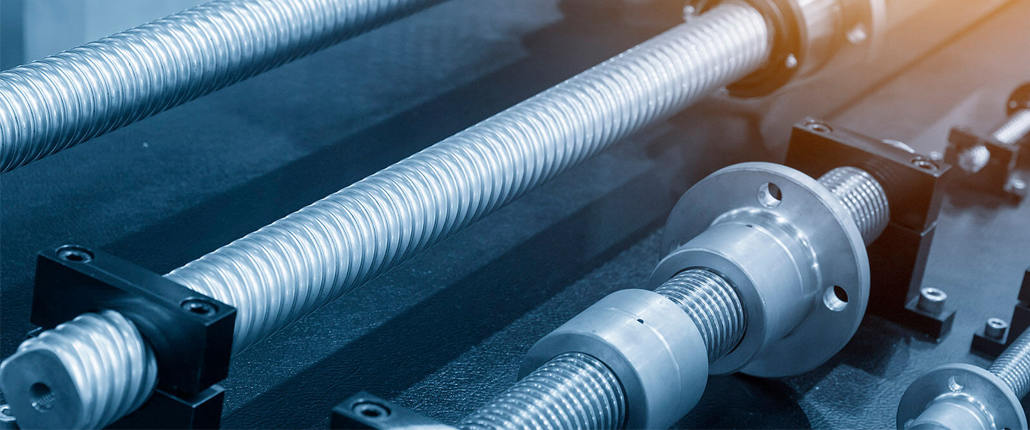

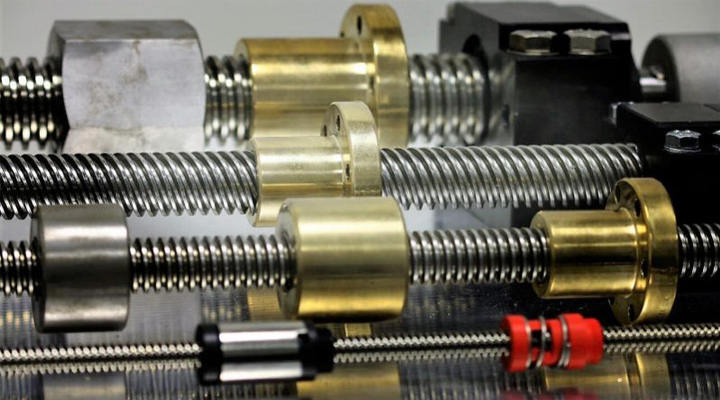

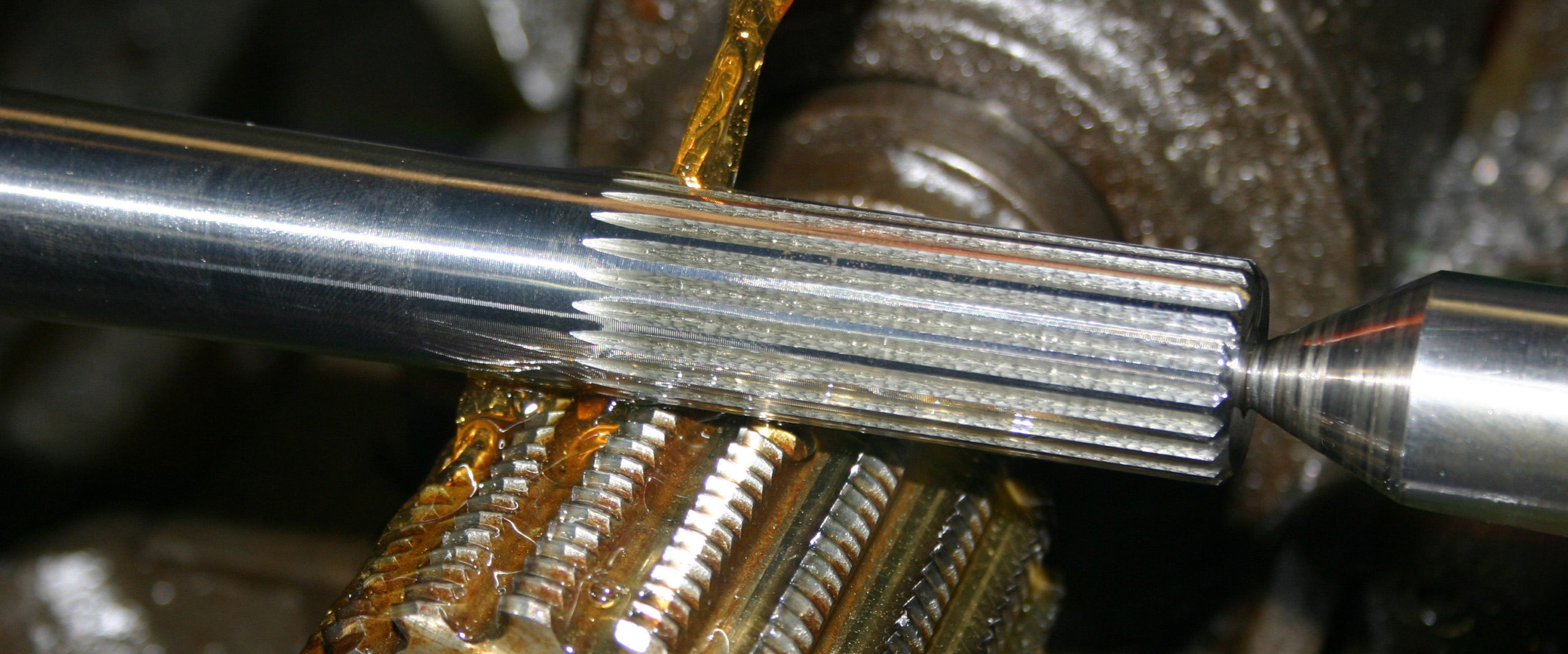

A screw shaft is one of those challenging parts to machine due to the need for high-precision threads or ridges. We typically use high-precision CNC machines and lathes to manufacture screw shafts.

But, like all other machined parts, screw shafts also come in different qualities, sizes, and shapes. Plus, each shape and form has its application and use. With so many materials, types, and sizes, how to choose the best screw shaft for your needs?

Let’s dive in and see the science behind screw shaft manufacturing, its features, and of course, all the different uses and applications.

What Is a Screw Shaft?

A screw shaft is a cylindrical-shaped thin rod or spike, fully or partially wrapped in a threaded spiral. The function of screw shafts is to hold objects together and to transmit torque and rotation. In most cases, screw shafts have a pointy tip which allows them to use their torque power to drill holes.

Usually, screw shafts are part of screws as fasteners. However, they do have many other applications throughout different industries.

How Do Screw Shafts Work?

A screw shaft functions by converting rotational to linear motion and torque to a linear force. With its torque and rotational power, with a screw shaft, you can either:

- drill a hole in an object; or

- you can rotate a threaded collar nut around it – to tighten the grip and hold of two things together;

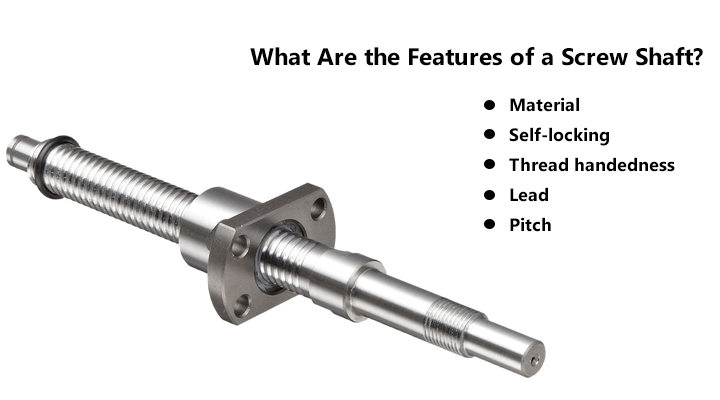

What Are the Features of a Screw Shaft?

Here, we’ll point out the most vital features of screw shafts:

Material

We usually manufacture screw shafts out of stainless steel, brass, titanium, or bronze. When machining screw shafts, manufacturers often apply a top coating such as chromium, brass, or zinc. Some screws can be from aluminum, but those are not durable and are easily affected by weather conditions.

Self-locking

Most screw shafts have self-locking features – they drill a hole, but you cannot pull them out backward. This feature makes them perfect for threaded fasteners, C-clamps, screw jacks, vises, and screw-top container lids.

Thread handedness

This feature refers to the direction in which you have to turn a screw to tighten it. Screws can be right-handed, which means you have to turn them clockwise to tighten them; or left-handed – you have to turn them counter-clockwise to tighten.

Lead

The lead of a screw is the axial distance that the screw shaft goes through in one full rotating circle of 360°. When the lead is smaller, the screw has a higher mechanical advantage.

Pitch

The pitch of screws is their distance between the individual threads. Similarly to lead, smaller pitches have a tremendous mechanical advantage.

Where Are Screw Shafts Used?

Due to the features of screw shafts mentioned above, and the wide variety of screws for different purposes, they have several various applications:

- In threaded fasteners, to hold two or more objects together. The type of screws you can usually use for this purpose are the wood screw, stud, bolt, nut, or sheet metal screw;

- Due to its self-locking property, a screw shaft has multiple applications: screw-top container lids, threaded pipe joints, screw jack, C-clamp, vise, corkscrew, etc.;

- As power transfer linkages in different machines – ball screw, worm gear, roller screws, and lead screws;

- We use precision-calibrated screws in micrometers;

- We use rotating helical screw chambers for moving materials in screw conveyors, auger earth drills, and Archimedes’ screws.

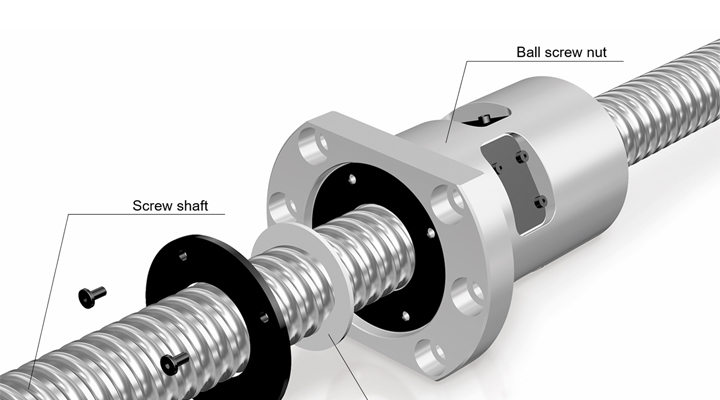

What Are the Parts of a Screw?

A screw has three different parts: the head, the threaded shank, and the point (tip). Each of these parts impacts the screw’s use, strength, and purpose. Let’s explain each of them.

Head

The head is the topmost wide part of the screw. The head of a screw is always larger and wider than the screw shaft, and it can be flat or domed. The indent on flat screws is called a drive, and this is where a screwdriver goes.

There are many different types of screw heads: oval, flat, truss, pan, round, hex, button, etc. The drives can also differentiate – slotted, combined, Phillips and Frearson, one way, square, etc.

The shape of a screw’s head is there for a reason – as a superior aesthetic finish to your projects or to use the correct tool that needs to fit the head’s drive. For example, using a round head instead of a flat one can make the screw visible instead of hidden and flat with the surface.

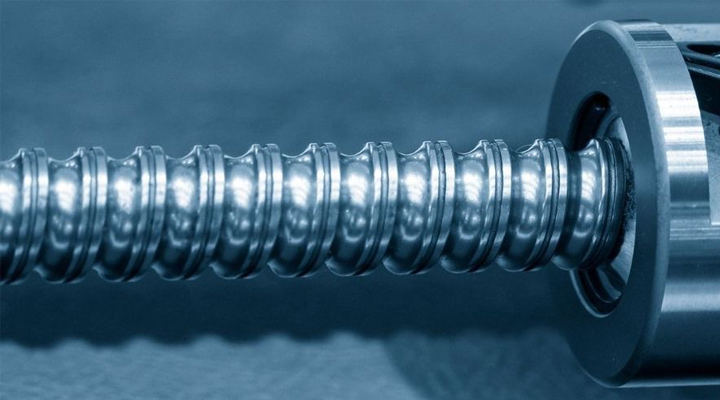

Threaded shank

The threaded shank of a screw is the spiral part or the part with ridges. Some screw shafts will have a fully threaded shank, while others will have a half-threaded one. Half-threaded screw shafts provide better stability because the non-threaded part has no weak points, and it’s stronger.

In threaded shanks, the thread angle and the distance between the individual threads are two things that determine the features and use of the screw. In regards to the direction in which you turn them, threaded shanks can be right-handed or left-handed.

Point

The point or the tip of the screw is typically spiky since this is the part that enters or drills into the other object. Sometimes, the tip of a screw can be flat. Flat tipped screws will require a previously drilled hole since you can’t use them for drilling.

What Is the Diameter of a Screw Shaft?

To measure the diameter of screw bolts, we have to look at two different numbers – the major and minor diameters.

The major diameter of a screw shaft is the distance between the outer edge of the thread on one side and the thread on the other side. The minor diameter is only the inner, smooth part of the screw shaft. If you strip the shaft from its threads – that’s the minor diameter. The diameter of screw shafts is typically anywhere between the numbers 2 and 16.

The Design of a Screw Shaft

Screw shafts have a cylindrical form with a pointy tip and a wider head/drive. There are also screw shafts with a flat end, but those require a previously drilled hole.

A screw shaft can have a different design for different purposes and applications. The head of a screw shaft can be flat, raised, hexagonal, square, and more. Screws can be entirely threaded or partially. Partially threaded screw shafts have better durability and strength.

And finally, screw shaft designs also differ in regards to their threads. Depending on their application, they all have a different thread angle and pitch.

We want to mention that screw shafts can be used as tools other than screws, and in these cases, they can have many different designs, depending on their purposes. In some cases, we can even manufacture screw shafts per the client’s request, and we can adjust them according to their needs.

Can You Offer a Customized Screw Shaft?

Absolutely yes! Our superior CNC 5-axis and lathe machines allow us to produce high-precision parts such as screw shafts in different forms, shapes, and sizes. Furthermore, we accept small volume orders and mass production, so no matter the number of parts you need, we can help.

At DEK, we are focused on high-precision, on-demand manufacturing. Our flexibility and cutting-edge machinery allow us to fulfill custom orders. With us, you can choose from countless different materials that best fit your needs and enjoy our fast 5 Axis CNC milling services.

On top of our low-volume service, we have zero MOQs – minimum order quantities! So, you can send us a drawing and get one prototype.

To Conclude

We’re enthusiastic that we’ve managed to transfer you the knowledge you need about screw shafts, what they are, what features they have, and what their applications are. The most important point we’d like you to take with you is to watch out for the quality of the screw shaft manufacturing process.

Screw shafts need the appropriate torque, strength, and material to have a safe application. Whether you use wire or rod to manufacture the screw shafts, ensure it’s the correct type of steel for the requirements.

Hopefully, now you can differentiate and choose the best screw shaft for your needs. If you’re looking for a quality, on-demand CNC manufacturer for screw shafts, we’re here for you. Submit your request, and we’ll send you a quote the same day.