In a CNC machine shop, skilled operators, expert engineers, and advanced machines work side by side to build accurate, reliable components. In this guide, you’ll learn what makes a good CNC precision machine shop and how you can choose the right one.

What is a CNC Machine Shop?

A CNC machine shop is a small but specialized workshop that makes custom parts and prototypes for clients in a short time. Sometimes, it’s part of a bigger factory that handles these same needs.

Many large companies have an R&D department that works closely with a CNC machine shop to design and test new parts or even create new products. Even though a precision CNC machine shop usually makes small batches, it has strong abilities to make it stand out.

CNC machine shops use advanced machines to create parts with high precision and complex shapes. They work with different materials such as metals, plastics, and special alloys. They focus on specific industries like aerospace or medical. They offer complete services from design and prototyping to testing and production.

To stay competitive, a CNC machine shop must work fast and accurately using the latest technology and skilled operators.

CNC Machine Shops for Various Industries

Many specialized CNC machine shops handle specific components. One shop might make turbofan blades, while another focuses on fuel nozzles. This means different industries work with different manufacturers to get the parts they need.

Here’s how they support different industries:

| Industry | Role | Sample Parts |

| Medical | Create safe, bio-compatible parts and tools | Surgical instruments, dental fixtures, implants, bone screws |

| Aerospace | Produce lightweight, strong, and precise components | Fuselage panels, landing gear, cockpit instruments, satellite parts |

| Automotive | Make high-precision parts for reliable performance | Engine blocks, gears, pistons, brake discs, camshafts |

| Electronics | Deliver parts with micro-level accuracy | Microchips, connectors, circuit boards, enclosures |

| Marine | Manufacture corrosion-resistant and durable parts | Shafts, housings, deck fittings, valve components |

| Energy | Build parts that handle extreme conditions | Drill bits, piping systems, solar frames, valves |

Equipment in a Reputable CNC Machine Shop

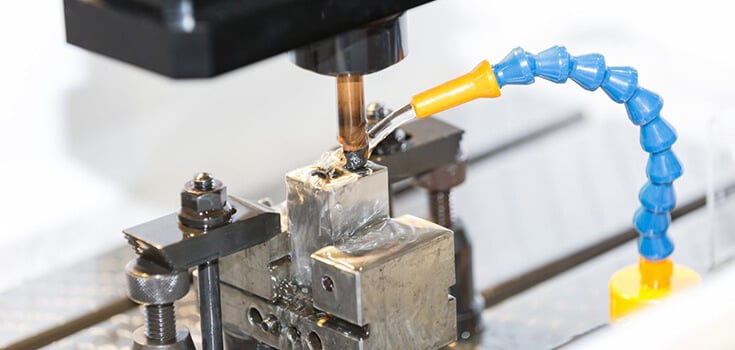

Milling Machine

A milling machine is one of the most common tools you’ll find in any CNC machine shop. It uses a rotating cutting tool to remove material from a workpiece. You can us it to make flat surfaces, grooves, and even threads. Some are called multi-milling machines when they have extra features.

Multi-Axis CNC Machine

Also known as machining centers, these are advanced machines that can cut on multiple axes, usually 3,4, or 5 and some even go up to 7. The more axes a machine has, the more complex the parts it can make.

If you need to produce simple parts, though, this machine may not be the best choice because it takes longer to set up. You usually need to make a 3D model in CAD/CAM software and create a CNC program before machining.

Lathe

A lathe works the opposite way of a milling machine. Instead of the tool rotating, the part spins while the tool moves in a straight line. CNC lathes, also called CNC turning machines, are used for sanding, knurling, and facing. They’re very common in modern CNC machine shops.

Grinding Machine

A grinding machine helps you smooth the surface of a part after machining. It uses a hard grinding wheel to remove all amounts of material for a finer finish. The type of wheel you use depends on how smooth you want the surface to be. Please note that smoother finished usually cost more.

Bandsaw

A bandsaw is used to cut large raw materials, like metal bars or slabs, into smaller pieces before machining. This makes it easier to handle and fit into other machines.

Drill Press

A drill press works like a regular drill but gives you more control and precision. You move the drill using a lever, and you can change the tool to perform other operations.

Micromachining Tools

These special tools help you create very tiny features and fine surface details. Not every CNC shop has them, but they’re useful when you need high-precision or microscopic finishes.

Electrical Discharge Machining (EDM)

EDM uses electric sparks to remove material instead of cutting it. This process is great for very hard materials because it doesn’t put force on the part, which helps avoid deformation.

Surface Finishing Tools

After machining, you may want to improve the look or properties of a part. Surface finishing tools help you do that. They can make parts smoother, shinier, or give them a special texture. Common processes include polishing, anodizing, painting, and sandblasting.

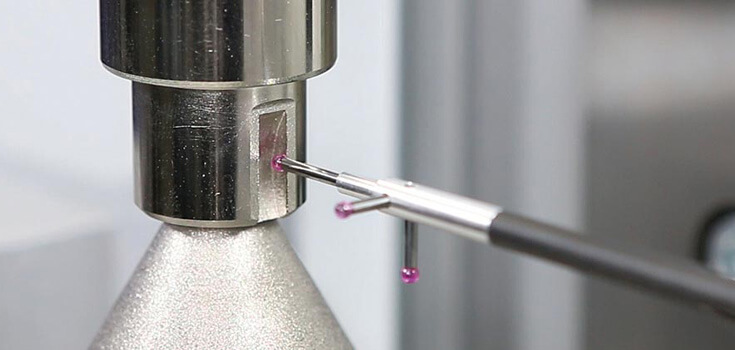

Coordinate Measuring Machine (CMM)

A CMM helps you measure parts very accurately. It checks dimensions and tolerances to make sure the parts meet your design requirements. Every CNC machine shop needs this for quality control.

Vernier Caliper

You use a vernier caliper to measure the inside, outside, and depth of a part. It’s one of the most basic and important measuring tools in a CNC machine shop.

Micrometer and Pin Gauges

For very precise measurements, you’ll use micrometers. They measure things like length, thickness, and depth. Pin gauges are used to check the size of small holes and ensure they meet tight tolerances.

Quality Control and Quality Assurance in a CNC Machine Shop

In a CNC machine shop, checking and verifying parts is important to getting high-quality results. This is what quality control and quality assurance are all about. Here’s how QC and QA are done:

Checking of Raw Materials

When the shop receives the materials for prototyping or production, the QC inspector make sure they are good to use.

Inspect During Machining

The machine operator is the first to see of a part is correct or has problems. The part must be checked while it’s being made or right after it comes off the CNC machine.

Use Process Probing

Many CNC machines can automatically check part dimensions while making them. This helps make sure everything stays within tolerance.

QC Department Inspection

After the operator and the machine checks, the QC department does a final inspection using statistical process control to ensure consistent quality.

Communicate With Your Client

The best way to confirm quality is by making sure you are happy. Clear and regular communication helps.

The Human Factor of a CNC Machine Shop

Technology helps, but human skills make precision possible. Machines can’t deliver quality results without the right input and control. You still need trained operators and engineers who can do the following:

- Fix errors, find ways to improve, and get the most out of the machines.

- Understand CAD/CAM software and other tools.

- Spot problems early and prevent accidents.

- Follow complex instructions and ensure parts meet exact measurements.

- Handle pressure and demanding work conditions.

CNC Machine Shop Main Safety Rules

Wear Personal Protective Equipment (PPE)

PPE includes helmets, google earmuffs, safety shoes, and protective clothing. You should wear the right gear depending on your job and the risks involved. This keeps you safe from cuts, impacts, and other hazards.

Follow Machine Operation Safety

Machines can be dangerous if they are broken, misaligned, or used incorrectly. You need to be trained and understand how each machine works and what can go wrong. The machines themselves should also be checked and maintained regularly. Digital monitoring can help track tool wear and machine health to prevent accidents.

Handle Materials Safely

Sharp or heavy materials can hurt you if handled carelessly. You should follow safe practices for lifting, moving, and storing materials. Using tools like conveyors and forklifts, and getting proper training, will keep you and others safe.

Advantages of Utilizing a CNC Machine Shop

Working with a CNC machine shop can bring many benefits to your business. You don;t need to invest heavily in machines or tooling. You can just send your design to a shop anywhere in the world and get your parts delivered.

High Precision and Consistency

CNC machines make parts very accurately and consistently, no matter how many you need. The computer guides the tools to cut the material exactly as planned.

Keep in mind that precision depends on the shop’s machines. Shops with more advanced machines can produce more complex and precise parts.

Faster Production and Efficiency

Because CNC machines are mostly automatic, they work faster and need less human help. They can even run 24/7 with proper care. This speed reduces production time and lower costs. CNC is usually 3-5 times faster than traditional machines.

Cost Effective Production

CNC machines use optimized tool paths, which means less waste and shorter setup times. Less human work also saves time. This makes CNC ideal for both prototypes and mass production.

Flexibility and Complexity

CNC machines can handle almost any design in a single setup. They can create complex shapes, deep cavities, or detailed surfaces. You can also change designs quickly and cheaply, so it is easy to customize parts and innovate.

Challenges Faced by CNC Machine Shops

- Machines, tools, and inspection systems are expensive, but they help lower part costs over time.

- New systems and software appear quickly, so keeping up requires money and constant learning.

- It’s hard to find trained operators, and CNC machines need regular care and software updates.

- Safety rules need constant training, equipment checks, and maintenance to protect workers and the environment.

How to Choose the Best CNC Machine Shop?

- Check if the shop has the right machines, materials, and surface finishes for your design. Make sure they offer the processes you need, like milling, turning, or drilling.

- Compare detailed quotes from different shops. Choose one that offers good quality at a fair cost, not just the cheapest.

- Make sure they can handle your order size and scale up later if needed.

- Pick a shop that has experience with your type of part or industry.

- Look for quality standards like ISO or FDA approval for industries that require it.

- Protect your designs with a non-disclosure agreement.

- Choose a shop that listens, responds quickly, and understands your needs.

Conclusion

When cost and precision is important, you need to choose a trusted CNC machine shop in China. With advanced machines, skilled workers, and a strong supply chain, you get high quality parts at fair prices. A good CNC machine shop gives you confidence that every part will fit, work, and last.

DEK has over 20 years of experience serving global industries. We offer 3-, 4-, and 5-axis milling, turning. EDM, finishing, and full inspection. We accept prototypes and mass production. Send us your design today and get a free quote.