One of the most pliable synthetic materials available today is Teflon because of its special easy-release and chemical-resistant qualities. It has become an essential component of a variety of industries, including aircraft and cookware.

Although you may think of it as the coating on your skillet, there are many more uses for it. In this blog, you will discover what Teflon is, how it is made, and why it costs so much in different industries.

What is Teflon?

Teflon is an artificial polymer made from tetrafluoroethylene monomers. Chemically, it belongs to the family of fluoropolymers, represented by powerful carbon-fluorine bonds. These types of bonds give Teflon maximum stability and chemical inertness.

It does not react with most kinds of chemicals and is very stable even under extreme heat or very low temperatures. This unique combination of strength and slipperiness made Teflon widely used across various industries.

Composition and How It’s Made

The manufacturing process for Teflon is also known as polymerization. Tetrafluoroethylene gas is converted into solid PTFE resin for high-pressure conditions in a controlled environment. Once produced, the resin is available for compression molding, extrusion, and surface coating.

In cookware, for example, metal surfaces are roughened to improve the adhesion of the Teflon coating. Several layers of PTFE are applied and baked at high temperatures to produce an exceptionally strong, smooth, and extremely durable nonstick surface.

Properties and Characteristics

Teflon’s popularity depends on its fusion of unique physical, mechanical, electrical, and chemical properties. The following are tables and insights for each category in depth..

Physical Properties

| Property | Value | Description |

| Density | 2.1–2.3 g/cm³ | Very Lightweight and Durable. |

| Melting Point | 327°C (620°F) | High Temperature Resistance. |

| Water Absorption | <0.01% | Extremely low moisture absorption |

| Color | White | Can be modified with fillers |

Mechanical Properties

| Property | Value | Description |

| Tensile Strength | 20–35 MPa | Moderate strength. |

| Elongation at Break | 200–400% | Excellent flexibility. |

| Hardness | Shore D 50–65 | soft yet resilient. |

| Coefficient of Friction | 0.05–0.10 | Very low-friction surface. |

Electrical Properties

| Property | Value | Description |

| Dielectric Strength | 60–100 kV/mm | Excellent Heat Insulation. |

| Volume Resistivity | >10¹⁸ Ω·cm | Highly resistant to electricity. |

| Dielectric Constant | 2 | Stable in All Frequencies. |

| Dissipation Factor | 0.0002 | Low electrical loss. |

Chemical Properties

| Property | Value | Description |

| Chemical Resistance | Excellent | Resistant to most acids, bases, and solvents. |

| Flammability | Non-flammable | Non-flammable. |

| Weather Resistance | High | Resistant to sunlight and moisture. |

| UV Resistance | Excellent | Keeps stables even under open-air conditions |

Optical Properties

Teflon has very low light transmission because of its dense structure. It has high light reflectivity. Hence, it is used in applications where optical clarity has to be overcome with durability, such as insulation or coating materials.

Types Of Teflon

Pure PTFE

The purest form of PTFE gives maximum resistance against chemicals and thermal stability, which is used for gaskets, seals, or electrical insulations.

In addition, pure PTFE has extreme temperature resistance, from cryogenic to above 260°C. Its non-stick and non-reactive properties make it an excellent candidate for the laboratory, piping, and lining systems that would be used in a highly corrosive environment.

Glass-Filled PTFE

Glass fibers improve strength, decrease deformation, and increase wear resistance. It is used mainly in valve seats and compressor parts.

This variety of Teflon also contributes to dimensional stability and excellent choice for applications subjected to high mechanical stress. It maintains PTFE’s low-friction features while offering good load-bearing capacity. It can be very beneficial in hydraulic and pneumatic applications.

Granular PTFE

Granular PTFE is produced through suspension polymerization of TFE. It is suitable for compression molding and machining into rods, sheets, or tubes.

This form of Teflon is popular in industries that need heavy-duty, precision-engineered parts. Due to its heavy structure, it can survive high pressures and maintain its properties even after prolonged exposure to heat and chemicals.

Fine Powder PTFE

Fine Powder PTFE is used in paste extrusion to form tubing or wire coatings that have very good flexibility and a smooth surface finish..

Fine powder PTFE provides maximum strength and stability with respect to the end product. It is often chosen for applications in the electrical and medical industries to confirm uniform thickness and immaculate insulation.

Micro Powder PTFE

Lubricants and coatings produce micro powders. They reduce friction and wear for any mechanical component.

Micro Powder PTFE enhances the performance characteristics of the paint and coating products by improving their durability and reducing surface energy. It is widely used in automotive and aerospace components where smooth and wear-resistant finishes are a must.

Dispersion PTFE

This liquid form is used for coating applications and presents even coverage on metal or glass surfaces.

Dispersion PTFE is valuable, particularly for making non-stick coatings for cookware, industrial rollers, and fabric filters. It has excellent adhesion and uniformity, ensuring that these surfaces retain their high heat, chemical, and moisture resistance over time.

Film PTFE

Thin sheets or films of PTFE are used in electronics and packaging due to their insulating and chemical-resistant properties.

These films are also used as barrier layers for solar panels, batteries, and flexible printed circuits. Their transparency, toughness, and resistance to harsh environments make them paramount in advanced manufacturing and cleanroom conditions.

Expanded PTFE

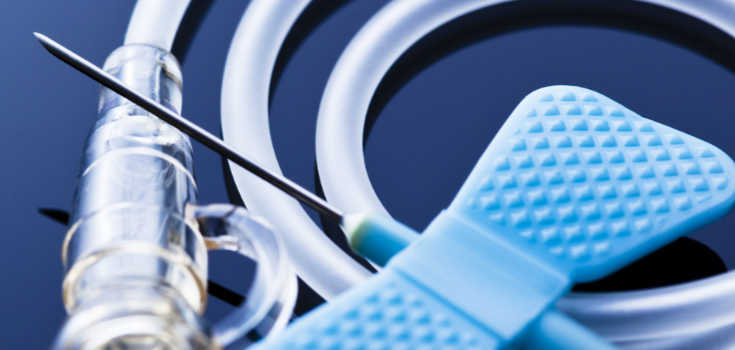

Expanded PTFE (ePTFE), a porous version, is also flexible and breathable. It has high applications in filtration and medical implants.

The microporous structure of this material allows gases and water vapor to have free passage, while liquids are blocked. This property makes it invaluable for breathable membranes, venting applications, and biocompatible medical devices.

Etch Teflon

Etch Teflon is chemically treated to promote adhesive bonding to composite structures and laminations.

Its treated surface guarantees a strong bond with metals, rubbers, and plastics, making it a perfect candidate for complex engineering assemblies. This is particularly important in aerospace, automotive, and electronic industries where adhesion and durability are critical.

Advantages Of Teflon

Teflon, or PTFE, has several benefits that make it widely regarded as a potential candidate in different industrial, electrical, and consumer applications. The following points summarize the main benefits in detail.

Nonstick Properties

The most familiar advantage of Teflon is that it has exceptionally nonstick characteristics. Its surface is not able to attract adhesion from different materials such as food, chemicals, and resins. That clearly believes in easy cleaning and maintenance.

This is particularly applicable to cookware, baking trays, and industrial molds by allowing smooth detachment with less residue.

High-Temperature Resistance

Teflon does not lose its properties even at extreme heat. It has a melting point of about 327°C (621°F) and a continuous service capability up to 260°C (500°F). It remains stable without deformation and degradation.

This makes it suitable for heat-intensive environments such as ovens, chemical reactors, and electrical components operating under thermal stress.

Chemical Inertness

One of the strongest and most outstanding properties of Teflon is its resistance to all types of chemical reactions. It is not affected by acids, alkalis, or solvents, ensuring durability even in the extremely corrosive conditions.

This property makes it significant in chemical processing, storage tanks, as well as laboratory equipment handling very aggressive chemicals.

Low Friction Coefficient

PTFE is reputed for one of the lowest friction coefficients among solid materials. Coatings with Teflon allow flat surfaces to move smoothly against each other with much reduced wear and energy losses.

Such components as bearings, gears, and valve seals benefit from this property, making mechanical operation more efficient.

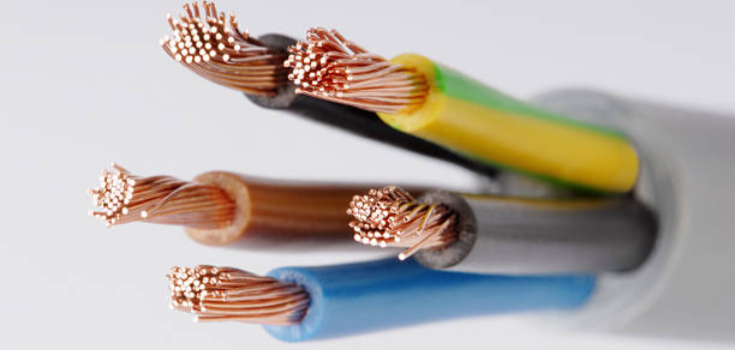

Excellent Electrical Insulation

Teflon is an excellent insulator of electricity. It shows great dielectric strength with low dissipation and stability at high temperatures.

Due to its properties, it is used in insulating wires, cables, and electronic connectors with an expected safe and reliable transmission of power in their important systems.

Weather and UV Resistance

Teflon survives damage produced by sunlight, moisture, and environmental exposure. The materials do not become brittle after being exposed to sunlight, making them ideal for outdoor applications.

Building coatings, parts for aerospace, and outside wiring depend heavily upon PTFE's long-lasting stability when exposed to harsh weather over time.

Mechanical Strength and Durability

Despite being lightweight, Teflon provides outstanding durability. It survives abrasion and mechanical stress, securing long service life even in demanding industrial environments. Its capability to maintain shape and performance over time decreases maintenance costs and downtime.

Compatibility With Other Materials

Teflon has a very good affinity for metals, plastics, ceramics, and elastomers. It is used to coat surfaces, as a liner, composite layer, improving performance and protection on that surface.

This flexibility allows it to be used in a wide variety of applications, from food processing to semiconductor manufacturing.

Moisture and Water Repellence

This is another advantage of Teflon, which is hydrophobic in nature, repels water and most liquids. Thus, it prevents corrosion, contamination, and accumulation of moisture. It is especially useful in pipelines, valves, and surface coatings exposed to humid or wet environments.

Longevity and Low Maintenance

Most Teflon-coated or Teflon-based components have a longer lifespan of operation. Such maintenance-free characteristics of nonstick materials, resistance to corrosion and wear, make their cleaning and replacement less often.

Disadvantages Of Teflon

Limited Load-Bearing Strength

Teflon is not designed for high mechanical strength applications. Over time, Teflon is susceptible to deformation from heavy loads and pressure.

Poor Adhesion

Teflon is very difficult to bond with other materials because of its nonstick surface, which prohibits its use in composite manufacturing without certain surface treatments.

Thermal Degradation at High Temperatures

Heat-resistant Teflon begins degrading and gives off toxic fumes if subjected to temperatures above 350 °C (662 °F).

High Cost

Compared to conventional plastics, Teflon is more expensive to produce and process and is not cost-effective for low-income applications.

Environmental Concerns

Manufacturing Teflon complex chemicals like PFOA (in older processes) increased environmental and health concerns. Modern production methods are improving safety standards.

Applications Of Teflon

The versatility of Teflon makes it applicable in a wide range of industries:

Cookware: Nonstick pans, bakeware, and utensils.

Automotive: Gaskets, seals, and fuel hoses.

Aerospace: Wire insulation, bearings, and protective coatings.

Electronics: Cable insulation, circuit boards, and connectors.

Medical: Catheters, implants, and tubing.

Chemical Processing: Linings for tanks, pipes, and pumps.

Construction: Sealants, waterproof coatings, and architectural membranes.

These applications use Teflon sheets on account of their chemical resistance, smooth, nonreactive surfaces, where corrosive substances are concerned.

Conclusion

Teflon is a special material that continues to shape modern industries. From cookware to space technology, its capacity to withstand extreme conditions while offering low friction and high resistance to chemicals differentiates it from any other material.

DEK offers you specialized machining and coating services for Teflon to meet your industrial requirements. Whether for precision parts or custom coatings, DEK's advanced fabrication ensures consistent performance and unmatched quality on your next project.

FAQs

Is Teflon harmful?

When used properly, Teflon is safe. However, overheating above 500°F can cause the release of fumes. Always use Teflon cookware on medium heat and replace scratched pans.

What is a Teflon sheet?

A Teflon sheet is a thin PTFE layer used for lining, sealing, or insulation. It is widely used in chemical processing, food production, and electrical applications due to its nonstick and corrosion-resistant nature.

What is the highest temperature PTFE can withstand?

PTFE can operate continuously at temperatures up to 260°C (500°F) and can tolerate short bursts of heat up to 327°C (620°F).