- Home

- Materials

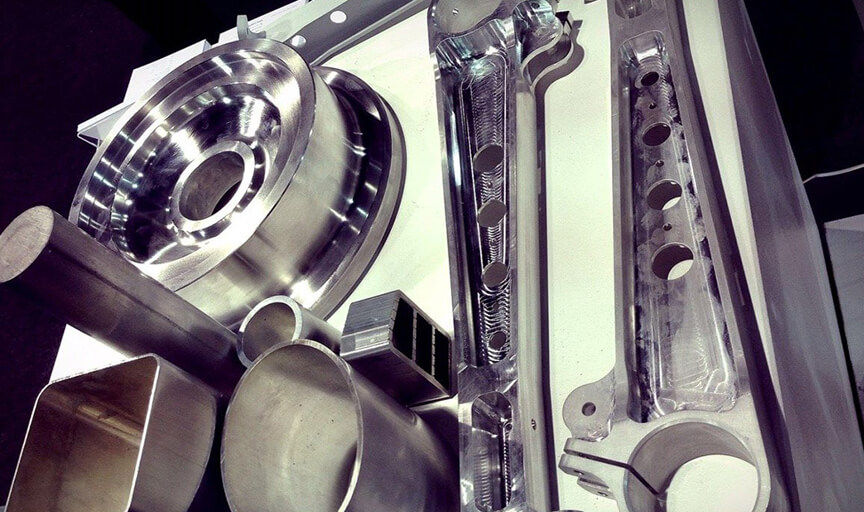

- CNC Machining Metal

- Magnesium

- Magnesium AZ91D

Magnesium AZ91D

Material Type

Metal

Material Name

Magnesium AZ91D

Alternative Names

M11916

Process Compatibility

CNC Milling, CNC Turning

Magnesium AZ91D in CNC Machining

Magnesium AZ91D is a high-purity magnesium die-casting alloy that offers a good balance of strength and weight, providing strength comparable to many aluminum alloys.

The alloy is named based on its composition, with "AZ" indicating the presence of aluminum and zinc and "91" specifying the approximate percentages of these elements in the alloy. In the case of AZ91D, it typically contains around 9% aluminum and 1% zinc. The letter "D" indicates that the alloy is suitable for die casting. AZ91D possesses moderately low tensile strength, electrical conductivity, and melting temperature compared to other magnesium alloys. The material has three common variations – AZ91D-F, AZ91D-T6, and AZ91D-T4.

It is well known for being highly corrosion-resistant and having good thermal conductivity. AZ91D is generally softer than aluminum or steel, making it easier to machine. However, this also means that special care must be taken to avoid machining-induced deformation or burrs. Additionally, it is highly flammable, and the chips produced during machining can be a fire hazard. We use water-soluble coolants to keep temperatures in check. Moreover, we choose coated carbide tools in machining for efficient results.

Properties Table of Magnesium AZ91D

| MECHANICAL PROPERTIES | |

|---|---|

| Brinell Hardness | 63 HB |

| Ultimate Tensile Strength | 230 MPa |

| Yield Strength(0.2%) | 160 MPa |

| Shear Strength | 140 MPa |

| Fatigue Strength | 97 MPa |

| Impact Strength | 3.0 J |

| Modulus of Elasticity | 44.8 GPa |

| Elongation | 3.0 % in 50mm |

| Physical Properties | |

| Melting Point(Avg.) | 533°C |

| Density | 1.81 g/cm³ |

| Electrical Conductivity | 12.2% IACS |

| Electrical Resistivity | 14.3 μΩ-cm |

| Thermal Conductivity | 72 W/mK |

| Casting Temperature | 640-675°C |

| Specific Heat Capacity | 1047 J/kg-°C |

| Coefficient of Thermal Expansion | 25.2 μm/m°K |

Basic Knowledge of Magnesium AZ91D

What is Magnesium AZ91D?

Magnesium is one of the lightest structural metals. Magnesium AZ91D is a wrought magnesium alloy with a specific composition, primarily composed of magnesium (Mg), aluminum (Al), and zinc (Zn). AZ91D, known for its high purity, overcomes magnesium's natural corrosion weakness by including aluminum and carefully controlling iron, nickel, and copper percentages.

Due to its corrosion resistance, it can be an effective alternative to aluminum die-casting alloys in certain situations. The alloy shares characteristics with pure magnesium, such as lower density than aluminum and zinc. However, it also exhibits lower thermal conductivity and a higher material cost. It may justify the added expense if you specifically need a lightweight material.

Advantages of Magnesium AZ91D

Lightweight

Good strength-to-weight ratio

High corrosion resistance

Excellent machinability

Good heat dissipation

Suitable for die-casting applications

Cost-effective

Recyclable

Applications of Magnesium AZ91D

Aerospace components

Automotive parts

Electronic housings

Portable electronic devices

Sporting goods

Medical implants

Marine components

Defense industry applications

Machining Magnesium AZ91D Buying FAQs

Other Materials

Inconel

Inconel is a group of high-performance alloys made of nickel, chromium, and iron, with additional elements like molybdenum and niobium. These alloys have outstanding resistance to corrosion, oxidation, and high temperatures.

Brass

Brass pairs well with various styles. Mixing it with natural materials can create a balanced and sophisticated look. Experiment with different textures for a stylish combination.

Alloy Steel

Powerful than carbon steel, more wear-resistant, more tear-resistant. Alloy steel is durable and can withstand high-temperature environments.

Get An Accurate Quote For Your Next Projects

No matter your project is complicated or simple, no matter is metal or plastic, you will get an accurate quotation within 6 hours.

Get A Quote Today