Insert Molding Service

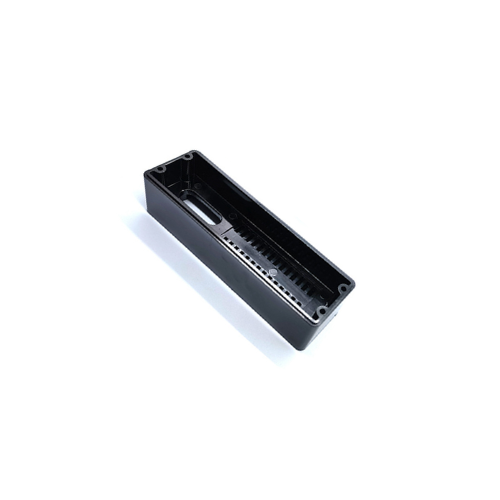

Insert molding lets you mold plastic over metal or other parts in one step. It saves assembly time, adds strength, and makes your design more reliable.

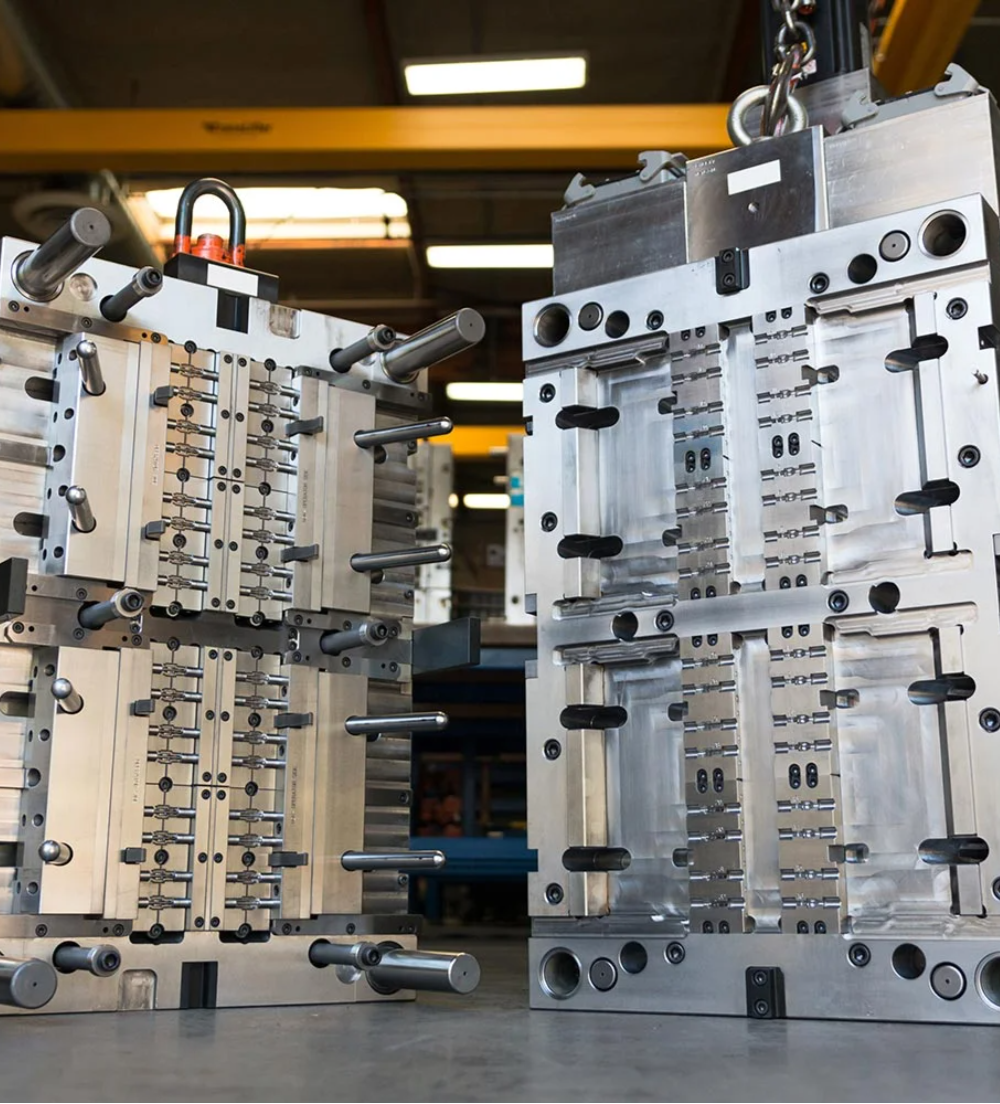

At DEK, we focus on delivering precise insert molding with clean finishes, strong bonds, and tight tolerances. We use smart tools and advanced machines to handle tough designs and large volumes with ease. You’ll get consistent quality, fast turnaround, and expert guidance, from first prototype to full production, all in one trusted place.

introduction

Insert Molding Services for Every Need - Custom, Scalable, and Precise

At DEK, we mold plastic over your inserts with care and accuracy, designed to match your specifications, volume, and performance needs across any industry or application.

We used advanced vertical and horizontal injection molding machines with servo-driven and hydraulic systems to give your parts the precision, speed, and consistency they need every time. Our experienced team supports a wide range of thermoplastics, including ABS, PC, Nylon, PEEK, and medical-grade resins. We mold plastic around metal, ceramic, or plastic inserts using custom tooling and precise control, making sure each part fits perfectly and holds up under pressure. From design support to full-scale production, DEK delivers clean finishes, strong bonds, and consistent part quality both for small batches or high-volume orders.

We are here to support more than just molding and provide full service. From helping you with parts design, insert selection, material sourcing, mold making to handling packaging and global shipping, we are with you every step of the way. Our goal is to make your whole project smoother, faster, easier, and more affordable from start to finish.

- Full-service support

- Low to high volume production

- Strong bonding of components

- Experienced team

- Industry versatility

- Material compatibility

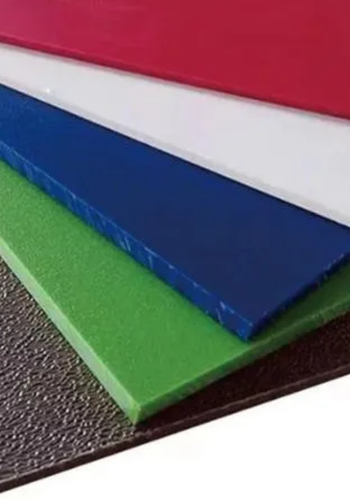

Materials for Insert Molding Services

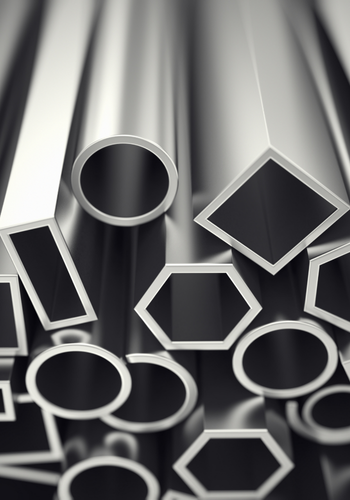

Metals

Plastics

Alloy Steel

Alloy steel inserts are strong, wear-resistant, and ideal for molded parts that need extra toughness. They handle stress, impact, and heat better than basic steels, making them reliable for heavy-duty and high-performance applications.

At DEK, we mold around alloy steel inserts for parts like structural housings, industrial gear mounts, and automotive sensor sleeves. Our precision machining, custom tooling, and tight mold alignment ensure consistent bonding. We help you select the best material to meet your insert’s strength and durability needs.

Alloys

4140, 4340, 8620, 1215, etc.

Aluminum

Aluminum is widely used in insert molding services because it’s lightweight, corrosion-resistant, and easy to machine. It also offers excellent thermal and electrical conductivity, making it ideal for technical applications.

At DEK, we use aluminum inserts to produce parts like electronic housings, sensor brackets, and surgical device frames. We ensure each insert fits tightly and bonds securely with plastic or ceramic materials. With tight tolerances, smooth finishes, and reliable lead times, we help you achieve strong, durable, and high-performance molded components.

Alloys

AL6061, AL6063, AL5083, AL5052, etc.

Brass

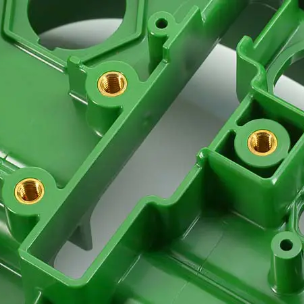

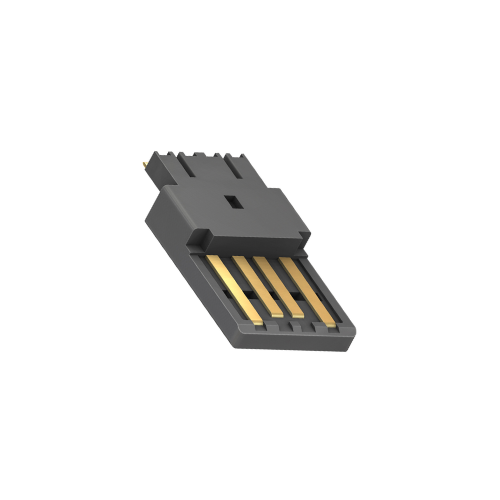

Brass is a versatile metal known for its corrosion resistance, electrical conductivity, and easy machinability, perfect for precision inserts in molded parts. Its antimicrobial and non-sparking properties make it ideal for medical, plumbing, and electronic applications.

At DEK, we use brass inserts in components like threaded bushings, fluid connectors, and electronic terminals. Our team ensures precise machining, tight placement, and strong bonding with plastic or ceramic. We also offer guidance on brass grades to meet your performance, conductivity, and durability needs.

Alloys

C260, C360, etc.

Copper

Copper is widely used in insert molding services for its excellent thermal and electrical conductivity. It’s the best choice for parts that need to transfer heat or electrical current efficiently.

At DEK, we produce copper inserts for electrical contacts, heat spreaders, and sensor pads. We use precise machining to avoid distortion and ensure clean, burr-free surfaces. Our molding process guarantees secure bonding with plastic or ceramic materials. We also help you choose the right copper grade for conductivity, corrosion resistance, and durability.

Alloys

C101, C110

Mild Steel

Mild steel is a cost-effective, strong, and easy-to-machine option for insert molding in structural parts. It provides reliable performance for general-purpose applications, with decent strength, toughness, and weldability.

DEK uses mild steel inserts for components like alignment pins, mounting brackets, and enclosures. Our precision machining ensures each insert meets tight tolerances, while our molding process guarantees strong adhesion to plastic or ceramic. We also help you choose materials and coatings to boost wear resistance, corrosion protection, and part life in industrial environments.

Alloys

Mild Steel 1018, 1045, etc.

Stainless Steel

Stainless steel is popular for its corrosion resistance, strength, and clean, polished appearance. It’s ideal for insert molding parts that face moisture, chemicals, or frequent cleaning, such as in medical or industrial settings.

DEK molds stainless steel inserts into parts like surgical handles, fluid system connectors, and precision sensor housings. We machine and mold to tight tolerances, with smooth surface finishes and strong material bonding. Stainless steel ensures long-term durability, hygiene, and reliable performance for high-demand applications across multiple industries.

Alloys

304, 316, 303, 410, 420, 430

Titanium

Titanium stands out in insert molding for being lightweight, corrosion-resistant, strong, and biocompatible. It’s especially useful in aerospace, medical, and high-performance industrial applications where both strength and safety matter.

DEK molds titanium inserts into surgical implants, aerospace mounts, and lightweight structural components. Each part is precisely machined, ultrasonically cleaned, and overmolded under controlled conditions to ensure reliable bonding and dimensional accuracy. We also assist with alloy selection to optimize performance in harsh environments or mission-critical designs.

Alloys

Grade 2, Grade 5 (Ti-6Al-4V)

ABS

ABS, or acrylonitrile butadiene styrene, is a tough, impact-resistant plastic used in insert molding for its strength, dimensional stability, and easy processing. It offers excellent surface quality and resists cracking under stress or temperature changes. ABS also bonds well to metal and ceramic inserts, making it ideal for structural parts that demand durability and long-term reliability.

DEK uses ABS to mold parts like sensor enclosures, automotive brackets, and handheld device housings. We ensure proper bonding, clean finishes, and tight tolerances for parts that perform reliably and look professional in any application.

Delrin

Delrin, also known as Acetal or Polyoxymethylene (POM), is a strong, low-friction plastic with excellent dimensional stability, wear resistance, and mechanical strength. It’s ideal for insert molding when parts need smooth movement, tight fits, and long service life.

DEK uses Delrin to mold components like gear housings, precision sliders, and valve seats. It bonds reliably with metal inserts and delivers repeatable performance under stress and motion. Delrin is often used in automotive, industrial, and consumer mechanical systems that demand strength and precision.

Grades

Delrin 150, Delrin AF

Nylon

Nylon is a durable, wear-resistant plastic widely used in insert molding services for its toughness, flexibility, and resistance to abrasion and chemicals. It performs well under mechanical stress and is excellent for both structural and functional parts.

DEK molds nylon parts such as cable clamps, bearing housings, and threaded fastener mounts. It bonds tightly with metal or ceramic inserts and holds up well in demanding environments. Nylon is ideal for automotive, electrical, and industrial products that require strength, longevity, and resistance to impact or vibration.

Grades

Nylon 6, Nylon 6/6

PC

PC or Polycarbonate is a strong, transparent plastic known for its high impact resistance and dimensional stability. It is a top choice for insert molding services that need toughness, clarity, and heat resistance. PCs also offer good electrical insulation and flame retardancy.

DEK uses polycarbonate to mold parts such as LED light housings, medical device covers, and structural electronics cases. We ensure a strong bond between PC and your inserts for reliable performance and clean finishes. PC is commonly used in the medical, automotive, and consumer electronics industries.

PE

PE or Polyethylene is a flexible, chemical-resistant plastic often used in insert molding for lightweight, durable parts. It offers excellent impact resistance, low moisture absorption, and good electrical insulation, making it suitable for both indoor and outdoor applications. PE resists wear and UV exposure, and it is also recyclable and cost-effective.

DEK uses polyethylene to mold parts like fluid system components, protective housings, and cable management clips. We ensure proper bonding and smooth molding around metal or ceramic inserts. PE is ideal for consumer products, automotive parts, and industrial equipment.

PP

PP or Polypropylene is a lightweight, semi-rigid plastic known for its excellent chemical resistance, fatigue strength, and affordability. It is widely used in insert molding services where flexibility, toughness, and moisture resistance are needed. PP also handles repeated stress without cracking and offers good electrical insulation. It bonds well with metal or ceramic inserts using adhesives or overmolding.

At DEK, we mold polypropylene into parts like dialysis machine components, chemical pump housings, and automotive fluid connectors. Our process ensures strong adhesion, clean surfaces, and tight dimensions for demanding applications.

PVC

PVC is a strong, flame-retardant plastic widely used in insert molding for durable, insulated, and chemically resistant parts. It performs well in moist, corrosive, or high-temperature environments and offers good electrical insulation. Available in rigid and flexible grades, it’s suited for both medical and industrial use.

DEK uses PVC around inserts to produce components like medical pump housings, fluid control manifolds, and power distribution blocks. Our process ensures clean surfaces, strong bonding, and accurate tolerances for safety-critical and high-reliability molded assemblies. We guarantee your PVC-molded parts meet both mechanical and regulatory standards.

Instant & Accurate Quotes

We don't use online automated quotation tools, because it is very inaccurate. Online quote platforms rely solely on calculations based on cutting amounts and fixed coefficients, they fail to account for actual processing nuances, such as material deformation after heat treatment, tight tolerance requirements, grinding after heat treatment, etc. Consequently, automated price calculations can lead to inaccuracies, ultimately increasing your costs.

But you can rest assured at DEK!

Our quotations are both cost-effective and accurate because we have a team of professional mechanical engineers who meticulously review each drawing. These engineers boast over 10 years of experience and possess deep expertise in programming, machine operation, post-processing, material properties, and more. Ensure you will get accurate quotes within 6 hours.

Our Advantages

2300+ Engineers Love Work With Us

Precision Tolerance Control

We deliver insert molded parts with tolerances as tight as +/- 0.005 mm. This level of accuracy ensures your components fit and perform exactly as designed, even for complex assemblies. Our advanced molding machines, skilled technicians, and strict inspection process help reduce rework and maintain consistency.

Fast Lead Times

Speed is built into our process. That is why DEK can deliver prototypes in as fast as 1 day and production parts in 4 to 7 days. With efficient setup, in-house tooling, and expert scheduling, we help you shorten development cycles, avoid delays, and meet tight deadlines.

Wide Material Options

DEK supports over 50 materials for insert molding. We mold around metal, ceramic, or plastic inserts. This gives you the freedom to select materials based on flexibility or resistance needs. Whether it’s for harsh environments or regulated applications, we’ll help match the right materials to your part’s performance goals.

Cost-Effective Production

We keep costs down without cutting corners. Our efficient insert molding process reduces waste, shortens cycle times, and limits manual assembly. You get excellent value with competitive pricing, often lower than industry averages, while still receiving high-quality parts with clean finishes and precise fit.

Certified Quality Systems

DEK is ISO 9001:2015 certified, ensuring your insert molded parts meet strict international standards for quality and consistency. We maintain full control over every step—from material sourcing to final inspection. Our certified systems are ideal for insert molding with plastics and metals.

Custom Surface Finishes

Get more than just function, DEK offers a variety of surface treatments to match your part’s performance and look. Choose from anodizing, powder coating, polishing, sandblasting, and more. These finishes improve wear resistance, corrosion protection, and overall durability. We also offer color-matching and texture options.

Our Ordering Process

Send RFQ

Send RFQ with 2D/3D drawings and detailed requirements via Email or online form.

Review & Quote

Our Engineer team will review every drawing carefully and provide an accurate quote within 6 hours.

Confirm Order

Confirm the quote, details and delivery schedule, then sign the contract.

Production

Arrange production process, start programming and machining.

Quality Control

Strict quality control during production and final inspection.

Packaging & Shipping

Pack the parts, attach part identification labels, and start shipping.

Send RFQ 222

Review & Quote

Confirm Order

Production

QC

Delivery

FAQ

Insert Molding Service Buying FAQs

Get An Accurate Quote For Your Next Projects

No matter your project is complicated or simple, no matter is metal or plastic, you will get an accurate quotation within 6 hours.

Get A Quote TodayKnowing Insert Molding Service

What is Insert Molding?

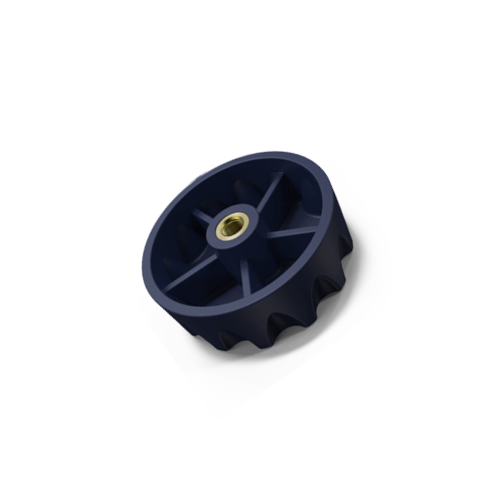

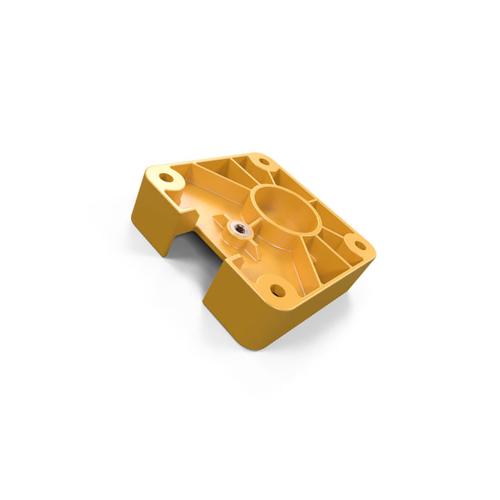

Insert molding is a process where plastic is molded around another part, usually made of metal. You place the insert, like a pin, screw, or connector, into a mold, and then molten plastic is injected around it. Once it cools, you get one solid part with both materials tightly bonded. This makes the part stronger, more compact, and reduces the need for extra assembly steps like gluing or fastening.

You can use insert molding to improve product strength, save time, and create cleaner designs. It’s often used in medical devices, electronics, automotive parts, and consumer products. At DEK, we help you choose the right insert, material, and mold design to make sure everything fits and performs exactly as needed.

What are the Advantages of Insert Molding?

Insert molding offers several benefits when you need strong, precise, and reliable parts. It helps improve performance and reduce production time, especially for complex components. You also get better consistency between parts, which is important for high-volume or safety-critical applications.

Key advantages:

- Improved strength at stress points

- Better durability and part life

- Reduced assembly time and labor

- Compact, space-saving designs

- Lower risk of part failure

- Cost-effective for any volume

When Do You Need Insert Molding?

You need insert molding when your part requires added strength, durability, or built-in metal features like threads, pins, or contacts. It’s a good choice when you want to simplify your product design without adding extra steps after molding. This process is especially helpful when your parts face repeated use or mechanical stress. It’s commonly used in parts for connectors, handles, housings, and enclosures where metal and plastic must work together.

Insert molding is also useful when you need to improve part quality and reduce errors during production. It gives you better control over fit, alignment, and performance—especially for high-precision or safety-critical applications. You get a cleaner build and fewer weak points in your final product.