Acrylic is a clear glass-like plastic with high strength, stiffness, and transparency. It is also known as “polymethyl methacrylate (PMMA)” and “plexiglass”. Acrylic is widely used in various industrial applications as an alternative to glass and polycarbonate. It is easy to fabricate and comes with some extraordinary weather-resistant properties compared to other plastics.

This article will discuss the various aspects of acrylic machining, like how to machine acrylic, tool selection, and finishing methods. Some of the difficulties that you may face during acrylic machining are also discussed in this article. The applications of acrylic products are also mentioned below. The material is highly brittle so it will become hard to rely on conventional machining processes. That’s why CNC machining is a suitable way to machine acrylic with extreme precision and accuracy. It is also used for rapid prototyping and to create high-quality acrylic parts for various applications.

DEK machining and manufacturing company is equipped with modern CNC machines for carrying out precise and quick machining operations. If you need acrylic machining services, then DEK should be your first choice. We are mainly concerned about our customer’s satisfaction through our high-quality and economical products.

What is Acrylic Machining?

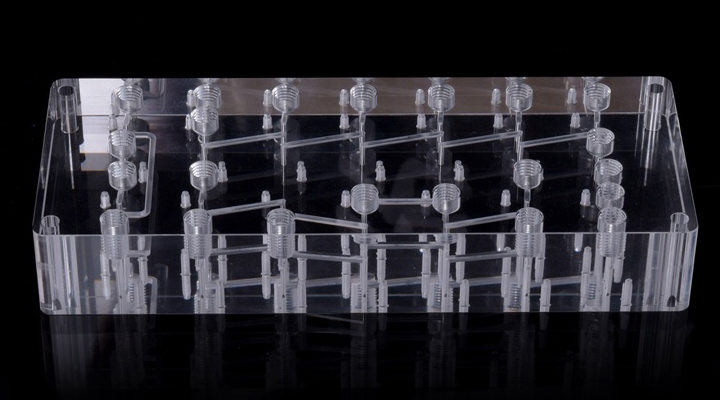

Acrylic material is used to develop various products like prototypes, jewelry, casings, and several other industrial products. CNC machines are used in this process to perform various machining operations like turning, milling, drilling, finishing, etc. Some of the CNC machines used to cut acrylic material are as below:

- Acrylic engraving machine

- Acrylic milling machine

- PMMA etching machine

- Acrylic laser cutting machine

- Acrylic die-cut machine

- Acrylic mini-laser cutting machine

Acrylic material selection for machining:

Acrylic is basically classified into two types cast acrylic and extruded acrylic.

- Cast Acrylic – It is produced by casting the poly resin into a mold. This manufacturing process creates less internal stress and it is suitable to be used as a laser cutting material and CNC machining material.

- Extruded Acrylic – In this method, the polyresin is forced between a set of steel dies to produce large-size sheets.

The material thickness varies from 1.5 – 25 mm for the above-mentioned methods. Extruded acrylic is more brittle as compared to cast acrylics. We only suggest you to choose cast acrylic for CNC machining purposes.

Advantages of choosing Acrylic:

Some of the reasons to choose acrylic for machining purposes are as below:

- Absolute impact on strength, this material is 5 times stronger than glass

- Excellent transparency among all other engineering materials

- Acrylic is durable, sustainable, and UV resistant

- Good electrical and thermal insulator

- Lightweight and easy to machine

- Provide excellent surface finishing.

Tool Selection for Acrylic Machining

While working in a machine shop, selecting an appropriate tool for any machining process is one of the most important tasks in executing CNC machining operations. Tools used to machine acrylic material are completely different from the tools used for metal machining. Specially developed plastic machining tools can also be used for acrylic machining. Avoid using a cutter that has been previously used to machine metals.

Some major tool properties that should be taken into consideration are discussed below.

Tool Geometry

An ideal cutting tool for acrylic machining comes with 5 degrees cutting edge rake angles and 2 degrees clearance angle. A clearance angle is necessary for carrying out a smooth machining process. A lot of cutting tools have only one single flute for chip removal whereas, a cutting tool (endmills) with up to 3 flutes can be used for CNC machining operations.

The main purpose for selecting the ideal tool geometry is to remove the chips without getting stuck or creating any trouble. Some of the properties of fewer flutes and more flutes cutting tools are:

Fewer flutes Cutting tool:

- It can operate at a low feed rate

- Generate less heat during the machining process

- Less rigid due to thin core

- Poor surface finishing with built-up edges (BUE)

More flutes cutting tool:

- It operates at a high feed rate

- It generates more heat during the acrylic machining operation

- More rigid due to thick core

- Good surface finishing as compared to fewer flutes cutting tool.

Using Upcut, Downcut, and Straight flute endmills

- Upcut Endmills:

While carrying out the machining operation with upcut endmills, you will observe that it provides smooth operation. The cutting tool pulls the chips out of the cutting place which reduces the risk of being re-cut. Upcut endmills also assist in maintaining the temperature of the cutting point. It requires rigid clamping and the parts with thin floors are not suitable for this type of cutting tool.

- Downcut Endmills:

It is suitable for some specific applications where the workpiece is not clamped very well. Downcut endmills are the best choice for sheet works.

- Straight flute Endmills:

A straight flute cutting tool is not the best choice for acrylic machining because its impact will dislodge the workpiece from the clamps. High helix tools are recommended for experiencing the best machining operation.

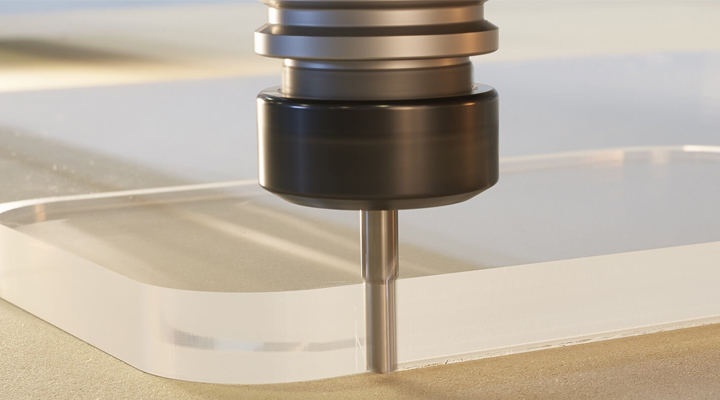

Tool Material and Coatings

A Carbide cutting tool is generally used to machine the acrylic material. For mass production, some manufacturers use diamond-coated cutters for acrylic machining. The material can also be machined by the high-speed steel cutter but it will give a rough surface finishing. Most of the machine shops prefer to use carbide cutters for cutting purposes.

The coating produces a slightly rounded cutting edge, making a cutter less sharp. Therefore, it is suggested to use the uncoated carbide endmills. The acrylic material is soft and it required a sharp cutting tool to reduce the heat effect due to friction.

For improving the tool’s life, the cutting tools are generally coated with polycrystalline diamond or PCD. If you need high work quality then consider polished endmills. So that the chips will glide across the flute face due to its smooth surface finishing. This will provide high surface finishing of the workpiece.

How to Machine Acrylic?

One of the fundamental principles of machining acrylic is to remove the heat via chips as quickly as possible. Acrylic has a low melting point of 320 F, that’s why high temperature will affect its cutting performance and surface quality. To reduce the frictional effect, the material is machined at a higher feed rate.

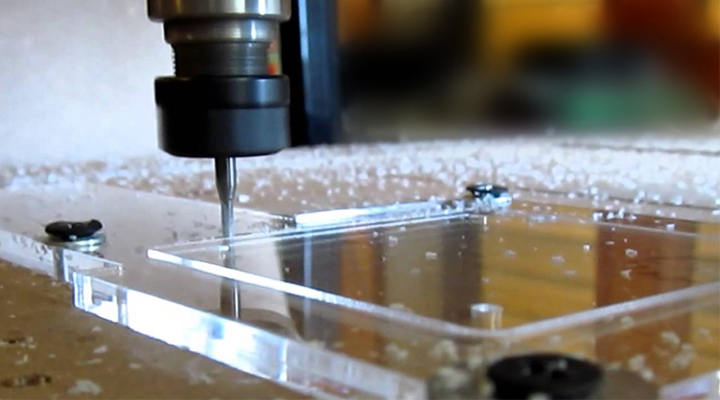

Milling

When performing milling operation, avoid plunging engagements in favor of surface ramping motions. If you don’t have any other option, then use the pecking cycle to reduce the chip’s length. These chips will stick to the tool and melt the acrylic material through friction. It will also block the coolant path to reach your cutting tool.

During milling, some of these factors should be taken into consideration:

- Workpiece should be hold perfectly

- The cutting tool should be sharp

- Continuous coolant supply

- Low rotational speed

- Surface finishing after milling

Turning

In turning operation, a single-point cutting tool moves along the rotating workpiece to remove the unnecessary material. CNC acrylic turning operation is used to perform grooving, facing, boring, and external thread cutting.

The two most common problems should be taken into consideration before performing a turning operation:

- During continuous operation, the temperature for the workpiece will increase gradually. To avoid this problem turning should be performed at a low speed and the workpiece should be cooled periodically.

- The second most common problem is the development of cracks in the workpiece during turning operation. It can be overcome by using a sharp edge cutting tool.

It is really hard to perform turning operations on acrylic material. If you want to perform a turning operation then you should choose the side with the least material. If you are going to perform a facing operation, it will be good if you do a rough cut with a Z feed and then leave the finishing for a light cut in the X.

Feed and Speed

Before machining any material you should be aware of its cutting parameters. In order to, carry out a smooth and comfortable machining operation.

We will suggest you to operate the machine at a low speed with a high feed rate. It offers the best chip control and prevents the material to stick with the cutting tool. Set the machine speed to 15000 – 18000 RPM and the feed rate should be double or triple than the cutting speed. If the federate is too small then the chips will start welding back to the cutting piece and result in poor surface finishing.

Coolant

Due to the low melting point of acrylic material, the temperature should be kept low during the cutting operation. Some of the most commonly used coolants are Oil misters and flood coolants. If you are using polished tools or diamond cutters then air blast cooling should be your choice. If the coolant contains oil then make sure that it will not react with PMMA. Using a high-pressure coolant can be the right choice to remove chips from the cutting place. We suggest you to use a paper filter instead of mesh filters for coolant filtration.

What is the best way to fix an Acrylic part for machining operation?

An appropriate fixing of the workpiece at the machine plays a vital role in achieving the desired product quality. The vibration is produced during the machining process and if the workpiece is not clamped tightly it will ruin the whole process. There are many ways to clamp the workpiece depending upon its size and machining operations.

Small acrylic parts can be fixed by using jigs and vises. If we are machining big parts then they can be fixed by using glue or tape. The manual fixing will take time and increase downtime. To avoid any delay, we suggest you to buy a vacuum hold table.

A perfect clamping will increase the work efficiency and it also helps in maintaining the product quality. DEK uses modern machines for acrylic machining so that the job will be carried out precisely. We are capable to develop custom acrylic parts according to our client’s requirement.

Finishing methods used in Acrylic machining

These are some of the finishing techniques used for finishing the CNC machined acrylic part.

- Polishing – It is the most widely used method to finish acrylic parts. By polishing, you can easily remove the visible marks from the surface of the workpiece. A perfectly polished part gives a glowing appearance.

- Texture finishing – It is also commonly used to finish the CNC machine acrylic parts. Sand spray way is used for texture finishing. We can produce various types of textures by using this technique.

- Flame polishing – This method is also used to produce a clear and shiny surface of acrylic products. But there are some drawbacks of using flame polishing. One of them is, it produces tension in the material which may lead to generating cracks in the workpiece.

Acrylic Engraving

Engraving is another type of CNC machining in which a texture or design is engraved on the surface of the workpiece. Acrylic engraving is performed similar to milling but it uses different cutting tools. With modern technology, you can easily engrave complex acrylic parts with extreme precision and accuracy. It can also be performed by using laser engraving machines. For making the design visible the engraved part can be filled with some paint.

DEK also offers cost-effective and high-quality engraving services to its clients. Products designed and developed by DEK machining and manufacturing company are extensively used by manufacturers around the world.

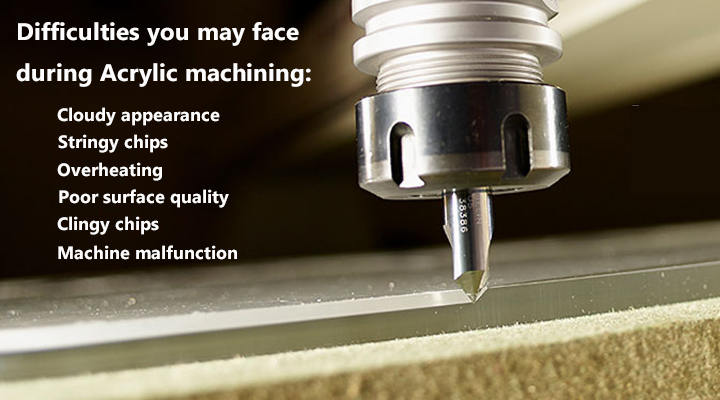

Difficulties you may face during Acrylic machining

These are some of the difficulties that you may face during acrylic machining.

- Cloudy appearance – Before using coolant or any solvent for cleaning purposes, make sure that they will not react with the acrylic material. Some solvents or oil-based coolants may react with the part or make it turn cloudy.

- Stringy chips – The continuous operation will develop some stringy chips. This is a serious safety concern for both operator and the equipment. Try anything you can to avoid these chips.

- Overheating – While machining acrylic parts you strictly need to follow the temperature requirements. Cutting at high speed with a lower feed rate will generate heat which will lead to melting the workpiece. To avoid overheating, try to machine at a slow speed with a higher feed rate.

- Poor surface quality – You may encounter a problem of poor surface quality. To avoid this issue, try to use a sharp edges cutting tool with coolant. It reduces the frictional effect and leads towards excellent surface quality.

- Clingy chips – Some chips cling around the machine tool or at the place of machining. It results in increasing the temperature of the workplace. To avoid chips clinging, use polished cutting tools at low speed and a higher feed rate.

- Machine malfunction – It is necessary to carry out preventive maintenance of the CNC acrylic machines to avoid any trouble or malfunction. Machining under unfavorable environmental and operating conditions will also cause machine malfunction.

Applications of Acrylic products

Acrylic products are widely used in various industries. Some of the typical applications of acrylic products are as below.

- Glass alternative

Due to its excellent transparency, this material is generally used as a glass alternative in various automotive, aerospace, and optical industries. In the automotive industry, PMMA is mainly used to develop headlamps with complex geometry. It is also used to manufacture high-quality eyeglass lenses.

- Medical

Due to its outstanding biocompatibility, it is highly recommended to be used in various medical applications. It is used in cosmetic surgeries as under-skin filler and it can also be used in orthopedic surgeries as bone cement.

- Rapid prototyping

Due to its affordability and sustainability, Acrylic material is also widely used to develop prototypes. Various manufacturing industries are using acrylic for rapid prototyping via the subtractive machining method.

- Consumer products

It is widely used in various consumer products such as electronics, furniture, musical instruments, etc. CDs and DVDs are also made up of acrylic material.

Conclusion

In the above article, we have discussed acrylic machining in detail. We found that cast acrylic is a suitable material for acrylic machining and several CNC machines are used in the machining process. We concluded that acrylic machining is widely used in various manufacturing industries. A cutting tool with more flutes is suitable for machining purposes. An ideal machining operation takes place at low speed and a higher feed rate. To avoid overheating, a polished cutting tool with coolant is used in this process.

Some of the appropriate ways to fix acrylic parts in machines are also discussed in this article. We mentioned some suitable techniques for finishing the acrylic material such as polishing, texture finishing, and flame polishing. Most commonly encountered problems with their solutions are also discussed in detail. In the end, some of the applications of CNC acrylic machining are also mentioned. Now you have enough knowledge about acrylic machining. After reading this article, you can easily set up an ideal operating condition for machining acrylic products.

If you need economical and high-quality CNC acrylic machining services then DEK should be your first choice. We will also provide services in developing custom parts according to our client’s requirements. Our products are highly recommended by our clients around the globe. Place your order today at DEK machining and manufacturing company and receive your product at your doorstep. If you need any technical support, feel free to contact our engineers.