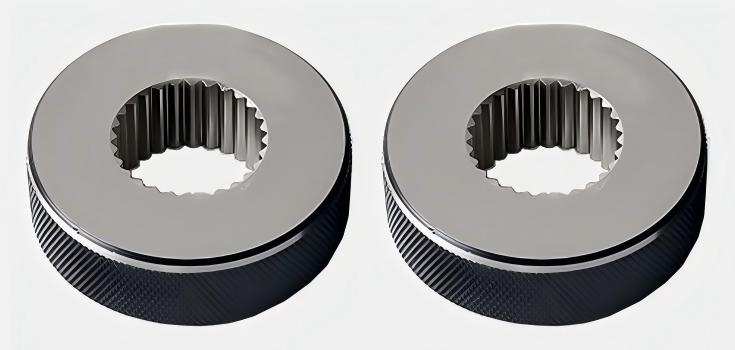

Spline shafts require precise control of tooth profile, pitch accuracy, and coaxiality. Achieving tight fit between mating components while maintaining overall shaft tolerance is challenging.

DEK utilizes gear hobbing, EDM for internal splines, and grinding processes to ensure dimensional stability. For hardened shafts, we employ post-heat-treatment grinding to maintain tolerance integrity.

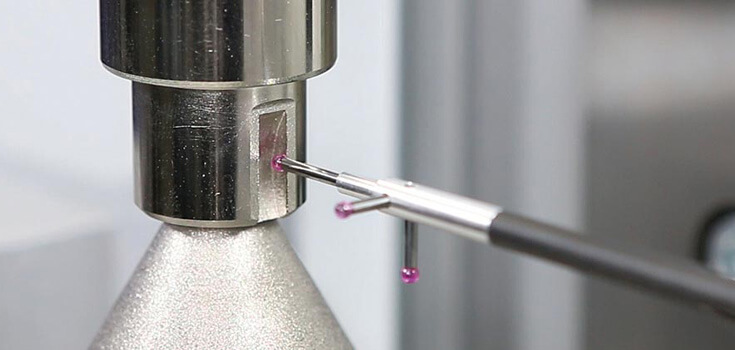

All shafts are checked using spline gauges, CMM, and roundness instruments to verify profile and concentricity. Process control ensures every shaft meets application-specific requirements.

Spline shafts often require post-heat-treatment grinding to achieve profile accuracy and surface finish. We use CNC spline grinders to maintain ISO 1328 Class 6–7 accuracy, controlling both lead and profile deviations.

For blind holes or non-through internal splines, DEK applies wire-cut or sinker EDM. This allows tight tolerance on internal features without tool deflection or overcut.

We ensure concentricity between spline and shaft by machining in a single setup or using custom fixtures. Runout is controlled under 0.015mm using dial indicators and CMM verification.

Most spline shafts are heat treated for strength. We offer quenching, tempering, or induction hardening per application. Grinding follows to correct distortion and meet tolerance.

Some spline shafts include cross holes, hex ends, or grooves. We apply 5-axis machining and live tooling lathes to complete these features in one setup, minimizing misalignment.

Precision, fast turnaround, and zero defects - mechanical engineers rely on DEK when failure is not an option.

Send us your drawing—we’ll provide fast DFM feedback and a precise quote, no minimum order.