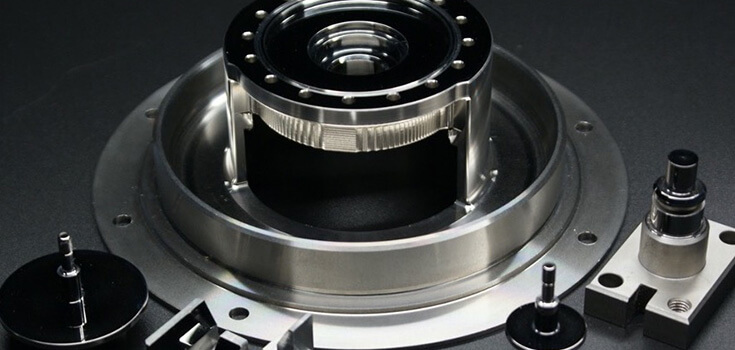

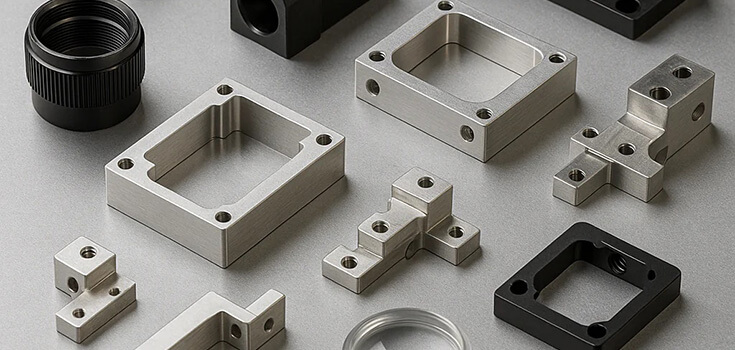

Optical parts require extreme dimensional stability, ultra-smooth surfaces, and tight feature tolerances. Thin walls and complex geometries increase the risk of deformation and tool marks.

At DEK, we use 5-axis CNC and custom cutting paths to maintain surface integrity and geometric accuracy. For critical features, EDM and diamond tooling are applied. All surfaces are mirror-polished or coated per spec.

We verify all parts using CMM, interferometers, and optical comparators. Cleanroom packaging is available upon request to prevent contamination during shipment.

Freeform and tilted features are completed in a single setup using 5-axis strategy. This avoids repositioning errors and maintains full-profile accuracy on complex lens holders.

We apply a mix of ultra-fine diamond tools and manual polishing to achieve Ra 0.1–0.2μm surfaces. Suitable for reflectors and precision optical mounts.

Critical optical bore features (e.g. lens alignment seats) are processed using fine boring tools with runout control below 0.003mm.

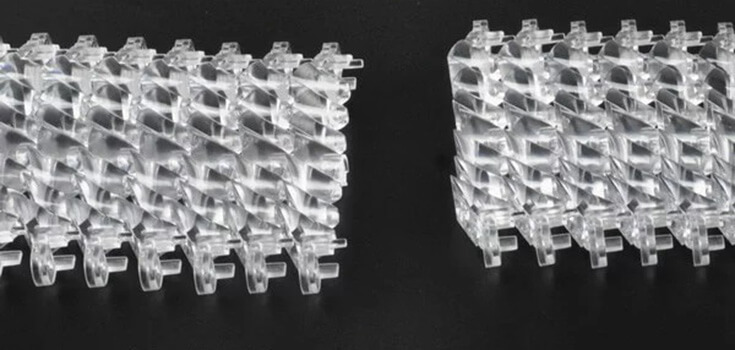

CAM strategy includes adaptive feed, step reduction, and vibration control to avoid chatter and part warping during thin wall machining (<1.0mm).

For internal slots or sharp optical mask edges, wire EDM achieves ±0.002mm positional accuracy with burr-free finish.

DEK provides the precision, speed, and zero-defect manufacturing that mechanical engineers trust for their most critical applications.

Send us your drawings—we’ll provide fast DFM feedback and a precise quote, no minimum order.