- Home

- New Energy

Precision Parts Manufacturing for New Energy Industry

DEK specializes in precision parts manufacturing for the new energy industry, providing rapid prototyping and on-demand production for renewable energy and new energy applications.

From new energy vehicle components to energy storage equipment, we deliver high-quality, durable, and consistently reliable parts to global new energy industry clients. We can rapidly process complex parts with tight tolerances controlled within +/- 0.005 mm, utilizing a variety of production-grade materials and surface treatment options.

- In-house Quality Control

- 24/7 Engineering Support

- Instant Quotes and DFM Feedback

- ISO 9001:2015 and ISO 14001:2015 certified.

- Quick Turn, Short Lead Time, not MOQ

Precision CNC Machined Components for New Energy Industry

DEK is renowned for its superior quality and comprehensive services, offering reliable, precise, and flexible custom solutions tailored to the specific needs of the new energy industry.

As an ISO 9001 certified manufacturer, DEK specializes in high-precision parts for energy storage equipment, achieving tight tolerances of up to ±0.005mm. We strictly adhere to new energy industry standards, excelling in machining aluminum alloys, stainless steel, alloy steel, copper, and engineering plastics, ensuring that every part produced by DEK offers durability, corrosion resistance, and wear resistance.

Additionally, we provide surface treatments such as anodizing, electroplating, nitriding, and PVD coating. Our typical applications include gearboxes, jigs and fixtures, generator parts, drill rig components, nozzles, impellers, and wind and water turbines. All quality inspections are conducted in-house, and we provide CMM inspection reports, FAI reports, and material certificates.

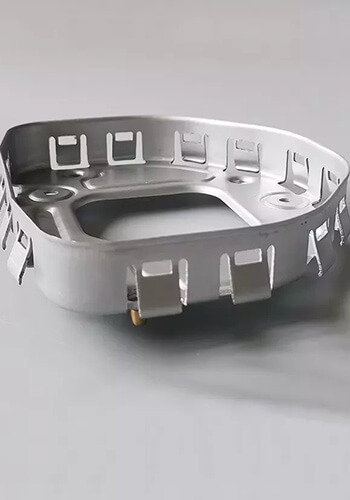

New Energy Vehicle Part

New Energy Component Manufacturing Capabilities

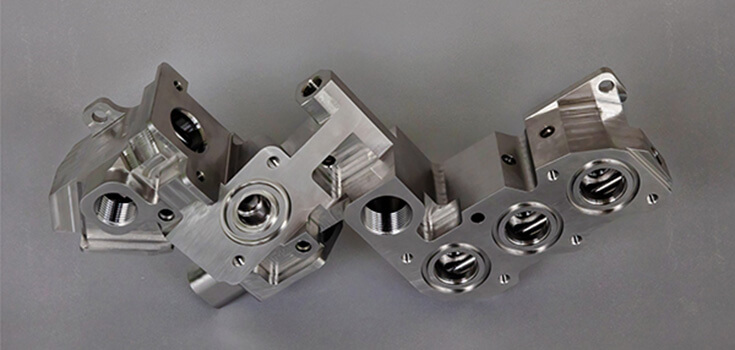

Precision CNC Machining

DEK possesses multi-axis CNC machining, precision turning, and complex component manufacturing capabilities, including milling, grinding, turning, boring, and reaming, meeting the stringent requirements of new energy applications. It is ideal for manufacturing hangers, gearboxes, main shaft housing, bearing seats, solar tracker mounts, and junction box covers.

Whether you need a prototype or are seeking a reliable partner for small to medium batch production, DEK focuses on using production-grade materials and implementing strict in-house quality control to provide one-stop, flexible, and efficient solutions.

Sheet Metal Fabrication

DEK specializes in machining high-quality custom sheet metal parts for the marine industry, including battery tray, ESS cabinet, liquid cooling plate, PDU enclosure,and EV charger pile enclosure, providing reliable structural support and protection for your key components.

We offer a variety of sheet metal materials, including stainless steel, aluminum, and steel. From instant quotes to rapid production, you can receive hundreds of premium sheet metal parts in just days. Additionally, we provide surface treatment options such as brushing, anodizing, and coating to meet your parts' high demands.

Industrial 3D Printing

DEK provides high-quality additive manufacturing services, enabling you to rapidly create prototypes at low cost and produce durable, wear-resistant parts with complex geometries on demand.

We can provide a variety of metals and plastics, including ABS, nylon, TPU, PC, and composites, for printing solar panel mounting brackets, microinverter housings, jigs and fixtures, spare parts, and wind turbine blade prototype. Additionally, we can offer surface treatments required for the project.

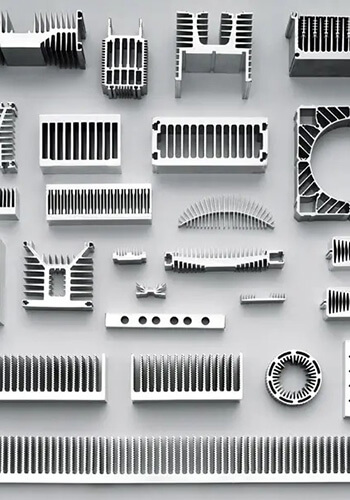

Aluminum Extrusion

Industrial aluminum profiles, with their high strength, lightweight, corrosion resistance, and exceptional design flexibility and modularity, have become indispensable structural materials in the new energy industry.

DEK provides high-quality aluminum extrusion parts for the new energy industry. Our classic cases include battery module frames, solar panel frames, and heat sink. We can flexibly handle your project, offering cost advantages in batch production.

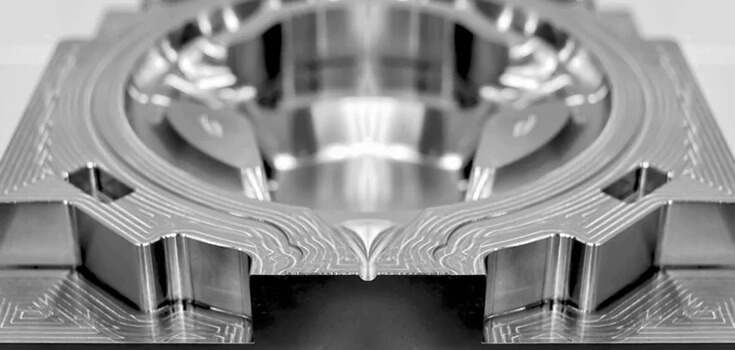

Die Casting

With the advantages of high efficiency, high precision, lightweight design, and cost control, die-cast components are widely used in critical fields such as new energy vehicles, energy storage systems, and solar and wind power generation.

DEK provides high-quality die-cast parts for the new energy industry, including motor housings, gearbox housings, and inverter enclosures. We can flexibly handle your project, offering cost advantages in mass production.

Materials

Materials Options

Aluminum

Aluminum and its alloys are among the most widely used metals in the new energy sector, serving as a core choice for achieving lightweight designs. They are highly suitable for manufacturing battery pack housings, motor housings, reducer housings, and controller enclosures.

High-strength Steel

High-strength steel is widely used in the new energy industry due to its high strength, low cost, and good processability, making it indispensable for critical safety structural components such as chassis structural parts, drive shafts, and suspension parts.

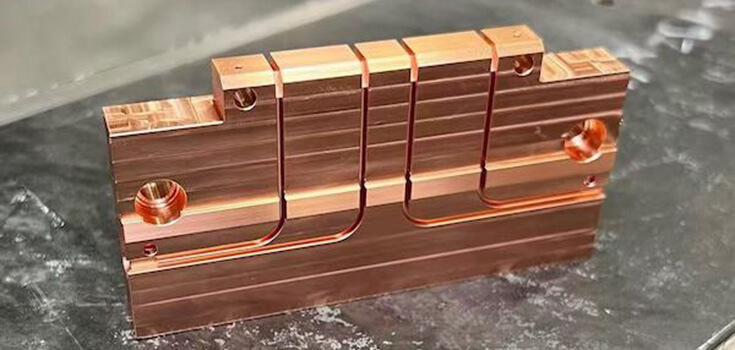

Copper

Copper and its alloys are primarily used in the new energy industry due to their excellent electrical and thermal conductivity, as well as their ease of processing and welding. They are highly suitable for manufacturing busbars, motor rotors, contact pins, motor terminals, and thermal baseplates.

Engineering Plastics

Engineering plastics play a crucial role in insulation, lightweight design, and functional integration. They are commonly used to manufacture connectors, battery module brackets, end plates, charging gun housings, PV junction box housings, and motor sensor brackets.

Instant & Accurate Quotes

We don't use online automated quotation tools, because it is very inaccurate. Online quote platforms rely solely on calculations based on cutting amounts and fixed coefficients, they fail to account for actual processing nuances, such as material deformation after heat treatment, tight tolerance requirements, grinding after heat treatment, etc. Consequently, automated price calculations can lead to inaccuracies, ultimately increasing your costs.

But you can rest assured at DEK!

Our quotations are both cost-effective and accurate because we have a team of professional mechanical engineers who meticulously review each drawing. These engineers boast over 10 years of experience and possess deep expertise in programming, machine operation, post-processing, material properties, and more. Ensure you will get accurate quotes within 6 hours.

Why Choose Our Services

One-stop production of high-quality parts saves you time and money.

Engineering Capabilities

Fast Lead Time

Quality Control

Surface Finishes

Precision Assembly

Packaging and Logistics

Our Ordering Process

Send RFQ

Send RFQ with 2D/3D drawings and detailed requirements via Email or online form.

Review & Quote

Our Engineer team will review every drawing carefully and provide an accurate quote within 6 hours.

Confirm Order

Confirm the quote, details and delivery schedule, then sign the contract.

Production

Arrange production process, start programming and machining.

Quality Control

Strict quality control during production and final inspection.

Packaging & Shipping

Pack the parts, attach part identification labels, and start shipping.