Metal CNC Machining

DEK offers a diverse range of metals for CNC machining, with applications in a variety of industries. Our tight tolerances can reach ±0.005mm, and we have extensive experience with difficult-to-machine materials such as titanium, Inconel, and Kovar. Whether for one-off prototypes or end-use custom parts, DEK is the ideal choice.

introduction

Precision CNC Machining Metal Services

In the mechanical manufacturing industry, metal machining is considered the most widely used technology for machining parts. CNC metal machining offers high precision, stable quality, and greater efficiency.

At DEK, with our advanced machining equipment and experienced operators, we are dedicated to manufacturing precision CNC metal parts. Our core capabilities include milling, turning, drilling, and EDM machining. Whether you require simple custom parts or those with complex geometries featuring thin walls, intricate surfaces, or micro-features, we can machine them perfectly.

Furthermore, we offer high-value-added options such as heat treatment, anodizing, and chrome plating to enhance part performance and appearance. Whether you need prototyping or small-batch custom machining, we are committed to providing the most suitable solution.

- Extensive Selection of Materials

- Fast Delivery, No MOQ.

- 24/7 Engineering Support

- 3-axis, 4-axis, 5-axis, or multi-axis Machining

- Material Certifications, FAI Reports, CMM Reports

Machining Capabilities

CNC Machining Capabilities

DEK combines extensive industry experience with advanced manufacturing processes to produce high-quality CNC metal parts and precision machined components.

CNC Turning Service

We provide CNC turning up to Ø300mm in metals and plastics, with optional threading, milling, and surface finishing.

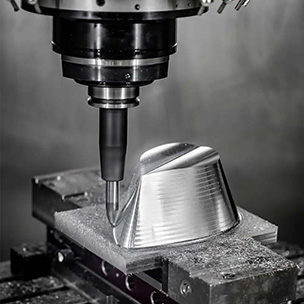

CNC Milling Service

We provide CNC milling with tight tolerances for complex 2D and 3D parts, available in metals and plastics with post-processing options.

CNC Machining Service

DEK offers high-quality, tight-tolerance on-demand CNC machining services using various materials for rapid prototyping and production part.

3 Axis CNC Machining

We offer 3-axis milling for simple to moderately complex parts, ideal for flat surfaces, pockets, and basic contours.

Swiss CNC Turning

Elevate your projects with Swiss CNC Turning Services for precision cylindrical parts. Our cutting-edge technology and skilled artisans guarantee flawless results.

EDM Machining

We offer Wire and Sinker EDM for machining hard metals and fine details, with accuracy up to ±0.001mm and sharp internal corners.

5 Axis CNC Machining

We offer 5-axis CNC milling for intricate geometries and multi-face machining in a single setup, perfect for aerospace and medical parts.

CNC Machining Materials

Metals

Metals

Aluminum

Aluminum is widely used in CNC machining due to its low density, excellent strength-to-weight ratio, high corrosion resistance, and high electrical and thermal conductivity.

At DEK, we offer comprehensive aluminum CNC machining services, including 6061, 7075, and 2024. Our precision manufacturing services ensure high-quality parts for industries such as aerospace, automotive, and medical, including aerospace components, automotive parts, medical devices, and electronic device housings.

Alloy

AL6061, AL7075, AL6063, AL5083, AL5052, etc.

Alloy Steel

Alloy steel is a material that alters the properties of steel by adding alloying elements such as chromium, nickel, and molybdenum. It offers high fatigue strength, toughness, wear resistance, excellent machinability, and impact resistance.

DEK offers comprehensive alloy steel processing services, including 4130, 4140, and 4340. We provide high-quality parts for industries such as construction, consumer goods, and automotive, including steel brackets, automotive parts, consumer goods, and heavy-duty equipment.

Alloy

Alloy Steel 1215, 4130, 4140, 4340, 8620, A514, etc.

Brass

Brass is primarily an alloy of copper and zinc that offers corrosion resistance, good electrical conductivity and machinability.

At DEK, we specialize in the machining of all types of brass, including 260 and C360, and our high-precision service ensures high-quality parts for industries such as industrial and electronics, and is ideal for fittings, bearings, connectors, radiators and more.

Alloy

Brass 260, C360, Cz121, etc

Bronze

Bronze is a copper-tin alloy with excellent corrosion resistance, electrical conductivity, and mechanical properties. The addition of lead alloy gives it excellent machinability.

At DEK, we specialize in bronze machining services, including 544 and 841 grades. Our outstanding services provide high-quality components for industries such as marine, construction, and aerospace, including bearings, roller,marine fittings, architectural hardware, switch components, and landing gear components.

Alloy

Bronze 544, 841, 932, 954, etc.

Cast Iron

Cast iron is an iron-carbon alloy that often contains 2% to 4% carbon and small amounts of silicon, manganese, phosphorus and sulfur, and has good mechanical properties that make it easy to machine and cast.

At DEK, our high-precision service ensures high-quality parts for industries such as engineering and construction, ideal for engine blocks, brackets, roller, and more.

Copper

Copper is a common metal material in life and is also widely used in CNC machining, featuring a distinctive orange-red appearance, excellent thermal conductivity, high ductility and corrosion resistance.

DEK provides high-quality copper CNC machining services, including 101 and 110 copper. Our top-notch services ensure high-quality parts for industries such as electrical engineering and automotive, including connectors, sensor components, heat exchangers, heat sinks, and radiators.

Alloy

Copper C101, C110, etc.

Magnesium

Magnesium is a light metal material with low specific gravity. It is widely used in CNC machining for its high strength, mechanical properties, corrosion resistance and excellent thermal and electrical conductivity.

At DEK, we specialize in machining all types of magnesium, and our precision services ensure high-quality parts for industries such as automotive and aerospace, ideally suited for engine housings, turbine blades, braking systems, radiators, and battery brackets.

Alloy

MgAZ318, MgAZ61B, MgAZ91D, etc.

Inconel

Inconel is a high-performance alloy made primarily from nickel, chromium and iron, with small amounts of molybdenum and niobium. It has excellent corrosion resistance, oxidation resistance and high temperature resistance.

At DEK, our high-precision service ensures high-quality parts for industries such as Oil & Gas and aerospace, ideal for underground drilling tools, gas turbine blades, and turbine disks.

Alloy

Inconel 718, 625, 600, etc.

Invar

Composed primarily of iron and nickel, Inva alloys are highly hard, corrosion-resistant, machinable and castable, making them ideally suited to applications requiring high dimensional stability.

At DEK, our high-precision service ensures the supply of high-quality parts for industries such as aerospace, ideal for making engine valves and molds for large aerostructures.

Alloy

Invar 36, etc

Mild Steel

Mild steel is a type of steel with a low carbon content (0.05% to 0.25%) that offers high toughness, high ductility, good plasticity and easy machinability.

At DEK, we specialize in machining all types of mild steel, including 1018 and 1045, and our high-precision service ensures high-quality parts for industries such as construction and automotive, ideally suited for structural steel plates, body support rods, bearings, and more.

Alloy

Mild Steel 1018, 1045, A36, 1215, etc.

Stainless Steel

Stainless steel is an ideal material for CNC machining projects due to its excellent machinability, good weldability, high ductility, corrosion resistance, and formability.

DEK provides stainless steel machining services in a variety of grades, including 304, 316, and 410 stainless steel. Our high-quality services ensure high-precision parts for industries such as construction, manufacturing, and medical, including precision gears, tractor components, medical instruments, and drive shafts.

Alloy

Stainless Steel 301, 303, 304, 304L, 316, 316L,17-4 PH, etc.

Titanium

Titanium is a widely used material for CNC machining and is popular for its light weight and high strength, excellent corrosion resistance, good biocompatibility, and strong fatigue resistance.

At DEK, we specialize in machining all types of titanium, including Grade 2 and Grade 5. Our high-precision service ensures high-quality parts for industries such as aerospace and shipbuilding, ideal for engine housings, turbine disks, hull structures and more.

Alloy

Titanium Grade 1, Grade 2, Grade 5, etc.

Tool Steel

Tool steel is a specialty steel used in CNC Machining to make tools and dies. With high hardness, good toughness, wear resistance and corrosion resistance.

At DEK, we specialize in machining all types of tool steels including A2, A3 and D2.Our high precision service ensures high quality parts for industries such as manufacturing, automotive and aerospace, perfect for stamping dies, engine parts, turbine blades and more.

Alloy

Tool Steel A2, A3, D2, S7, etc.

Tungsten Steel

Tungsten steel has extremely high hardness and density. It has good resistance to high temperatures, wear and corrosion.

At DEK, we specialize in machining all types of tungsten steel, and our precision services ensure high-quality parts for industries such as industrial manufacturing and aerospace, perfect for jet engine nozzles, aircraft fuselages, grinding wheels, and more.

Alloy

Tungsten Steel YG6, YG8, YG15, YL50, etc.

Surface Finishes

Anodizing

Anodizing is an electrochemical process that enhances metals' corrosion resistance, durability, and appearance, particularly aluminum.

Black Oxide

Get functional and aesthetic benefits in one with Black Oxide surface finishing. It's a matte black finish that also adds protection to metals, reducing corrosion and wear over time.

Bead Blasting

We can effectively remove rust, paint, scale, and other contaminants from various surfaces using bead blasting. Get a uniform and matte finish on surfaces to enhance the aesthetic appeal of […]

Polishing

We enhance the visual appeal of components by providing a smooth and reflective finish with our polishing services. Polished surfaces can also serve as excellent bases for coatings, providing better […]

Electropolishing

Electropolishing enhances the corrosion resistance of metal by removing impurities and creating a clean, passive surface.

Heat Treatment

Improve the physical and mechanical properties of materials through heat treatment. Improve hardness, increase strength, enhance toughness, stress relief, and more.

Passivation

We form a thin, inert layer on the material's surface that protects it from environmental factors that could lead to corrosion. Passivation is commonly used in metals like stainless steel […]

Laser Marking

We provide high precision and accuracy, enabling intricate designs, fine details, and small text to be marked clearly on a wide range of materials, including metals, plastics, glass, ceramics, and […]

Electroless Nickel Plating

DEK offers electroless nickel plating’s adjustable hardness levels, can be engineered to be non-magnetic, adheres tightly to substrates, and the thickness is precisely controllable.

Nickel Plating

A uniform thickness and smooth finish contribute to an aesthetically pleasing appearance and consistent protective qualities. We ensure our process results in materials that can withstand friction and abrasion for […]

Zinc Plating

The compatibility of zinc plating with various materials adds to its appeal, while its ease of application and established use make it a readily available option.

DLC Coating

The low friction coefficient of DLC coatings reduces resistance between surfaces, providing durability to components like tools and mechanical parts.

PVD Coating

We offer a wide range of decorative finishes with PVD coating, including various colors and aesthetic effects. This process can also make materials more resistant to wear, abrasion, and scratching.

Powder Coating

Get a resilient finish that is resistant to chipping, scratching, and fading. Powder coating is your low-cost, eco-friendly finish that has long-term benefits, including reduced maintenance and enhanced longevity

CNC Machining Metal

| Name | Description | Price |

| Aluminum | High machinability and ductility, good strength-to-weight ratio. | $ |

| Stainless Steel | High tensile strength, corrosion and temperature resistant. | $ $ $ $ |

| Mild steel | High machinability and weldability, high stiffness. | $ $ |

| Brass | Low friction, excellent electrical conductivity, golden appearance. | $ $ |

| Copper | Excellent thermal and electrical conductivity | $ $ |

| Alloy steel | High strength and toughness, fatigue resistant. | $ $ $ |

| Tool steel | High hardness and stiffness, abrasion resistant. | $ $ $ |

| Titanium | Excellent strength to weight ratio, used in aerospace, automotive and medical industries. | $ $ $ $ $ |

| Inconel | High-strength and corrosion-resistant nickel alloy. | $ |

| Invar 36 | Nickel alloy with a very low coefficient of thermal expansion. | $ $ $ $ |

| Magnesium | Lightweight, high strength-to-weight ratio,good thermal conductivity, and biocompatibility | $$$ |

| Molybdenum | High strength, durability, excellent heat, and corrosion resistance | $$ |

Instant & Accurate Quotes

We don't use online automated quotation tools, because it is very inaccurate. Online quote platforms rely solely on calculations based on cutting amounts and fixed coefficients, they fail to account for actual processing nuances, such as material deformation after heat treatment, tight tolerance requirements, grinding after heat treatment, etc. Consequently, automated price calculations can lead to inaccuracies, ultimately increasing your costs.

But you can rest assured at DEK!

Our quotations are both cost-effective and accurate because we have a team of professional mechanical engineers who meticulously review each drawing. These engineers boast over 10 years of experience and possess deep expertise in programming, machine operation, post-processing, material properties, and more. Ensure you will get accurate quotes within 6 hours.

PRODUCTION CAPACITY

Production Capacity Guarantee

With perfect production and quality process, you can place your order with confidence.

Advanced CNC Machine Shop

Quality Control

Custom Packaging

Global Shipping

Our Advantages

2300+ Engineers Love Work With Us

Cost Saving

DEK employs professionals to produce parts using state-of-the-art CNC equipment, which increases productivity and reduces production costs accordingly. By purchasing raw materials in large quantities, DEK can effectively reduce your purchasing costs.

Fast Turnaround

Using state-of-the-art equipment and skilled operators, we are able to program operations proficiently and adjust production plans according to demand to meet customer requirements for fast delivery and quality assurance, enabling DEK to produce high-precision, accurate parts within a few days.

Scalable Volume

From 1 to 100k+, no matter prototype production, low volume cnc machining, or high volume cnc machining, our CNC machining metal services can support you to achieve.

First-class Professional Team

DEK's engineers have over 10 years of experience in CNC machining. From simple to complex production drawings, our engineers will provide DFM feedback and offer a variety of solutions based on your needs.

Diverse Material Selection

DEK can process more than 20 production-grade materials for your project. Metal materials include aluminum alloys, titanium alloys, stainless steel, brass, copper, bronze low-carbon steel, invar, inconel, kovar, and more.

Custom Surface Finishes

DEK offers a variety of surface treatment solutions to meet the specific application requirements of different projects. We have advanced aluminum anodizing, bead blasting, polishing, electroplating, passivation, DLC coating, QPQ Coating, PVD Coating, and black oxided, which can enhance the functionality and aesthetics of cnc machined parts.

Global Logistics

DEK has established a long-term good relationship with UPS, FedEX, DHL and other courier companies, which can provide global transportation services for your project, guaranteeing the timely delivery of goods, and delivering the goods to you within 3 days at the earliest.

Our Ordering Process

Send RFQ

Send RFQ with 2D/3D drawings and detailed requirements via Email or online form.

Review & Quote

Our Engineer team will review every drawing carefully and provide an accurate quote within 6 hours.

Confirm Order

Confirm the quote, details and delivery schedule, then sign the contract.

Production

Arrange production process, start programming and machining.

Quality Control

Strict quality control during production and final inspection.

Packaging & Shipping

Pack the parts, attach part identification labels, and start shipping.

Send RFQ 222

Review & Quote

Confirm Order

Production

QC

Delivery

FAQ

CNC Machining Metal Buying FAQs

Get An Accurate Quote For Your Next Projects

No matter your project is complicated or simple, no matter is metal or plastic, you will get an accurate quotation within 6 hours.

Get A Quote Today