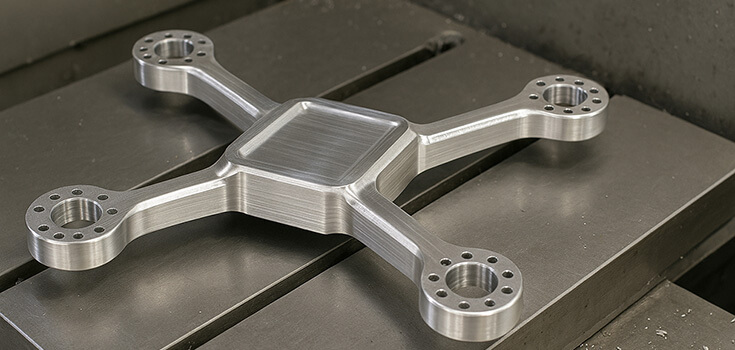

Drone components often require thin-wall structures, complex curved surfaces, and precise coaxiality. Maintaining dimensional stability while reducing weight presents machining challenges, especially on aluminum and magnesium alloys.

DEK applies 5-axis machining to control contour accuracy, EDM for narrow cavities, and precision grinding for critical fits. Toolpath planning minimizes deformation in thin sections while meeting ±0.01mm tolerances.

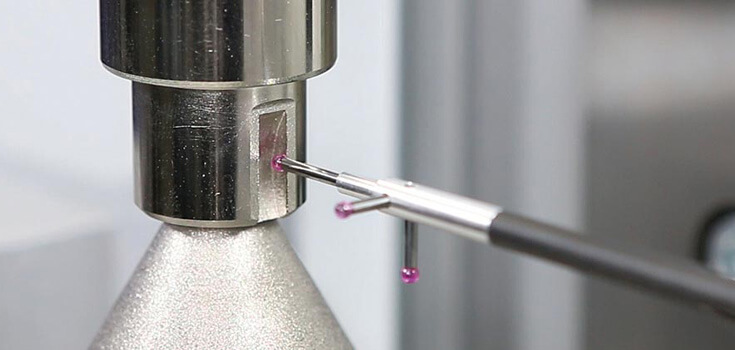

All parts undergo CMM and optical measurement to verify runout, perpendicularity, and surface finish. This ensures stable flight performance and long-term reliability.

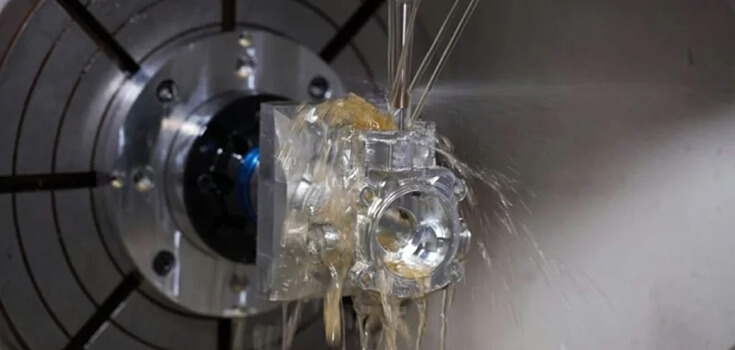

We control deflection in 0.8mm thin-wall drone housings by optimized toolpath and step-down strategy. Fixtures with soft clamping reduce stress. CMM checks wall thickness after machining.

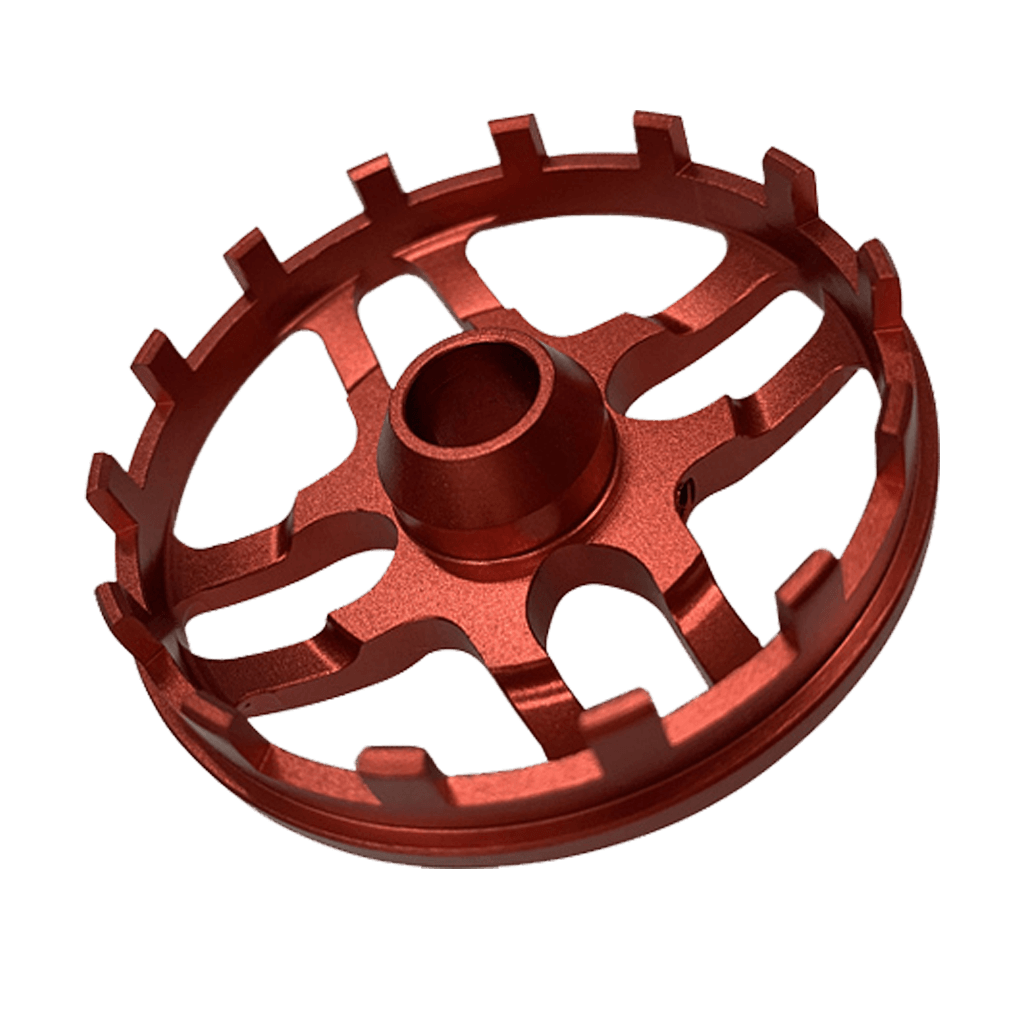

Drone propeller hubs require precise aerodynamic surfaces. We use simultaneous 5-axis milling to maintain contour accuracy within ±0.01mm. Surface roughness reaches Ra0.4 after finishing passes.

Critical fastener holes and threaded inserts are processed by precision tapping and thread gauges. Concentricity and pitch diameter are checked with GO/NOGO gauges. Thread runout kept within 0.02mm.

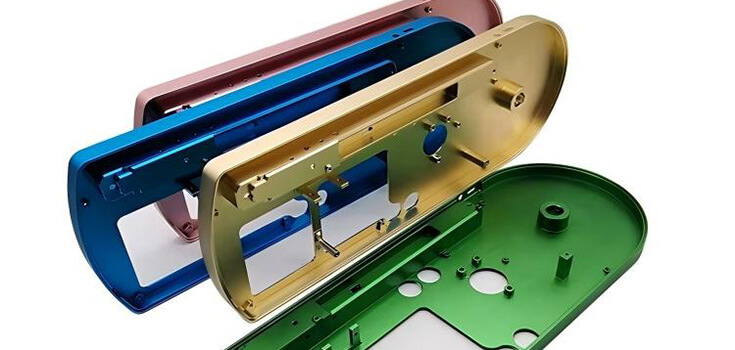

Aluminum drone arms receive Type III hard anodizing for wear and corrosion resistance. Thickness controlled at 20–25μm. Adhesion tested per MIL-A-8625 standards for aerospace compliance.

Precision, fast turnaround, and zero defects - mechanical engineers rely on DEK when failure is not an option.

Upload your CAD file now for a free DFM review and a precise quote from our engineering team.