When you work with CNC machines, it is important to know the difference between 3-axis, 4-axis, and 5-axis CNC Milling. Each one moves in its own way and is made for different types of jobs.

In this guide, I’ll explain how each machine works, what it can do, and where it’s best to use it. If you’re trying to choose between 3 axis vs 4 axis vs 5 axis CNC milling, this simple guide will help you make the right choice.

What is 3-axis CNC Milling?

3-axis CNC milling is the simplest and most common type of CNC machining. You can use it to make simple shapes, holes, and flat surfaces. You’ll find it useful for projects that don’t require complicated angles or details. It is reliable, easy to run, and handles most basic jobs without a problem.

How 3-axis CNC Milling Works?

In 3-axis CNC milling, the cutting tool moves in three directions: left to right (X), front to back (Y), and up and down (Z). The part stays in one position while the tool moves to cut, drill, or shape it. You can use this method on many different types of parts and for everyday machining.

Capabilities of 3-axis CNC Milling

3-axis CNC machines are usually used for simple jobs, like:

2D and 2.5D machining: Good for pieces needing work on one or two sides.

Accurate cutting: Holds tight tolerances and makes clean and smooth cuts.

Versatility: Works with plastic, aluminum, steel, and other materials.

Lower cost: More affordable than 4-axis and 5-axis CNC.

Limitations of 3-axis CNC Milling

Here are a few limits of using 3-axis CNC:

Limited access: It’s harder to machine complex shapes or parts with multiple sides.

Undercuts: It’s hard to machine areas or parts you can’t see or reach from above the part.

More setups: Complex parts need multiple setups, which can slow down production.

Tool interference: Longer tools might be needed for deep areas, which can reduce accuracy.

Applications of 3-axis CNC Milling

3-axis CNC is useful for many everyday jobs, like:

Prototyping: Making test parts quickly with lower costs.

Flat parts: Perfect for parts with flat surfaces that don’t need work on every side.

Simple to moderately complex shapes: Handles most common parts without extra setups.

Small to medium batch production: Good for producing multiple parts while keeping costs down.

Learning and Practice: Good for beginners to learn CNC programming and the machining setup.

What is 4-axis CNC Milling?

4-axis CNC milling is like an upgraded version of a 3-axis machine with one extra movement. You can use it for more complicated parts and get better results on jobs that need work on different sides. It’s a good choice when you need more flexibility and faster setups for certain projects.

How 4-axis CNC Milling Works?

In a 4-axis CNC milling, the three directions X, Y, and Z are still the same as 3-axis, with one additional movement, which allows the part to rotate, and it is called the A-axis. This extra movement lets you work on different sides of the part without stopping to reset it.

The machine usually rotates the part in one of two ways:

Rotary Table: the part sits on a table that turns

Indexing Head: the part is held in a spindle that rotates to set positions

This makes it faster and easier to machine parts with multiple sides with better precision and fewer setups.

Capabilities of 4-axis CNC Milling

A 4-axis CNC milling gives you more options and makes certain jobs easier. Here’s what you can do with it:

Machine multiple sides: Work on multiple sides of a part in one setup.

Save setup time: No need to stop and move the part manually as often.

Better surface finish: The rotating A-axis helps the tool cut smoothly on curved or angled surfaces.

Efficiency: Handles complex parts faster by cutting from different angles.

Accuracy: Reduces mistakes from moving the part between setups.

Limitations of 4-axis CNC Milling

4-axis CNC milling has an advantage over 3-axis CNC milling, but it also has limitations. Here are a few:

Limited undercut capabilities: Some hidden areas are hard to reach, especially shapes with complex geometries.

More complex programming: You’ll need extra skills to program 4-axis jobs compared to 3-axis.

Higher cost: It costs more to buy and maintain to have a 4-axis machine.

Applications of 4-axis CNC Milling

You can use a 4-axis CNC milling for many types of parts, especially shapes with more than one side.

Cylindrical parts: Great for cutting round or tube-shaped parts.

Multi-sided parts: Makes it easy to work on different sides in one setup.

Spiral shapes: Perfect for grooves, threads, and other helical features.

Complex shapes: Handles detailed parts that are tough for a 3-axis machine.

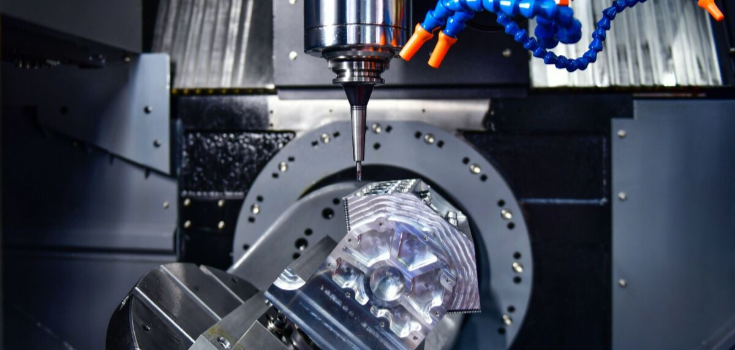

What is 5-axis CNC Milling?

5-axis CNC milling is the most advanced type of CNC machining. It’s used for highly complex, detailed, and precise parts that can’t be handled easily by 3-axis and 4-axis machines. It moves in three straight directions, the same as 3-axis and 4-axis, but with two extra axes.

If you want to learn about the production data set for 5-axis CNC milling, you can check this article: Production Data Set for 5-axis CNC Milling with Multiple Changeovers

How 5-axis CNC Milling Works?

In a 5-axis CNC milling, the cutting tool and the part can be moved and tilted at different angles. This is done using a mix of straight and rotating movements.

- X, Y, and Z axes move the tool in three directions

- A-axis or B-axis tilts the part or tool

- C-axis rotates around the part

This setup lets you reach the part from almost any angle, so it is possible to machine complex shapes in just one setup without stopping to reposition the part.

Types of 5-axis Machines

There are two main types of 5-axis CNC machines you’ll work with:

3+2 axis machines (also called 5-axis positional)

You can tilt and turn the part or tool to the angle you need, then it locks in place while cutting. The machine moves in three directions at a time. It’s great for parts that need work from different sides but don’t need the tool moving in all five directions while cutting.

Simultaneous 5-axis machines

This type moves in all five directions at a time while cutting. It’s ideal for very complex shapes, like curved or rounded surfaces. If you need the highest accuracy and want to machine complicated parts in one go, this is the right machine for the job.

Capabilities of 5-axis CNC Milling

Here’s what a 5-axis machine can do:

Make complex shapes: Easily machine detailed, curved, and complicated parts.

Finish parts in one setup: Cut all sides without stopping to reset, saving time and improving accuracy.

Get better surface finishes: Keep the cutting tool at the best angle for smoother surfaces.

Protect your tools: The right tool position means less wear and lets you use shorter, stronger tools.

Easily machine undercuts: Reach deep pockets and hidden areas without trouble.

Limitations of 5-axis CNC Milling

Even though 5-axis CNC machines have a lot of advantages, there are also a few limitations to consider:

Expensive: 5-axis CNC machines cost a lot more than 3-axis and 4-axis machines.

More complex to use: You’ll need advanced programming skills and extra time to learn how to use them.

Higher maintenance: These machines need more care and can be costly to fix.

Not needed for simple parts: For basic shapes, a 5-axis machine might be too much and not worth the extra cost.

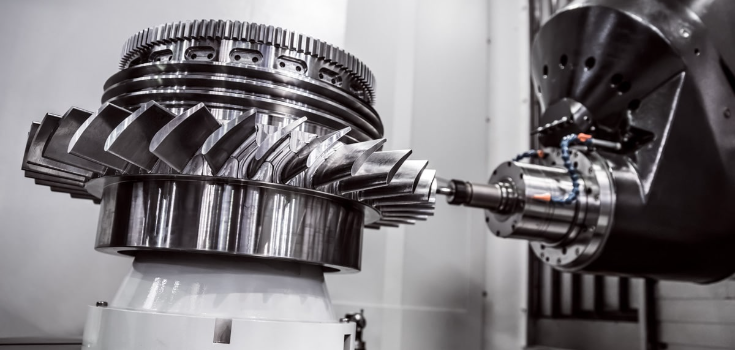

Applications of 5-axis CNC Milling

You can use 5-axis CNC machines for many advanced and detailed jobs, like:

Aerospace parts: Making turbine blades, impellers, and other complex shapes.

Medical tools and implants: Such as dental parts and surgical tools.

Molds and dies: For parts with small details and complicated shapes.

Car engine parts: Like engine blocks, cylinder heads, and custom pieces.

Energy equipment: Including pump parts and turbine pieces.

Art and decorations: For carvings, sculptures, and other creative designs.

What are the Differences Between 3 Axis vs 4 Axis vs 5 axis CNC Milling?

The biggest difference between 3 axis vs 4 axis vs 5-axis CNC is how they move while cutting a part.

A 3-axis machine moves the cutting tool in three directions: up and down, left to right, and front to back. The tool stays in one position while cutting.

A 4-axis machine adds one more movement. It can rotate the part around one axis, making it easier to cut different sides without removing and resetting the part.

A 5-axis machine adds two rotations. This lets you tilt and run the part or the tool to reach deep angles, making it perfect for detailed and complex shapes.

The more axes you have, the more complex shapes you can create. But remember - more movement also means higher cost, and requires more advanced skill.

Comparison Table

Here’s a simple breakdown to help you choose which one is the best fit for your work:

| Feature | 3-axis CNC | 4-axis CNC | 5-axis CNC |

| Movement Directions | X, Y, Z (3 directions) | X, Y, Z + 1 rotation | X, Y, Z + 2 rotations |

| Part Complexity | Simple parts | Medium complexity | Very complex, tight angles |

| Positioning | Limited, needs repositioning | Better, rotates part on one axis | Excellent, works from almost any angle |

| Programming | Easiest | Moderate | More complex |

| Machining Speed | Slowest | Faster than 3-axis | Fastest |

| Operator Skill | Basic skills | Intermediate | Advanced |

| Customization | Limited | Good | Excellent |

| Material Handling | Hard on tools for tough materials | Better than 3-axis | Easiest on tough materials |

| Tool Life | Shorter, more breakage | Improved | Best, shortest tools, less breakage |

| Tool Collisions | Low risk | Moderate risk | Higher risk without careful programming |

| Surface Finish | May need extra finishing | Smoother | Best surface finish |

| Accuracy | Multiple setups can cause small errors | Fewer setups, fewer errors | Most accurate in a single setup |

How to Choose Between 3-axis, 4-axis, and 5-axis Milling Machines?

Choosing the right machine is easier when you know what to look for. Here are the things you should consider:

Cost

If you’re on a budget, 3 axis vs 5 axis milling, go with a 3-axis machine because it’s the most affordable. Otherwise, choose a 5-axis machine if really needed and you have the budget.

Application

Some jobs need very high precision that can be best made with a 5-axis machine.

Part Shape

If your part is simple, 3-axis milling will work for you and save you money. But for more complicated parts and shapes, you’ll need 4-axis or 5-axis machines to avoid mistakes.

Machining Process

If you already have a CNC machine, your options might be limited by what it can do. For example, vertical milling is usually capable of 3-axis movement only. A milling machine with a rotary table is a 4-axis machine. Some machines are built with 5-axis movement from the start. If you’re considering a machine upgrade, this article about a Decision-making Tool for Moving from 3-axis to 5-axis CNC Machine Tool can help you decide.

Production Volume

For small batches, the 3-axis machine works fine. If you need to produce more parts quickly, 4-axis or 5-axis machines can handle the work faster and more efficiently

Precision and Surface Finish

3 axis vs 5 axis milling, the latter lets you machine all sides in just one go, reducing errors and giving a smoother finish. With 3-axis, you may need to repeat the process and make extra setups, which can cause mistakes and take more time.

Start your CNC Milling Project with DEK

Start your CNC milling project with DEK’s trusted expertise and advanced technology. We offer a wide range of 3-axis, 4-axis, and 5-axis CNC milling services, handling everything from simple cuts to complex, high-precision parts.

No matter your industry or production size, we’ll customize our solutions to match your exact needs. Contact us today and let’s bring your designs to life.

Conclusion

To sum it up, choosing between 3 axis vs 4 axis vs 5 axis CNC milling depends on your project’s shape, detail, and budget. Understanding their differences will help you choose the most appropriate, cost-effective machining process for your project.