Metal galling is a common problem you’ll face when working with metal parts, and it’s something you don’t want to ignore. This can lead to damaged tools, costly downtime, and broken parts if not handled properly.

To avoid this problem, you need to understand what causes it, when it happens, and which materials are more at risk. I’ll also share simple ways to prevent it and tips to fix damaged parts if galling occurs.

What is Metal Galling?

Here’s a simple metal galling definition: it’s when two metal surfaces slide against each other, stick, and tear under pressure. This sticking happens at contact points and can cause serious damage when the parts move or separate.

You’ll often see it in bolts, bearings, pistons, and sliding metal parts. It gets worse with high loads, poor lubrication, heat, and soft metals like aluminum and stainless steel. Galling can be small or very visible, but it always affects part performance.

When Does Galling Occur?

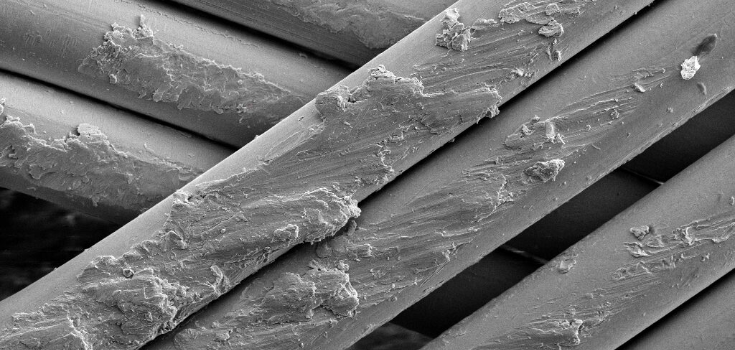

Metal galling usually starts when the thin protective oxide layers on metal parts wear off. Once that layer is gone, the bare metal surfaces come into direct contact and bond together at certain points.

As the parts keep moving, pressure and friction tear these bonded spots apart. This is a type of adhesive wear, where bits of metal stick, pull away, and create rough patches and bumps. Softer, ductile metals are more likely to gall because they easily deform and bond under pressure.

Any type of metal machinery exposed to too much friction is also at risk of galling, especially without proper lubrication.

Types of Metals Prone to Galling

Some metals are more prone to galling than others. That’s why it’s important to know about these types to help you choose the right material and keep your parts working for a long time:

Stainless Steel

Stainless steel can gall when parts slide and press against each other. It can tear or lock up, which weakens your setup. To avoid this, choose the right stainless steel grade, treat the surface, and always use proper lubrication.

Aluminum

Aluminum is soft and tends to gall when loaded parts rub together. The surfaces can stick, bend, and wear out fast. You can prevent this by using harder aluminum alloys, adding coatings, or applying lubricants.

Titanium

Titanium bonds to itself under pressure, especially in moving or rotating parts. This makes it difficult in some jobs. To manage this, use smooth surfaces, good lubrication, and make sure the parts you pair together are a good match.

Different Factors Causing Metal Galling

Before discussing the preventions, it is best that you know the factors that cause galling, such as the following:

High Pressure

When you push two metal surfaces together with a lot of pressure, the contact points get stressed. This stress makes the metal soft and deformed. If the pressure stays high, the surfaces can start to stick and tear. The more pressure you apply, the higher the chance of galling.

Relative Motion

When metal parts move against each other under pressure while in contact, like sliding, twisting, or rotating. The constant rubbing creates heat and breaks down surface layers. As these surfaces wear, they start sticking together, and small bits of metal transfer from one surface to the other. This is how galling begins and gets worse with continued moving.

Pairing of Similar Metals

If you use metals with the same properties, for example, stainless against stainless, they’re more likely to stick to each other. Their atoms bond easily when pressed together and moved, which makes galling happen faster.

Lack of Lubrication

If you don’t use enough lubrication, metal parts will rub directly against each other. This increases friction and heat, making it easier for the surfaces to stick, lock up, and tear.

Debris

If small chips, dirt, or metal particles get between the moving parts, they’ll act like tiny cutting tools. They will scratch and damage the surfaces, which will cause galling eventually.

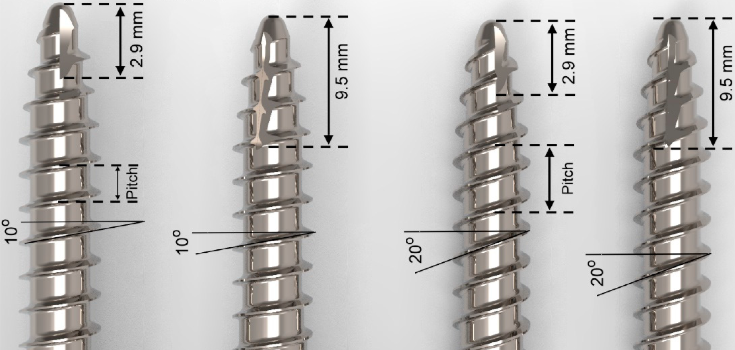

Surface Texture

The texture of a metal affects how easily galling can happen. If the surface is rough, it has tiny peaks and valleys that can catch and stick when you press the parts together. That leads to tearing and damage. If the surface is too smooth, it won’t catch as easily, but the large contact area can still make the metals stick when they move.

Freshly cut or machined surfaces are also a problem. If there’s no protective layer, the bare metal sticks easily under pressure and movement. This makes new parts more likely to gall if you don’t use the right precautions.

Temperature, Humidity, and Corrosive Environments

High temperatures make metal softer and stickier. If you add moisture, it can cause corrosion, which changes the surface and removes any protective layer. In corrosive environments, like places with saltwater, chemicals, or acidic vapors, corrosion happens faster and leaves the surface rough and exposed.

How to Prevent Galling?

Now you know the cause of metal galling, so it will be easier to understand how to prevent it. These are the common ways to prevent galling:

Lubrication Solutions

The easiest way to control galling is by using proper lubricants. Oils, greases, and anti-seize products create a thin layer between metal surfaces. This reduces metal-to-metal contact, lowers friction, and keeps heat under control.

Load Management

High pressure, heat, and speed increase the risk of galling. You can reduce this by lowering the load, tightening bolts to the correct torque, and slowing down moving parts when possible. Reducing temperature through cooling systems also helps.

Surface Coating

Since galling starts at the surface, adding protective coatings can help. Options like nitriding, anodizing, or Teflon coatings make surfaces harder or smoother, which keeps metal from sticking.

Material Selection and Treatment

The right selection of materials is important since some metals gall more easily than others. Always check a metal galling chart when choosing material pairs. As much as possible, avoid using similar metals together.

For example, stainless steel pairs better with brass, bronze, or zinc-coated parts. Also, picking grades like 304 or 316 stainless is better than 410 because of their resistance. Heat treatment and surface processes can improve performance, too.

Increased Contact Area

Spreading the load over a bigger surface lowers contact pressure. Less pressure means a lower chance of galling. You can adjust your design to increase the contact area where needed.

Optimize Surface Finish

Aim for a finish that is smooth enough to reduce friction but not overly polished. A metal galling chart often recommends surface finishes for different material pairs.

Design Considerations

Smart designs lower the risk of galling. Reduce contact pressure and add grooves or channels to hold lubricants. Pairing a hard material with a soft one also works better than pairing two similar materials.

Use Clean and Undamaged Parts

Always keep parts clean and scratch-free. Dirt, dust, and surface damage make galling worse. Handle, store, and ship parts carefully to protect the surfaces and avoid problems during assembly.

Common Occurrences of Galling

You’ll often see metal galling in these kinds of situations:

Threaded Fasteners: Bolts and nuts, especially stainless steel, can stick or seize if not properly installed. This is called thread galling; it’s one of the reasons stainless fasteners jam.

Valve Stems and Seats: In engines, valves slide against the seat under heat and pressure. And, this rubbing causes galling as part of normal wear.

Dies and Molds: In injection molding, parts like ejection pins slide against each other every cycle. Thousands of cycles a day cause galling between these moving parts.

Bearings: Bearings work under heavy loads and high temperatures. The rolling parts slide against the rings, which leads to galling and shortens the bearing’s service life.

Tips to Repair Galled Metal Surfaces

You can’t always stop galling, but you can fix it when it happens. First, check how bad the damage is. If it’s deep or affects part strength, you may need to replace it. If it’s minor, try these:

Grinding or Machining: For shallow damage, you can grind or machine off the rough spots. But if the part needs a precise size or shape, this might not work.

Polishing with Fine Abrasives: Light galling can be cleaned up using fine sandpaper, lapping paste, or polishing tools to smooth the surface.

Re-Tapping or Re-Threading: You can re-tap the holes or re-thread the bolts if they’re galled, but make sure to use proper lubrication to avoid galling again.

Differences Between Galling and Other Wear Types

Below is the list of other wear types and how they differ from galling:

Cold Welding: This happens when two metal surfaces press together so tightly that they bond without moving. It’s like they fuse into one piece.

Abrasive Wear: This is when a harder material or sharp particles scrape against a softer one, cutting and removing bits of the surface.

Corrosive Wear: Caused by chemical reactions like rusting. Over time, the metal weakens and breaks down because of moisture, chemicals, or gases.

Conclusion

To sum up, metal galling is one of the main causes of surface damage in metal parts. The good news is, you can reduce the risk by choosing the right materials, using lubricants, and making smart design choices.

If galling happens, check the damage and decide whether to repair or replace the part. For reliable solutions and technical support, reach out to us. At DEK, we manufacture high-quality products with no defects or issues. Get a free quote today!