CNC machining brass is a great option when you need high-quality, precise parts. Brass is easy to cut, gives a smooth finish, and doesn’t damage your tools quickly. That makes it a favorite material for machining.

In this guide, you’ll learn what CNC machining brass is, its advantages, the properties and types of brass, and a lot more. If you want to save time and get clean results, this guide will help you get there.

What is CNC Machining Brass?

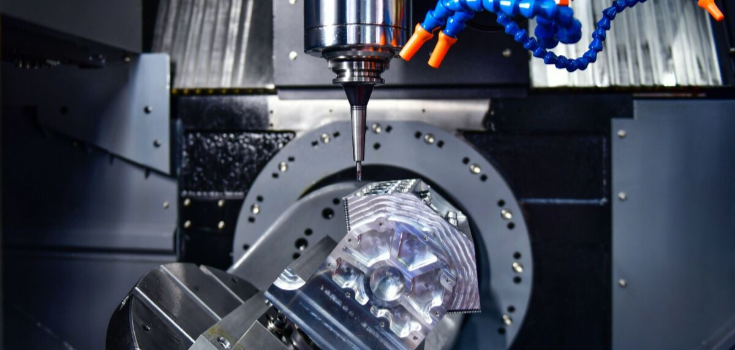

CNC machining brass means using computer-controlled machines to cut, shape, and form brass parts. These machines are very accurate and can make detailed and complex parts with ease.

Brass is composed of copper and zinc. It’s popularly used in machining because it’s easy to work with, resists rust, and conducts electricity well.

Advantages of CNC Machining Brass Parts

There are many benefits of CNC machining brass, and some of these are the following:

High Precision & Accuracy

You program the machine with G-code, and it follows the code exactly. Your parts come out the same every time.

Easy to Machine

Brass cuts smoothly. You can make complex shapes faster, your tools last longer, and you spend less on production.

Cost-Effective

Brass CNC machining delivers high-quality parts without a high price tag. You save money on materials and machine time.

Rust Resistance

Brass stands up to moisture and water without corroding. Your parts stay strong and last longer in a damp or wet environment.

Versatility

You can tweak the combination of copper and zinc to get different strengths, colors, or other traits. That means you can customize brass to your exact needs.

Good Conductivity

Brass moves heat and electricity well. If you need electrical connectors or heat-dissipating parts, use brass.

Fast Production

CNC machines work quickly and run unattended. You get your parts sooner and can meet deadlines.

Nice Appearance

Brass has a warm, golden shine that looks great on visible parts. Your components can be both functional and attractive.

What Properties of Brass Make It Ideal for CNC Machining?

Brass has several properties that make it a great choice for CNC machining, and here are some of them:

| Property | Brass |

| Melting Point | 885 to 890 °C |

| Density | 8.5 g/cm³ |

| Modulus of Elasticity | 97 GPa |

| Thermal Conductivity | 115 W/m·K |

| Electrical Resistivity | 6.3 × 10⁻⁸ Ω·m |

Thermal Conductivity

Brass contains copper, which is a good conductor. That’s why it is a good choice for electrical or heat-related applications.

You can also use EDM as part of the CNC machining process, as it works well with brass and helps you cut parts faster and more accurately.

Highly Machinable

Brass is one of the easiest metals to machine. The lead in its alloy makes it more flexible and easier to cut.

Because it’s so machinable, you can get good results even if you’re still learning. That’s a big reason why many machinists choose brass for CNC projects.

Strength and Hardness

Even though brass is easy to machine, it’s still strong and durable. It might not be as strong as steel, but it holds up well and is tough enough for many jobs.

Some brass types include aluminum, which adds strength by forming a hard layer on the surface. You will need to use special tools like carbide cutters when machining this stronger type of brass.

Malleability

Brass is easy to shape; that’s why it’s perfect for CNC machining. You can bend or form it into different shapes without cracking it.

Brass gets this quality mainly from the copper in it. The more copper a brass alloy has, the easier it is to shape. That’s why you’ll find brass useful when making custom parts with complex designs.

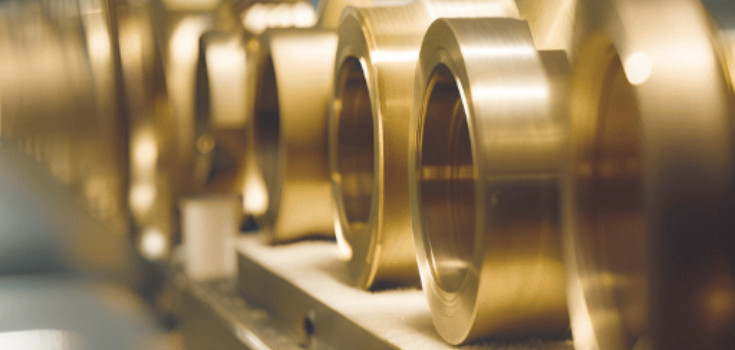

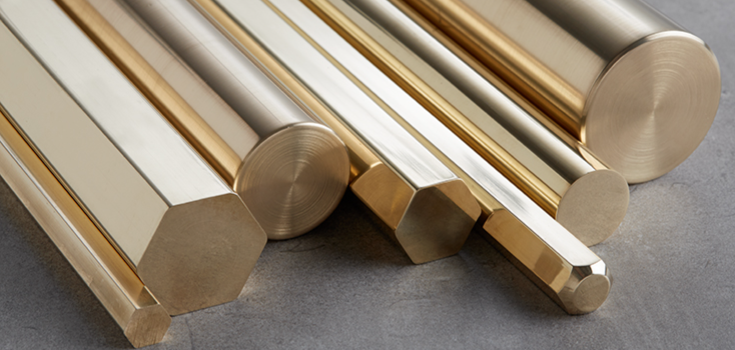

Common Types of Brass Alloys Used in CNC Machining

Below are the most commonly used types of brass alloys, as well as their advantages and disadvantages.

Brass C230

C230 is called the red brass because of its reddish color. It’s made of about 85% copper and 15% zinc. It’s softer than other types but still strong.

You’ll like using C230 if you need something that resists water and doesn’t rust easily. That’s why it’s often used in plumbing, roofing, jewelry, and decorations.

Pros:

- Doesn’t rust or corrode easily

- Easy to bend, shape, and join (soldering or brazing)

- Nice color for decorative parts

Cons:

- Not as easy to machine as C360

- Softer so it can get scratched or dented

Brass C260

C260 has a nice yellow color and is easy to shape, bend, and weld. It’s called cartridge brass because it’s often used to make ammunition shells.

This brass is great for hardware, plumbing, electrical parts, architectural work, and consumer products.

Pros

- Very ductile

- Resists corrosion well

- Easy to form and work with

Cons

- Doesn’t react well to acids like acetic, hydrochloric, or nitric

- Not good around ammonia or ammonia-based compounds

Brass C360

C360 is the most popular brass for CNC machining. It’s also called free-cutting or free-machining brass because it has about 3% lead, which makes it really easy to machine.

You’ll find it great for parts like screws, valves, fittings, fasteners, and joints, especially if you need to solder or braze them. It also holds up well under pressure and doesn’t crack easily.

Pros:

- Resists corrosion well

- High tensile strength

- Easy to shape and machine

Cons:

- Doesn’t hold up against acid

- The lead in it is not good for medical use

Surface Finishing Options for CNC-Machined Brass

Here are some of the common finishes you can choose for your machined brass parts:

Polishing: For a Shiny, Mirror-Like Look

Polishing is a great choice when you want your brass part to look really shiny, like a mirror. It’s perfect for parts that people will see, like musical instruments or decorative pieces. Aside from making your part look better, it also helps in protecting it from rust.

Brushing: For a Soft, Textured Look

Brushing gives your brass part a soft, even texture instead of a shiny look. It’s a good option when you want the part to look more subtle and less flashy. People often choose brushing for architectural designs where a clean, simple style is best.

Plating: For Stronger Protection and a New Look

Plating covers your brass part with another metal, like gold, silver, nickel, or chrome. It makes the part stronger and better at resisting rust and damage. Plating also changes how your part looks, depending on the metal you use.

Applications of CNC Brass Components

Many industries use CNC brass parts, such as the following:

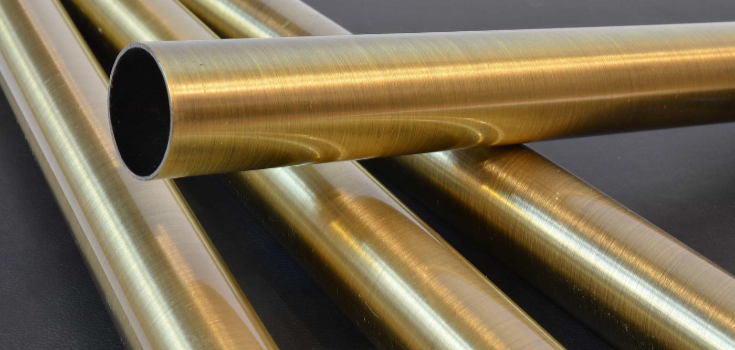

Plumbing and Heating

You use brass to make parts like valves, fittings, and fixtures because it resists rust and transfers heat well. Brass parts are strong and can handle tough conditions, so they are perfect for these jobs.

Automotive

In the automotive industry, you use brass for things like radiator cores, sensors, and electrical connectors. Brass is easy to machine and very durable, which is important when you need precise parts that last a long time.

Electrical and Electronics

You can choose brass for making electrical parts such as connectors, switches, and terminals. It conducts electricity well, is easy to machine, and resists corrosion. Plus, brass looks good, so it’s great for high-end electronics too.

Marine Industry

If you build parts for boats or anything used in the ocean, you choose brass. Saltwater, humidity, and temperature changes can damage other metals, but brass stays strong and resists corrosion, so it is ideal for propellers, fittings, and fasteners.

What are the Factors to Consider for Custom Brass Parts?

There are many things you need to keep in mind when machining custom brass parts, and these are the following:

Material properties: Make sure the type of brass you choose matches what your project needs.

Production volume: CNC machining works for small or large orders. Think about the costs and choose the best option for your budget.

Tolerances and dimensions: CNC machines can make very precise parts. Check that the machine can meet the exact sizes you need.

Design complexity: CNC machining is great for making detailed and complicated parts. But make sure your design is not too difficult to manufacture.

Lead time: Think about how fast you need the parts. Check things like material availability, tooling, and how busy the production schedule is.

Conclusion

If you’re looking to create high-quality brass parts, DEK is ready to help. Our expert team specializes in CNC machining services, including milling, turning, drilling, and EDM. With years of experience working with different brass alloys, we know exactly how to handle your project, no matter how simple or complex it is.

At DEK, we are ISO 9001 certified, which means you can count on us for consistent, reliable results. Plus, we guarantee fast communication; you’ll always hear back from us within 12 hours. Contact us today to get started!

FAQs about CNC Machining Brass

What is the tolerance range for brass?

The typical tolerance range for CNC-machined brass parts is ±0.005 mm, depending on the design and machining process.

Is there any disadvantage to brass CNC machining?

Yes, some types of brass are not suitable for medical or food-related applications due to potential toxicity. Also, brass is softer compared to steel, so it may scratch or dent more easily in some environments.

What is the lead time for machining brass?

At DEK, the typical lead time for machining brass parts is around 4-7 days, depending on the complexity and volume of the order.

When you need strong and light custom parts, you can opt for CNC machining aluminum. The properties of aluminum will tell you if it’s exactly what you need.

In this guide, I’ll help you understand how CNC machining aluminum works. You’ll learn why aluminum is a good material for your custom project.

What is CNC Machining Aluminum?

CNC machining aluminum means using computer-controlled machines to cut, shape, and make parts from aluminum material. With this process, you can create very detailed and complex designs that would be hard to do by hand.

CNC machines control everything carefully, so the custom aluminum parts you make are accurate and consistent. There are also special machines that can be set up just for working with aluminum’s unique properties.

CNC Machining Aluminum Process

Here are the CNC machining processes you can use for your custom aluminum parts:

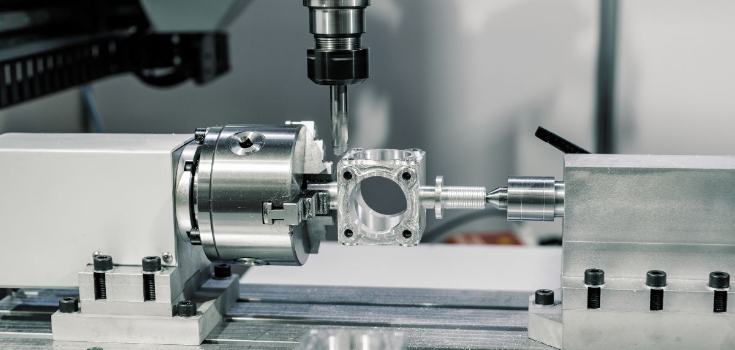

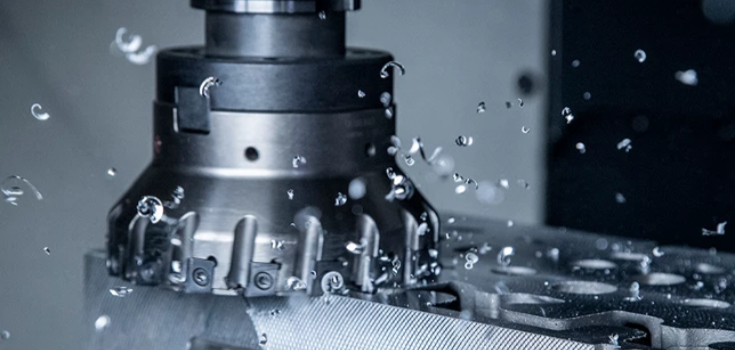

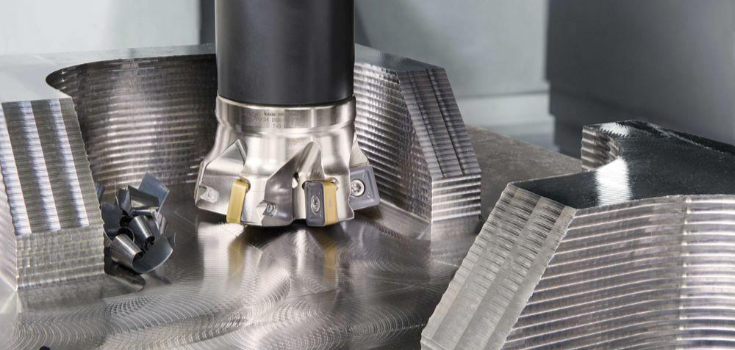

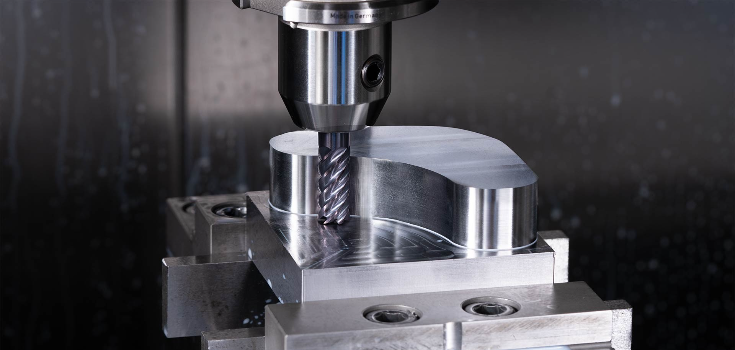

CNC Milling

CNC milling is a way to make custom aluminum machined parts by using a rotating cutting tool. The tool spins while the aluminum piece stays still. The machine removes material little by little in a very controlled way.

It can move in different directions to create complex shapes. With CNC milling, you can get very accurate and detailed parts.

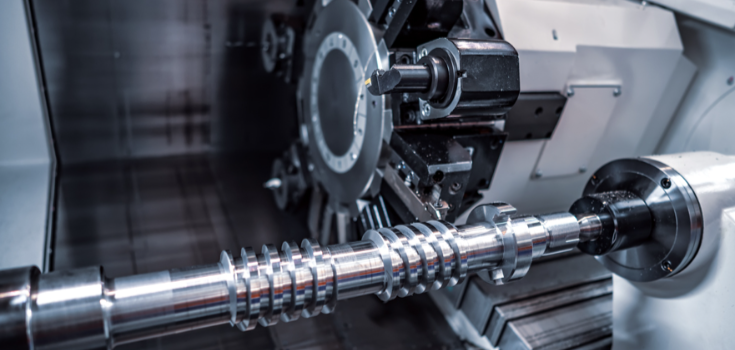

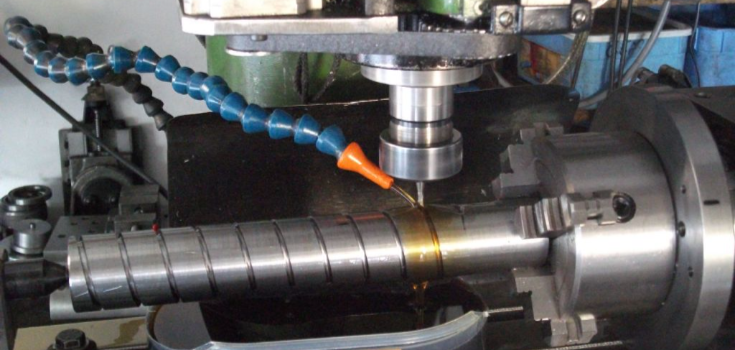

CNC Turning

In CNC turning, the aluminum piece spins at high speed while a cutting tool stays in one place. The tool moves slowly against the spinning part to cut away material and shape it. CNC turning is perfect when you need round parts like tubes, rods, or rings.

CNC Drilling

CNC drilling is used when you need to make holes in your aluminum machined parts. A drill bit spins and moves straight down into the material to create the hole. This method is great when your parts need to fit screws, bolts, or other pieces together.

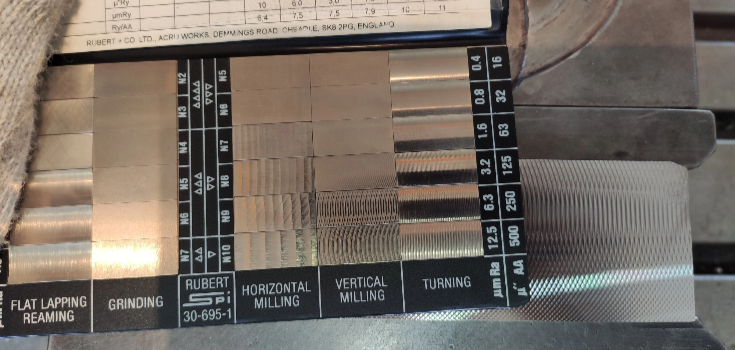

CNC Grinding

CNC grinding is used when you need a very smooth and precise finish on your aluminum machined part. In this process, a spinning grinding wheel slowly removes tiny amounts of material from the surface.

It’s a great way to make parts very flat, very smooth, or to meet very tight size tolerances. You usually use CNC grinding as a final step after milling or turning.

Benefits of Aluminum that Make it Suitable for CNC Machining

Using aluminum for CNC machining has many advantages, and these are the following:

Corrosion Resistance

Aluminum naturally resists corrosion and scratching in normal air and marine environments. You can make it even more resistant by anodizing it.

Keep in mind that different grades of aluminum have different levels of corrosion resistance, but the ones most commonly used in CNC machining are very good at it.

Machinability

Aluminum is easy to cut, shape, and work with. Because it is soft and chips easily, you can machine it quickly without using a lot of power. It also costs less to machine than steel.

For you, this means faster production, lower costs, and more accurate parts. Aluminum doesn’t deform much during machining, so it’s easier to reach tight tolerances.

Low Temperature Performance

Most materials get brittle and weak at very cold temperatures, but not aluminum. It keeps its strength, softness, and flexibility even when it’s freezing. This makes it a good choice if your parts need to work in very cold environments.

Strength-to-Weight Ratio

Aluminum is about three times lighter than steel, but it’s still very strong. This strong yet lightweight quality is called the strength-to-weight ratio.

Because of this, you can use aluminum for parts that need to be strong without being heavy, like in cars, airplanes, and other high-performance products.

Recyclability

CNC machining creates a lot of leftover chips and waste. Luckily, aluminum is highly recyclable. It doesn’t take much energy, time, or money to recycle aluminum, which can help save costs and reduce waste. Plus, using recyclable materials like aluminum is better for the environment.

Electrical Conductivity

Pure aluminum conducts electricity very well. Even though aluminum alloys conduct a little less, they are still good enough for making electrical parts. But if you need a part where conductivity is a problem, aluminum might not be the right material.

What Types of Aluminum are Used in CNC Machining?

There are different types of aluminum that are commonly used in CNC machining, and some of these are the following:

| Aluminum Alloy | Composition | UTS (MPa) | Density (g/cm³) | Specific Strength (kN·m/kg) |

| 7075-T651 | AlZn5.5MgCu | 490 | 2.81 | 170 |

| 2024-T351 | AlCu4Mg1 | 430 | 2.79 | 150 |

| 6082-T651 | AlSi1MgMn | 310 | 2.68 | 120 |

| 6061-T6 | AlMg1SiCu | 310 | 2.7 | 115 |

| 5052-H32 | AlMg2.5 | 260 | 2.68 | 97 |

Aluminum 6061

You can use 6061 aluminum for many things, like manufacturing, building, making consumer products, and even in airplanes. It’s very versatile and easy to weld.

This aluminum is medium-strong, can be heat-treated, and resists rust very well. You’ll find it easy to machine and work with, especially when it’s softened/annealed.

Aluminum 7075

If you need very strong aluminum, you should choose 7075 aluminum. It’s one of the strongest types you can get. It also holds up well under repeated stress, which is why it is perfect for parts that go through a lot of pressure.

Aluminum 7075 is very popular in the aerospace industry, where parts need to be both strong and complex.

Aluminum 5052

You should use 5052 aluminum when you need something that bends easily without cracking. It’s very good at resisting rust, especially from saltwater, so it’s great for marine uses.

You can’t heat treat it to make it stronger, but it’s still a strong and flexible aluminum that’s easy to work with.

Aluminum 2024

If you need aluminum that’s strong and handles stress well, 2024 is also a good choice. It’s often used in airplanes and vehicles because it is tough.

But you should know that it doesn’t resist corrosion as well as other types, so it usually needs a protective coating.

Aluminum 6082

When you want a strong and tough aluminum that’s still easy to machine and weld, you can use 6082 aluminum. It’s great for building structures like bridges and towers.

It resists corrosion well and is often used when you need strength and good durability together.

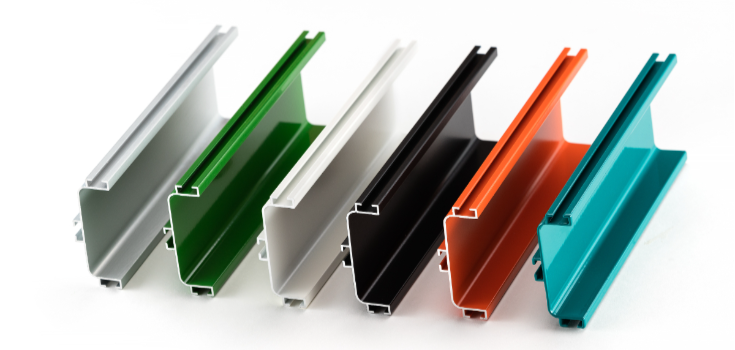

Surface Finishes for CNC Aluminum Parts

After you finish machining an aluminum part, you can do a few extra processes to make it look better, work better, and last longer. Here are the most common ones:

Coating

You can coat the aluminum part with another material, like zinc, nickel, or chrome. This makes the part stronger and protects it. Usually, you do this using an electrochemical process.

Another way to protect and color a part is by powder coating. You spray a dry colored powder onto the part using an electrostatic spray gun. Then you heat the part to about 200°C so the powder melts and sticks.

Bead Blasting

If you want a nice-looking finish, you can try bead blasting. In this process, you blast tiny glass beads at the part using a high-pressure air gun. This smooths the surface and gives a satin or matte look.

The main things you control are the size of the beads and the air pressure. Only use bead blasting if the exact size of your part is not super important, because it can change the dimensions a little.

Anodizing

If you want to make the surface harder and non-reactive, you can anodize the part. In anodizing, you dip the part into a diluted sulfuric acid solution and run electricity through it. This creates a tough aluminum oxide layer on the surface.

How thick and strong the layer gets depends on the solution, how long you anodize it, and the amount of electricity used. You can also anodize parts to add color.

Heat Treatment

If your part is made from a heat-treatable aluminum alloy, you can heat-treat it to make it stronger and improve its mechanical properties.

Applications of Aluminum Machined Parts in Industry

Below are some of the industries that commonly use aluminum machined parts:

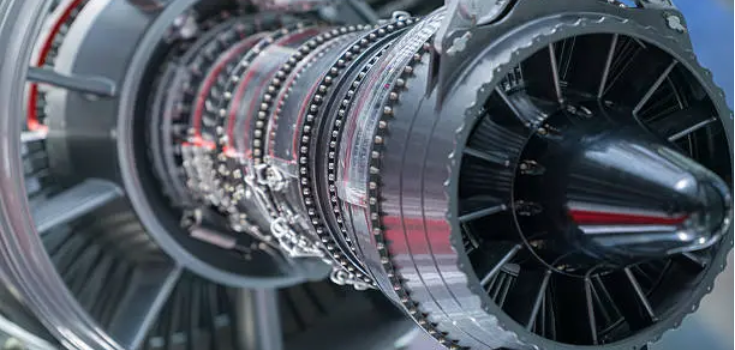

Aerospace

Aluminum CNC machined parts are strong, so they are perfect for making aerospace structural parts like engine components, airframes, and landing gear.

Since aluminum is lightweight, it reduces the weight of airplanes. CNC machined aluminum parts are also important for building parts like wing panels and fuselage sections.

Automotive

In the automotive industry, CNC machined aluminum parts are used in engine components, suspension systems, transmission housing, and electric vehicle parts. Aluminum’s strength, durability, and light weight help reduce the overall weight of vehicles and improve their durability.

Consumer Electronics

Aluminum CNC machined parts are widely used in consumer electronics like laptops, smartphones, tablets, and audio equipment. Aluminum is ideal for making device casings because it is lightweight and provides protection for internal components.

High-end audio equipment such as amplifiers, headphones, and speaker enclosures often uses aluminum parts because it helps reduce vibrations and dissipates heat effectively.

What are Some Design Tips for Aluminum CNC Machining?

Here are some design tips to make sure your aluminum part is both functional and easy to make:

- Deep cavities can be hard to machine and may cause tool damage. Keep deep features to a minimum or split them into multiple steps for easier machining.

- Keeping the wall thickness uniform helps avoid wasting material or causing distortions. Too much variation can create weak spots or uneven stress.

- Sharp internal corners are hard to machine. Adding rounded edges helps make smoother cuts and reduces stress.

- Ensure that the cutting tool can access all parts of the design. Think about tool size and shape when designing features like holes or slots, so the tool doesn’t get blocked.

- Very thin walls can vibrate during machining and affect surface quality. Stick to a reasonable thickness for strength and stability.

- When adding threads to aluminum, make space at the bottom of the threads so the cutting tool can exit cleanly and produce high-quality threads.

- If your parts will have additional finishes like anodizing or bead blasting, make sure your design accounts for the extra material that may be removed or added during these steps.

Conclusion

Now you know how CNC machining aluminum works and why it’s a good choice for many custom parts. You also understand the benefits of aluminum and how to design better parts of it.

At DEK, we can help you create strong, lightweight, and high-quality custom aluminum machined parts. Contact us now to get fast, reliable CNC machining services for your project.

FAQs

How much does CNC machining aluminum cost?

The cost of CNC machining aluminum depends on factors like the type of aluminum, part complexity, and order size. Larger orders often reduce the cost per part by spreading setup and tooling expenses over more units.

What are the alternatives to aluminum in CNC machining?

If aluminum is not suitable for your project, you might consider other materials. Steel offers high strength but is heavier and more challenging to machine. Stainless steel provides excellent corrosion resistance.

Brass is easy to machine and has good corrosion resistance. Plastics like ABS or Delrin are lightweight and cost-effective for non-structural parts.

What factors should be considered when machining aluminum?

When machining aluminum, you should pick the right alloy for strength and corrosion resistance, use tools with sharp angles for easy cutting, and set the cutting speed and feed rate correctly to avoid tool wear.

Always use coolant to keep things cool and protect the tools, make sure chips are cleared away properly, and remember that aluminum can expand with heat, so plan for tight tolerances carefully.

When you make medical parts, you need to be very exact because a small mistake can cause serious problems. That’s why it’s important to know how to achieve precision in medical parts.

In this guide, you’ll learn what precision machining is and how you can make sure every part you make is accurate, safe, and ready to use for the medical industry.

What is Precision Machining?

Precision machining means making parts that are almost exactly the same size with little difference. You do this by using machines controlled by computers, like CNC machines or lasers. You also want the parts to match the original design exactly.

The Role of Precision in Medical Parts Manufacturing

As medical care improves, the need for precise devices grows to help people stay healthy. Since these devices affect health, every part must be made with great care. They must work perfectly, especially inside the body, where mistakes can be serious.

To achieve this, you can use different precision machining processes that we will discuss further below.

Benefits of Precision Machining in the Medical Industry

You can get a lot of benefits when you use precision machining in the medical industry, and some are discussed below.

Make Precise Devices

With precision machining, you can create medical devices that are very accurate. Tools like 5-axis milling and EDM allow for detailed and smooth parts, even with tough materials.

Make Devices from Different Materials

Precision machining lets you use strong materials like surgical steel and titanium, which meet FDA safety standards. These materials are used in things like implants and surgical tools.

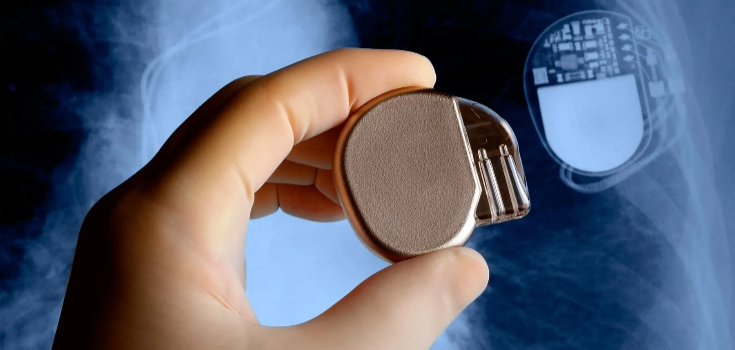

Make Smaller Devices

Precision machining helps create smaller devices like insulin pumps and pacemakers. These devices are comfortable and don’t get in the way, so it is easier for people to live their daily lives.

Tools and Technologies Used in Precision Machining

Precision machining in making medical components uses different tools and technologies, such as:

CNC Machines: These machines are controlled by computer programs to ensure precise and repeatable machining for you.

CAD/CAM Software: This software helps you design medical components and generate instructions for the machining process.

Advanced Cutting Tools: Tools made of carbide, ceramic, and high-speed steel are used to get the precision and quality you need for medical components.

High-Speed Machining (HSM): This technology speeds up machining. It makes the process more efficient and improves your productivity.

Multi-Axis Machining Centers: These machines can perform complex operations from different angles. They can help you create detailed medical parts.

Metrology Equipment: Tools like coordinate measuring machines (CMMs) and laser trackers check the accuracy and quality of the components you make.

Precision Machining Processes for Medical Component Manufacturing

Here are some of the precision machining processes that you can use:

CNC Machining

This method uses computers to control machines. It makes parts precise and consistent every time.

5-Axis Milling

The advanced technique lets you create complex shapes in one setup, reducing mistakes and saving you time.

Electrical Discharge Machining (EDM)

This is used for hard materials like titanium and tungsten. It uses electrical discharge to shape the material. It makes highly detailed and precise parts.

Importance of Quality Control in Precision Machining for Medical Industry

Below are the main reasons why it’s so important:

- Ensure every part is made exactly right for patient and user safety.

- Regular quality control leads to parts that are less likely to fail.

- Catch problems early to avoid costly fixes and delays.

- Follow industry rules to maintain safety and quality standards.

Challenges for Precision Medical Machining

In medical machining, you need to avoid contamination, keep up with new tech, and manage high costs. Below are some of the other challenges you might encounter and how to solve them.

Working with Titanium

Titanium is a hard material, so it is often used because it’s strong and lasts a long time. You might use it to make biopsy tubes or surgical scissors. These tools help doctors collect tissue samples or perform surgeries.

But titanium is hard to work with, so you must use special tools and make the machining speed slower if needed.

Making Complex Parts with CNC

The human body is complicated, and medical tools need to match that. Use 5-axis CNC machines for detailed, multi-angle cuts. Use software to simulate the process before cutting real material.

Handling Tight Tolerances

When you make medical parts with CNC machines, you often deal with very tight tolerances. Use high-precision machines and inspection tools. Run regular quality checks to catch problems early.

Small Batch Orders

A small batch order usually means fewer than ten parts. You can make these small batches with CNC machines or 3D printers.

Applications of Precision in Medical Parts

Now, here are some examples of medical parts that need precision machining:

Implantable Devices

When you’re working with pacemakers, stents, or bone implants, you need tiny, precise parts made from safe materials like titanium.

Diagnostic Equipment

You use precision-machined parts in MRI machines, CT scanners, and ultrasound devices. These parts help you get clear, high-resolution images, which are important for making the right diagnosis.

Surgical Instruments

You use precision machining to make sharp tools like scissors, forceps, and other surgical instruments. This process helps you get clean edges without rough spots, so your tools are safe and work well during surgery.

Endoscopic Tools

You count on flexible, detailed tools to look inside the body. Precision machining helps you build parts that move easily and work exactly as needed during challenging procedures.

Hearing Aids

For hearing aids, you need tiny, detailed parts. Precision machining lets you create these small pieces and circuits with the accuracy and size needed to keep the devices light, comfortable, and effective.

Respiratory Equipment

You use precision-machined parts in ventilators and other breathing devices. These parts must work perfectly, especially in emergencies.

Precision Machining for Medical Devices From DEK

DEK offers precision machining for medical devices. We use various tools and methods, like CNC and EDM machining, laser cutting, laser welding, and additive manufacturing. We also handle sheet metal fabrication and other finishing services.

We can give you different options, so you get what works best for your needs. Contact us to talk about your next medical device project or get a free quote.

Conclusion

Precision machining is important for improving medical technology. It helps make tiny, accurate parts needed for advanced medical devices. This process makes sure the parts are lightweight, strong, and work well.

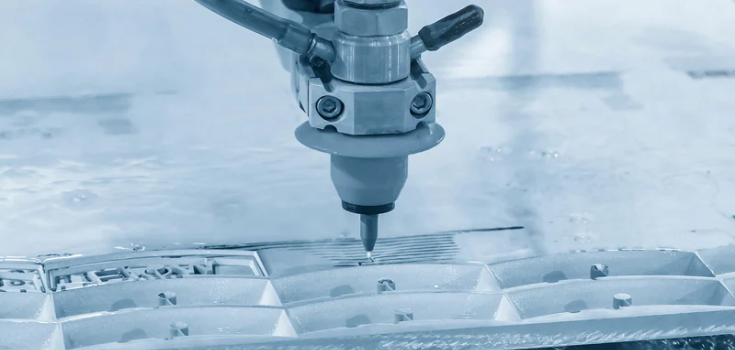

If you work with waterjet cutting, you know how important the nozzle is. It directs the high-pressure water stream to cut through materials accurately. Choosing the right nozzle affects cutting speed, precision, and durability.

In this guide, we’ll explain everything you need to know about waterjet cutting nozzles.

What are Waterjet Cutting Nozzles?

A waterjet nozzle is the part of a waterjet machine that directs the water stream to cut a material. It is also called a focusing tube or mixing tube. The nozzle is very strong because it needs to handle high-pressure water.

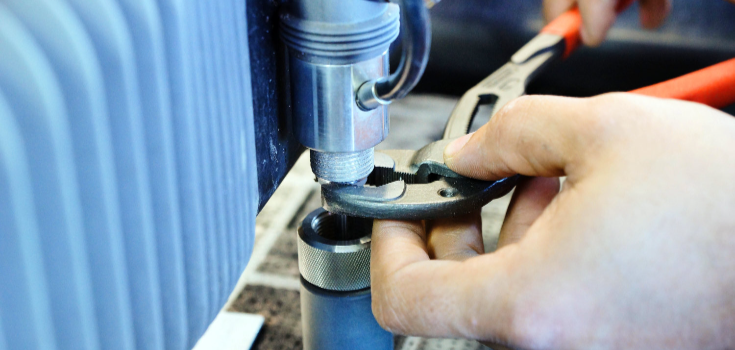

Over time, the nozzle wears out due to the pressure, so you need to replace it regularly.

What is the Purpose of the Water Jet Nozzle?

The main job of the waterjet nozzle is to focus the water stream for precise cutting. The size of the water stream depends on the material and its thickness.

Inside the nozzle, there is a jewel orifice, which controls the water flow. This helps the nozzle last longer and improves cutting accuracy.

Key Components of a Waterjet Cutting Nozzle

Waterjet nozzles have three main parts: the jewel orifice, the mixing tube, and the focusing tube. Each part helps the waterjet cut materials accurately and efficiently.

The jewel orifice, usually made of sapphire or diamond, pushes high-pressure water into the mixing tube. Here, the water mixes with abrasive materials. Then, the mixture moves through the focusing tube to make precise cuts.

Using high-quality parts makes the nozzle last longer and work better over time.

How Waterjet Nozzles Work?

Waterjet cutting nozzles convert high-pressure water into a fast-moving stream. When mixed with abrasives, this stream can cut through tough materials like metal and ceramics. This makes water jet operation useful for many industrial and manufacturing applications.

The nozzle controls the speed and precision of the cut. A smaller nozzle creates detailed cuts, while a larger one increases cutting speed for bigger projects. It also focuses the water stream, turning pressure into cutting power

Waterjets can cut almost any material, including glass, marble, wood, and even food. They can drill titanium, make fine details in stone and metal, and sterilize liquids. Each material and thickness requires the right nozzle size to get the best results.

Types Of Waterjet Cutting Nozzles

Here are the two types of waterjet nozzles:

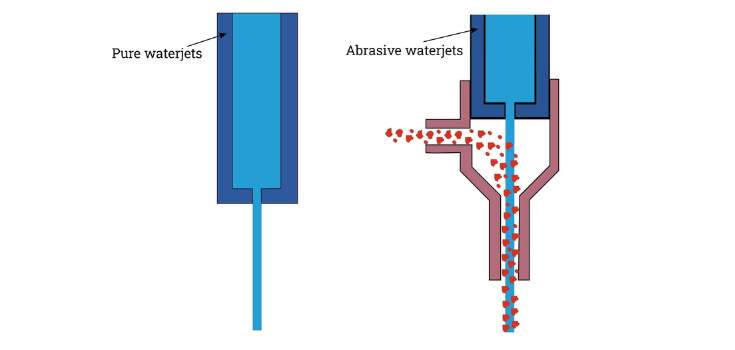

1. Pure Waterjet Nozzles

- Uses only water (no abrasives).

- Cuts soft materials like paper, foam, rubber, textiles, cardboard, and plastics.

- Has a very small opening because no abrasive particles are used.

2. Abrasive Waterjet Nozzles

- Uses water and abrasive particles to cut harder materials.

- Has a special mixing chamber where abrasive particles are added to the water.

- The high-pressure water speeds up the abrasive particles to cut materials like metal, ceramics, stone, glass, and composites.

Specifications of a Water Jet Nozzle

A water jet nozzle has different features that affect how it works. Here are the main things you need to know:

Orifice Diameter

The orifice diameter is the size of the hole in the nozzle where water comes out. A smaller hole creates a stronger water jet but also wears out the nozzle faster. The diameter of the water jet cutting nozzle is usually three times the orifice diameter. A small orifice helps with accuracy, but if it is too small, it slows down cutting and wears out quickly.

Flow Rate

The flow rate is how much water passes through the nozzle in a certain time. It is measured in liters per minute (LPM) or gallons per minute (GPM). A higher flow rate makes cutting faster but also causes more wear on the nozzle.

Nozzle Size

The nozzle size is the width of the bore hole, usually three times the orifice diameter. There are three types of nozzle sizes. Small nozzles, which range from 0.254 mm to 1.016 mm (0.01 in to 0.04 in), are used for precise and detailed cutting.

Medium nozzles, which range from 1.016 mm to 2.032 mm (0.04 in to 0.08 in), are used for general cutting where high accuracy is not needed. Large nozzles, which range from 2.032 mm to 6.35 mm (0.08 in to 0.25 in), are used for fast cutting of large materials.

Pressure Rating

The pressure rating tells you the highest amount of water pressure a nozzle can handle properly. If the pressure goes beyond this limit, the nozzle can get damaged or even break. Different nozzles have different pressure ratings, and manufacturers provide this information when you buy a replacement nozzle.

A modern waterjet cutting nozzle can reach pressures as high as 90,000 psi. But at such high pressure, the nozzle and other parts wear out quickly. The best pressure for long-lasting performance is between 40,000 psi and 60,000 psi.

Material Used For Making Waterjet Nozzles

Waterjet nozzles come in different materials, depending on how long they need to last, how much pressure they can handle, and their cost. Here are the most common materials:

Tungsten Carbide

Tungsten carbide is the most popular choice. It is very strong—almost as hard as diamond. These nozzles work well under very high pressure (up to 90,000 psi). If you use them properly, they can last over 200 hours. If used roughly, they may need to be replaced after 100 hours.

Diamond

Diamond nozzles are the hardest and most durable. They can handle extreme pressure and cut the toughest materials. These nozzles can last up to 1,000 hours. However, they are the most expensive, costing about 20 times more than sapphire nozzles. If you do a lot of heavy cutting, diamond nozzles may be the best choice.

Sapphire

Sapphire nozzles are strong and affordable. They do not react with chemicals. However, they have a shorter lifespan, usually between 50 to 100 hours. They can handle water pressures between 60,000 and 70,000 psi. Ruby nozzles are very similar to sapphire nozzles.

Ceramics

Ceramic nozzles are a newer option. They can be even stronger than hardened steel and are resistant to rust and corrosion. Their lifespan depends on the type of ceramic used.

What Materials Can a Waterjet Nozzle Cut?

A waterjet nozzle can cut almost any material. Here are some common ones:

Metals: You can cut even the hardest metals, like hardened steel. For a smooth and fast cut, you’ll need an abrasive jet nozzle.

Plastics: You can cut any plastic without melting it. Most plastics need an abrasive jet nozzle.

Ceramics: Waterjets are often used to cut ceramic tiles and stone. Depending on the ceramic type, you may use either an abrasive or a pure waterjet nozzle.

Rubber: A pure waterjet nozzle at low pressure is perfect for cutting rubber. This method is cost-effective.

Glass: You can cut glass for art, construction, and decoration. An abrasive jet nozzle can even cut bulletproof glass.

Thin Films: You can cut thin foils, like aluminum foil, using a pure waterjet nozzle. Even thin metal foils can be cut this way.

Foam: Waterjet cutting gives clean cuts on foam without burn marks. A pure waterjet nozzle works well and is affordable.

Wood: Soft or thin wood can be cut with a pure waterjet nozzle. For thick or hardwood, you’ll need an abrasive jet nozzle.

Nozzle Connection Type

When choosing a waterjet cutting nozzle, you have different ways to connect it. Here are three common types:

Threaded Nozzles

Threaded nozzles have screw-like threads on the ends. You need special tools to attach and remove them, but they provide a very secure fit. These nozzles can handle extremely high pressure without leaking. Once properly installed, you don’t have to worry about them disconnecting by accident.

Quick-Connect Screw Nozzles

Quick-connect screw nozzles are a mix of snap and threaded nozzles. They have a locking system like snap nozzles but also require some screwing to secure them in place. This makes them more reliable than snap nozzles, as they are less likely to disconnect accidentally. At the same time, they are still easier to use than fully threaded nozzles.

Quick-Connect Snap Nozzles

Quick-connect snap nozzles, also called quick-disconnect nozzles, do not require any tools to attach or remove. They use a snap-lock system to stay in place, and they are very easy to use. However, they are not as strong as threaded nozzles and may not handle very high pressure. In some cases, the locking mechanism can accidentally release during operation.

How to Choose the Right Waterjet Nozzle?

Choosing the right waterjet nozzle depends on a few key factors:

- Think about what you need the nozzle for. Some jobs limit your options. For high pressure, avoid snap connection nozzles.

- Nozzles wear out at different rates. If using abrasives, pick a tough material. Diamond lasts the longest but costs more. Tungsten carbide is a solid, common choice.

- The hole size affects cutting. There’s no one-size-fits-all, so check the manufacturer’s guide or test different sizes.

- Choose a nozzle that can handle more pressure than your system uses for safety and durability.

- Use a machinability chart to match the right nozzle to your material. This improves cutting and extends nozzle life.

Applications of Waterjet Cutting Nozzles

Here are some key areas where you might see them in action:

Aerospace Industry

If you’re working in aerospace, you need precise cuts for strong but lightweight materials like titanium, aluminum, and composites. Waterjet nozzles help you create complex parts, such as aircraft panels and engine components, without weakening them.

Automotive Industry

In the automotive world, waterjet nozzles let you cut metal, rubber, and composite materials quickly and accurately. Whether you’re making engine parts, car body pieces, or custom modifications, waterjet cutting is a great way to get clean, precise results.

Electronics Industry

If you work with electronics, you know how delicate materials like circuit boards and semiconductor wafers can be. Waterjet nozzles allow you to cut these fragile components without causing damage. They also help in making connectors, housings, and other small electronic parts with tight tolerances.

Medical Devices Industry

Waterjet cutting is essential for making medical devices like surgical tools, implants, and diagnostic equipment. Since it can cut materials like stainless steel, titanium, and ceramics without heat, you don’t have to worry about damaging delicate medical parts.

Effects of Water Quality on Nozzle Lifespan

The quality of water you use directly affects how well your waterjet nozzles work and how long they last. Dirty water with impurities can wear down the nozzles, so it can make the cutting process less effective. Using clean, high-quality water helps keep your nozzles working properly for a longer time.

Filtering your water or using a water treatment system can greatly reduce the damage caused by impurities, helping your nozzles last longer. Paying attention to water quality ensures your cutting system works consistently and reliably. By taking care of the water you use, you improve the efficiency and performance of your waterjet cutting.

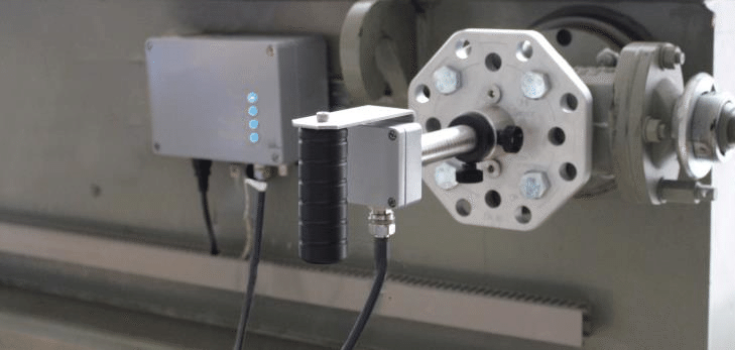

Tools for Monitoring Nozzle Lifespan

To keep your waterjet cutting nozzles working well and lasting longer, you need to check their condition regularly. There are several tools that help you catch problems early, saving you time and money on unnecessary repairs.

Here are some useful tools for monitoring nozzle performance:

Wear Monitoring Sensors

Wear monitoring sensors track changes in the nozzle’s size or performance over time. They provide real-time data, helping you detect early signs of damage. By catching these issues early, you can schedule maintenance before the nozzle fails, reducing unexpected downtime.

Laser Alignment Systems

Laser alignment systems make sure the nozzle is positioned correctly. Proper alignment ensures clean, precise cuts and even wear on the nozzle. If the nozzle is misaligned, it can cause uneven cutting and wear out faster. Using a laser alignment tool regularly helps maintain accuracy and extend nozzle life.

Pressure Gauges

Pressure gauges measure the water pressure in the system. Keeping the pressure steady ensures the nozzle works properly. If the pressure suddenly drops or spikes, it could mean the nozzle is wearing out or getting clogged. Monitoring pressure helps you spot issues before they affect cutting quality.

Inspection Cameras

Inspection cameras let you take a close look at the nozzle without taking the system apart. You can check for cracks, wear, or erosion quickly and easily. Regular inspections with a camera help you catch problems early and keep your nozzles in good shape.

Flow Rate Meters

Flow rate meters check how much water and abrasive material are moving through the nozzle. If the flow rate changes, it could mean there’s a clog or the nozzle is wearing down. These meters help ensure smooth operation and prevent buildup inside the nozzle.

Common Problems of Waterjet Cutting Nozzles

Waterjet cutting nozzles are tough, but they can develop problems over time. Knowing what to watch for and fixing issues early will keep your cuts clean and your nozzle working longer. Here are some common problems and how to solve them:

Clogging Issues

Dirt, abrasive particles, or leftover materials can clog the nozzle, blocking water flow and making cuts less precise.

Clean the nozzle regularly with high-pressure air or water. Use a good filtration system to prevent clogs in the first place.

Overheating

Running the system too long without breaks, using too much pressure, or poor maintenance can cause the nozzle to overheat, reducing efficiency.

Keep the system well-ventilated. Take breaks during long cuts and monitor pressure levels to avoid overheating.

Uneven Cuts

If your cuts look rough or uneven, the nozzle might be misaligned, parts may be worn out, or the water and abrasive flow may be inconsistent.

Check that the nozzle is aligned correctly. Make sure water pressure and abrasive flow are steady. Replace worn parts like focusing tubes or orifices when needed.

Leaks

Leaks can happen at connection points due to worn-out seals or damage, reducing cutting power and wasting water.

Check the nozzle and fittings for wear or loose connections. Tighten or replace seals as needed.

Excessive Wear

Nozzles wear down over time from constant high-pressure water and abrasives. This can make your cuts less accurate.

Inspect your nozzle often and replace worn-out parts. Use high-quality abrasives and adjust pressure settings to slow down wear.

Conclusion

Keeping your waterjet cutting nozzles in top condition is important to achieving precise, high-quality cuts. By choosing the right nozzle, monitoring wear, and maintaining clean water, you can extend the lifespan of your equipment and improve efficiency.

At DEK, we manufacture precision components using advanced waterjet cutting machines. If you need high-quality nozzles or custom-cut parts, contact us today to see how we can support your production needs!

FAQs

How are waterjet cutting nozzles made?

Waterjet cutting nozzles are made from tungsten carbide, a hard but brittle material. They are formed by pressing powdered tungsten carbide into a mold and heating it under high pressure.

What is a water jet cutting nozzle’s diameter?

The size of a water jet cutting nozzle depends on the type of cutting you’re doing. For abrasive waterjet cutting, the water stream is round and usually between 0.030” and 0.040” (0.76 mm and 1.02 mm) wide. Because of its round shape, it’s hard to cut perfectly square inner corners—the jet will always leave a small curve.

How long does a waterjet nozzle last?

You should replace your waterjet nozzle after 40 to 1000 hours of use. The lifespan depends on what you’re cutting, water pressure, abrasive quality, and nozzle material. Check it regularly to catch wear early and keep your cuts precise.

What is the cost of waterjet cutting nozzles?

Waterjet cutting nozzles cost between $20 and $400+, but the price doesn’t always mean better value. A $400 diamond nozzle may save you money by lasting longer than a $20 sapphire one. Tungsten carbide nozzles ($50-$100) offer a good balance of cost and durability.

How do you know when it’s time to get a new waterjet nozzle?

Replace your nozzle if cutting is less precise, abrasive use increases, or the machine slows down. Check for wear regularly to avoid downtime and keep your waterjet running smoothly.

What factors describe the lifespan of waterjet cutting nozzles?

Your waterjet nozzle lasts longer if you use clean water, high-quality abrasives, and the right cutting pressure. Heavy use wears it out faster. To extend its life, maintain proper pressure, use good abrasives, and follow best practices.

You might be asking, does brass rust? It’s a good question because rust can cause big problems for many metals, especially iron and steel.

In this guide, you will learn what happens to brass over time and how it reacts to different conditions.

What is Brass?

Brass is an alloy of mostly copper and zinc. Usually, it has about 60-70% copper and 30-40% zinc. Changing these amounts changes how strong, flexible, and resistant to corrosion the brass is. Sometimes, other metals like lead, tin, or aluminum are added.

Does Brass Rust?

No, brass does not rust because it does not have iron. Rust happens only to metals with iron. But brass can still corrode in tough conditions

One common change is tarnishing, which makes the surface look dull because of a layer called patina. Patina is greenish and made of copper compounds. In very harsh places, brass can lose zinc, a process called dezincification, which can make it weaker.

Brass Rusting Properties vs. Alloy Composition

These parts of brass change how it behaves:

Zinc: You add zinc to make brass stronger and more flexible. But if there is too much zinc, brass can lose zinc in tough conditions, which can cause damage. Brasses with less zinc, like naval brass and tin brass, resist rust better.

Copper: More copper means better rust protection. Copper reacts with water and air to make a thin layer that protects the brass underneath. Red brasses have about 80% copper and resist rust better than yellow brasses, which have 60-70% copper.

Other metals: Adding tin helps stop zinc loss and protects brass from rust. Lead makes it easier to shape and machine. Aluminum makes brass stronger and more rust-resistant.

Comparing Brass Rusting to Brass Oxidation and Brass Tarnish

Let’s compare brass rusting vs oxidation vs tarnish to understand them better.

Brass Oxidation

Brass has copper in it. When you leave it in the air and moisture, the copper reacts and forms a thin layer called copper oxide. This layer protects the brass. You might see the color change, sometimes turning green over time (called a patina).

Brass Rusting

Brass doesn’t rust. Rust only happens when iron reacts with air and moisture. Since brass doesn’t have iron (it’s made of copper and zinc), you don’t have to worry about rust.

Brass Tarnish

Tarnish happens when the copper in brass reacts with sulfur in the air. This makes a dark layer on the surface. But don’t worry, you can clean it off and bring back the shine.

Key Standards for Brass Corrosion Resistance

Here’s what you need to know about the main standards that help check how well brass resists corrosion:

ASTM Standards (from the U.S.)

The American Society for Testing and Materials (ASTM) has a few rules that help you test brass and see how strong it is against corrosion.

ASTM B887: This tells you what kind of brass is good at resisting dezincification (a type of corrosion). It also explains what the brass should be made of and how strong it needs to be.

ASTM B858: This shows you how to test brass by putting it in a chemical solution to see if it resists dezincification.

ISO Standards (from International Guidelines)

The International Organization for Standardization (ISO) also gives you clear steps to test brass and make sure it meets quality standards.

ISO 6509: This test checks if brass can resist dezincification. You put the brass in a copper chloride solution and see how deep the corrosion goes.

ISO 18086: This standard covers all copper alloys (like brass) and makes sure they need certain performance and corrosion resistance levels.

Types of Corrosion Brass Might Face

Here’s a simple table that can help you understand the types of corrosion brass might experience.

| Type of Corrosion | What Happens |

| Tarnishing | Your brass can look dull or discolored. This is just on the surface and easy to clean. |

| Dezincification | In salty or chlorine-heavy places, your brass can lose zinc and become weak and porous. |

| Stress Corrosion Cracking | If your brass is under stress and exposed to certain chemicals, it can crack or break. |

| Galvanic Corrosion | If your brass touches a more noble metal in a wet area, it can corrode faster. |

| Pitting Corrosion | Tiny holes or pits can show up on the surface of your brass in very harsh conditions. |

Factors Affecting Brass Corrosion and Rusting

Below are some of the things that can affect how brass corrodes or rusts:

Composition of Brass

If the brass has a lot of copper, it resists corrosion better. But if it has too much zinc, it can lose zinc over time (this is called dezincification). Adding things like tin, silicon, or aluminum helps protect it from corrosion.

Environmental Conditions

If the brass gets wet often, it corrodes faster (but it doesn’t rust like iron). Saltwater can pull zinc out of the brass. Acidic places also make brass corrode quickly.

Chemical Exposure

Being around sulfur can make the brass tarnish by forming copper sulfide. Ammonia is even worse — it can cause cracks in brass that’s under pressure or stress.

High Temperatures

If you use brass in very hot places, it will corrode faster, especially in tough environments.

Mechanical Stress

If the brass is bent, stretched, or under pressure, it can crack more easily due to stress and corrosion.

Protective Coatings

If you coat the brass with something that protects it, it won’t corrode as quickly.

Applications of Brass due to Rust-Resistant Properties

Here are some common ways you might use brass in everyday life:

Plumbing Accessories: You can use brass for water pipes, pumps, faucets, and boat parts. It doesn’t rust, so it lasts long around water.

Electrical Connectors: Brass works well for plugs, sockets, and wires. It lets electricity flow and doesn’t rust or break easily, so it’s great for things like switch parts and electrical pins.

Musical Instruments: Brass is perfect for making instruments like trumpets, trombones, and tubas. It sounds great and is easy to shape.

Decorations in Architectural Structures: You can use brass for fancy items like lamps, railings, and door handles. It looks good and doesn’t wear out easily, so it’s also used in building parts that need to last and look nice.

Automotive Parts: Brass is used in car radiators and heaters because it moves heat well and doesn’t get damaged by coolants.

Bearings and Bushings: If you need parts that move smoothly and last in tough places, brass is a good choice. It’s used in machines for low-friction parts. It’s also used in gloves made for working in rusty or chemical-filled places.

Rust-Resistant Coins: Some coins are made from brass because it doesn’t rust, is strong, and easy to press into shape.

Weapons: You can use brass to make tools that won’t spark, which is important in places with flammable materials, like chemical plants. It’s also used for bullet casings because it doesn’t rust, is strong, and easy to work with.

Methods for Preventing and Treating Brass Corrosion

Below are easy tips to help you protect and care for your brass items.

Preventing Brass Corrosion

- Choose brass alloys with nickel, chrome, or DZR brass to resist corrosion.

- Apply zinc, nickel, or chrome plating, or use clear lacquers and nano coatings to block moisture and air.

- Apply anti-tarnish treatments to create a protective layer to stop tarnish and corrosion.

- Try cathodic protection; this method uses a sacrificial metal to protect brass from rusting.

- Wash brass with mild soap and water often.

- Look for early signs of corrosion so you can act fast.

- Wear gloves to avoid skin oils causing corrosion.

- Keep brass in dry, temperature-controlled places.

- Avoid exposing brass to ammonia, sulfur, salts, and other harmful chemicals.

Treating Existing Corrosion

- Use brass cleaners and polish with a soft cloth to remove tarnish and oxidation.

- After cleaning, add coatings or inhibitors to prevent new corrosion.

- For severe corrosion, use cathodic protection systems. This can stop damage, especially on large brass items.

Prevent Dezincification

- Choose brass with less than 15% zinc.

- Flush water lines regularly to avoid chemical buildup.

- Test water quality to spot and fix problems like high chloride.

Conclusion

Now you know that brass doesn’t rust because it has no iron. But it can still corrode in some conditions. Things like water, salt, chemicals, and stress can affect how your brass items wear over time. The good news is, with the right care and coatings, you can keep brass looking great and working well for a long time. Whether it’s for plumbing, music, or decoration, brass is a strong and useful metal you can count on.

If you ever need custom brass parts made with care and precision, DEK is here to help. You can count on us to deliver parts that last and fit your needs.

FAQs

How quickly does brass rust?

Brass doesn’t rust, but it can still corrode or change color over time. If you don’t use any protective coating, you might see signs of corrosion or a greenish layer within a few months or years, depending on the environment.

Does brasso remove rust?

Brasso is made to clean and shine brass, copper, and similar metals. It’s good at removing tarnish and making the metal look bright again. But it’s not meant to remove rust. If you need to get rid of rust, use a product that’s made for rust removal.

Does brass rust in salt water?

Brass doesn’t rust because it has no iron. But if you put it in salty water, it can corrode over time.

Does brass turn green?

Yes, brass can turn green over time. When it’s exposed to air, moisture, or certain chemicals, it can form a green layer called patina. This happens naturally and doesn’t always mean the brass is damaged.

Does solid brass rust?

No, solid brass does not rust because it does not contain iron. It can tarnish over time, but it won’t get rusty like steel or iron.

Does brass rust in water?

No, brass does not rust in water. Brass can only corrode, and this happens only if it faces very harsh conditions.

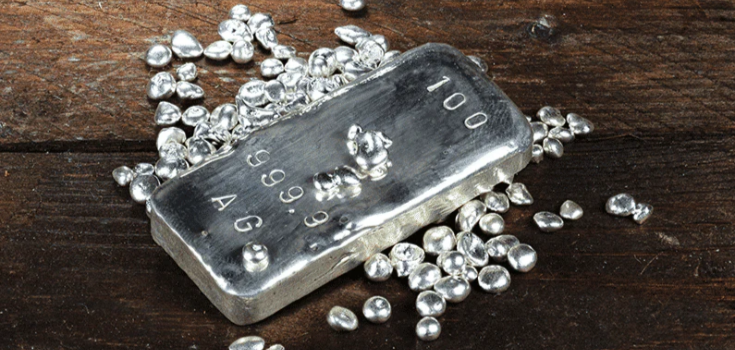

When you work with silver, you need to understand its basic properties. One important property is the density of silver. It helps you when you are making parts, checking materials, or planning costs.

In this guide, you will learn everything you need to know about the density of silver. You’ll see why it matters, how to measure it, and how it compares to other metals.

What is the Density of Silver?

The density of silver is about 10.49 grams per cubic centimeter. Silver is heavier than many other metals. This makes it a good choice when you need something strong and heavy for your project.

Silver is one of the most useful and valuable metals. People love it for both its beauty and how well it works in different products. Its density makes it special as it is important when silver is used for coins, jewelry, and many other things.

Importance of Silver’s High Density

Silver’s high density helps it carry electricity and heat very well. That’s why you see it used a lot in electronics and electrical parts. Because silver is dense, it stays strong under high pressure and doesn’t change shape easily. This makes it a good choice for many mechanical and industrial jobs.

Silver’s density also plays a big part in why it is so valuable. It’s one of the reasons silver is used for jewelry, coins, and investments. The high density of silver makes it easy to shape and work with.

Silver Density Chart

Here’s the density of silver in different units:

| Measurement | Silver Density |

| Kilograms per millimetre | 0.0105 |

| Grams per cubic centimeter | 10.49 |

| Tonnes per cubic meter | 10.49 |

| Kilorams per litre | 10.49 |

| Kilograms per cubic meter | 10,490 |

| Ounces per cubic inch | 6.069 |

| Ounces per cubic foot | 10,488 |

Measuring Silver Density

Measuring the density of silver is a simple and smart way to check if it’s real. You just divide the weight by the volume. For example, if a silver bar weighs 500 grams and takes up 47.68 cubic centimeters, the density would be 10.49 grams per cubic centimeter. That shows the silver is pure.

This is a good way to spot fake silver. Metals like zinc or tin are lighter and won’t match silver’s density. With the right tools or basic measurements, you can catch differences in weight or size and avoid getting tricked.

Factors Affecting Silver’s Density

Many things can change the density of silver. Here are a few you should know:

Purity of Silver: Pure silver (99.9%) has a density of about 10.49 g/cm³. Sterling silver, which is 92.5% silver and mixed with metals like copper, is a little less dense.

Temperature: When silver gets hot, it expands and becomes less dense. When it cools down, it shrinks and becomes a little dense. These changes are small but can matter in some jobs.

Alloy Composition: Silver is often mixed with other metals to make it stronger. What you mix it with, like copper or palladium, can slightly change the density.

Impurities or Contaminants: If silver has unwanted materials mixed in, the density can go up or down. It depends on what kind of impurities are present.

Porosity: If silver has tiny air holes inside it, it becomes less dense. This can happen with raw silver or during manufacturing. Porosity makes the silver less solid and can affect how strong it is.

Practical Applications of Silver Density

As mentioned earlier, density makes silver valuable and because of that, it’s useful in many ways.

- Silver’s weight and strength make it perfect for detailed jewelry that stays elegant and keeps its shape.

- Silver coins feel solid and heavy, which is why collectors and investors like them.

- Silver’s density and ability to carry electricity make it essential in electronics, solar panels, and medical devices.

- It works well in small parts like wiring and switches, where other metals might not work.

- Silver helps solar panels last longer and perform better.

- If you’re investing, the increasing demand for silver in technology and energy shows it’s a valuable material.

Pure Silver vs. Alloys

Pure silver is soft, so it’s not the best for everyday items. By adding other metals, you get a silver that lasts longer and holds up better. Here are the different types of silver alloys:

Sterling Silver

This is the most popular silver alloy. It’s 92.5% silver and 7.5% other metals, usually copper. Sterling silver is strong and durable, so it is perfect for jewelry, flatware, and other items you want to use regularly.

Coin Silver

Coin silver used to be common in U.S. coins. It’s usually 90% silver and 10% other metals. While it’s not as strong as sterling silver, it’s still used for things like jewelry and decorative pieces.

Mexican Silver

This term refers to silver items made in Mexico. It usually contains at least 92.5% silver, just like sterling silver, and is often used for high-quality jewelry and crafts.

Argentium Silver

This modern alloy contains silver and a small amount of germanium. It resists tarnishing better than sterling silver. It is a good choice for jewelry that you wear frequently.

Comparing the Densities of Silver and Other Metals

You can use the table below to compare silver to some common metals, so you can decide if you really need to use silver.

| Metal | Density (g/cm³) | Description |

| Silver | 10.49 | Silver is fairly dense, making it great for electronics, jewelry, coins, and more. |

| Gold | 19.32 | Gold is almost twice as dense as silver, so it’s heavier and more valuable. |

| Copper | 8.96 | Copper is slightly less dense than silver, used for electrical work and alloys. |

| Aluminum | 2.7 | Aluminum is much lighter than silver, ideal for lightweight designs in aerospace and cars. |

| Iron | 8 | Iron is less dense than silver, but it’s cheap and widely used in construction. |

| Titanium | 4.54 | Titanium is lighter than silver but stronger, used in aerospace and tough applications. |

| Lead | 11 | Lead is slightly denser than silver, but its toxicity limits its use. |

| Stainless Steel | 7.75 – 8.05 | Stainless steel is lighter than silver but strong and resistant to rust, used in buildings and medicine. |

| Platinum | 21.45 | Platinum is denser than gold, making it one of the heaviest precious metals, used in high-end jewelry and chemicals. |

Conclusion

The density of silver is important because it gives certain qualities that make silver useful in different ways. If you’re making jewelry or using silver in industries, knowing its density can help you improve your work.

Understanding how silver compares to other metals lets you meet specific needs for weight, strength, and how the material functions.

FAQs

Is silver more dense than gold?

Gold is denser than silver. With a density of 19.32 g/cm³, it is heavier and more valuable. While silver is less dense, it’s still strong enough for use in coins, cutlery, and some industrial applications.

What is the relative density of silver compared to water?

The relative density of silver is about 10.49, which means it is 10.49 times denser than water. This makes silver stable and consistent for the same volume.

What does one troy ounce mean in silver investing?

One troy ounce equals 31.1035 grams. It’s the standard unit used for silver coins and bars.

Iron is a strong metal that you use in many things, like buildings, machines, and tools. It’s a good choice because it’s tough and easy to shape when heated. If you want to melt or join iron, you need to know the melting point of iron. This helps you heat it the right way and avoid mistakes.

In this guide, you’ll learn why the melting point is important and how you can use it when working with iron.

What is the Melting Point of Iron?

Pure iron melts at about 1,538°C (2,800°F). That’s really hot because the atoms in iron are held together tightly, and it takes a lot of heat to break those bonds.

But the melting point can change a little. If the iron has other materials mixed in, like carbon or other metals, it might melt at a lower or higher temperature. So, always check what kind of iron you’re using.

Melting Points of Different Iron Types

Below is a table where you can see the difference in melting points of different iron types.

| Type of Iron | Iron Melting Point in °C |

| Cast iron | 1150 to 1200°C |

| Wrought iron | 1482 to 1593°C |

| White iron | 1130 to 1350°C |

| Grey iron | 1150 to 1200°C |

| Ductile iron | 1150 to 1200°C |

| Malleable iron | 1170 to 1350°C |

Importance of Knowing Iron Melting Point in Metal Processing

Here’s how the melting point of iron matters in different metal processes:

Casting

When you melt iron to pour it into molds, you need to set the furnace to the right temperature. If it’s too cold, the iron won’t flow well. If it’s too hot, you might damage the mold or the metal. Knowing the melting point helps you melt iron just enough to get smooth, clean castings.

Welding

In welding, you join pieces of iron using heat. If you know the melting point, you can choose the right welding tools and heat settings. This helps you make strong welds without hurting the metal.

Making Alloys

If you’re mixing iron with other metals to make alloys like steel, you need to know when iron melts. This helps you heat it correctly and mix in other elements the right way. A small change in temperature can affect the final mix.

Forging

When you forge iron, you don’t melt it; you heat it until it’s soft enough to shape. This usually happens between 900°C and 1,200°C. That’s below the melting point, but still hot enough to work the metal. If it gets too hot, the iron can become weak or damaged.

Heat Treatment

In heat treatment, you change how iron behaves by heating and cooling it in certain ways. Knowing the melting point tells you how hot you can go without melting it. For example, when you anneal iron, you heat it just below the melting point to make it softer and less stressed.

How Melting Iron Affects Its Properties

Here’s what happens when iron goes from solid to liquid:

- Iron turns from solid to liquid. This is the most obvious change.

- Iron gets bigger in size when it melts. This makes it less dense.

- Liquid iron doesn’t carry heat as well as solid iron. So, heat spreads more slowly.

- Iron also carries electricity poorly in liquid form. It’s not as good as solid iron for electrical use.

- Melted iron flows easily because it’s less thick (low viscosity). This makes it great for casting or molding.

- The way melted iron forms drops and spreads changes. This helps in welding and casting, where smooth flow matters.

- When iron is melted, it loses its strength and stiffness. But when it cools and becomes solid again, it gets those properties back.

- Molten iron reacts more with other elements. It can oxidize or mix with other metals easily, which is useful for making alloys.

Boiling Point of Iron vs. Melting Temperature of Iron

The boiling point of iron is much higher than its melting point; this is the temperature at which liquid iron turns into gas.

So, when you heat iron, it first melts at 1,538°C. If you keep heating it past that, it will eventually boil and become gas at 2,862°C. You usually don’t need to reach the boiling point in normal metal work.

Factors Affecting the Melting Point of Iron

Several things can change the melting point of iron, and here are some of them:

- If iron has impurities like carbon, its melting point can go higher or lower.

- Different forms of iron, like austenite and ferrite, have different melting points.

- More pressure makes iron melt at a higher temperature. Less pressure can make it melt at a lower temperature.

- Adding elements like nickel, chromium or manganese changes the melting point of iron

- The size of iron’s grains can slightly change its melting point because it affects the overall strength of the material.

- The way you heat iron, like through annealing, can change its internal structure, which affects the melting point.

How to Melt Iron

Melting iron is a process with specific steps, and here’s how it works:

- You start by getting raw materials like scrap metal or iron ore.

- Make sure the raw materials are clean and free of any impurities or contaminants.

- Pick the right furnace for the job. You can use a cupola, blast, electric arc, or induction furnace, depending on your needs.

- Put the raw materials into the furnace. Add limestone, coke, or another fluxing agent to help remove impurities.

- Turn on the furnace and heat the materials to about 1,538°C, which is the ideal melting point. Make sure the heat is steady and even.

- Keep an eye on the melting process to make sure the iron turns into a complete liquid. Adjust the temperature and flux as needed to prevent overheating.

- As the iron melts, impurities form a slag on the surface. Remove this slag to keep the molten iron pure.

- Once the iron is fully melted, tap the furnace to pour the molten iron into ladles or molds. Control the flow to prevent splashes.

- Allow the molten iron to cool in the molds or ladles. If needed, you can use controlled cooling or annealing to get the right shape.

- Once cooled, check the iron for quality and consistency. You can also have it tested to make sure it meets the standards.

Applications of Iron Based on Melting Point

Here’s how iron’s physical properties are used in different fields:

Construction and Infrastructure

Iron is needed in making steel, which is used in building bridges, skyscrapers, and railways. Steel is strong and can hold heavy loads. It also handles changes in temperature without breaking down, so it is perfect for long-lasting structures.

Machinery and Manufacturing

Iron is also used in tools and parts for machines because it can handle high heat and pressure without losing its strength. This makes it perfect for heavy equipment, cookware, and molds used in manufacturing. It ensures everything works well in tough conditions.

Automotive Industry

In cars, iron helps with heat resistance. Cast iron is often used for engine parts because it keeps heat well and resists wear. This makes it important for parts like engine blocks and crankshafts, helping cars run smoothly and last longer.

Environmental Applications

Iron’s ability to resist high temperatures also makes it useful in renewable energy. It is used in heat exchangers and solar thermal systems, helping improve energy efficiency and contribute to sustainable energy solutions.

Emerging Technologies and Advanced Materials

Iron-based superalloys are used in parts like turbine blades and aerospace components. These materials can handle extreme heat, which is why they are important in industries where reliability and performance are needed.

How Iron Melting Point Compares to Other Metal Melting Points

You can compare iron’s melting point to other metals to know which one you need to use for your project. Check the table below.

| Metal | Melting Point (°C) | Melting Point (°F) |

| Aluminum | 660.3°C | 1,220.5°F |

| Copper | 1,984°C | 3,623°F |

| Gold | 1,064°C | 1,947°F |

| Silver | 961.8°C | 1,763°F |

| Lead | 327.5°C | 621.5°F |

| Nickel | 1,455°C | 2,651°F |

| Titanium | 1,668°C | 3,034°F |

| Zinc | 419.5°C | 787.1°F |

| Platinum | 1,768°C | 3,214°F |

| Molybdenum | 2,623°C | 4,753°F |

| Tungsten | 3,422°C | 6,192°F |

| Cobalt | 1,495°C | 2,723°F |

| Magnesium | 650°C | 1,202°F |

| Palladium | 1,555°C | 2,831°F |

| Rhodium | 1,964°C | 3,567°F |

Conclusion

You can see that iron melts at a slightly higher temperature than many other metals. That’s why iron alloys also tend to have higher melting points.

At DEK, we’ll help you choose the right metal alloy for your project. Contact us now and get a free quote.

FAQs

What is the melting point of iron in Fahrenheit?

Iron melts at about 2,800°F.

What is the melting point of iron chloride?

There are different types of iron chloride. Iron(II) chloride (FeCl₂) melts about 1,121°F (605°C). Iron(III) chloride (FeCl₃) melts at about 172°F (78°C).

What is the melting point of iron in Kelvin?

Iron melts at about 1,811 K.

Why is melting point of iron so high?

Iron has strong bonds between its atoms. Because of this, you need a lot of heat to break those bonds and turn it from solid to liquid. That’s why the melting point of iron is so high.

If you build or work on cars, you know how important metal parts are. Most of those parts come from flat sheets of metal that are cut, bent, and joined together.

In this guide, I’ll explain what automotive sheet metal fabrication is, how it’s done, and why it matters.

Basics of Sheet Metal Fabrication

You start by picking the right metal based on what you need, such as strength, light weight, or rust resistance.

Then, you cut, bend, and shape the metal. You can use tools like lasers or waterjets for cutting. Bending helps you form it without changing the amount of metal.

Next, you join the parts using welding, rivets, or glue, depending on how strong and neat it needs to be.

Last, you finish it with paint, powder, or planting to make it look better and last longer.

Sheet Metal Fabrication in the Automotive Industry

Cars started with wooden chassis, similar to horse-drawn carriages, but wood couldn’t bend well. The brief history of metal fabrication and its use in automobiles changed when Ford used steel for the 1908 Model T, and Dodge built the first all-steel car body in 1914. This made cars safer and stronger. By the 1970s, aluminum was used for lighter, more fuel-efficient parts.

Today, you still see metal fabrication everywhere in automotive manufacturing. Sheet metal is used for doors, fenders, and hoods because it’s strong and safe. You also rely on metal parts for engine brackets and mounts, which must be made exactly right to keep the car working well.

Thanks to new technologies like hydroforming, car makers can now shape metal into complex designs, helping build cars that are sleek, fast, and efficient.

Types of Sheet Metals Used in Automotive Fabrication

Here are some common metals you’ll use in automotive fabrication:

Aluminum

Aluminum is lightweight and resistant to corrosion. It’s one of the most common metals for car parts because it has a high strength-to-weight ratio. This means your car parts will be lighter, which helps reduce fuel use and lowers the carbon footprint. Even with less weight, the parts will still be strong. You’ll find aluminum in parts like hoods, doors, and fenders.

Stainless Steel

Stainless steel is strong, durable, and looks good. It’s often used for parts like exhaust pipes, body panels, and seat frames.

Cold Rolled Steel

Cold-rolled steel is strong and accurate in size and finish. You’ll use it for parts like door panels, frame rails, brackets, and interior components, such as seat frames and dashboard structures.

Galvanized Sheet

Galvanized steel is coated with zinc to resist corrosion. It’s perfect for car parts like body panels and chassis.

Titanium

Titanium is a strong, corrosion-resistant metal that works well for parts dealing with heavy loads or harsh conditions. It’s also heat-resistant, that is why it is ideal for parts exposed to high temperatures. However, it’s expensive, so you’ll mostly use it for high-end custom parts.

Copper

Copper is great for electrical parts because it has excellent electrical conductivity. It’s also good for parts that need to handle heat, like radiators and heat exchangers.

Magnesium

Magnesium is a lightweight metal with a great strength-to-weight ratio, just like aluminum. It also has good thermal conductivity. You’ll use magnesium in parts like steering wheels, instrument panels, and transmission cases.

Sheet Metal Fabrication Techniques for Automotive Parts

Sheet metal fabrication includes different methods to create parts with unique shapes. Some of these methods are used during the design of car sheet metal parts.

Sheet Metal Cutting Techniques

These methods help cut sheet metal into smaller parts of various sizes:

Laser Cutting

Laser cutting is often used for car parts because it’s very precise. A focused laser beam melts and vaporizes the sheet metal to create a clean cut.

When CNC technology is used, laser cutting becomes even more accurate. This makes it ideal for car parts with complex designs. It’s also compatible with many materials and is commonly used for parts like body panels and engine components.

Plasma Cutting

Plasma cutting uses high-velocity ionized gas (plasma) to melt and blow away the metal, cutting the sheet. It’s great for cutting thick metal sheets, so it’s often used for making car frames.

Shearing

Shearing uses a shearer, which applies a downward force to cut the sheet metal.

Unlike laser and plasma cutting, shearing is less precise, so it’s best for car parts that don’t need tight measurements. Examples include brackets and supports.

Sheet Metal Forming Techniques

Forming techniques like bending and stamping help you shape materials into parts.

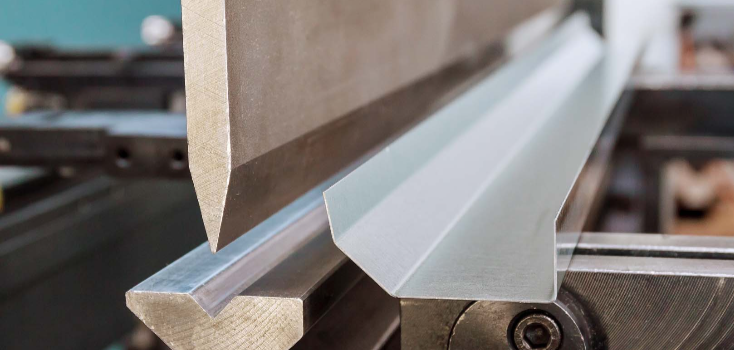

Bending

Bending is a common technique where a press brake machine is used to bend sheet metal into angles and curves. The machine applies force at specific points to form the desired shape. Bending is great for making auto parts like brackets, frames, and doors with complex designs.

Stamping