Electroplating is a way to cover one metal with another using electricity. If you’ve ever seen shiny chrome on a car or gold on jewelry, there’s a good chance it was electroplated.

In this guide, I’ll discuss what is electroplating, what is the purpose of electroplating, and other things that you need to keep in mind.

What is Electroplating and How Does It Work?

Electroplating is a process where you coat one metal with a thin layer of another metal. It started in 1805 to apply gold to other metals and is now used in many industries to improve appearance and protect surfaces.

The four primary components of the electroplating process are the anode, cathode, plating solution, and a direct current (DC) power supply.

To electroplate, you place your item (the cathode) and the coating metal (the anode) into a special liquid called electrolyte. Then, you connect them to a power source. When electricity flows, metal from the anode moves through the liquid and sticks to your item, forming a smooth layer. Read further to know the process in detail.

If you use metals like chrome, nickel, or zinc, you make your item stronger, more durable, and rust-resistant. If you use gold or silver, you get a shiny and decorative finish, often used in jewelry and ornaments.

Electroplating Working Principle

Electroplating works through a process called electrolysis. Here’s a step-by-step:

Electrolyte Breaks Into Ions

You start with an electrolyte, which is a liquid that contains a metal salt. When you pass electricity through it, the salt breaks into two parts: positive metal ions and negative ions.

For example, if you’re using copper sulfate (CuSO₄), it breaks into:

- Copper ions (Cu²⁺)

- Sulfate ions (SO₄²⁻)

Like this:

CuSO₄ → Cu²⁺ + SO₄²⁻

The Anode (Plating Metal) Releases Ions

You connect the metal you want to use for plating (like a copper strip) to the positive side of the power source. This is called the anode. When current flows, the metal at the anode loses electrons and turns into metal ions.

For copper:

Cu → Cu²⁺ + 2e⁻

These copper ions go into the solution and are ready to move toward the item you’re plating.

The Cathode (Your Item) Gets Coated

You connect the item you want to coat (like aluminum or stainless steel) to the negative side of the power source. This is called the cathode. The metal ions in the solution move toward it and stick to the surface, forming a thin layer of metal.

For copper plating:

Cu²⁺ + 2e⁻ → Cu (solid)

This is how the metal builds up on your item. The longer you run the current, the thicker the coating gets.

The Anode Releases Ions and the Reaction Keeps Going

While the metal coats your item, the other ions (like SO₄²⁻) return to the anode and help keep the reaction going. This allows the plating to continue as long as you want.

Types of Electroplating Methods

Over time, electroplating methods have changed to meet different needs. Here are the main types of electroplating methods:

Mass Plating (Barrel Plating)

You use mass plating for high-volume production. It’s perfect for small parts that need a thin metal coating. Barrel plating is a common mass plating method where you place the parts in a rotating barrel with metal salt (electrolyte) and the metal anode.

As the barrel spins, it cleans, descales, and coats the parts evenly. It works well for small, strong items like nuts, bolts, and screws, but not for parts that need a fine finish or detailed coating.

Rack Plating

Rack plating is better for larger parts that can’t go through mass plating. You place the parts on racks and dip them into the electroplating bath. This method is great for delicate or fragile parts and can coat the inside and deep areas of complex parts.

It’s more expensive than mass plating but gives a better finish. You’d use rack plating for large or complex items that need coating like gold, silver, copper, tin, or nickel.

Continuous Plating

You use continuous plating for long products like metal tubes, wires, or strips. The product moves through the electroplating bath at a steady rate. For thin strips, this is called reel-to-reel plating. The product is uncoiled, coated, and recoiled for easy storage. This method also allows you to shape the product later.

In-line Plating

In-line plating uses an assembly line to apply metal coatings. The metal moves through different stations where automated machines help with the chemical process. This method is cheaper than others because it uses less chemical solution per piece. You usually use in-line plating to coat copper, zinc, chromium, and cadmium.

Brush Plating

In brush plating, you use a soft cloth or cotton wrapped around an electrode to apply a metal coating. First, you soak the cloth in a plating solution with metal ions. Then, you manually apply the coating to the specific areas you want to coat.

This method is portable and gives you high customization. It’s perfect for localizing coatings, selective coating, and repairs. However, it’s not good for large or complex parts.

Pulse Plating

Pulse plating uses electrical pulses to coat the surface. The current quickly switches between two levels and drops to zero in between. By controlling the pulse width and strength, you can get a smooth, even coating with fine grains.

Pulse plating is great for parts that need a finish with less porosity, micro-cracking, and roughness. However, it’s a bit more complicated to set up and use than other methods.

When to Use Electroplating?

Here are five situations when you can use electroplating:

Fixing Dimensions (Build Thickness)

If parts or products are smaller than expected, electroplating can add a metal layer to make them the right size. You can control how thick the plating is by adjusting things like voltage, time, and the chemicals used.

For Better Appearance

Electroplating can make a surface look better by adding a shiny metal coating. It gives the part a permanent appearance of that metal, like chrome plating on aluminum or steel to make it shiny.

For Corrosion Protection

If your parts are made of materials that rust or corrode easily, you can use electroplating to coat them with a hard, resistant metal. The coating will protect the part by wearing down first in harsh conditions like moisture or chemicals.

For Better Electrical Conductivity

If you need better electrical conductivity, you can electroplate connectors or terminals with metals like gold, silver, or copper. These metals are good at conducting electricity, so your parts will work more efficiently.

For Heat Resistance

If parts need to withstand high temperatures, you can electroplate them with nickel or chrome. This helps the part stay strong and intact even when it gets very hot, like in car exhaust systems.

Suitable Materials for Electroplating

You can electroplate with one metal or a mix of metals. Engineers use many metals for this process, but here are some of the most common ones:

Gold Plating

Gold plating gives a luxurious look to items like jewelry, light fixtures, and decorative pieces. It’s more durable than foil coating and is strongly bonded. Gold is also a great conductor of electricity, that is why it is perfect for high-performance electrical components like connectors, circuit cables, and microelectronics.

Palladium Plating

Palladium is a cheaper alternative to gold and is resistant to wear and corrosion. It also has a shiny, bright silver-white appearance. Palladium plating is used on copper, brass, and other metals to prevent damage. It’s often applied before gold plating to balance conductivity and surface hardness. It’s used in electronics connectors and medical or dental components.

Silver Plating

Silver is another good plating metal because it’s highly conductive and resistant to wear. It costs less than gold and resists oxidation better. Silver plating also reduces friction, so parts are easier to solder. However, it’s not as corrosion-resistant as gold or palladium. You can use silver plating for electronic connectors, solar panels(from solar panels suppliers such as HBOWA), semiconductors, and bearings.

Zinc Plating

Zinc is a cheap plating metal that protects against moisture and gives a shiny, silver-like look. It forms a protective layer on metals like steel, iron, copper, and aluminum that are prone to rust. Over time, the zinc layer breaks down first, protecting the metal beneath it. You can use zinc plating on screws, springs, switch plates, brake pipes, and other small hardware.

Copper Plating

Copper is commonly used for electroplating because it’s highly conductive and relatively inexpensive. Copper plating gives a smooth, shiny surface and excellent electrical and thermal conductivity. It’s used for a variety of materials where conductivity is important.

Nickel Plating

Nickel plating on metals like steel, copper, and aluminum gives a smooth, durable finish. It’s sometimes used as a base for other coatings like silver or gold. Nickel plating offers corrosion resistance, durability, and magnetism. It can also be heat-treated to make the surface harder. You can choose from bright or dull finishes and customize its color.

Chrome Plating

Chrome is resistant to corrosion and offers great mechanical strength, wear resistance, and durability. It gives a shiny finish and adds strength and hardness to the underlying metal. Chrome plating is often applied to metals like aluminum and steel, especially for decorative items or industrial parts like automotive and aerospace components.

Benefits of Electroplating

- Electroplating with metals like chrome, nickel, or gold protects your parts from rust.

- Electroplating gives surfaces a shiny, smooth look and covers small imperfections.

- Plating with strong metals like nickel and chrome makes surfaces tougher and more durable.

- Plating with copper or gold helps your parts conduct electricity better.

- Plating reduces friction, which helps your parts last longer.

- Electroplating bonds tightly to surfaces, so it won’t peel off easily.

Limitations of Electroplating

You can only electroplate conductive materials because the process needs electricity to work. The heat and waste from electroplating can be harmful to both your health and the environment.

Setting up electroplating can be expensive because it requires equipment, tanks, chemicals, and other materials.

Industrial Applications of Electroplating

Electroplating is used in many industries. Here are some examples:

Aerospace

In the aerospace industry, manufacturers coat titanium parts with nickel to resist thermal changes and environmental stress. Examples of aircraft parts that need electroplating are engine parts, turbine blades, hydraulic systems, fasteners, structural items, valve bodies, and sensor components.

Automotive

Electroplating with chrome, zinc-nickel, or palladium makes automotive parts resistant to wear and environmental damage. Manufacturers also use plating for design purposes. Some examples of car parts that are electroplated are bumpers, pistons, cylinder liners, shock absorbers, radiator grills, fuel injectors, battery terminals, and interior trims.

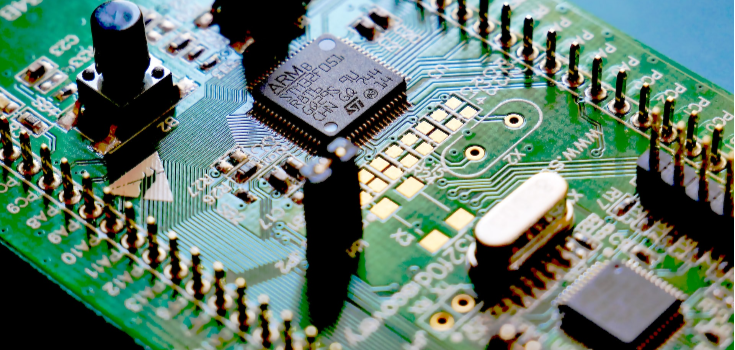

Electronics

Plating with conductive metals improves the electrical properties of connectors, contacts, and cables. It boosts the performance of electrical circuits.

Electroplating also protects electronic parts like PBCs, semiconductors, capacitors, switch plates, sensors, and many more from UV, corrosion, and damage. Common metals used in electronics plating include gold, copper, nickel, and palladium.

Jewelry

Gold and gold alloys are popular for plating jewelry because they make pieces look better and last longer. Combining different metals can create unique designs. Other precious metals, like silver and rhodium, can also be used.

What Influences Electroplating Costs?

The cost of electroplating depends on a few things, like the type of metal you want to plate, how thick the coating needs to be, how complex the parts are, and how many parts you need. Metals like gold, platinum, and palladium are more expensive, while copper, nickel, and zinc are cheaper.

A thicker coating also costs more. If your parts have complicated details or hidden areas. It takes more time and care, which makes the process more expensive. If you need a lot of parts, the cost per unit usually goes down, but if you only need a few. It costs more per piece. You can get a clear quote for your electroplating project at DEK.

Electroplating vs Electroless Plating

Electroplating uses electricity to add a metal layer. Electroless plating, on the other hand, uses chemicals and heat to bond the metal without electricity. It’s often used for nickel and chrome plating.

Electroless plating works on non-conductive materials like plastics. It’s cheaper and easier to set up than electroplating. It can create thick, hard layers with good wear resistance.

But, electroless plating is slower and harder to control. It’s also difficult to automate compared to electroplating.

Electroplating vs Electroforming

Both electroplating and electroforming use electricity to add metal, but they do it in different ways. Electroplating adds a thin metal layer to an existing item to make it look better and last longer. Electroforming creates a new part by building up metal inside a mold, which is removed after the metal has formed.

Electroplating makes thin coatings and works on materials like metal, plastic, or ceramic. It’s simpler and cheaper, used for things like jewelry or industrial parts.

Electroforming makes thicker, self-supporting parts from a mold. It’s more complicated and used for small, detailed parts. The process costs more because it’s harder to do.

Choose DEK for Your Electroplating Needs

DEK provides high-quality electroplating with expert handling and the right materials. We deliver top surface finishes to make your product stand out.

Our in-house factory speeds up production, and we ensure you get precision metal parts, from CNC machining to sheet metal fabrication. With strict quality checks, you’ll get great finishes and looks. Get a free quote easily by contacting us now.

Conclusion

Electroplating has been around for a long time. It helps create parts that are stronger, last longer, and look better. To electroplate, you need an anode, a cathode, an electrolyte, and a power source.

Electroplating is risky to try without the right training. You should message DEK to learn more about your electroplating needs.