- Home

- Consumer Products

Consumer Products Manufacturing for Prototyping and Production

DEK has been specializing in the precision manufacturing of electronics parts for 20 years, and we offer high-precision machining services to customers around the world at cost-effective prices, so you can get high-quality electronics products. We can quickly machine complex parts with tight tolerances up to +/- 0.005mm, a wide range of production grade materials, and surface finish options. Get A Quote!

- Instant pricing & DFM

- 24/7 Engineering Support

- ISO 9001:2015 and AS 9100D certified.

- Rapid Tooling and Functional Prototypes

- Quick Turn, Short Lead Time, not MOQ and Low TCO.

Accelerating Development for the Consumer Products Industry

DEK offers fast and efficient rapid prototyping solutions for a wide range of industries, including consumer electronics, personal and home goods, toy prototypes, sports equipment, and communication products. From early prototype design to final production, we focus on customer needs to deliver consumer products that meet both functional and aesthetic requirements.

We offer a wide range of high-quality materials, including aluminum, stainless steel, ABS, PC, elastomers, and more. Additionally, we provide surface treatments such as anodizing, passivation, electroplating, polishing, and powder coating. Our CNC machining, injection molding, and 3D printing technologies enable us to produce stylish, durable, and precision components, accelerating the time-to-market for innovative consumer products.

Our typical application cases include: custom fixturing, custom tooling, jigs, brackets, and chassis for manufacturing, electronic devices, enclosures, wearable devices, and smart home products. We adhere to industry standard processes and certifications to ensure product quality, and can provide CMM inspection reports, FAI reports, material certificates, and PPAP inspection reports.

Tattoo Pen Machine Motor Housing

Laser Scanner Head Galvanometer

Electronic Laser Pointer Pen

Consumer Products Manufacturing Capabilities

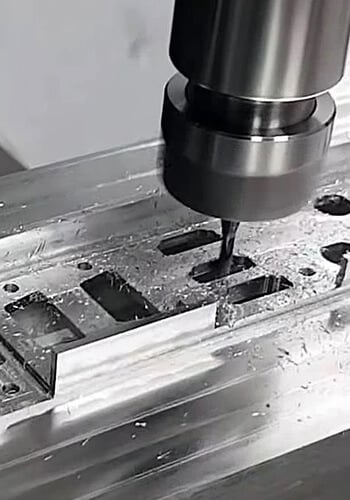

Precision CNC Machining

DEK provides fast, accurate, and reliable CNC precision machining with strict tolerances of ±0.005mm, ideal for precision electronic products, wearable devices, and smart home devices.

We specialize in precision metal casing machining for consumer electronics and excel at 5-axis machining of complex parts. We offer fast CNC prototyping services and free DFM analysis to reduce costs, with prototypes delivered in 3-5 days, and cost-efficient machined parts at higher volumes.

Sheet Metal Fabrication

At DEK, we offer six types of sheet metal materials, including aluminum, stainless steel, steel, brass, and copper. From instant quotes to rapid production, you can obtain more than 300 high-quality sheet metal parts in just a few days.

In addition, we can also provide a range of surface treatments, such as bead blasting, electroplating, powder coating, and screen printing, to meet the functional and aesthetic requirements of consumer products.

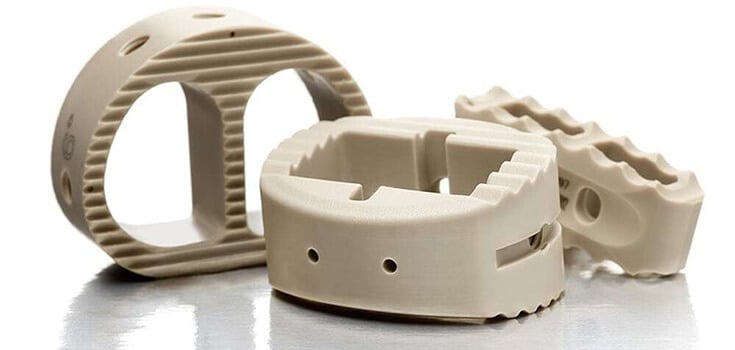

Injection Molding

At DEK, we rapidly produce high-quality molded parts and bridge toolings, ensuring repeatability for each part and maintaining consistent quality optimization for mass production.

Our injection molding process enables screw threads, snap-fits, thin walls, and other assembly-free designs, making it ideal for both small and large production runs. There is no minimum order quantity, and we offer 30 types of plastic, elastomer, and silicone rubber materials.

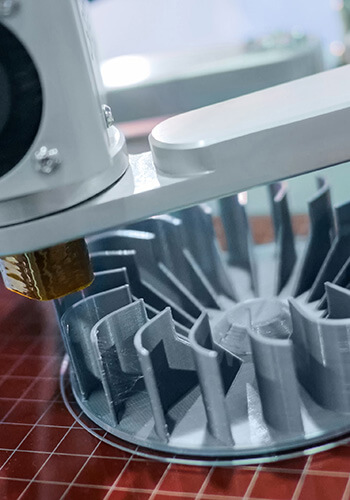

3D Printing

DEK offers high-quality additive manufacturing technologies including metal 3D printing, SLA, SLS, and FDM. We help you create low-cost prototypes of consumer products and produce high-precision, consistent parts.

We offer more than 20 types of metals and plastics, including aluminum, stainless steel, nylon, ABS, TPU, PP, and resin. In addition, we can also provide surface treatments required for your project.

Materials

Materials Options

Aluminum

At DEK, we specialize in machining aluminum alloys through sheet metal fabrication to manufacture electronic equipment housings, brackets, or metal parts that require lightweight, high strength, and high-end texture.

ABS

ABS is a thermoplastic material with high impact resistance and good surface treatment properties, widely used in the consumer electronics industry. It is the material of choice for handheld devices and router housings, offering low cost and excellent processing performance.

Polycarbonate

This high-performance thermoplastic combines excellent mechanical strength and impact resistance with low shrinkage characteristics and outstanding dimensional stability. Its transparency offers a range of optical-grade transparency options, making it an ideal material choice for manufacturing transparent protective covers and housings.

PEEK

This high-performance engineering plastic is renowned for its excellent strength-to-weight ratio, high temperature resistance, and dimensional stability. It is a unique-looking material that offers a range of options from natural colors to custom black, making it ideal for use in lightweight frames and sturdy casings for high-end electronic devices.

Instant & Accurate Quotes

We don't use online automated quotation tools, because it is very inaccurate. Online quote platforms rely solely on calculations based on cutting amounts and fixed coefficients, they fail to account for actual processing nuances, such as material deformation after heat treatment, tight tolerance requirements, grinding after heat treatment, etc. Consequently, automated price calculations can lead to inaccuracies, ultimately increasing your costs.

But you can rest assured at DEK!

Our quotations are both cost-effective and accurate because we have a team of professional mechanical engineers who meticulously review each drawing. These engineers boast over 10 years of experience and possess deep expertise in programming, machine operation, post-processing, material properties, and more. Ensure you will get accurate quotes within 6 hours.

Why Choose Our Services

One-stop production of high-quality parts saves you time and money.

Engineering Capabilities

Fast Lead Time

Quality Control

Surface Finishes

Precision Assembly

Packaging and Logistics

Our Ordering Process

Send RFQ

Send RFQ with 2D/3D drawings and detailed requirements via Email or online form.

Review & Quote

Our Engineer team will review every drawing carefully and provide an accurate quote within 6 hours.

Confirm Order

Confirm the quote, details and delivery schedule, then sign the contract.

Production

Arrange production process, start programming and machining.

Quality Control

Strict quality control during production and final inspection.

Packaging & Shipping

Pack the parts, attach part identification labels, and start shipping.