Aluminum gears are popular due to their good balance of light weight, strength, and smooth performance. You see them in machines where lighter parts enhance operation, such as in vehicles and aircraft. They are also simpler to handle than steel, making the price affordable.

This guide will take you through what aluminum gears are, how they are produced, the various types, and where they are applied. You will also see their advantages and disadvantages, plus tips on selecting the best one.

What are Aluminum Gears?

Aluminum gears are gears constructed from aluminum alloys. They transmit motion and torque from one machine component to another, similar to steel gears, but lighter in weight. Aluminum spur gears, for instance, are widely utilized for smooth and uncomplicated power transfer.

Since they are light, compact, and corrosion-resistant, you can apply them in a wide variety of uses. Whether it is a small device or heavy machinery, aluminum gears provide you with a functional alternative that offers strength as well as efficiency.

How Aluminum Gears Are Made?

These are the steps to make aluminum gears:

Material Selection

Start by picking the right aluminum alloy to use; grades like 6061 and 7075 are selected for balancing durability with good machinability.

Casting or Forging

Gear blanks are formed by either casting aluminum gears, molten aluminum into molds, or forging them under high pressure for added toughness.

Machining

CNC machining cuts accurate gear teeth and complex profiles with high accuracy and repeatability.

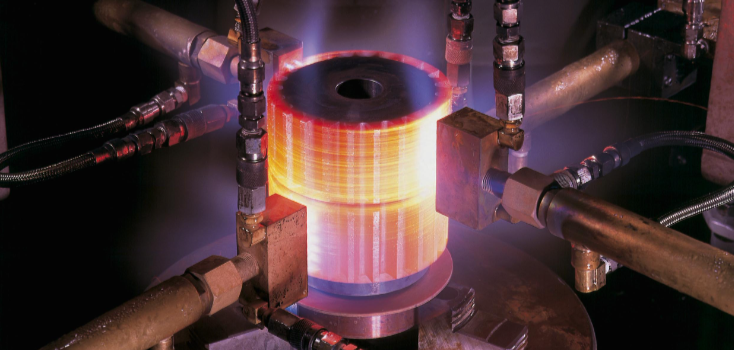

Heat Treatment

Certain alloys need heat treatment, like annealing or hardening, to help boost wear resistance and service life under heavy use.

Surface Finishing

The final step includes polishing, coating, or anodizing for corrosion protection and a finish that looks clean and long-lasting.

Types of Aluminum Gears

Here are the main types of aluminum gears designed for specific jobs:

Spur Gears

These are the most common gears. Aluminum spur gears’ teeth are straight and set parallel to the gear’s axis. They are affordable, efficient, and useful when you need fast and reliable power transfer.

Helical Gears

These gears have teeth cut at an angle. This design runs smoother and quieter, good for noise-sensitive systems.

Bevel Gears

Aluminum bevel gears have teeth shaped like a cone. They can be straight, spiral, or hypoid, used for changing shaft angles.

Worm Gears

Worm gears combine a screw-like worm with a worm wheel. This setup provides you with a strong turning force and large speed reduction in a compact space.

Rack and Pinion Gears

This system uses a round gear (the pinion) that meshes with a flat toothed bar (the rack). It converts rotary motion into straight-line movement.

Properties of Aluminum Gears

High Thermal Conductivity

It transfers heat quickly, helping prevent overheating and reducing wear during operation.

High Strength-To-Weight Ratio

These gears may be light, but it has solid strength. You can use them in aircraft engines, racing car transmissions, drones, and robotics.

Non-Magnetic

They don’t interfere with electronics, making them a safe choice for sensitive equipment.

Ductility

You can easily shape aluminum into complex gear designs without cracking, allowing detailed gear shapes.

Recyclability

At the end of the gears’ life, you can recycle aluminum with little energy, supporting sustainability.

Easy Machinability

Aluminum is simple to cut and machine, giving you precise dimensions and detailed designs with less effort compared to harder metals.

Corrosion Resistance

A natural oxide layer protects aluminum from rust and chemicals, making the gears durable even in harsh environments.

Benefits of Aluminum Gears

Lightweight

Aluminum is much lighter than steel. This makes it a good fit for cars, planes, and machines. When you compare aluminum gears vs steel, you will see that aluminum reduces weight without losing strength.

Corrosion Resistant

These gears can handle exposure to moisture and chemicals without damage

High Thermal Conductivity

Aluminum conducts heat very well, keeping gears cool during intense use. This reduces wear and keeps machines running reliably.

Machinability

You can machine aluminum into precise shapes at a lower cost, getting accurate gears without spending as much time or money.

Aesthetic Appeal

Aluminum gears have a clean, professional look. With finishing options, they can also be made more visually appealing. When comparing brass vs aluminum gears, aluminum is usually preferred if you need both a polished finish and lower weight.

Cost Effectiveness

Aluminum is affordable and easier to process compared to many other metals. You get durable gears at a reasonable price without sacrificing quality.

Disadvantages of Aluminum Gears

Aluminum gears have a few downsides you need to know. They don’t hold up well under constant heavy loads, and their fatigue strength is lower than that of steel. This makes them a less suitable option for high-load applications.

Another limitation is heat transfer; since it carries heat quickly, you should avoid it in systems where heat insulation is important. When you compare aluminum gears vs steel, steel handles tough jobs better, while aluminum fits best for lighter, faster systems.

Applications of Aluminum Gears

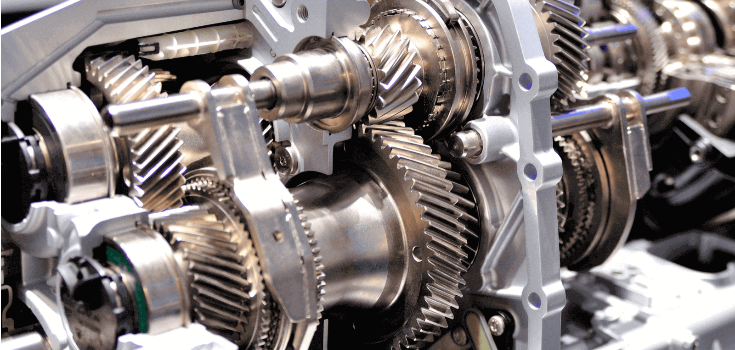

Automotive Industry

These are used in transmissions, accessory drives, and other drivetrain parts for better fuel economy and performance.

Aerospace

Aircraft need parts that are strong but not heavy, making aluminum gears a perfect fit.

Robotics

Aluminum gears are built into robots’ arms, joints, and moving parts to keep motion smooth.

Consumer Electronics

You will see it in printers, cameras, and small appliances.

Industrial Machinery

These gears show up in conveyors, packaging equipment, and automation systems.

Choosing the Right Aluminum Gear

Load Requirements

Think about the force your gear will handle. Load, speed, and torque decide the right size and type of gear for your system.

Manufacturing Process

These gears can be made by casting, forging, or machining. Each method has its own pros and cons, so choose the one that matches your performance needs.

Budget and Cost

Aluminum gears are more affordable, but don’t just focus on the lowest price. Look at long-term value and reliability; this ensures you don’t give up quality for cost.

Material Selection

Choose the right aluminum gear or alloy based on your needs. Check for properties like resistance to corrosion, machinability, or strength before making a decision.

Conclusion

If you need light and dependable gears, aluminum is a strong choice. They work well in designs where fuel savings, speed, or precision are most important. From industrial machines to consumer products, they bring both function and efficiency.

The right choice depends on load, heat, and long-term use. If you match the design to your needs, you get a solid performance without overspending. At DEK, we can help you design, machine, and finish custom aluminum gears to your specifications. Contact us and get a free quote today.