Zinc plating vs nickel plating are two essential techniques used in the metal finishing process. While both offer amazing, unique features and benefits, understanding how they both work is important to making your choice.

In this guide, you will get to understand the difference between the two, their pros and cons, applications, and lots more.

What is Zinc Plating?

Zinc plating is a metal material finishing process that involves coating the surface of a metal with a zinc layer to prevent the metal from wear and tear and corrosion, and also improves its final appearance.

Beyond the fact that the process is cheaper and highly reliable, it is also a great option for manufacturing purposes when durability is essential.

How Zinc Plating Works?

Zinc electroplating involves some steps you should know. Here they are:

Metal Surface Preparation

The first step is to clean up the metal material in preparation for the actual zinc plating process. As such, you would need to degrease or descale the material to remove all unwanted surrounding particles, coating, or grease within.

Activation

Next, the cleaned metal surface is then placed in an acidic solution to get it activated. With this, a receptive surface is formed to allow for zinc plating.

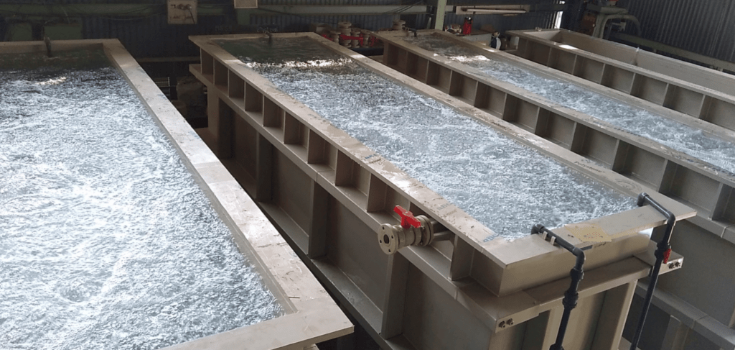

Electroplating

Now, you would immerse the metal material in a zinc-based electrolyte solution, which is the plating bath. Once that is done, an electric current will be applied. This makes the zinc ion present in the solution be reduced and deposited on the metal surface.

Passivation

In this step, you would treat the zinc-plated material with a chromate to improve the metal's resistance to corrosion. Going through the passivation process, however, depends on the application, as it might not be necessary.

Cleaning and Drying

Lastly, you would rinse the zinc-plated material to eliminate any residual substance within before drying it up.

Features of Zinc Plating

In this section, let’s discuss the main reasons why it is best to use zinc plating on your project:

Cost Effectiveness

Zinc plating is quite cheaper than many other popular techniques, and this makes it highly favored by different industries and experts.

Electrical Conductivity

Zinc plating allows for great electrical conductivity, so it is applicable in situations where electric current flow is vital.

Corrosion Resistance

Zinc has great resistance against corrosion, and this makes it act as a protective agent for the underlying metal. Through zinc plating, many metal materials are protected against corrosive environmental factors like moisture and chemicals.

Galvanic Compatibility

Also, zinc plating is possible with several varieties of metals. These metals, together with zinc, create a galvanic couple that provides resistance against corrosion.

Aesthetics

Zinc plating also provides an attractive finishing appearance, thereby enhancing the appearance of the metal.

Pros and Cons of Zinc Plating

Pros

- It is applicable for use in several industries, including automotive, household appliances, etc.

- It is cheaper and readily available.

- Zinc plating also provides strong protection against corrosion. This, in turn, improves the metal object's lifespan.

- Maintenance of zinc-plated material is quite easy, as it only requires more zinc application.

- Zinc plating is applicable for use with different metals like steel, iron, etc.

Cons

- Zinc plating might not be applicable if the metallic material comes into contact with other moving parts, as it could cause friction.

- Large-scale zinc plating processes can be quite expensive.

What is Nickel Plating?

Nickel plating is a metal finishing process that involves coating metal surfaces with nickel to improve the durability, functionality, resistance to wear, and enhance its final appearance.

How Nickel Plating Works?

Here are the steps involved in nickel plating:

Surface Preparation

The first step is to clean the metal in preparation for the actual zinc plating process. You would need to degrease and descale the metal surface a needed.

Activation

Next is to get the metal object activated by submerging it in an acidic or alkaline solution to allow for nickel deposition.

Electroplating

Now, you would also immerse the surface in a nickel-based electrolyte solution, which would serve as a plating bath.

Following that, an electric current will be applied. This makes the nickel ion present in the solution be reduced and deposited on the metal surface.

Brightening

Depending on your specific requirements, you might include a brightening process in the nickel plating. As such, you will apply a brightening agent to the plating bath. This would give it a shinier, smoother, mirror-like finish.

Cleaning and Drying

Finally, you would clean the plated material to remove any excess chemicals and then dry it.

Features of Nickel Plating

Another surface finishing that you may consider using on your project is nickel plating, and here are the main reasons why:

Wear Resistance

Nickel plating offers metal materials great hardness and high resistance to wear. This makes it applicable for use in industries where durability is important.

Corrosion resistance

Nickel plating also acts as a protective shield for the coated metal, as it prevents it from corrosion.

Aesthetics

Nickel plating provides an attractive, sleek surface finish to metals, which makes them suitable for applications where aesthetics and visual appeal are crucial.

Thermal Conductivity

Nickel plating allows for great thermal conductivity. Nickel can withstand high temperatures, making it suitable for applications where moving components and friction are involved.

Electrical Conductivity

It also offers great electrical conductivity, which makes it ideal to use in applications where electric current is involved.

Pros and Cons of Nickel Plating

Pros

- Nickel plating offers great hardness and resistance to wear, and as such, it is useful in applications requiring durability.

- It also offers a sleek, shiny finish, making it suitable for aesthetics.

- It is also a good conductor of electricity and can therefore be used when electrical components are involved.

- It forms one of the cheapest techniques to provide resistance to corrosion features to other metals.

- Its ability to withstand high temperatures makes it suitable to use when friction and moving parts are involved.

- Nickel-plated material requires little to no maintenance due to its high durability.

- Nickel plating can also be used on many metals like copper, brass, steel etc.

Cons

- Nickel may be irritating to some people, especially if there's direct contact with it.

- It isn’t environmentally friendly like zinc, and thus every waste generated from it must be disposed of properly.

Zinc Plating vs Nickel Plating: Differences Comparison

Below are some key differences between zinc and nickel plating:

Corrosion Resistance

Zinc is considered a sacrificial material because of its intense ability to protect the coated metal from corrosion.

It can prevent the underlying metal from environmental factors like moisture and chemicals. While nickel plating also offers resistance against corrosion, it doesn’t provide long-term protection like zinc.

Hardness and Wear Resistance

Nickel plating is widely recognized for its hardness and wear resistance, which is why it is suitable for applications where durability and longevity are essential.

The nickel plating protects the coated material from physical wear, ensuring that it maintains its functionality for a long period.

Zinc plating, though, also has a wear resistance feature, but not as compared to nickel plating. As such, there could be some wear and tear, especially in applications involving moving parts and friction.

Aesthetic Appeal

While zinc and nickel plating provide an attractive finish, nickel plating offers a brighter, sleek finish, making it suitable for aesthetic purposes. Although zinc plating also offers a good metallic look, it might not be applicable where a shiny finish is required.

Electrical Conductivity

Both zinc and nickel plating offer good electrical conductivity, making them suitable for applications involving electrical components. However, nickel offers a higher electrical conductivity.

Environmental Impact

Zinc is a naturally occurring and environmentally friendly material. Nickel, on the other hand, generates some harmful waste that must be disposed of properly.

Cost and Energy Efficiency

In terms of the cost of the materials and energy consumption, zinc plating is generally cheaper and thus suitable to use when the budget is tight. Nickel plating is quite more expensive in terms of the material and the rate of energy consumption.

Plating Flexibility

In terms of flexibility, nickel offers more flexibility features considering its thickness and volume when compared to zinc.

Ductility

Zinc plating generally gives more ductility than nickel plating. It can be bent or shaped without fracture. Although nickel plating offers the same feature, it is not as effective as zinc.

Contrast Table

| Features | Zinc Plating | Nickel Plating |

| Electrical Conductivity | Moderate | High |

| Corrosion resistance | Excellent | Good |

| Ductility | High | Moderate |

| Aesthetics | Matte/Dull Finish | Shiny Sleek Finish |

| Environmental Impact | Highly Sustainable | Less Sustainable |

| Cost Effectiveness | More cheaper | More expensive |

| Hardness and Wear resistance | Moderate | High |

Zinc Plating vs Nickel Plating: Applications in Different Industries

Zinc and nickel plating are valuable in many industries due to the specific properties they offer.

Zinc Plating in the Automotive Industry

Fasteners

Zinc plating is used for bolts and nuts, which are valuable in the automotive industry. Zinc plating provides corrosion resistance that ensures the longevity of these parts.

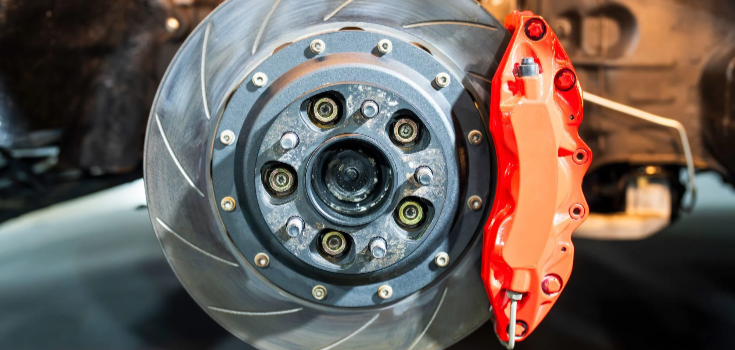

Brake

Brake components like calipers go through zinc plating to protect against corrosion.

Nickel Plating in the Aerospace Industry

Turbines blades

Turbine blades also go through nickel plating to provide wear resistance and withstand high temperatures in jet engines.

Landing gear

Gear components are also plated to protect against abrasion in order to provide the necessary safety during takeoff.

Engine Parts

Engine parts like shafts are also nickel-plated to protect against wear and improve durability and longevity.

Zinc vs Nickel Plating in the Construction Industry

Zinc Plating

Outdoor Structures

Zinc plating is also used in outdoor structures like railings and gates since it protects them from harsh weather conditions.

Marine Environments

They are also used in marine construction as they offer protection against saltwater, protecting components from corrosion.

Fasteners

Building components like screws and nails are also zinc-plated to protect them from environmental conditions like moisture.

Nickel Plating

Interior Fittings

Nickel plating is used for indoor fixtures like light and door fixtures since it gives visual appeal and wear resistance to the components.

Decorative elements

Since nickel plating offers better aesthetics, they are used for decorating interior designs and components.

Hydraulic Systems

Hydraulic systems and other heavy machinery are nickel-plated for durability and wear resistance.

Zinc Plating vs Nickel Plating: How to Choose?

Zinc and nickel plating offer unique features and benefits, which must be put into consideration when choosing between the two. Considering your specific project needs is another point to look out for. Here are some points to consider when making your decision.

- Since zinc has a high corrosion resistance ability, it’ll be the best if your application involves protecting the coated metal against environmental factors.

- If you require material plating that is suitable for moving parts, high friction components, and wear resistance capacity, nickel plating is the best.

- Nickel plating also offers a shiny, mirror-like finish, which makes it suitable for aesthetic purposes. So it’s best if visual appeal is vital.

- Since nickel plating conducts heat and electricity better, it's best for components involving electricity.

- Zinc, on the other hand, is cheaper and highly sustainable, and so it’s the best choice when you’re on a budget and when environmental sustainability is crucial.

Conclusion

Deciding whether to choose between zinc plating vs nickel plating involves considering their features, pros and cons, and how they align with your specific application.

At DEK, we specialize in manufacturing different kinds of metal and providing them with the final finishing looks that suit your needs. If you’re contemplating the metal finishing to use, we have expert teams that are always available to help.

FAQs

Which is better nickel or zinc plating?

While zinc plating offers high corrosion resistance, relatively cheaper, and highly sustainable, nickel plating provides resistance against wear, high durability, thermal and electrical conductivity, and very attractive finishing.

Deciding on which is better thus depends on your specific project requirements and application.

What’s the difference between electroless nickel plating vs zinc plating?

The difference between electroless nickel plating and zinc plating is that in zinc plating, an electric current is applied to deposit zinc on the metal surface to be plated, whereas in electroless nickel plating, the deposition of nickel onto the metal surface involves chemical reactions.

What is zinc nickel plating?

Zinc-nickel plating is a metal finishing process that involves coating the surface of a metal with zinc-nickel alloy to provide high durability, corrosion resistance, and wear resistance, and enhance the final look of the metal.