There are several categories of milling cutter tools available based on their cutting edges, shapes, and the materials they are made from.

In this article, you will get to understand the various types, materials used, their applications, and lots more.

Basic Structure of Milling Cutter Tools

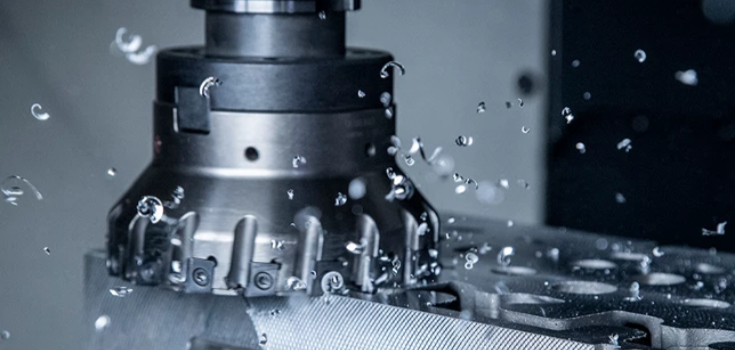

Milling cutter tools are objects or equipment used to remove excessive materials from a workpiece to get a desired shape or result.

Using milling cutter tools is quite easy. Simply mount the cutter tools to the milling machine, allowing the cutter to move quickly at high speeds and against the workpiece to get a cut, drill, or shape.

Before you learn about the different types of milling cutters, it helps to understand their basic structure. A milling cutter has three main parts: the shank, the body, and the cutter edge. These parts work together to get the milling job done.

- The shank is the part you connect to the spindle of the milling machine. It holds everything in place.

- The body is the main middle part. It connects the shank to the head and supports the whole tool.

- The cutter edge is the part that does the actual cutting. It includes the tip, the main cutting edge, and the teeth.

How are Cutting Tools Used in Milling Machines?

The milling cutter tool works by spinning and cutting materials from the workpiece. You feed the workpiece into the spinning cutter, which quickly removes metal or plastic. The milling machine can hold one or more cutters at once to speed up the process and create the shape you need faster.

When milling, it’s a good idea to change the tool to get the shape you want.

Importance of Milling Cutter Tools

Milling cutters are important because they help you remove extra material from the part you’re working on. You’ll find that a milling machine is very flexible. You can use it for many different machining tasks and to create parts in all kinds of shapes and sizes. The milling cutter is what allows you to do this work with both accuracy and speed.

Types of Cutting Tools for Milling Machines

There are several types of milling cutter tools, each with its specific functions and operation, suitability, cutting edges, shapes, and sizes. Here are the most popular ones you should know.

Face Milling

These tools are used for face milling, which involves removing part of the surface of a workpiece. The cutting edges of a face milling tool cut horizontally, unlike end mills that cut vertically. They are mostly used to trim the outside of a workpiece.

End Mill

End mills cut in all directions, unlike drill tools that cut only straight down. They are used for various milling tasks like cutting tool steel, drilling, slotting, and more. Below are some types of end mills:

Ball Mill Cutters: These cutters have a round, ball-shaped nose. They are great for milling curved surfaces.

Square End Mills: These have flat ends and are used for general milling tasks like plunging, profiling, and slotting.

Radius End Mills: These have rounded corners that help make cuts smoother and last longer.

Undercutting End Mills: Also called lollipop cutters, these are flexible and ideal for machining undercuts.

Rounding End Mills: These have strong, rounded ends for milling rounded edges.

Corner Radius End Mills: Known for rough finishes, these cutters remove large amounts of material quickly.

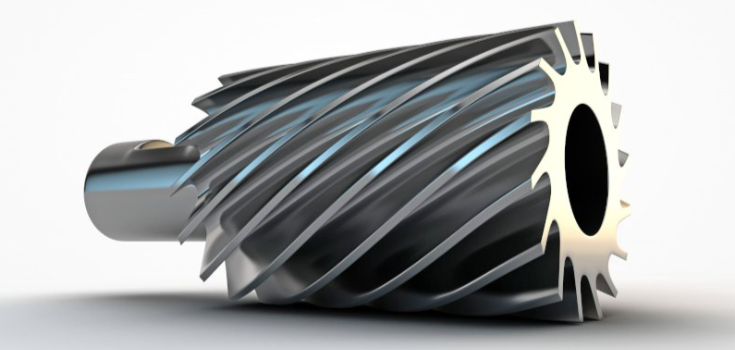

Cylindrical End Mill (Plain Milling Cutter)

You use a cylindrical end mill to cut flat surfaces on a horizontal milling machine. When working with gears, you can sort them by their tooth shape into spur gears and helical gears. You can also group them based on how many teeth they have—coarse-pitch gears have fewer teeth, and fine-pitch gears have more.

Three-Edge End Mill

This is a basic tool you use on a horizontal milling machine. It’s mainly for cutting grooves and steps. Since it has three cutting edges, it can cut on three surfaces at the same time.

Keyway Milling Cutter (T-slot Cutter)

This cutter looks similar to the plain milling cutter, but it’s different because it has two cutting edges and no center hole. You use it to cut keyways and grooves, but it’s not made for flat surface milling.

Saw Blade Milling Cutter

The saw blade cutter has thin teeth, and it’s great for cutting narrow and deep grooves in materials that aren’t too hard. When the cutter gets dull, you can sharpen it with a grinding machine and use it again.

Angle Milling Cutter

This type of cutter helps you cut precise angles and grooves in different materials. There are two main kinds: single-angle cutters and double-angle cutters. Single-angle cutters can range from 18 to 90 degrees in angle and 6 to 35 mm in thickness. Double-angle cutters range from 30 to 120 degrees and are 10 to 45 mm thick.

Form Milling Cutter

Form milling cutters are used for shaping complex surfaces, like gears or intricate contours. They come in various shapes and are ideal for tasks like chamfering and radius milling.

Some common types of form milling cutters are the following:

Convex Milling Cutters: These create inward-curving half circles.

Corner Rounding Milling Cutters: Used for rounding corners and creating radii.

Inserted Tool Milling Cutters: These have teeth made from carbide or tool steel, which are attached to the cutter body.

Gear Milling Cutter

You use this cutter to shape gears by following the outline of the gear. The process is easy and works well when you only need to make one gear or a small number of them.

Hollow Mill

A hollow mill looks like a tube with cutting teeth on the outside. The inside is empty so you can mount it on a shaft. It’s good for quickly shaping parts before threading and helps you work faster.

Thread Mill

Thread milling is a way to cut threads using a three-axis machine like a machining center. It doesn’t matter what kind of thread or which way it turns—you can cut it either way. This method is accurate and flexible.

Chamfer Mill

You use a chamfer mill to smooth out sharp edges by cutting a slanted or rounded corner instead of a sharp 90-degree angle. The cutter can have one or more blades, and you can choose the shape and angle based on how you want the edge to look.

Materials Used for Milling Cutter Tools

As earlier mentioned, cutter tools are made from different materials, which makes them suitable for varying machining needs and operations. Here are some of the materials they are made from.

Stellite

This is a non-ferrous alloy, which means it doesn’t contain iron. It’s made by grinding or casting. It has chromium and cobalt in it. And sometimes it also has tungsten or molybdenum. If you use this material for cutting edges, they stay sharp even at very high temperatures and speeds.

When using large cutters, manufacturers attach stellite teeth to a steel disk. For smaller cutters, they use solid stellite. If you need to make things like car engine parts or other items in large quantities, stellite cutters work really well.

High Speed Steel

High speed steel is generally known for its hard nature and ability to withstand high cutting speeds. They are resistant to high temperatures; however, they require a temperature of not more than 650 degrees Celsius to maintain their hardness.

Considered a more versatile and general-purpose material for cutters. HSS is suitable for milling materials like steel and aluminum.

To increase the hardness and temperature resistance of a cutter tool, manufacturers often add cobalt in low quantities to give a resulting HSCO, High-Speed Cobalt Steel. This, in turn, improves its durability and makes it ideal for more complex machining operations.

Carbide

They are also referred to as cemented carbide, and they are a combination of tungsten carbide and a metallic binder, cobalt.

Carbide is an extremely tough and hard material, can resist so much heat and cutting speed, and is capable of withstanding temperatures as high as 1000 degrees Celsius.

Due to its very hard nature, cemented carbide is mostly used for milling harder materials like cast iron, stainless steel, titanium, etc. They are also made durable but less economical compared to HSS.

Ceramics

Ceramics are quite harder compared to carbide; however, they are less tough. They are also suitable for high-speed cutting and are heat resistant. Ceramic-made cutters are a combination of silicon nitride and aluminum oxide. They are ideal for machining materials like cast iron, superalloys, and so on.

Although they are heat resistant, they could be brittle or break when exposed to shock or mishandled. Beyond that, you could expect to use them for more specific operations compared to HSS, which is versatile in its usage.

Carbon Steel

Carbon steel materials, unlike HSS, carbide, or ceramics, have low durability, cannot withstand heat, and are only suitable for operations requiring low speed. They can only withstand a temperature of 200 degrees Celsius and below, and as such, we can say they aren’t as hard as other cutter materials.

Polycrystalline Diamond

This is one of the hardest materials cutters are made from. They contain diamond particles, can withstand extreme heat, and are suitable for high cutting speeds. They are usually used for milling non-ferrous metals like aluminum and copper.

Because of their wear-resistant capacity, they tend to maintain their sharp edges even when used for a long period. Compared to other materials, they are quite expensive.

Best Milling Cutter Tips

Here are some milling cutter tips to help you make the best choice:

Milling Cutter Size and Diameter

The size of your milling cutter depends on the depth and width of the cut. Deeper and wider cuts need larger cutters. Standard milling cutter diameters range from 16mm to 630mm.

If you’re milling a large surface, use a smaller diameter cutter– ideally, 70% of the cutter’s edges should be engaged in cutting.

The cutter diameter also depends on the machine’s spindle size. A good rule is D = 1.5d, where D is the cutter diameter and d is the spindle diameter.

When milling holes, make sure the cutter is not too big or too small compared to the hole size as this can damage the tool or the workpiece.

Milling Tool Body

The number of teeth affects performance. Dense-tooth cutters (more teeth) give a smoother cut, while coarse-tooth cutters (fewer teeth) are better for rough machining.

Coarse-tooth cutters also reduce friction by having larger chip flutes. At the same feed rate, dense-tooth cutters take smaller loads per tooth.

Milling Cutter Power

Consider both the cutting power and the size of the workpiece. When choosing a face milling cutter, ensure its power needs match the milling machine’s capacity.

For small-diameter end mills, check that the machine can reach the minimum required cutting speed, which is at least 60 m/min.

Milling Tool Blade

Use grinding blades for smooth and precise cuts. For rough cutting, pressed blades are cheaper and work better. If using carbide inserts, choose ones with sharp angles for small cuts and low feeds to make them last longer.

Difference Between End Mill Cutter and Face Mill Cutter

When you’re choosing between a face mill and an end mill, here are some key things to think about:

Shape

An end mill has a round (sometimes ball-shaped) cutting head and a thinner body. A face mill has a wide, flat cutting head and a thicker, stronger body.

When to Use Them

Use an end mill when you need to make detailed shapes, small grooves, or edges like chamfers. Use a face mill when you want to remove a lot of material or smooth out a big, flat surface.

Cutting Power

End mills are good for small, careful cuts. Face mills can handle bigger, faster cuts and work well on large surfaces.

How They Cut

An end mill cuts more along the tool’s axis (up and down). A face mill cuts across the surface (side to side).

Finish Quality

End mills give you smooth finishes and clean edges—great for detailed work. Face mills don’t leave the smoothest surface, but they remove material quickly and cover more area.

Conclusion

Milling cutter tools are a big part of the milling process. You attach them to a milling machine to cut or shape materials for different jobs. There are many types of milling tools, and each one works best for a specific task. If you’re not sure which one to use, it’s a good idea to ask a professional.

At DEK, our team is here to help with all your manufacturing needs. We offer CNC milling, CNC turning, 3D printing, rapid tooling, and more. With more than 20 years of experience, our engineers know how to pick the right milling cutters for your parts. You can count on us to deliver high-quality products that meet your standards.

Got questions about milling or anything else? Just reach out and ask for a free quote today!