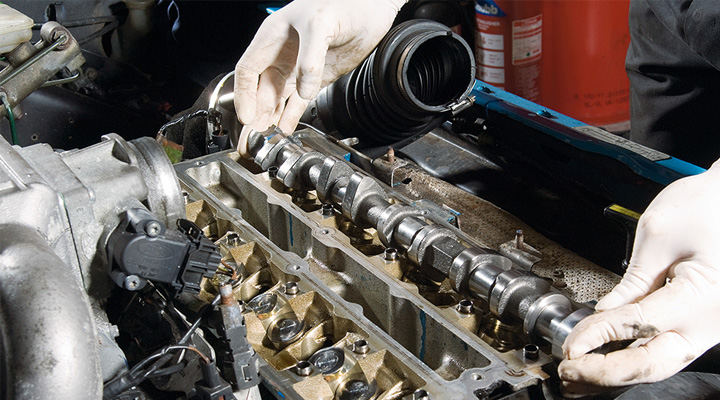

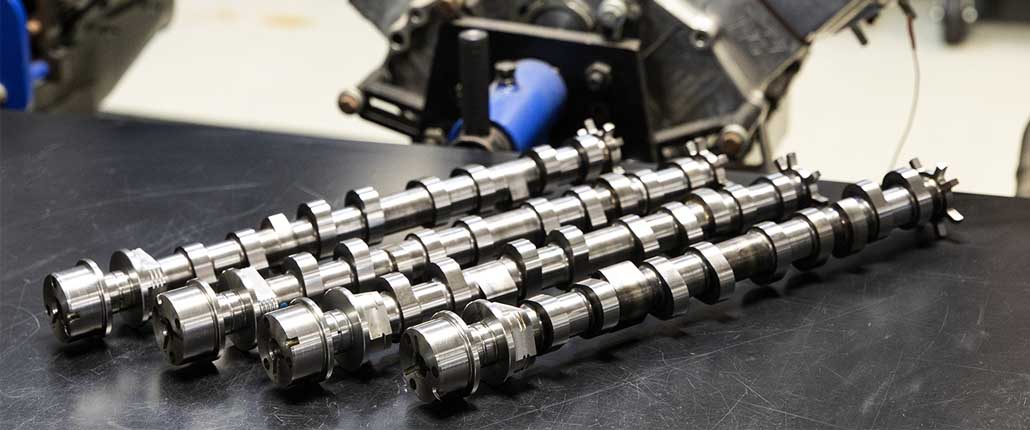

For a combustion engine to operate smoothly, the camshaft is one of the critical components. The camshaft and the crankshaft have to work synchronized to provide the proper mechanical control of ignition systems. Due to its vital role, machining a camshaft is always a tight-tolerance job.

But, do you know what precisely a camshaft is? And what does a camshaft do? Are there different types of camshafts?

We’ve composed a quick guide to a camshaft to give you all the answers you need. Let’s get started.

What Is a Camshaft?

The camshaft of a combustion engine is the part of the valve train that regulates fuel input and the output or exhaust of fumes. A camshaft is typically located at the top of the engine (above the cylinder). The camshaft is connected to the crankshaft with a belt and chain.

One of the most basic and main functions of a camshaft is to power the closing and opening of the intake/exhaust valves.

A camshaft is made of different types of metal, and it has the shape of a cylindrical shaft or a rod with egg-like cams which rotate to produce power. To a large extent, camshafts influence your engine’s performance when you speed up.

What Is the Function of a Camshaft?

The camshaft as a component is used in internal combustion engines. The camshaft’s primary function is to open and close the engine valves with the help of its many cams (egg-shaped lobes).

A camshaft has several applications and uses – in internal combustion engines, mechanically controlled ignition systems, and as early motor speed controllers.

Furthermore, camshafts are composed of four different parts – the cam lobes, the main journals, the ends, and the cam bearings. Each of these parts is vital to manufacturing a camshaft with tremendous peak torque.

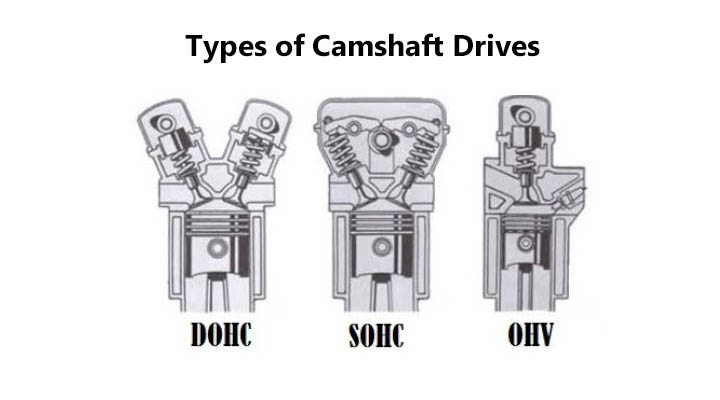

Types of Camshaft Drives

Generally speaking, there are three types of camshaft drives: the single overhead camshaft (SOHC), the double overhead camshaft (DOHC), and the Pushrod or overhead valve (OHV). Let’s look at each of them.

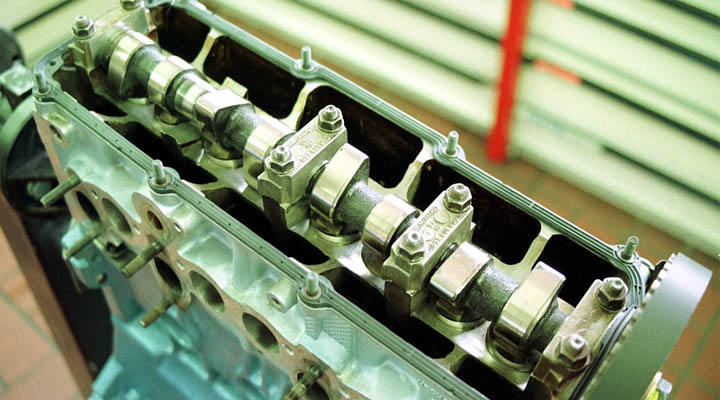

Single overhead camshaft (SOHC)

The single overhead camshaft engine has one camshaft per head (bank of cylinders). That’s the oldest design of overhead camshaft engines. The majority of SOHC engines will have two valves for each cylinder.

The crankshaft is the part that powers the SOHC through the connected timing chain. This chain or belt needs to be aligned and looked at regularly. A damaged or misaligned timing belt could break and cause serious problems.

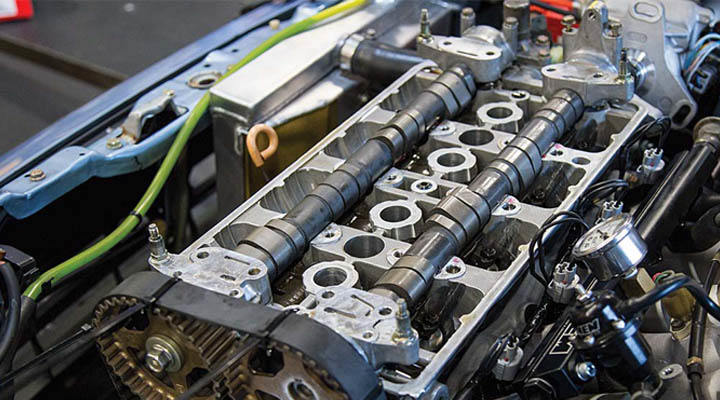

Double overhead camshaft (DOHC)

As the name itself suggests, DOHC engines have two camshafts per bank. Dual overhead camshafts are also known as twin-cam engines. Engines that have over four valves per cylinder typically use double overhead camshafts.

Using a double instead of a single overhead shaft will allow greater engine power. The logic behind this is simple – with DOHC, you can use more intake and exhaust valves, which means there will be larger openings for gas flow. At the start of the 2000s, the majority of cars were already using DOHC engines.

Overhead valve (OHV) camshafts

OHV engine camshafts are also known as Pushrod engines. Like the DOHC and SOHC, the OHV engine also has valves above the cylinder, in the engine’s head. But, as opposed to DOHC and SOHC, where the camshaft is in the head, the OHV engine has a camshaft inside the engine block.

In Pushrod engines, the camshaft is driven via a gear drive chain. With these gear drives, Pushrod engines are less prone to breakage. However, they have a limited speed potential.

How Does a Camshaft Work in an Engine?

A camshaft is located at the top end of the engine, above the engine cylinder. Typically, the camshaft is connected to the crankshaft at the bottom with the help of a timing belt. To control the combustion properly, the manufacturer needs to synchronize the camshaft and crankshaft gears. This procedure is called valve timing.

Triggered by the crankshaft, the cylindrical camshaft starts spinning, and the cam lobes throughout the length of it start pressing on the levers, which open the engine valves.

What Spins Faster – the Camshaft or the Crankshaft?

To explain the camshaft and crankshaft speed and how they work together, we have to start by explaining the combustion cycle. A typical cycle has four points: intake, compression, power, and exhaust. To get this four-stage combustion cycle going, the camshaft and the crankshaft, connected with a timing chain, start working together.

During one combustion cycle, the crankshaft makes two full circles while the camshaft makes one. That means that the crankshaft spins faster – with double the speed. When compared to the piston, each valve opens once for each two crankshaft turns.

What Material Is a Camshaft Made Of?

Due to the need for stability, durability, and temperature resistance, camshafts are typically made of certain types of metal. Most commonly, manufacturers use two types of materials to produce camshafts – cast iron and forged steel.

Cast iron

As one of the most common camshaft manufacturing materials, cast iron is typically the first choice for high-volume orders.

Cast iron is typically used for camshafts due to its durability and resistance to wear and tear. Cast iron camshafts are manufactured with a chilling process that gives them the necessary hardness. Usually, manufacturers mix other elements before casting the iron. Doing that gives them the required features based on the camshaft’s application.

Forged steel

Otherwise known as billet steel, forged steel camshafts can have higher quality but are usually more suitable for low volume manufacturing. However, due to their superior quality, forged steel camshafts are often more ideal for specific applications.

To produce forged steel camshafts, manufacturers use forging or machining with a milling machine. Typically, manufacturers use different material steel bars to produce camshafts. When they use steel such as the EN40b, the camshaft also has to go through heat treatment.

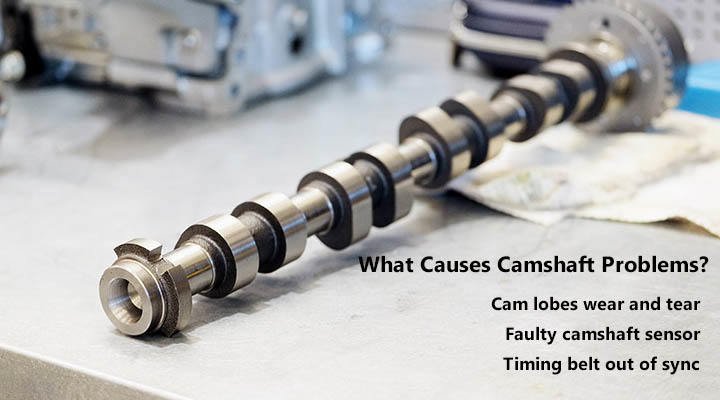

What Causes Camshaft Problems?

As an integral engine component, a camshaft always has to be in top-notch form. Yes, of course, you can use an engine with a damaged camshaft, but doing this can result in a more significant problem. There are several common camshaft problems:

Cam lobes wear and tear

One of the most common issues that require camshaft repair or replacement is the cam lobes’ wear. As moving components, cam lobes will frequently get in touch with debris, dirt, and improper oiling. So, in time, they can get damaged and need a replacement.

Faulty camshaft sensor

The second cause of camshaft problems is a faulty camshaft sensor. The job of the camshaft sensor is to monitor the synchronization of the camshaft and crankshaft turning. Based on this sensor’s reports, we control the ignition and fuel injection systems. Needless to say, if this sensor is faulty, the vehicle can experience different performance or ignition problems.

Timing belt out of sync

And finally, the third and most serious cause of camshaft problems is an out-of-balance camshaft and crankshaft movement, usually caused by a faulty timing belt.

A timing belt that’s damaged or out of sync can be detrimental to the camshaft and the entire engine. For instance, it can cause damaged pistons, valves, lobes, rocker arms, or even break your whole camshaft.

What to Replace When Changing a Camshaft?

If you need to change your engine camshaft, there are several other parts you might want to replace while you’re at it.

For instance, check and replace if necessary the following components: valve springs, valve seals, timing chain or gears, distributor gasket, manifold gasket, harmonic balancer, cam bolts, carb gasket, water pump gasket, T-stat gasket, fuel pump gasket, the engine crankshaft bolt, oil pan gasket, roll pins, etc.

Aside from the above components, we recommend that you do an oil changing and a complete engine service checkup.

How Much Does a Camshaft Cost?

A camshaft replacement is a financially challenging service. Of course, a camshaft replacement or repair cost will depend on the type of camshaft and the damage caused.

For example, if you’re replacing only the camshaft sensor, it might cost you anywhere from $150 to $250. However, if you’re replacing the entire camshaft, labor costs plus materials could cost you anywhere from $1500 to $3000.

Camshafts are built to last as long as the engine lasts, so they typically shouldn’t cause any short-term problems. However, if you notice signs of camshaft damage such as trouble accelerating, “check engine” lights blinking, or a reduced gas mileage – a camshaft replacement is in order.

Can You Offer Customized Camshafts?

Yes! In the past, camshaft manufacturing processes were not as advanced, so high-quality manufacturing was reserved only for low volume, expensive orders. Nowadays, our high-tech, cutting-edge machining, and milling technologies allow us to offer customized camshafts with no MOQs.

If you need a particular type of camshafts, don’t hesitate to reach out. Our quality, on-demand CNC machining services make it possible to offer a dedicated manufacturing team and produce customized camshafts at any quantity.

Conclusion

All in all, we sincerely hope that our guide to camshafts and their function was practical and answered all the questions you had on the topic. Knowing that the camshaft is such an integral part of internal combustion engines, the importance of its precise manufacturing and durability becomes evident.

If you need help designing your customized camshaft, get in touch, and we’ll create your camshaft prototype. Regardless of the type of camshaft in question, the principle stays the same – quality and safety first! Hopefully, this comprehensive guide to a camshaft and its function helped you learn a lot.