Face milling vs end milling are two essential machining processes that serve different purposes to shape metals with precision. Understanding the differences between the two is crucial for choosing an efficient and appropriate method in manufacturing to help you achieve the desired surface finish of a project.

What is Face Milling?

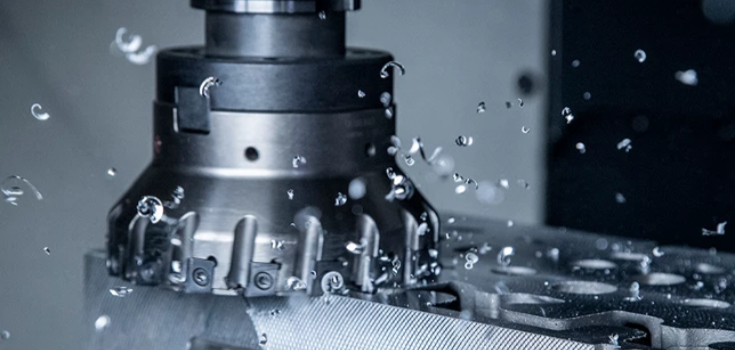

Face milling is a machining process that uses a cutting tool called a face mill. This tool has cutting edges around the disk, and it cuts across the surface as the tool spins.

This process is used to create flat and smooth surfaces on a workpiece. Face milling is ideal for producing large flat areas with a smooth surface finish.

Face milling has provided ease for the automotive, aerospace, and general manufacturing industries and has proven its efficiency on every project.

Features of Face Milling

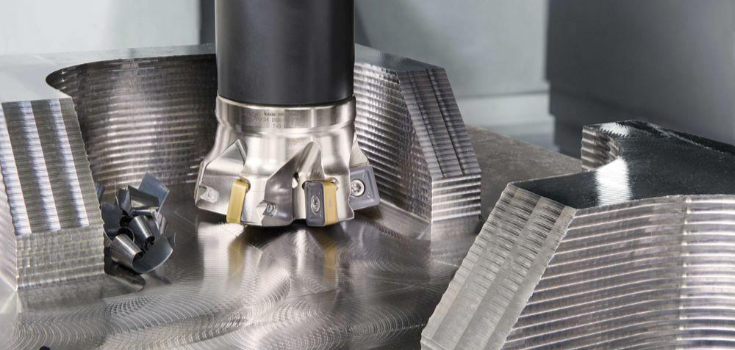

Variety of Replaceable Cutting Inserts

With interchangeable cutters, face milling allows easy material removal and provides more accuracy and speed. The cutting load is distributed among a variety of inserts, which means it reduces stress on the tool, giving it a longer tool life.

Geometric Inserts

These inserts are designed to meet material and surface finish needs depending on the shape, profile, and angle.

Wider Tool Diameter

This feature makes face milling a cost-efficient and productive process because it enables wider coverage of surface areas.

Applications of Face Milling

Refining Surfaces

For aesthetic and precision purposes, industries like aerospace highly depend on face milling when finishing the surface of a workpiece. The process not only refines the surface but also provides uniform pieces for the project.

The tools’ aligned and perfectly synchronized process avoids flaws, resulting in a more efficient and smooth surface finish that meets the industry’s critical needs.

Refining Surfaces for Further Processes

Some projects don’t end with the surface finish. Some require further processing before reaching a certain product result. Face milling helps shorten the process with its speed and efficiency. Plus, it also provides an aesthetically presentable surface finish.

Machining Complex Surface Sizes

Custom machinery components may require complex sizes. With the help of several cutting inserts, face milling can cover even larger surface areas, depending on the needs of an industry. This time-saving and efficient process eases worries of uneven results, as the tool itself is designed to produce consistent and accurate finishes.

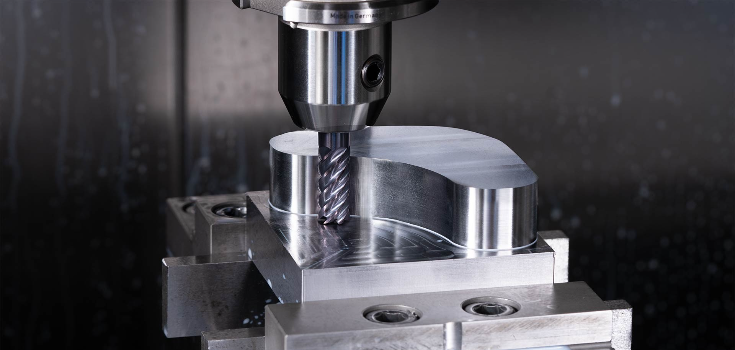

What is End Milling?

End milling is a machining process that uses a cutting tool called an end mill. This process is used for tasks such as slotting, profiling, and contouring. It is a fundamental process in manufacturing widely used in industries such as the medical device industry and the automotive industry. These industries depend on end milling to shape and cut metals, wood, plastics, and even stone.

Features of End Milling

Versatile Cutting Capability

The versatile cutting capability of end milling is essential for cutting different shapes, contours, and slopes. Through this feature, you are able to cut slots and holes in complex angles.

Variety of Geometric Tools

The end mill tool comes in different shapes. These shapes are designed for surface sculpting or finishing of edges. The use of the right tool not only saves time and increases productivity, but it also delivers quality results.

Coolant and Chip Control

It is crucial to manage heat in end milling. The coolant cools down the tool and the workpiece, while the chip control removes the metal shavings from the surface, ensuring the process runs smoothly.

Applications of End Milling

Slotting and Pocketing

Slotting and pocketing are two important manufacturing processes that industries rely on for tools and molds, assembly parts, and mechanical designs.

3D Surface Machining

This process is used for curved surfaces that are often designated for custom shapes and designs. With the use of the ball nose end mill, the tip glides through the curve to contour the surface with precision.

Logo Cutting and Engraving

This process is useful for customization, branding, and labeling. It is also useful for identification, often used by industries like the defense and aerospace industries.

Pros and Cons: Face Milling vs End Milling

| Process | Pros | Cons |

| Face Milling | Ideal for surface preparations | Limited to flat surfaces |

| Excellent surface finish | Costly due to insert cutters | |

| Great on large surfaces | Not suitable for detailed finishes | |

| Stable tool engagement | ||

| End Milling | High precision and detailed | Tool engagement varies |

| Geometrical tool availability | Needs attention for chip removal | |

| Works on curves and 3D surfaces | Slow on bigger surfaces | |

| Flexible cutting directions |

How to Choose Between Face vs End Milling

Face milling and end milling are both essential process that serves different purposes, and choosing the right one depends on the needs of your project. Understanding the difference between the two will help you pick the right one for your needs.

Cutting Direction

Face milling cuts perpendicular to the workpiece, while end milling cuts on the sides and face.

As far as the tools are concerned, face mills and end mills both have a variety of interchangeable tools designed for complex shapes and contours. It is helpful to note that the face milling can work on larger surfaces, while end milling has a smaller diameter.

Chip Formation

For the chip formation, face milling produces shorter and broader chips coming from a wide and shallow cutting, while end milling produces longer and narrower chips that are usually from side cuts.

With the use of airblast and coolants, chip removal is generally easier with face milling, while it could be trickier with end milling because it is prone to chip buildup.

Tool Engagement

Face milling offers a more stable tool engagement due to the cutter’s position on the surface, while it is slightly unstable for end milling, depending on the support and tool speed when navigating through slopes and curves of surfaces.

Both are efficient processes. However, it is important to note that with end milling, a sturdy support needs to be provided to avoid the tool from shifting its focus on the surface.

Helix Angle

Face milling uses inset cutters with neutral or low helix angles, while end milling comes with high or variable helix angles depending on the material and the designed finish.

When choosing between face milling and end milling, it is helpful to understand that face milling offers the capability of removing large material at once, while end milling is designed to deliver a detailed finish.

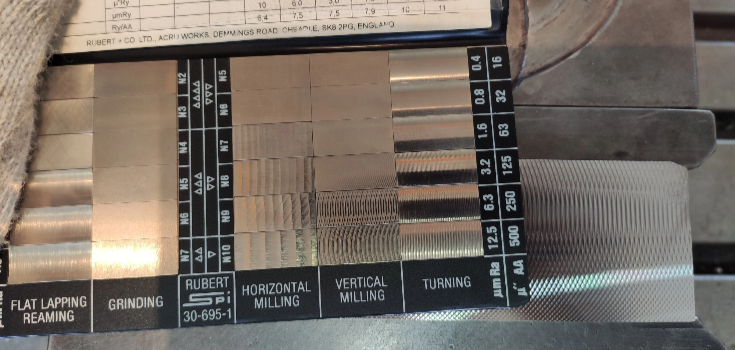

Surface Finish

In terms of the smooth surface finish, face milling is ideal for the job, especially on larger surfaces. End milling is good for detailed surface shaping, but it may require a secondary tool for flat surface finishing.

Depending on the design of the surface, you may need to use different insert cutters and different tools for both to create your desired shapes and contours.

Summary Table

| Feature | Face Milling | End Milling |

| Tool Orientation | Perpendicular to the surface | Parallel to the surface |

| Cutting Surface | Mainly the outer area | End and sides |

| Application | Flat surfaces | Complex shapes and slots |

| Speed | High | Low |

| Precision | Moderate | High |

| Machine Type | Horizontal Milling | Vertical Milling |

| Material Removal Rate | High | Low to moderate |

| Surface Finish | Smooth, flat | Detailed, intricate |

Face Mill vs End Mill: Process

Face milling and end milling are two machining processes that serve different purposes and utilize different tools to shape materials.

Face milling uses the bottom cutting edges of the tool with a sweeping pattern that can cover a wider area. This process is usually used to prepare workpieces and take up parts from larger surfaces to prepare for further manufacturing processes. It increases productivity because it can cover a large surface at once.

End milling uses the side milling process with a narrower tool. This process offers flexibility in terms of movement. It can move in different directions, which is great for contours and 3D shapes. It is good at highlighting and finishing the curves of a surface, and even engraving.

Both processes are helpful and efficient, but the choice of process to pick depends on the needs of a project or material.

When to Use Face Milling vs End Milling

Use Face Milling When:

- You need to take a workpiece from a large surface

- There is a need to take a huge block to prepare it for other processes.

- You want high material removal and a smooth finish

- The part you need to cut is not complicated and has no odd shapes or slopes.

Use End Milling When:

- The material requires holes, slots, and pockets

- The part needs detailed finishes like contours and 3D shapes

- You need a flexible tool that offers a variety of cutting directions.

- When you need to engrave on metals and other surfaces.

How Face Milling and End Milling Work Together

Face milling and end milling are two different processes that serve different purposes in machining, but both can also be used together to come up with a perfect finish to a material.

Face milling can take on the initial process of creating a flat workpiece, as it only prepares a material for further enhancements and finishes. When the material is ready, end milling can take charge of the intricate details needed, such as pockets, slots, contours, and 3D shapes. The end mill handles the final form of the material.

Conclusion

Face milling and end milling both play crucial roles in machining processes. Face milling is ideal for surface preparations, while end milling highlights the details, shapes, and features of a material. Choosing the right process depends on the design, needs, and manufacturing goals.

Here at DEK, we offer competitive milling services using both processes to help you produce high-standard and quality parts. Contact us today for a quote and let us discuss your projects with our machining experts.