Most people are hopeless when it comes to automobiles. The very mention of oil changes, gearboxes, axle alignment, crankshaft and camshaft sends them into utter panic. However, most of these are basic concepts that operate on simple principles. Let’s take a look at crankshafts and camshafts, their uses, and the different types.

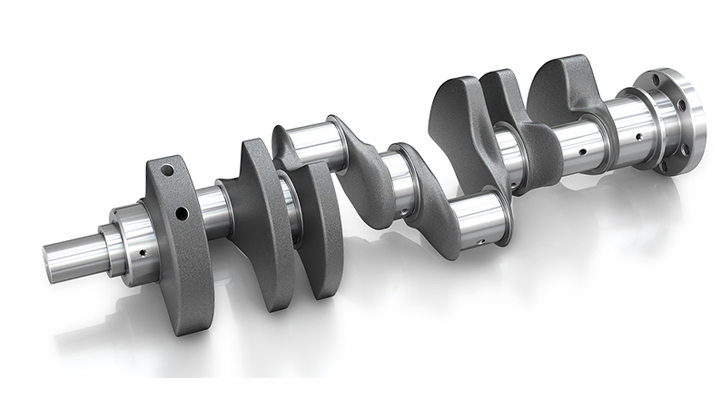

What Is a Crankshaft?

The crankshaft is a heavy-duty component of the internal combustion engine (ICE) found in a different type of locomotives, such as modern tractors, cars, and so on. A crankshaft is essentially a metal rod with several attached appendages that spin about rapidly (about 14,000 rpm) and is essential for transmitting power from the engine to the wheels.

What Does a Crankshaft Do?

In more technical terms, the main function of the crankshaft is converting the linear motion of the pistons into rotational motion transmitted to the flywheel and transmission. The crankshaft also transmits power to other core components of the engine such as the oil pump, cooling pump, valve timing, air conditioning compressor, alternator.

Therefore, the crankshaft is in constant motion and has to be made from a durable material that is highly resistant to wear, fatigue and heat. The most commonly used materials are forged steel or cast iron.

What Are the Different Types of Crankshafts?

The connecting rods and the way they are connected vary depending on the design of the crankshaft. Crankshafts are broadly classified into two types:

The Monolithic Crankshaft

This type is commonly used in multi-cylinder engines, most commonly the four-stroke engine seen in most automobiles.

The Assembly-type Crankshaft

This type is commonly used in a single cylinder, twin-cylinder, four-stroke engines, and two-stroke engines.

Because of the high strength of cast iron, it is generally used in the construction of high-volume, low-load production vehicles. For fuel-efficient engines which require a higher power-to-displacement ratio, the forged steel crankshafts are preferred.

What Are the Components of a Crankshaft?

The crankshaft is built to have a tough core and sturdy surfaces in order to withstand the wear due to its constant rotatory motion. Its main components are:

- Main journals: This runs in the bearing and determines the axis that the shaft rotates.

- Crank pins: The crank pins are connected to the connecting rods.

- Crank webs: The crank webs connect the crankpins to the main journal.

- Flywheel/force transfer: The flywheel helps to make the engine torque smoother and decreases

- Oil bore: It is an opening running through the shaft. Oil flows through the oil bore when the engine is in action and provides lubrication to the moving parts.

- Counterweights: As the name implies, they bring balance in weight in the crankshaft by reducing the load on the main bearing. They are fixed either directly on the crankshaft or are connected to it via the crank webs.

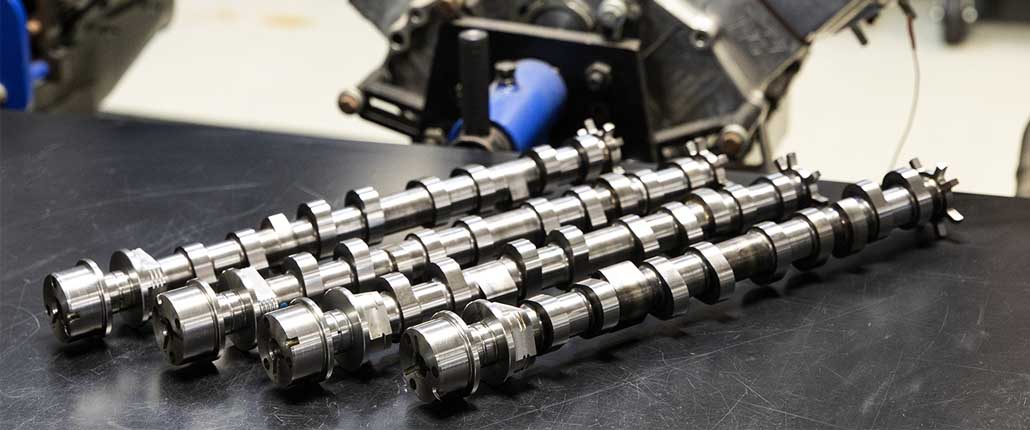

What Is a Camshaft?

A camshaft is a very important component of the internal combustion engine. They—to a large extent—determine how your engine performs at different speeds. It is shaped like a rod with lobes called cams positioned along its length.

What Is it Used For?

The main function of the camshaft is to control the opening and closing of the exhaust and intake valves. It makes sure that the intake valve opens at the right time for feeding the air-fuel mixture to the engine. This is important for changing the rotational motion to reciprocal motion. Improving the function of the camshaft can boost efficiency, peak torque, horsepower, and overall performance.

The camshaft has essentially two parts—the cams and the shaft, both of which sync the opening or closing of the valves with the crankshaft gear. Automobiles make use of camshafts made of forged steel or cast iron.

What are the Different Types of Camshafts?

There are generally two types of camshafts depending on the type of “lifter” they use.

The Flat Tappet Camshafts

This camshaft is situated where the lifter and the lobe rub against each other—the site the lifter swirls on the lobe. This spinning motion is very crucial in forestalling the wear of the constantly moving parts of the camshaft. The flat tappet camshaft operates with hydraulic and solid flat tappets (also called followers and lifters).

Roller Camshafts

As the name implies, the nose is rounded, to ensure the roller holds the valve open at a higher lift for an extended time. This setting impacts fuel-air charge demand and opens the valve quicker. Like the flat tappet, the roller camshaft operates with hydraulic and solid roller lifters.

What Are the Different Components of a Camshaft?

The main parts of the camshaft include:

- The journals: They keep the camshaft in place so that it does not veer off as the shaft spins at tremendous speed.

- The lobes: They regulate the opening and closing of the intake and exhaust valves while the camshaft is spinning. The rate of opening and closing of the valves tells on the engine performance. They change their speed as the engine speed changes.

- The ends: The front end of the cam sync the motion of the engine with the crankshaft, the rear end keeps the ignition in time with the rest of the internal combustion engine.

- The cam bearing: They are additions to improve the performance of camshafts. The bearing acts to insulate the cam so that it won’t be affected if the engine malfunctions.

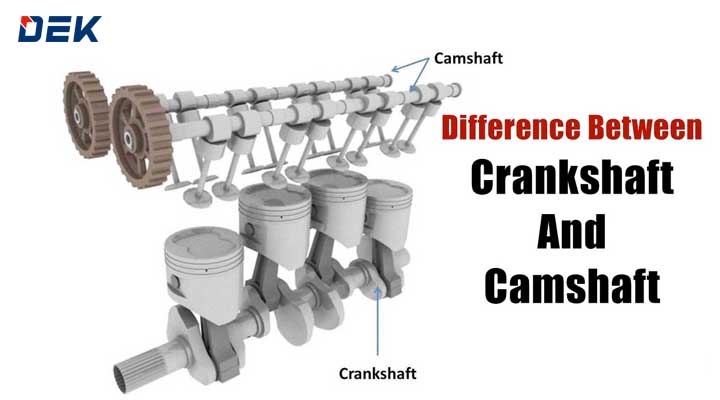

What Are the Differences Between a Crankshaft and a Camshaft?

There are several key differences between a camshaft and a crankshaft aside from their function. Let’s take a look at some key differences:

Location

The crankshaft is located under the cylinder, whereas the camshaft is located above the cylinder.

Mode of Operation

The crankshaft converts the linear motion of the piston to circular motion while the camshaft is used to time the right opening and closing of the inlet and outlet valves.

Make

The crankshafts are commonly made from forging alloyed steel while camshafts are usually made from forged steel or cast iron.

The Bottom Line

The crankshaft and the camshaft are both vital parts of the internal combustion engine and have different parts that articulate in different ways to make sure the shaft works properly. While the crankshaft is built to transform linear to circular motion, the camshaft regulates the opening and closing of the intake and exhaust valves. The energy from the camshaft is transmitted to the crankshaft to runs its operation.

FAQs

What is common with both the crankshaft and camshaft?

They are both rods though designed differently and connected to different parts of the engine. The camshaft motion is driven by the crankshaft through a chain or gears at its front end. The crankshaft utilizes the energy generated by the closing and opening of valves in the combustion process to power the engine.

What are the signs of a malfunctioning crankshaft?

There are several important signs which point towards a faulty crankshaft. They include blinking indicator lights, a stalking engine, misfires, uneven acceleration, reduced gas mileage and a roughly vibrating engine.

What is the main function of the camshaft?

To regulate and time the closing and opening of the inlet and outlet valves.

Which turns faster the crankshaft or the camshaft?

The crankshaft is twice as fast as the camshaft. This is because it takes only one turn of the camshaft to completes the valve operation for one complete cycle of the engine while the four-stroke-cycle engine(crankshaft) has to make two turns to complete one cycle.

What is the main function of a crankshaft?

It is the most integral part of the internal combustion engine, it changes the linear motion to rotational motion.