Heavy Component Machining Service

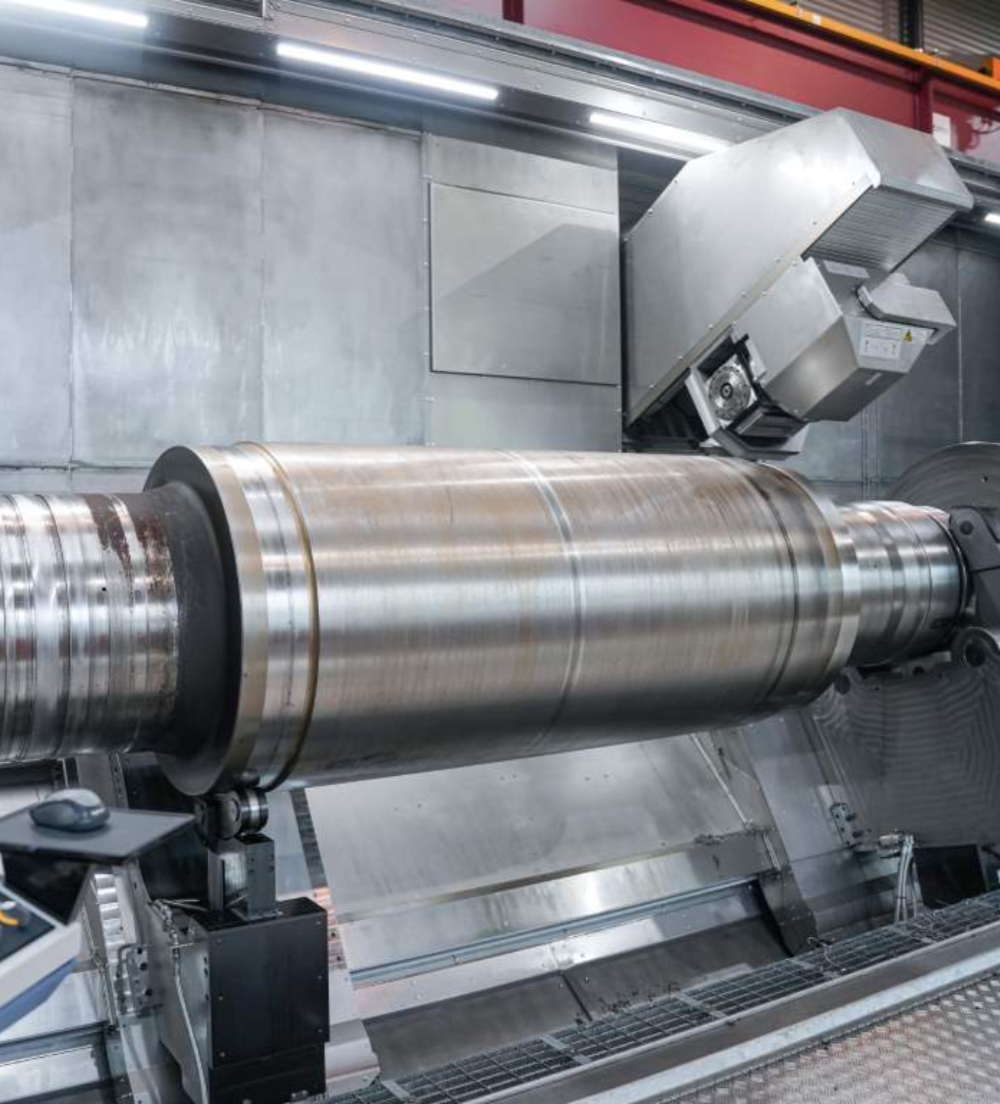

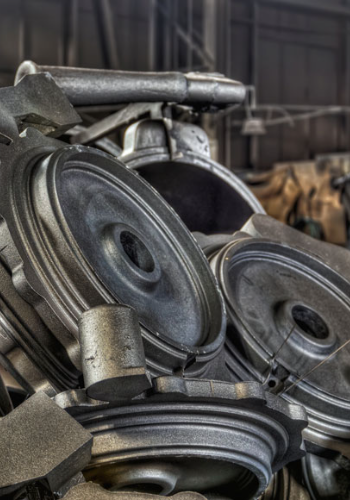

Heavy component machining is for shaping large, dense materials, such as steel or titanium, in industries such as aerospace, energy, and heavy equipment manufacturing.

Designed to cater to complex, large-scale parts with tight tolerances, DEK provides precision heavy component machining services. As a leading machining provider in the industry, DEK stands out for its advanced equipment, quality control, and engineering support, ensuring consistency and quick turnaround times.

introduction

Precision Solutions in Heavy Component Machining

DEK provides high-precision heavy component machining service with expert engineering support and reliable quality to meet the needs for large, complex parts for demanding industrial applications.

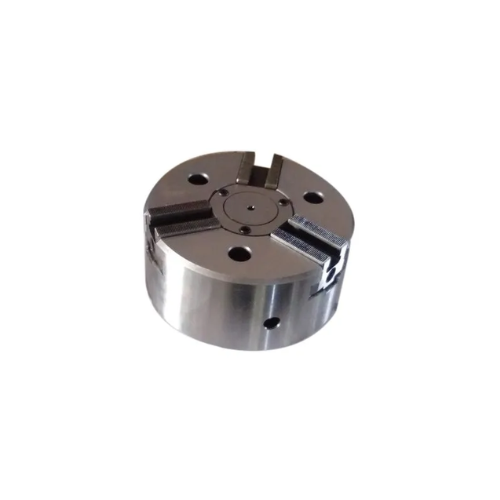

Our expertise in heavy component machining makes us distinguished in the industry. We deliver quality and efficient solutions for complex parts to meet the strict standards of industries like aerospace, construction, energy, and marine. With the use of our state-of-the-art CNC equipment, such as multi-axis machining centers, heavy-duty turning machines, and large-format gantry mills capable of handling oversized and high-weight components.

We also offer design support for your manufacturing needs for both small and large-scale productions, making us a reliable partner for your machining projects, no matter how strict your demands may be.

- Large-capacity CNC machines

- High-precision tolerances

- Handles tough materials

- Custom fixtures and lifts

- In-house finishing and QA

- Expert engineering support

Materials for Heavy Component Machining

Metals

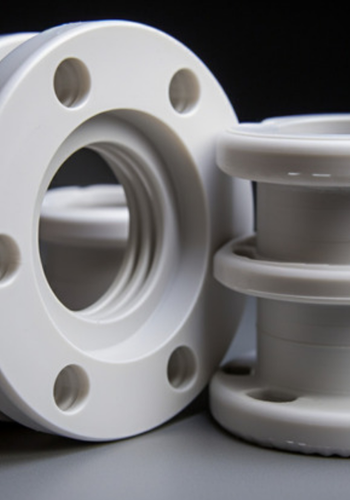

Plastics

Aluminum

Aluminum is a lightweight, corrosion-resistant metal widely used in aerospace, automotive, and structural industries. Its excellent strength-to-weight ratio, combined with good machinability, makes it perfect for producing large, complex parts that demand both precision and durability.

DEK’s heavy component machining utilizes advanced CNC technology to expertly machine aluminum alloys such as 2024, 6061, and 7075. We manufacture high-value components like aircraft brackets, heat exchangers, and structural frames, ensuring tight tolerances, superior surface finish, and reliable performance in critical applications.

Alloy

AL6061, AL6063, AL5083, AL5052, etc.

Brass

Brass is known for its excellent machinability, corrosion resistance, and high conductivity, making it a preferred material for precision components in plumbing, electronics, and decorative hardware. Its low friction and smooth finish also make it suitable for moving parts and fittings.

DEK offers heavy component machining services for brass alloys such as C260, C360, and C464. We produce detailed parts like electrical connectors, valve components, and precision bushings with exceptional surface quality and dimensional accuracy.

Alloy

Brass 260, C360, Cz121, etc.

Cast Iron

Cast iron offers exceptional rigidity, wear resistance, and vibration damping, making it ideal for heavy machinery and engine components. Its properties allow for durable, robust parts that withstand harsh industrial environments, while still providing good machinability for heavy component machining.

DEK specializes in machining various cast iron grades, including gray and ductile iron. We produce critical components such as pump housings, valve bodies, and heavy equipment frames with precise dimensional control and reliable performance tailored to demanding applications.

Copper

Copper is highly valued for its exceptional electrical and thermal conductivity, making it essential in applications related to power transmission, electronics, and heat management. It is also naturally corrosion-resistant and antimicrobial, commonly used in medical, HVAC, and industrial systems where reliability and cleanliness are critical.

DEK utilizes advanced multi-axis CNC machining to process copper alloys such as C101, C110, and C145. We manufacture complex, high-precision components like heat exchangers, RF parts, and electrical terminals with excellent surface finish and dimensional accuracy.

Alloy

Copper C101, C110, etc.

Inconel

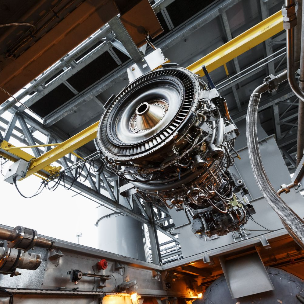

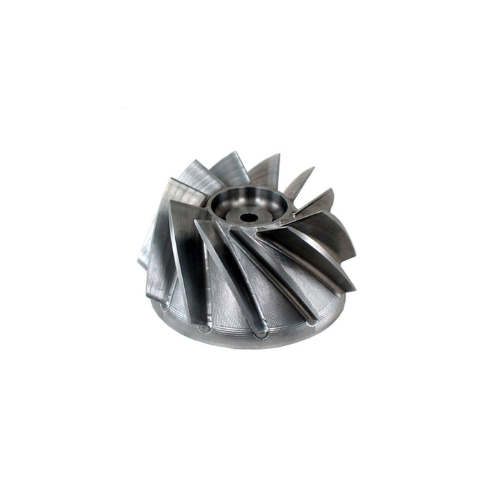

Inconel is a high-strength nickel-chromium alloy recognized for its exceptional resistance to heat, oxidation, and corrosion, making it ideal for extreme environments. It is commonly used in aerospace, energy, and marine applications where stability under high temperatures and pressure is essential for performance and safety.

DEK’s heavy component machining capabilities include Inconel alloys 625 and 718. We manufacture high-value components such as turbine parts, heat exchangers, and exhaust systems with precise tolerances, excellent surface quality, and consistent performance in demanding applications.

Alloy

Inconel 718, 625, 600, etc.

Stainless Steel

Stainless steel is a corrosion-resistant, high-strength material widely used in aerospace, medical, and chemical industries due to its durability and resistance to harsh environments. It performs exceptionally well in heavy-duty applications where hygiene, heat resistance, and mechanical strength are essential.

DEK machines stainless steel grades, including 304, 316, and 17-4 PH, with precision CNC equipment. We produce high-value components such as pressure vessels, surgical tools, and pump shafts with exacting tolerances, smooth surface finishes, and reliable long-term performance.

Alloy

Stainless Steel 301, 303, 304, 304L, 316, 316L, etc.

Titanium

Titanium combines lightweight properties with exceptional strength and corrosion resistance, making it critical in aerospace, marine, and medical industries. It withstands high-stress environments and aggressive elements while reducing overall part weight—ideal for high-performance applications.

DEK’s heavy component machining focuses on Ti-6Al-4V, a popular titanium alloy. We manufacture precision components such as aircraft structural elements, medical implants, and engine parts with superior dimensional accuracy, surface quality, and compliance to industry-specific standards.

Alloy

Titanium Grade 1, Grade 2, Grade 5, etc.

ABS

ABS is a strong, impact-resistant thermoplastic widely used for industrial applications and rugged prototypes. It offers excellent toughness, dimensional stability, and machinability, making it ideal for large plastic components subject to mechanical stress or vibration. ABS performs well in both indoor and outdoor environments, holding its shape and finish over time.

Our heavy component machining services at DEK use advanced CNC technology to process ABS into high-quality housings, protective enclosures, and electrical insulators. We ensure precise tolerances, smooth finishes, and reliable performance even in high-impact or heavy-duty applications.

Delrin

Delrin (acetal) is a high-performance engineering plastic known for its excellent wear resistance, low friction, and dimensional stability. It’s ideal for mechanical applications involving sliding or rotating parts under load. Delrin also offers good chemical resistance and performs reliably in moist or humid environments.

DEK machines Delrin with advanced CNC systems to create bushings, valve components, and high-precision gears for heavy component machining projects. Our process ensures each part meets strict dimensional standards while delivering long-term performance under demanding industrial conditions.

Nylon

Nylon is a tough, semi-crystalline plastic known for high mechanical strength, abrasion resistance, and low friction. It performs well in high-load, high-speed environments, making it a go-to material for industrial and automotive components. Nylon also offers good chemical resistance and can handle exposure to oils, fuels, and greases.

DEK’s heavy component machining services deliver high-precision nylon parts like rollers, bushings, and structural spacers. We provide excellent dimensional accuracy and surface finish, ensuring that your components withstand long-term dynamic stress in harsh operating environments.

PEEK

PEEK is a high-performance thermoplastic valued for its excellent resistance to heat, chemicals, and mechanical stress. It's commonly used in aerospace, medical, and high-end industrial applications where both strength and thermal stability are required. PEEK maintains its performance under continuous use in extreme environments.

DEK machines PEEK into precision parts like valve seals, electrical insulators, and structural elements using advanced heavy component machining processes. We achieve tight tolerances and smooth finishes, ensuring your PEEK components meet the high-performance standards your project demands.

PET

PET is a strong, dimensionally stable plastic widely used for precision mechanical and structural components. It offers excellent wear and chemical resistance and maintains its strength and form under temperature and load variations. PET is a cost-effective choice for industrial parts that demand both durability and accuracy.

Our heavy component machining at DEK transforms PET into gears, fittings, and custom supports. We utilize high-end CNC machines to achieve excellent dimensional control and surface finish, delivering dependable plastic parts ready for tough environments and long-term service.

PTFE

PTFE is a chemically inert, low-friction plastic that offers excellent resistance to heat and harsh chemicals. It is widely used in sealing, insulation, and chemical handling applications due to its non-stick properties and thermal stability. PTFE is especially valued in environments that require minimal wear and friction.

DEK machines PTFE into liners, gaskets, and bushings with exceptional precision through our heavy component machining services. We deliver components that meet strict industrial specifications, providing high-performance solutions for the most demanding chemical and mechanical conditions.

UHMW

UHMW (ultra-high-molecular-weight polyethylene) is a tough, wear-resistant plastic that handles heavy impact, abrasion, and friction extremely well. It’s commonly used in mining, food processing, and material handling applications. UHMW also offers good chemical resistance and can perform in wet or corrosive environments.

DEK uses advanced heavy component machining techniques to fabricate UHMW parts such as conveyor rollers, wear strips, and liners. Our capabilities ensure outstanding dimensional accuracy, smooth finishes, and consistent reliability, making UHMW ideal for long-lasting components in extreme operating conditions.

Instant & Accurate Quotes

We don't use online automated quotation tools, because it is very inaccurate. Online quote platforms rely solely on calculations based on cutting amounts and fixed coefficients, they fail to account for actual processing nuances, such as material deformation after heat treatment, tight tolerance requirements, grinding after heat treatment, etc. Consequently, automated price calculations can lead to inaccuracies, ultimately increasing your costs.

But you can rest assured at DEK!

Our quotations are both cost-effective and accurate because we have a team of professional mechanical engineers who meticulously review each drawing. These engineers boast over 10 years of experience and possess deep expertise in programming, machine operation, post-processing, material properties, and more. Ensure you will get accurate quotes within 6 hours.

Our Advantages

2300+ Engineers Love Work With Us

No MOQ Required

DEK supports both small and large orders, making it ideal for clients needing prototypes, limited batches, or ongoing high-volume production. With no minimum order quantity, we give businesses flexibility in sourcing heavy components for testing, development, or specialized use.

Custom Finishes

We offer a wide range of surface finishing services, including painting, anodizing, powder coating, polishing, and more. These finishes enhance durability, corrosion resistance, and appearance, we are a one-stop shop for both machining and post-processing of large components.

Complex Geometry Capable

Using multi-axis CNC machines and advanced programming, DEK can handle intricate and non-standard geometries in large, heavy parts. We achieve high accuracy even in the most demanding designs, perfect for custom or highly engineered components.

Material Flexibility

Our heavy machining capabilities extend across a wide range of materials. This material versatility allows us to produce parts that meet the strength, durability, and resistance needs of industries operating in harsh environments.

High Precision

DEK delivers unmatched precision in heavy component machining, maintaining tight tolerances across large, complex parts. With advanced CNC technology and expert operators, we ensure every component meets exact dimensional and performance requirements.

Full Quality Control

DEK performs rigorous inspections throughout the machining process using advanced tools like coordinate measuring machines (CMMs). From raw material verification to final dimensional checks, our quality assurance system ensures each heavy component meets exact specifications before it ships out.

Our Ordering Process

Send RFQ

Send RFQ with 2D/3D drawings and detailed requirements via Email or online form.

Review & Quote

Our Engineer team will review every drawing carefully and provide an accurate quote within 6 hours.

Confirm Order

Confirm the quote, details and delivery schedule, then sign the contract.

Production

Arrange production process, start programming and machining.

Quality Control

Strict quality control during production and final inspection.

Packaging & Shipping

Pack the parts, attach part identification labels, and start shipping.

Send RFQ 222

Review & Quote

Confirm Order

Production

QC

Delivery

FAQ

Heavy Component Machining Buying FAQS

Get An Accurate Quote For Your Next Projects

No matter your project is complicated or simple, no matter is metal or plastic, you will get an accurate quotation within 6 hours.

Get A Quote TodayKnowing Heavy Component Machining

What is Heavy Component Machining?

Heavy component machining is a specialized manufacturing process focused on the precision machining of large, high-mass parts made from materials like steel, titanium, cast iron, or Inconel. These components are typically used in demanding industries such as aerospace, energy, defense, marine, construction, and heavy equipment manufacturing, where strength, durability, and exact specifications are critical. Due to their size and weight, heavy components require robust machinery such as large-scale CNC mills, turning centers, and gantry machines, along with custom fixtures and handling systems to ensure safety and precision throughout the machining process.

Unlike standard machining, heavy component machining involves unique challenges, including managing thermal expansion, minimizing vibrations, and maintaining tight tolerances over large surface areas. It requires advanced programming, skilled operators, and strict quality control protocols to produce complex geometries with high accuracy.

What are the Advantages of Heavy Component Machining?

Heavy component machining offers significant advantages for industries that require large, durable, and highly precise parts. By using specialized equipment and techniques, this process ensures consistent accuracy across oversized components, reduces the need for manual assembly or welding, and supports complex designs with tight tolerances. It enhances production efficiency, improves structural integrity, and enables cost-effective manufacturing of high-performance parts.

- High precision on large parts

- Handles tough, high-strength materials

- Minimizes part assembly and welding

- Enhances structural integrity

- Supports complex geometries

- Faster production of large components

- Scalable for any volume

- Ideal for critical industries

When Do You Need Heavy Component Machining?

Heavy component machining is essential when your project involves large or high-mass parts that must meet strict dimensional tolerances and performance standards. If the components are too big or heavy for conventional CNC machines—such as engine blocks, turbine housings, press frames, or structural beams—this specialized process ensures they can be accurately produced without compromising quality or safety. It’s particularly necessary when the part must maintain its precision under heavy loads, high temperatures, or harsh environments.

You’ll also need heavy machining when the material involved is difficult to cut—like hardened steel, titanium, or Inconel—or when your part design includes complex geometries and deep cavities. Industries such as aerospace, oil and gas, power generation, defense, and marine frequently require heavy component machining due to the scale and performance demands of their equipment.