Large Part CNC Machining Service

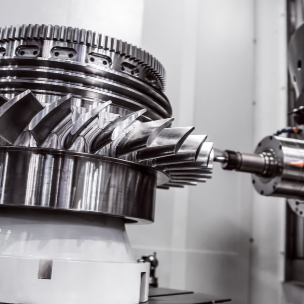

Large part CNC machining lets you make big, heavy parts with tight accuracy. You can shape, drill, and finish oversized components for strong, reliable performance.

At DEK, you get full support for large part CNC machining, from heavy milling and deep drilling to complex surface finishing. Our team works with strong materials and advanced machines to keep your parts accurate, durable, and ready for real-world use across aerospace, energy, construction, and industrial applications.

introduction

Large Part CNC Machining | Advanced, Accurate, End-to-End

DEK provides full-scale CNC machining for oversized parts, combining advanced machines, skilled operators, and precision workflows to meet strict tolerances across aerospace, energy, construction, and industrial sectors.

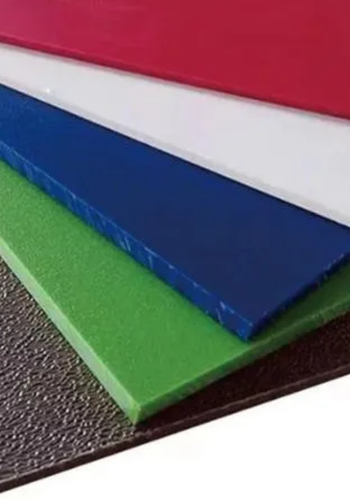

At DEK, we work with a wide range of materials for large part CNC machining, including aluminum, steel, stainless steel, titanium, and engineering plastics. Our full-service capabilities include heavy milling, deep drilling, multi-axis turning, and precise surface finishing. We handle everything from prototypes to small runs and full-scale production, ensuring each component meets strict specifications and performs reliably in demanding applications. Beyond machining, DEK provides complementary support services to optimize your parts. This includes design review, material guidance, and finishing processes that enhance strength, durability, and functionality.

By combining advanced equipment, skilled operators, and end-to-end services, we deliver ready-to-use, high-quality components for aerospace, energy, construction, and industrial projects, all from a single, streamlined workflow.

- Multi-Axis Machining

- High Load Capacity

- Custom Fixturing

- Rapid Turnaround

- Integrated Quality Control

- Scalable Production

Materials for Large Part CNC Machining

Metals

Plastics

Aluminum

Aluminum is lightweight, corrosion-resistant, and easy to machine, making it ideal for large, precise components. With DEK’s large part CNC machining services, we can shape, mill, and drill aluminum parts with tight tolerances for industrial and aerospace applications. Typical parts include aircraft fuselage panels, engine housings, and custom structural frames.

DEK’s advanced CNC setups provide accurate cutting, multi-axis machining, and detailed surface treatments on aluminum components. Its strength-to-weight ratio also supports complex assemblies that demand durability and efficient performance.

Alloys

6061, 6063, 7075, 2024, etc.

Brass

Brass is durable, machinable, and resistant to wear and corrosion, making it suitable for large, intricate parts. With DEK’s large part CNC machining services, we can process brass into components such as valve bodies, marine fittings, and instrumentation housings. Its thermal and electrical conductivity allows detailed features to be produced without losing strength or accuracy.

DEK’s advanced CNC setups deliver consistent surface quality, tight tolerances, and dimensional accuracy for oversized brass parts. Brass also supports decorative finishes while keeping mechanical performance strong.

Alloys

C360, etc.

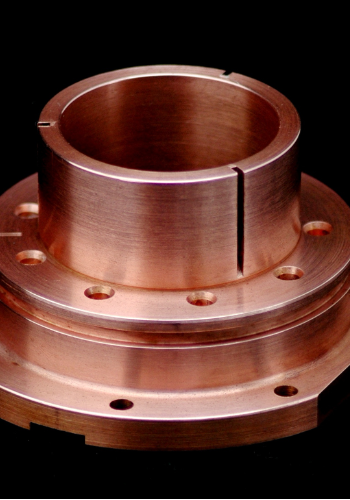

Copper

Copper provides excellent conductivity, corrosion resistance, and ductility, making it suitable for large CNC-machined parts. DEK can machine large copper components like heat exchanger plates, electrical busbars, and industrial connectors. Its malleability allows for detailed features while maintaining structural integrity.

With careful process control, DEK ensures tight tolerances and accurate geometry, enabling large copper parts to meet performance and durability requirements for demanding applications. Copper also performs well in thermal management applications requiring precise, large-scale components.

Alloys

C101, C110

Inconel

Inconel is a high-strength, heat-resistant alloy that performs well under stress. DEK can machine large Inconel components with complex shapes, deep cavities, and tight tolerances. Its oxidation resistance allows for durable, long-lasting parts. Advanced CNC setups enable precise milling, turning, and drilling on oversized pieces.

DEK ensures surface quality, dimensional accuracy, and structural integrity even for intricate or heavy components, making Inconel ideal for challenging machining tasks. It also maintains stability and strength in extreme temperature environments.

Alloys

625, 718, 600, etc.

Mild Steel

Mild steel is strong, tough, and easy to work with, making it suitable for large, heavy components. With DEK’s large part CNC machining services, we can process mild steel into parts such as industrial frames, construction brackets, and heavy equipment housings.

Our CNC setups ensure accurate machining of oversized steel pieces, delivering consistent dimensions, smooth edges, and lasting durability. Mild steel also offers excellent weldability, making it an ideal choice for large-scale assemblies that demand strength and precision.

Alloys

A36, AISI 1018, etc.

Stainless Steel

Stainless steel combines strength, toughness, and corrosion resistance, ideal for large, precision components. DEK can machine stainless steel into components like chemical processing tanks, aerospace brackets, and medical equipment frames. Its rigidity allows for reliable multi-axis milling, turning, and drilling.

DEK’s CNC processes ensure smooth finishes, consistent tolerances, and structural integrity, making stainless steel components durable and precise even at large scales and intricate designs. It also resists corrosion and wear in long-term applications.

Alloys

304, 316, 17-4 PH, etc.

Titanium

Titanium is strong, lightweight, and corrosion-resistant, suitable for large, precise components. DEK can produce titanium components such as aircraft landing gear sections, aerospace structural frames, and industrial pump housings. Its strength-to-weight ratio allows complex geometries to be machined without adding excess mass.

DEK’s advanced CNC setups support detailed features, multi-step operations, and smooth finishes, ensuring large titanium components are accurate, durable, and structurally reliable. Titanium also withstands extreme conditions while remaining lightweight for structural applications.

Alloys

Grade 2, Grade 5 (Ti-6Al-4V), etc.

ABS

ABS is a strong, rigid, and impact-resistant plastic, ideal for large CNC-machined components. With DEK’s large part CNC machining services, we can mill, drill, and turn ABS into parts such as machine guards, instrument housings, and structural panels. Its toughness allows complex shapes and enclosures to be machined precisely while keeping surfaces smooth.

ABS is also resistant to heat, chemicals, and impact, making it a reliable choice for functional and protective applications. DEK ensures large ABS parts hold tight tolerances, stable geometry, and long-term durability.

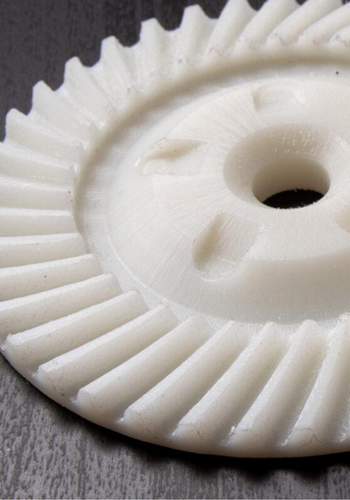

Delrin

Delrin is a strong, low-friction plastic that is perfect for precision parts in large formats. With DEK’s large part CNC machining services, we can create gear wheels, bearing housings, and conveyor rollers with excellent dimensional accuracy. Its self-lubricating properties make it ideal for moving parts that require low wear and smooth operation. Delrin also resists moisture, chemicals, and fatigue, keeping parts durable over time.

DEK’s machining expertise ensures oversized Delrin components achieve tight tolerances, smooth finishes, and long-lasting stability even under repeated stress.

Grades

Delrin 150, Delrin AF, etc.

Nylon

Nylon is a tough, flexible plastic with excellent wear resistance, making it useful for large, functional parts. DEK’s large part CNC machining services can produce parts such as pulleys, wear plates, and structural bushings with precision and consistency.

Nylon’s ability to handle heavy loads, combined with impact and abrasion resistance, makes it reliable in demanding environments. It also has good chemical stability and can reduce noise in moving systems. DEK ensures large Nylon parts are machined accurately, with stable dimensions and long service life.

Grades

Nylon 6, Nylon 6/6 30% Glass Filled, etc.

PC

PC, also known as polycarbonate, is a strong, transparent, and heat-resistant plastic that can be machined into large, precise components. DEK can produce machine windows, protective covers, electronic housings, and other oversized parts with exact dimensions.

PC’s toughness allows machining of large parts that resist cracking, even under stress or heat. It also provides transparency where visibility is required, while maintaining structural strength. DEK’s machining expertise ensures polycarbonate components achieve smooth edges, precise tolerances, and long-term durability in both protective and mechanical roles.

PE

Polyethylene is lightweight, flexible, and resistant to chemicals and moisture, making it excellent for large CNC-machined parts. With DEK’s Large Part CNC Machining services, we can produce cutting boards, storage tanks, and pipe fittings with precise dimensions. Its toughness and low friction make it easy to machine into components that handle wear and impact.

PE also offers excellent electrical insulation and stability in outdoor conditions. DEK ensures oversized polyethylene parts maintain smooth finishes, reliable geometry, and durability across multiple machining processes.

PP

PP or Polypropylene is durable, lightweight, and chemical-resistant, suitable for machining large structural and protective components. DEK can create pump housings, chemical containers, and automotive panels with tight tolerances and smooth finishes. Its toughness and fatigue resistance allow PP parts to perform well under repeated stress. The material also provides excellent resistance to moisture and corrosion.

With DEK’s advanced machining processes, we ensure polypropylene components are produced with stable geometry, reliable strength, and high-quality performance in large-scale applications.

Grades

PP Homopolymer, PP+GF(30%), etc.

PVC

PVC is a strong, versatile plastic that resists chemicals, moisture, and corrosion, making it well-suited for large CNC machining. We can produce valve bodies, pipe connectors, and electrical housings with precise fits and consistent geometry. PVC machines smoothly and provides durable strength while keeping weight low. It also offers excellent insulation and stability in harsh environments.

At DEK, we ensure oversized PVC parts meet exact dimensional requirements, reliable performance, and clean finishes across complex and multi-step machining operations.

Instant & Accurate Quotes

We don't use online automated quotation tools, because it is very inaccurate. Online quote platforms rely solely on calculations based on cutting amounts and fixed coefficients, they fail to account for actual processing nuances, such as material deformation after heat treatment, tight tolerance requirements, grinding after heat treatment, etc. Consequently, automated price calculations can lead to inaccuracies, ultimately increasing your costs.

But you can rest assured at DEK!

Our quotations are both cost-effective and accurate because we have a team of professional mechanical engineers who meticulously review each drawing. These engineers boast over 10 years of experience and possess deep expertise in programming, machine operation, post-processing, material properties, and more. Ensure you will get accurate quotes within 6 hours.

Our Advantages

2300+ Engineers Love Work With Us

Precision Machining

DEK’s large part CNC machining delivers exceptional accuracy, maintaining tolerances as tight as ±0.005 mm even on oversized components. Our advanced multi-axis machines and expert operators ensure precise dimensions, smooth surfaces, and consistent geometry.

Flexible Production

DEK accommodates both single-piece prototypes and full-scale production runs for large parts. You can test designs, iterate quickly, or scale manufacturing without restrictions. Our workflow and equipment are designed to handle oversized, complex components efficiently.

Cost Efficiency

DEK delivers large part CNC machining at competitive pricing by optimizing machine setups, tooling, and production efficiency. Our streamlined processes reduce labor and material waste while maintaining high precision.

Full Inspection

DEK implements comprehensive quality inspection for large parts using IQC, QE, and OQC procedures. Precision measurement tools verify dimensional accuracy, flatness, and surface quality.

Custom Finishes

DEK offers a wide range of finishes for large CNC-machined parts, including anodizing (Type II & III), electroplating, sandblasting, powder coating, and polishing. These treatments enhance corrosion resistance, wear protection, and visual appearance.

Secure Shipping

DEK ensures large CNC-machined parts are securely packaged to prevent damage during transit. Using foam, anti-rust paper, corrugated boxes, or wooden crates, we protect oversized components of any shape or weight.

Our Ordering Process

Send RFQ

Send RFQ with 2D/3D drawings and detailed requirements via Email or online form.

Review & Quote

Our Engineer team will review every drawing carefully and provide an accurate quote within 6 hours.

Confirm Order

Confirm the quote, details and delivery schedule, then sign the contract.

Production

Arrange production process, start programming and machining.

Quality Control

Strict quality control during production and final inspection.

Packaging & Shipping

Pack the parts, attach part identification labels, and start shipping.

Send RFQ 222

Review & Quote

Confirm Order

Production

QC

Delivery

FAQ

Large Part CNC Machining Buying FAQs

Get An Accurate Quote For Your Next Projects

No matter your project is complicated or simple, no matter is metal or plastic, you will get an accurate quotation within 6 hours.

Get A Quote TodayKnowing Large Part CNC Machining

What is Large Part CNC Machining?

Large part CNC machining is the process of producing oversized or heavy components using specialized CNC machines. These machines have extended travel, high spindle power, and reinforced structures to handle big parts. The process includes milling, turning, drilling, and finishing, allowing for precise, durable parts used in demanding industries.

Large part CNC machining also allows for customization and adaptability. You can create parts with unique features, intricate designs, or integrated assemblies that would be difficult with standard equipment. Advanced software and multi-axis tooling enable complex tool paths while maintaining precision and structural integrity, making it ideal for components with unique requirements or strict engineering standards.

What are the Advantages of Large Part CNC Machining?

Large part CNC machining provides high precision and efficiency for oversized components.

Key advantages include:

- Ability to handle very large or heavy parts

- Enhanced accuracy and repeatability

- Capability to work with tough materials

- Support for multi-step operations

- Efficient and cost-effective production

- Reduces manual labor

- Minimizes the risk of errors

When do you need Large Part CNC Machining?

You need large part CNC machining when producing oversized or heavy components for industries like aerospace, energy, oil and gas, shipbuilding, construction, and heavy equipment. It is essential for parts requiring high strength, tight tolerances, complex surfaces, and consistent quality over large dimensions.

Large part CNC machining is also necessary when your project involves integrating multiple functions into a single component. By machining large parts in one setup, you can combine mounting features, channels, or assembly points directly into the part, reducing the need for additional welding or fabrication. This approach improves structural integrity, streamlines assembly, and ensures that critical alignment and performance requirements are met from the start.