Are you looking for an ultimate and complete guide that can help you know all the minor and major details of the splined shaft? You have landed at the right place. This guide will tell you everything you need to know about the splined shafts. From the function to applications and production, every detail is given here.

What is a splined shaft?

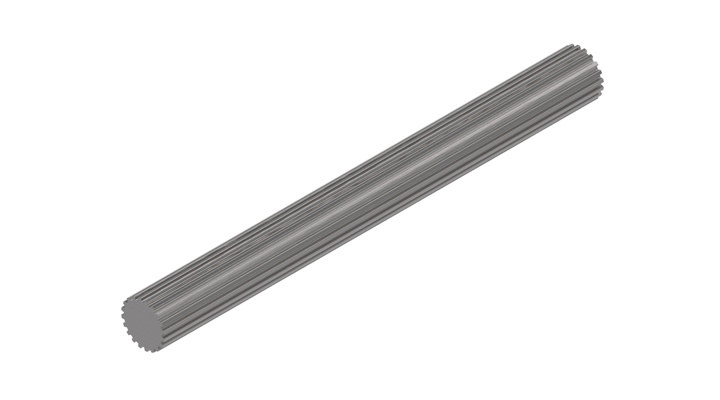

A spline is a ridge or teeth that mesh with the groove and transfer the torque. It maintains the angular correspondence between the tracks and the shaft. A splined shaft can be defined as a shaft with several grooves cut in the shaft. All these grooves are equally spaced around the circumference, and they form a series of projecting keys. They give the shaft a shape that helps it fit into an internally grooved cylindrical member.

A spline shaft is a mechanical component that can perform various functions. It can work as an anti-rotational device, and at the same time, you can use it to transmit torque to any other device. It is used in various industries. There are many types of alternative shafts like the key shafts, but the splined shafts are the most convenient way to transfer the torque.

What is the function of the splined shaft?

The most common function of the spline shaft is to act as an anti-rotatory device. This function appears to be happening when working in the linear guide positions. If it is not working as a linear guard, the spline shaft works to transmit torque to another device. The function of the splined post is varied depending upon certain factors.

The spline shaft functions to mate with the female version and interlock to transfer the rotatory movement. The splined shaft works as a linear guide when coupled with a bearing with an internal spline gear mechanism. The function of a spline shaft depends upon the construction and type of spline applied to the shaft.

The functions of a typical spline shaft are often undertaken. It is because the splines of the gear are processed into the length of the post. There are different spline designs and shapes, and they have different roles and functions when mesh with the shaft.

What are the applications of the splined shaft?

Splined shafts are needed in several applications. They include manufacturing, locomotives, industrial facilities, automobiles, and many others.

Its most common application is in the automobile industry, aviation, and earth-moving machinery. The splined shafts are used at several places.

Splined shafts can easily handle high rotation speeds and deliver torque. It is easy for splined shafts to deliver more torque than other shafts because of their structure. The splined shafts have an equal distribution of load across every teeth or groove.

Spline shafts are very crucial for the production of many items as well as machinery in many industries. A splined shaft helps provide a uniform and controlled torque. It can also reduce the chances of misalignment with the parts.

What is the construction of a splined shaft?

The materials used in the splined shafts is very sturdy because it has to reduce deflection. The deflection and bending tooth profile start to distort with time. The materials for splined shafts are different metals, non-metals, and other materials. These materials include bronze, brass, stainless steel, titanium, Delrin, nylon, and steel alloys.

A spline is defined as a strip of wood, plywood, or some other materials. This strip is inserted into the grooves along the edges of the boards. Moreover, the ends of the splines are set to avoid stress as much as they can. Splined shafts are occupied in a massive variety of lengths and diameters, materials and types of grooves.

One thing that is focused on in the construction of a splined shaft is the load capacity. The capacity must be enough to carry the force across the axis so it can transfer the torque. The load capacity should be perfectly balanced; it should be neither too much nor too light. The use of high-quality material in the splined shaft, so the machines work properly.

What materials can be made of the splined shaft?

Splined shafts are made from different materials. The metals used in the manufacturing of the splined shaft are selected by checking for localized stress between the grooves of the shaft. Some of the materials are common in every splined shaft. These are as follows:

Stainless steel

Stainless steel is the alloy that contains chromium or nickel additions in the steel. It is highly wear-resistant and exceptionally durable. In splined shafts, stainless steel is the best option to provide tensile strength and prevents corrosion.

Carbon steel

Carbon steel is best known for its malleability, the property that lets the material be used and hammered into sheets. The carbon content of the carbon steel is shallow, nearly 1.7%.

In splined shaft engineering, carbon steel is used because of its valuable properties. The spline shaft having high-quality carbon steel helps to provide a reliable and smooth motion.

Alloy steels

The ferrous alloys of steel contain iron, carbon, nickel, chromium, and molybdenum. The alloys are used in splined shafts, and each one of them plays its part with its properties. The alloys include high-strength low-alloy steels, managing steels, harden-able high-alloy steels, and many other special alloy sheets of steel.

Aluminum alloys

Aluminum alloys are very useful in splined shafts. Aluminum alloys have less density than steel alloys, almost half of them. They provide more toughness at even moderate strengths. Aluminum alloys are very much resistant to corrosion.

How to use a splined shaft?

Splined shafts are used in various vehicles. Different designs of the post are responsible for different kinds of use. Following are some kinds and their services.

Crowded

This type of splined shaft has modified splines that become narrow as we move towards the end face. This splined shaft produces angular misalignment on the surface.

Parallel key

The parallel key in the splined shafts has separate profiles and ridges. They can be cut or cold roll-formed. This kind of splined shaft finds its uses in places where accuracy, high strength, and smooth finish in needed.

Involute

This type of splined shaft has been designed with tapered ridges. Its uses are found in the functions where stress concentrations need to be reduced. They help in preventing any movement between the internal and external parts. It is specifically helpful in the transmission of torque.

Helical

This type of splined shaft design is made with an involute spline. It can also be made from the parallel spline. The teeth or ridges in this spline make a spiral pattern. The most crucial use of helical pattern is that it allows both linear and rotatory motion.

Serrations

Serrations are designed at such an angle that they allow many teeth on the shaft with a relatively more minor diameter shaft. Serrations have straight flanks, but their grades are adjusted. The most significant advantage of serrations is the hub resulting in the splines that are self-centered. In the serrated splines, there are linear contacts and wears. The angles are set to provide maximum advantages.

How to clean the splined shaft?

The life expectancy of the splined shafts depends upon the cleaning and lubrication of the shaft. Good lubrication is easily achieved by submerging the spline into the oil. The cleaning of the shafts is also necessary to improve their function.

The dirt on the splined shaft is removed easily with a damp cloth. The grim of the shaft should be adequately cleaned and dried with a towel. Although the material used in the manufacture of the splined shaft is rust-free, if there happens to be any rust on the surface of the shaft, you can remove it with vinegar. The teeth or grooves in the shaft and the holes should be thoroughly cleaned and checked. Any residue should not be left in the shaft. Make sure to be careful while cleaning the shaft. Any scratch or harsh cleansing can be damaging.

How to produce a splined shaft?

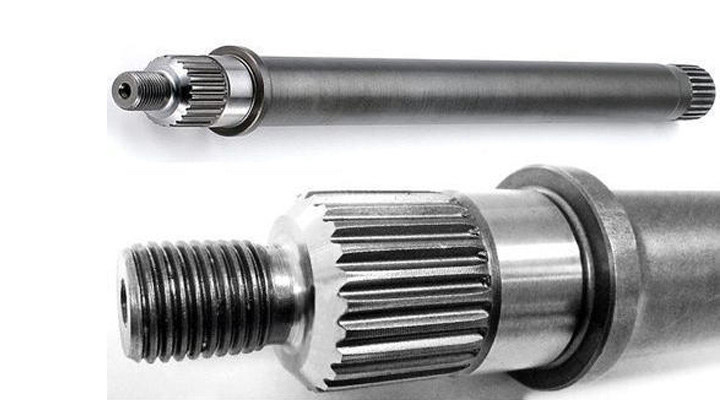

There are two types of spline shafts; internal and external. There are different methods of manufacturing these types of spline shafts. With some bit amendments, these methods are used by experts for both types. These methods include broaching, shaping, milling, threading, hobbing, grinding, and extrusion.

Broaching

Broaching is a process that uses a toothed tool to remove the material from any surface. The toothed tool is called a broach. Broaching is used despite being an expensive process because it can give precise machining for odd shapes. In the manufacture of spline shafts, external broaches are used. These are also called blind broaches. They are used to cut furrows on the surface of the material along the length of the shaft.

Shaping

Shaping is the traditional method used for gear cutting. The blank gear is rotated alongside a piece of incomplete equipment. A shaper is a tool used for cutting internal and external teeth. It is a simple, reliable, and general method for gear cutting.

Milling

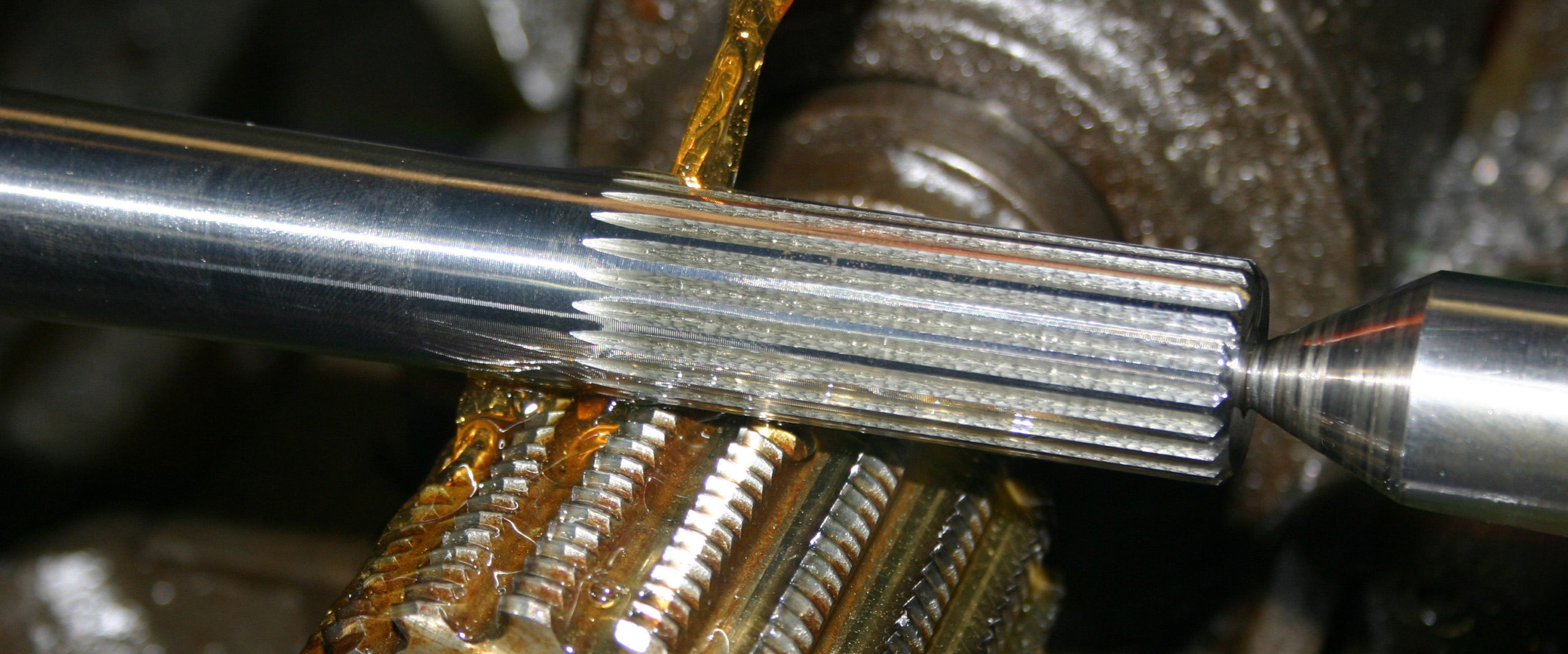

Milling is the process that uses a milling cutter to remove material from the surface of a workpiece. A milling cutter is used in splines because it has multiple cutting points on its rotatory cutting tool. The milling cutter can move perpendicularly on a surface which helps in the cutting to occur on the circumference of the edge. Spline milling can be used for the transfer of power throughout a mechanical system.

Hobbing

Hobbing is a machining process used to cut splines. Hobbing is a relatively inexpensive process as compared to the other cutting splines. The surprising fact is that it is an accurate method, and hence it is used on a wide range. Hobbing is helpful for the manufacture of external spline shafts only. This method is not accessible for the internal spline shaft.

Rolling

In the process of rolling, some synchronized shapes are formed on different parts of the shaft. These shapes are mostly threaded and splined, which shorten the manufacturing cycle. As a result, the relative phase between the spline and thread remains stable during mass production.

Grinding

It is an abrasive machining process. It uses a grinding wheel as a cutting tool.

Grinding is a metal cutting process. It is commonly used to cut out the minor details on the surface. Grinding is used on various types of steel, so it is helpful in the manufacture of a splined shaft. Surface grinding helps in the grinding of materials of the post with a unique technique.

Extrusion

Extrusion helps in the creation of objects with a fixed cross-sectional profile. Extrusion can help tackle particular simple things more efficiently with a spline shaft rather than extruding them by hand. It is pretty helpful as it allows various options in a simple operation.

However, there are some accessibility restrictions due to which the methods of manufacture of internal splines are significantly less. Mostly the methods used for external shafting are applicable. Hobbing is not accessible, and hence you cannot use it to manufacture the internal shaft.

Can you offer a custom splined shaft?

Yes, the splined shafts can be customized at DEK. If you want the machines to work efficiently, you should select the right size and type of the splined post. We can customize the splined shafts for you.

We use the material with uncompromised quality. We have great expertise in our field. The grooves, as well as the spacing between them, are also altered according to your need. Welcome to contact our sales team to get more information.

Summary

The splined shafts have found uses in several industries. They are the machines that make the work easy. The manufacturing of these splined shafts does not even require some fancy materials. We can easily customize the shafts and their designs according to your need and taste. You can contact various websites that have high ratings and experience in this field. We would recommend you to go to the sites that use high-quality material and advanced technologies for precision. Their customer service and expertise should have their name.