Medical machining is known for its precision, speed, and material versatility.

It’s crucial for medical machining to have the capability of fabricating parts with extremely tight tolerances and focus on bio-safe and biocompatible materials.

You will also understand the way DEK controls the medical machining and able to output medical parts of utmost quality and high performance.

In this FAQ guide, you will also learn medical machining benefits and capabilities for your parts and how it can be extremely productive.

What Is Medical Machining?

Medical machining is precision machining that holds the technical resources to fabricate the medical parts.

Moreover, the medical parts that require utmost precision and extremely tight tolerances require medical machining services.

By utilizing medical-grade materials, it’s easy to fabricate parts related to the medical industry.

Medical machining helps to fulfill every medical industry need, from surgical tools to monitoring devices.

Medical machining has the capability to make parts of extreme complexity and of the highest possible quality.

The medical-grade material for medical machining can be:

- Titanium

- Stainless Steel

- Chrome

- Bass

- Polymers

And it’s also important to know that medical machining is not just limited to these materials.

To support the machining requirements of the medical sector, a comprehensive range of medical machinery is available.

What Is The Importance Of Precision In Medical Machining?

Through medical machining, you can achieve tighter tolerances, utmost accuracy, and great precision in your parts.

Moreover, precision has a great value and reputation in the medical industry.

The manufacturing of medical parts requires working with:

- Tighter Tolerances

- Medical Grade Material

- Advanced Machining

- Technology Advanced Equipment

- Knowledgeable Staff

- Heightened Controls

The one medical machine shop that has the following is able to give the qualified results that are admired by the medical industry.

The important thing about surgical equipment and other complex and sensitive medical parts is that a little mistake can cause critical issues.

That’s what makes precision a priority and extremely important in medical machining.

Precision medical machining also offers custom medical parts for a perfect fit and to meet your designing and accuracy needs.

What Are The Technologies Of Medical Machining?

Medical machining is all about parts manufacturing technologies.

Eliminating extra material from a workpiece to shape it into an intended design is what the medical machining process does.

The medical machining technologies involve the use of:

- Material

- Design

- State-of-the-art machining equipment

- Precision medical part manufacturing

- Quality Assurance

- Detailed Inspection

Most importantly, the use of advanced and modern machining equipment like 5-Axis CNC machines is the latest medical machining technology.

Investing in medical technology can give you the most innovative solutions for your part fabrication.

The use of AI is common in today’s medical machining and enables you to have the best design, development, and production of your medical parts.

What Are The Applications Of Medical Machining?

Sometimes, parts are required by medical industry applications that are precise enough to cut an eye’s lens without any causalities.

Hence, the greatest precision with the highest standards to ensure reliability and safety is an essential medical machining requirement.

The following are core applications of medical machining in the medical industry:

- Electronic Medical

- Micromachining

- Cardiovascular Devices

- Orthopedic Devices

- Surgical Instrumentation

- Implants

The main thing about these applications is that they require an extreme level of precision and contain complex designs.

No type of other machining and manufacturing technique is capable enough to give the results that precisely reflects what is required.

Hence, medical machining gives you the guarantee of the highest precision results.

Moreover, the optimal medical machining environment also helps fabricate optimal medical parts by achieving the tightest tolerances of +/- 0.001mm.

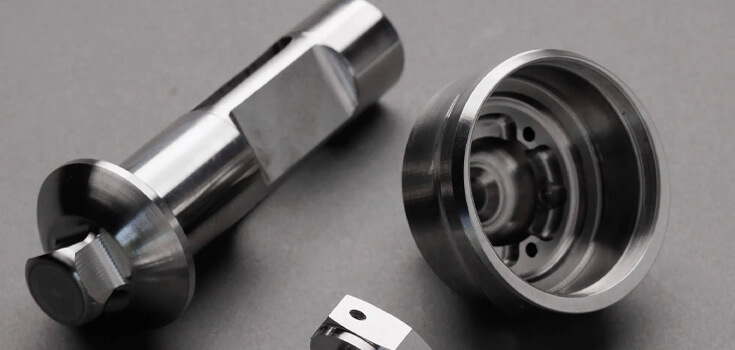

What Parts Can Medical Machining Manufacture?

Medical machining is known to be a precision manufacturing process.

In order to achieve higher precision in parts designing, pre-programmed computer software is used to handle the part fabrication, for example, the use of CNC machining for medical part manufacturing.

By doing so, the machines can have greater control over your part manufacturing and eliminate human error risk.

By keeping this in mind, the medical machining can manufacture the following parts:

- Medical Implants

- Testing & Analysis Components

- Medical Instrument Components

- Drug Delivery Components

- Pump Components

- Respirator Device Components

- Ventilator Components

- Precision Shafts, Brass Inserts

- Complex Multi-Component Assemblies

Medical machining can rapidly produce the highest quality precision machine parts cost-effectively and with a superior surface finish.

What Are The Requirements For Medical Machining?

In order to achieve successful machined medical parts, meeting standards and optimizing the machining process have more excellent value.

There are many requirements for medical machining if your focus is to get the best quality results possible.

The medical industry is a critical field, and accuracy is what it requires because sometimes human lives depend on these machined medical parts’ success or failure.

The following are the requirements for medical machining to achieve success in medical part manufacturing:

- Precision medical machining to tighter tolerances (as tight as +/- 0.002mm for some medical equipment)

- 5-Axis CNC machining for complex part geometries

- The extreme level of surface clearance (mostly for the implant devices)

- A comprehensive medical grade material selection

- High-level surface finishing and coating capabilities

How To Achieve Tighter Tolerances Through Medical Machining?

Medical machining is mostly referring to the use of computer-aided machinery to fabricate medical parts.

The necessary requirement of the medical industry is tighter tolerances of minimum +/- 0.02mm.

Moreover, the tightest tolerance of +/- 0.001mm is also achievable only if it is in your request.

In medical machining, adopting the followings can help you achieve tighter tolerances:

- With the right manufacturer experience and machinery

- Through precision machining

- By controlling the medical machining environment

- Through a quality controlled and stabilized temperature

- With the use of advanced and technologically enhanced machinery

- Through a dynamic balance of tool holder

- Eliminating misalignment, asymmetrical design, concentricity error

- With the use of the correct sharp cutting tool

- With the selection of medical grade material

- Through detailed inspection

Furthermore, medical parts manufacturers’ experienced engineers and strong quality control also help you achieve tighter tolerances.

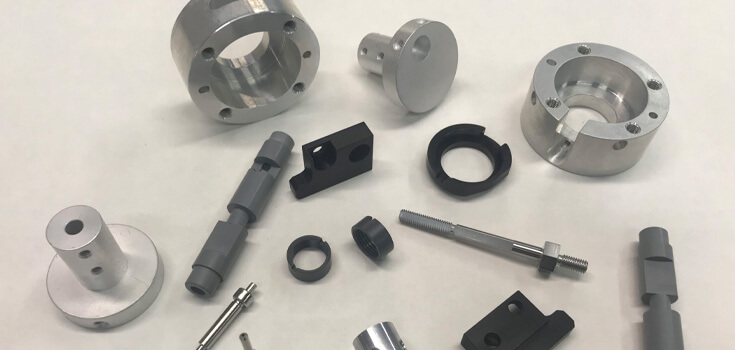

What Are The Capabilities Of Medical Machining?

In order to fabricate medical parts, including orthopedic implants, instruments, and tooling, it’s important for medical machining to be capable of achieving the highest quality and most efficient results.

Medical machining should be reliable enough to achieve accuracy, efficiency, and precision, even for parts with complex geometries.

In the modern medical industry, medical machining is only successful if it has the following capabilities:

- Achieving high-quality surface finishes

- Achieving dimensional accuracy

- The use of 5-Axis CNC machining

- Achieving tightest tolerances

- Maintaining machining stability

Moreover, a detailed inspection is also required to finalize the part’s quality and performance before delivery.

How To Maintain Process Stability In Medical Machining?

In medical machining, it’s crucial to completely stabilize the part manufacturing process to achieve exceptional efficiency without sacrificing surface quality.

It is also cost-effective from a financial perspective and increases the medical part machining process’s speed.

The medical machining equipment design is the most important factor to consider in regards to improving the process stability.

Moreover, the following can help you maintain the high process stability of the medical machining:

- Achieving inherent geometric accuracy

- Achieving thermal stability

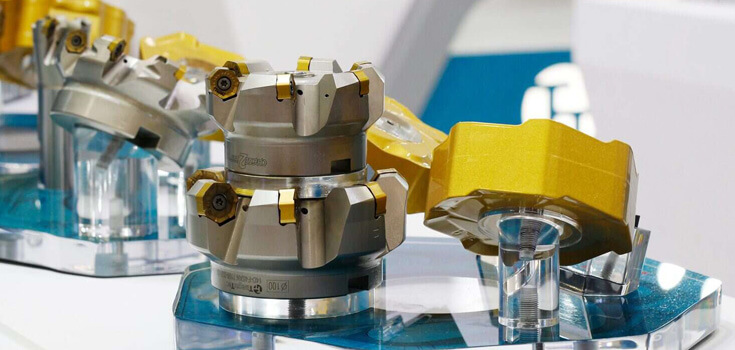

Why Prefer 5-Axis CNC In Medical Machining?

5-Axis CNC machining is preferred in medical machining because otherwise, it’s challenging to achieve precision and tighter tolerances of +/- 0.005mm.

The 3D parts and tooling shapes are also common in the medical industry. Machining these parts became easy through 5-Axis CNC machining.

3-Axis CNC machining also helpful in the fabrication of some of the tasks but can decrease the performance, speed, surface finish quality, and precision.

However, in the fully optimized manufacturing environment, the use of a 5-Axis CNC machine can be:

- Extremely productive

- Cost-effective

- Eco-friendly and Pollution-free

Furthermore, 5-Axis CNC is required to increase the medical part production speed without losing performance.

It also helps you to have medical parts with an Incredibly balanced surface.

What are the Advantages of Medical Machining?

If there is a field that benefits from medical machining’ precision, accuracy, efficiency, and speed, it is the medical industry.

Medical machining has many science and technology-related benefits, and it’s flexible enough to adopt modern technologies and advanced machining processes.

Medical machining’s edge-cutting technology is also proven life-saving because of its ability to safely made critical and complex medical parts.

Medical machining has the ability to design and develop complex parts that also require micromachining with utmost precision.

Furthermore, the following are some core advantages of medical machining:

- Made higher quality parts

- Decreases energy costs

- Decreases labor costs

- Eliminate chances of human error

- No volume restrictions

- Works with many materials

- Fast Machining

- Easy to achieve tight tolerances

- Offer reliability

- Reduce effort and increase productivity

- Improve efficiency

- Enhance safety

- Offer precision micro-machining

Furthermore, medical machining enables us to fabricate extremely small parts of greater complexity with exceptional precision.

Who Can Make Parts Through Medical Machining?

Medical machining is not like some ordinary part manufacturing process and is also does not utilized to make parts for consumer goods.

However, the standard machined parts are required to meet ISO 9001 quality management requirements.

Hence, medical machined parts require much more and need to meet further quality standards.

The only manufacturers that can meet the medical machining quality standards are authorized to make medical parts.

According to ISO, manufacturers involving the design, development, production, and inspection of medical machined parts must meet all the customer requirements.

What are the Medical Machined Implants?

The production of bodily implants is one of the essential uses of medical machining.

The bodily implants like knee implants and hip replacements require detail in design with precision and robustness.

Achieving this detail in design is possible through medical machining. Medical machining is mostly suitable for patient-specific implants.

There will be no tooling costs for you through medical machining, which also makes the implants manufacturing rapid and cost-efficient.

In general, implants mostly utilize medical-grade titanium as a raw material.

The materials for implants need to be biocompatible, and being strong and durable is sometimes doesn’t prefer.

Medical machining also helps eliminate the patient’s health risks by providing harmless machined parts.

The standard machined implants through medical machining are:

- Knee Implants

- Hip Implants

- Spine Implants

Moreover, the following are medical grade materials for machined implants:

- Titanium

- Cobalt-Chrome

- Stainless Steel

- Polyether Ether Ketone

Medical machining is also extremely popular in the production of one-off medical implants.

What are the Medical Machined Surgical Instruments?

It’s important to understand the importance of precision and tight tolerances in surgical instruments.

Because, through this knowledge comes the understanding of why medical machining is vital in the medical industry.

The medical professionals use surgical instruments during operations and for other critical activities.

The success and failure of operations depend on surgical tools and medical professional performance.

The medical professional performance improves with the high quality and accurately manufactured surgical instrument.

Hence, surgical instruments need to be highly accurate and perfectly designed.

Achieving this accuracy through tighter tolerances of +/- 0.002mm is possible through medical machining.

A single and micro defect can even be a matter of death and life, so care, and precision in medical machining is required.

Medical machining help manufacture the following surgical instruments:

- Handles

- Saws

- Holders

- Spacers

- Clamps

- Forceps

- Cutters

Moreover, the common medical-grade material for surgical instruments is stainless steel and titanium.

Through medical machining, medical professionals will also get the ease of sterilization.

What is the Importance of Medical Machining in the Electronic Medical Industry?

Part design complexity is not a problem for medical machining. Parts related to surgical are an easy task for medical machining.

The parts related to the electronic medical field are even more complex, and medical machining still has the capability to precisely fabricate them.

Like, heart rate monitors, MRI scanners, and X-ray machines, which are incredibly complex and require utmost precision to make.

Similar equipment sometimes contains hundreds of microparts, and manufacturing them is also not challenging for medical machining.

Medical machining is essential to fabricate these parts because of their high standard requirements and the need to eliminate every chance of machine failure.

Medical machining can manufacture electronic medical parts that are the part of the following:

- Ultrasound equipment

- CT scanners

- MRI scanners

- Monitors

- Lightning

- Diagnostic equipment

What is Micro Medical Machining?

The medical industry is a gigantic one and sometimes required minimal parts to be manufactured.

Precision manufacturing technologies help carry out the microparts manufacturing requirements.

Performing micromachining of these parts is a basic feature of medical machining.

These parts can be:

- Stents

- Catheters

- Pacemaker components

- Drug delivery systems

- Ophthalmic devices

- Miniature screws for implants and devices

- Tiny plastic tubes

It is helpful performing medical machining with an outstanding cutting ability to meet these tiny part’s tight tolerances.

What are the Materials for Medical Machining?

Medical machining has the ability to manufacture every kind of medical parts no matter what the tolerance, material, and surface finish are required.

Some parts require CNC milling, and others are dealt with CNC turning, and both are useful to achieve tighter tolerances up to +/- 0.002mm.

It’s easy to process medical-grade materials through medical machining’s strong manufacturing capability.

Medical machining has a long list of available materials from hard to soft, including:

Aluminum

- Highly ductile material

- Easy to machine

- Good strength-to-weight ratio

- Available in many types for a range of medical applications

Copper

- Exceptional electrical and thermal conductivity

- Good plasticity

- Highly ductile material

- It can be readily weld

- Offers excellent resistance against corrosion

Brass/Bronze

- Low friction

- Excellent electrical conductivity

- Golden appearance

Steel

- Good machinability

- Excellent electrical conductivity

Stainless Steel

- Great tensile strength

- Excellent corrosion resistance

Titanium

- Offers up to 99.30% purity

- Superior electrical conductivity

How to Maintain and Improve the Medical Machining Quality?

Optimizing the medical machining processes is one way to enhance its quality and performance in a cost-effective manner.

Optimizing medical machining will also help you eliminate unnecessary steps and reduce the waste of material, energy, and resources.

Furthermore, maintaining a standard and clean environment for machining is the core concept behind its exceptional performance and can increase its quality.

The use of quality raw material and upgrading the medical machining based on the latest technology and also improving its overall quality.

What are the Size Limitations of Medical Machining?

With the limited technology, medical machining also has some size limitations; for example, it’s uncommon to achieve tight tolerances of +/- 0.0001mm for your medical parts.

Moreover, the following are some size limitations of medical machining:

- Forming and Bending: +/- 0.4mm

- Bending: +/- 0.2mm

- Linear Dimensions: +/- 0.1mm

- Diameters with Inserts: +0.06mm / -0.0mm

- Angularity: +/- 2°

- Surface Roughness: Ra 100 uin max

What is the Surface Finishing in Medical Machining?

Surface finishing in medical machining can be a single or series of processes that alter your medical part’s surface to achieve a specific look or different properties.

There can be many surface finishes for medical equipment based on your requirements.

The following are some of the commonly used surface finishes for medical machined parts:

Anodizing

- Improves corrosion resistance

- Enhances wear resistance

- Improves hardness

- Protect surface

Dead Blasting

- It offers a smooth surface with a matte texture

Powder Coating

- Increase durability

- Enhances wear and corrosion resistance

Electroplating

- Functional and decorative

Polishing

- Offers smooth and shiny surface

- Increase reflection properties

- Reduce diffuse reflection

Brushing

- Surface treatment process

Painting

- Improves aesthetic appearance

- Highly protective

How DEK Offers the Best Medical Machining Services?

At DEK, we offer quality medical parts on demand.

From rapid medical machining to custom and precision medical part fabrication, DEK is able to provide every related service.

Our medical machining enables you to get precision parts through CNC machining.

At DEK, we believe that all you need is quality and precision in your parts in a rapid and cost-effective way.

DEK’s medical machining capabilities also include the most advanced part fabrication technologies like 5-Axis CNC machining and Micromachining.

DEK is certified and can work with a vast library of medical grade materials.

The most beautiful thing about working with DEK is we give you the freedom of full customization of your medical parts.

Our medical machining promotes a pollution-free environment and is eco-friendly.

You can rely on DEK from your prototyping to medical part production.

How to Order Medical Machining Parts?

Ordering your medical machined parts from DEK is extremely easy.

DEK offers a standard ordering process that includes:

- Uploading the requirements and essential information

- Getting quotation from us

- Placing your order

- Clear the payments

- Start manufacturing

- Detailed Inspection and Packaging

- Delivery

It’s important for you also to understand how much respect DEK has for your intellectual property and all information provided by you for quotations only.

At DEK, our success is your complete satisfaction, and we achieve it by giving you the medical machined parts of exceptional quality.