expedient to have a rich understanding of how these elements comparingly relate to one another so we don’t mistake one for the other. Issues like this cause a lot of stirs on tech enthusiasts and it leads to confusion problems. So, having a sound understanding of how they distinctly function will prevent future stress.

Below is a concise comparison, and it’ll expose inherent disparities that’ll help you discern whichever aluminum case is best for you. Below is a table showing the comparisons.

Plastic keyboard case

|

Aluminum keyboard case

|

Polycarbonate keyboard case

|

Aluminum keyboard case

|

Acrylic keyboard case

|

Aluminum keyboard case

|

Wooden keyboard case

|

Aluminum keyboard case

|

Does DEK offer the customized Aluminum keyboard case?

Yes, you can get custom keyboard cases in DEK.

DEK helps many clients to produce their unique aluminum keyboard case, below are some cases:

For small quantities, we will use CNC machining technology, for large quantities, we will using die casting + CNC machining. Not matter what quantity you need, all we have corresponding cost-effective solutions.

You design it, we produce it. If you need a quote, welcome to contact me at any time.

Summary

In this post, you may get a comprehensive guide on aluminum keyboard cases. Most importantly, you can make a better choice the next time you need a keyboard case. DEK is known for being a top supplier of top-notch aluminum keyboard cases.