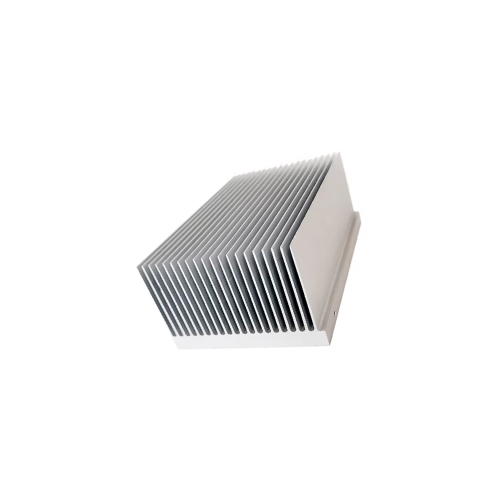

Custom Aluminum Heat Sink Manufacturing

Custom aluminum heat sink manufacturing creates tailored cooling parts that help manage heat in electronics and equipment, built to fit specific shapes and performance needs.

DEK provides custom aluminum heat sinks with fast prototyping, CNC machining, and flexible production volumes. Unlike others, DEK delivers tight tolerances, quick lead times, and reliable quality, making it a trusted choice for both simple and complex cooling solutions across various industries.

introduction

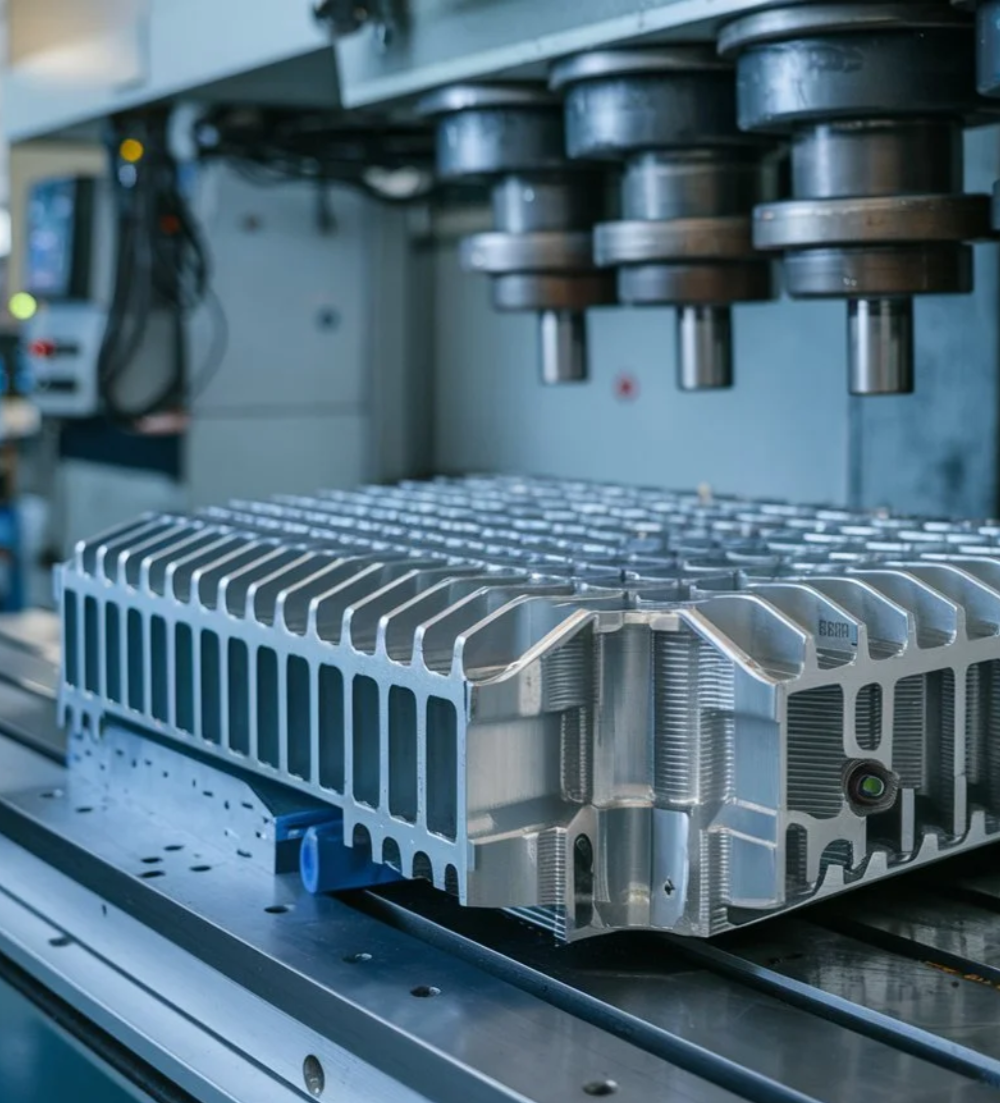

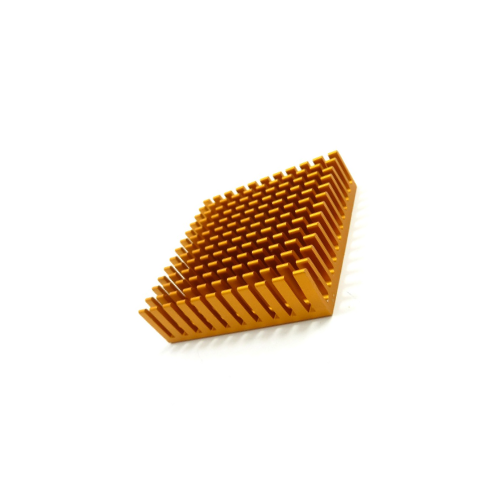

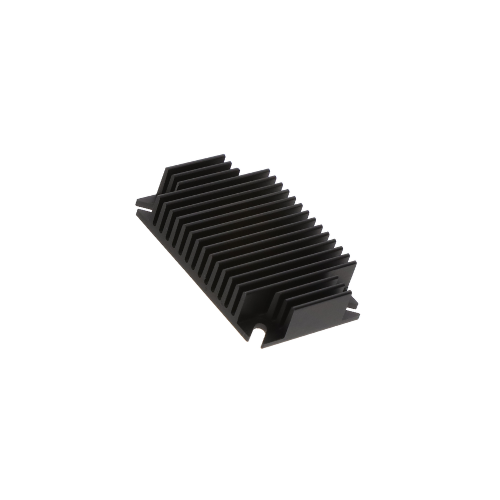

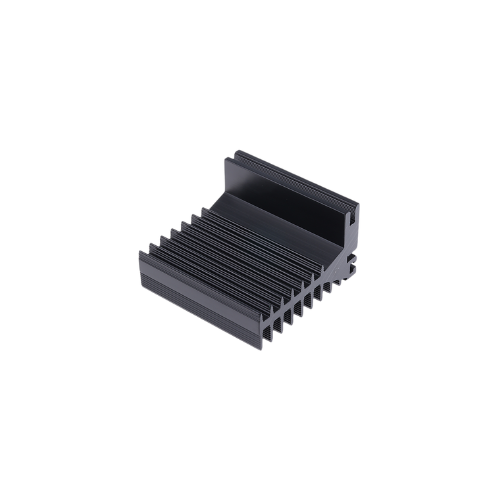

Precision Custom Aluminum Heat Sink Manufacturing Solutions

DEK provides custom aluminum heat sink solutions with precise machining, fast prototyping, and flexible production to deliver reliable, efficient cooling tailored to your exact needs.

DEK specializes in custom aluminum heat sink solutions, using advanced CNC machining equipment to create precise and complex designs that optimize heat dissipation. Our capabilities include rapid prototyping, low- to high-volume production, and a variety of surface treatments such as anodizing and powder coating to enhance durability and performance. With experienced engineers working closely with clients, we ensure each heat sink meets specific thermal requirements and fits perfectly within your device or system.

We also offer thorough quality control with inspection reports and fast turnaround times to keep your project on schedule. Our flexible manufacturing process accommodates both small prototype runs and large-scale production, making DEK a reliable partner for all your thermal management needs.

- Advanced CNC machining

- Rapid prototyping

- Flexible production volumes

- Surface treatment options

- Strict quality control

- Fast turnaround times

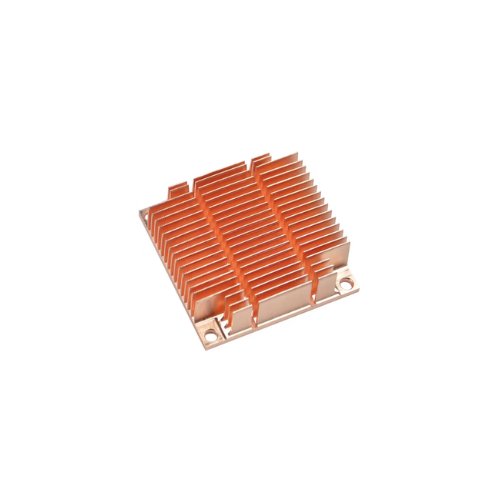

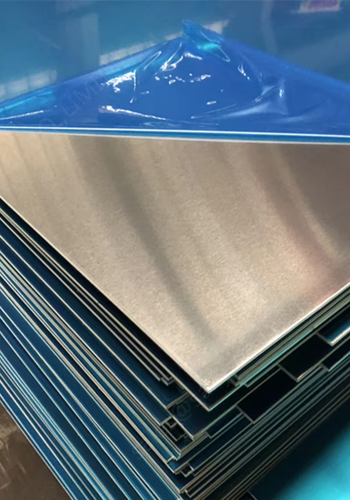

Materials for Custom Aluminum Heat Sink Manufacturing

Aluminum

6061

AL6061 is a popular choice for custom aluminum heat sink manufacturing due to its excellent strength, solid corrosion resistance, and reliable thermal conductivity. It's ideal for precision CNC machining, allowing for complex, tight-tolerance heat sink designs.

This alloy is widely used in demanding applications such as automotive engine components, aerospace electronics, and industrial control systems, where strong structural support and efficient cooling are both essential. Its versatility makes it suitable for both small prototypes and high-volume thermal management parts.

6063

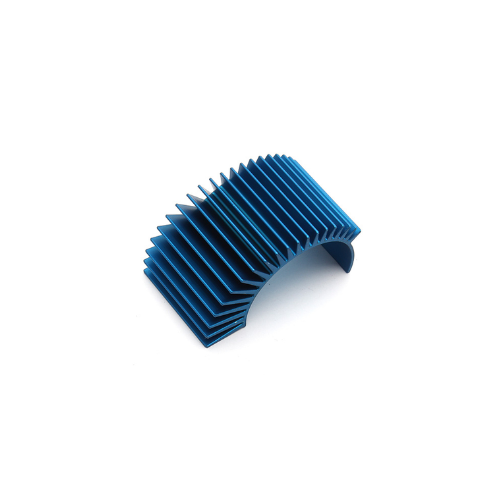

AL6063 is well-suited for custom heat sinks that require smooth surface finishes and high thermal efficiency. Known for its excellent extrusion capabilities, this alloy is often used in manufacturing heat sinks with detailed fin structures to maximize airflow and cooling surface area.

It’s lightweight yet strong, making it ideal for LED lighting, consumer electronics, and decorative thermal applications where appearance matters. AL6063 is a go-to choice for extruded heat sinks with complex shapes and visual appeal.

5083

AL5083 is an excellent material for custom aluminum heat sink manufacturing as it can be used in harsh or outdoor environments. It offers superior corrosion resistance, especially in saltwater or chemically exposed conditions, making it ideal for marine electronics, outdoor LED systems, and industrial machinery.

Although its thermal conductivity is moderate, its toughness and durability under extreme conditions make it reliable for long-term performance. AL5083 is perfect for applications where environmental protection is as important as heat dissipation.

5052

AL5052 is valued in custom aluminum heat sink manufacturing for its good balance of strength, corrosion resistance, and formability. It performs well in stamped or bent heat sink parts and is often used in compact thermal systems for electronics and automotive components.

This alloy is ideal for lightweight enclosures and integrated heat-dissipating structures where moderate heat loads are managed in confined spaces. Its versatility and cost-effectiveness make AL5052 a smart choice for custom thermal solutions in high-volume applications.

Instant & Accurate Quotes

We don't use online automated quotation tools, because it is very inaccurate. Online quote platforms rely solely on calculations based on cutting amounts and fixed coefficients, they fail to account for actual processing nuances, such as material deformation after heat treatment, tight tolerance requirements, grinding after heat treatment, etc. Consequently, automated price calculations can lead to inaccuracies, ultimately increasing your costs.

But you can rest assured at DEK!

Our quotations are both cost-effective and accurate because we have a team of professional mechanical engineers who meticulously review each drawing. These engineers boast over 10 years of experience and possess deep expertise in programming, machine operation, post-processing, material properties, and more. Ensure you will get accurate quotes within 6 hours.

Our Advantages

2300+ Engineers Love Work With Us

Cost-Effective

DEK uses smart processes to keep costs low while still delivering high-quality heat sinks. You get great performance without spending more than you need to. We make sure you get value without cutting corners.

No MOQ

Whether you need one heat sink or a thousand, DEK is ready to help. You can start small for testing, then increase your order later. This flexibility helps reduce costs and gives you room to perfect your design before mass production.

Tight Tolerances

DEK makes custom aluminum heat sinks with very high accuracy, so every part fits exactly right. This helps your electronics stay cool and run smoothly. Even tiny errors can affect how well parts work, so we make sure everything is just right from the start.

Complex Geometry Capability

Our equipment can make heat sinks in many shapes and sizes, even ones with tricky or detailed designs. This is great if your product has a tight space or special layout. No matter how simple or complex, we can bring your design to life.

Material Versatility

We work with many types of aluminum, like 6061 and 6063, so you get the right kind for your project. If you need a special type of aluminum, we can use that too. This means you’re not limited to just one material option.

Rapid Turnaround

We can finish sample heat sinks in just one day, and regular orders usually ship in 4–7 days. If you need a quote, we’ll get back to you fast, usually within 6 hours, so you can plan your project without delay. We’re built for speed and reliability.

Our Ordering Process

Send RFQ

Send RFQ with 2D/3D drawings and detailed requirements via Email or online form.

Review & Quote

Our Engineer team will review every drawing carefully and provide an accurate quote within 6 hours.

Confirm Order

Confirm the quote, details and delivery schedule, then sign the contract.

Production

Arrange production process, start programming and machining.

Quality Control

Strict quality control during production and final inspection.

Packaging & Shipping

Pack the parts, attach part identification labels, and start shipping.

Send RFQ 222

Review & Quote

Confirm Order

Production

QC

Delivery

FAQ

Custom Aluminum Heat Sink Manufacturing Buying FAQS

Get An Accurate Quote For Your Next Projects

No matter your project is complicated or simple, no matter is metal or plastic, you will get an accurate quotation within 6 hours.

Get A Quote TodayKnowing Custom Aluminum Heat Sink Manufacturing

What is Custom Aluminum Heat Sink Manufacturing?

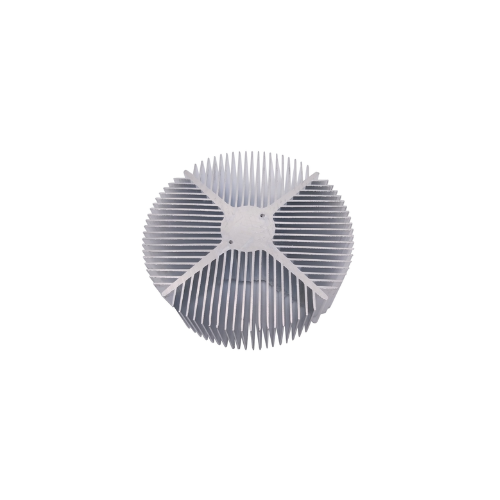

Custom aluminum heat sink manufacturing involves designing and producing heat sinks specifically made from aluminum to manage and dissipate heat from electronic devices or machinery. Aluminum is widely used because it’s lightweight, cost-effective, and has excellent thermal conductivity, meaning it efficiently transfers heat away from sensitive components. In this process, manufacturers create heat sinks tailored to the exact size, shape, and cooling requirements of a particular application, whether for computers, LED lighting, automotive electronics, or industrial equipment. By customizing the design, these heat sinks maximize cooling performance, helping devices run smoothly and preventing overheating.

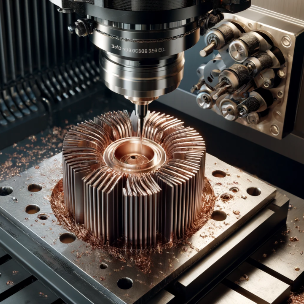

The manufacturing process typically involves advanced techniques like CNC machining, extrusion, and surface treatments. CNC machining allows for the precise shaping of aluminum to create complex fins and grooves that increase surface area for better heat dissipation. Extrusion is used for simpler shapes where aluminum is forced through a mold to create consistent profiles. After shaping, surface treatments such as anodizing can be applied to improve corrosion resistance and enhance thermal efficiency. Custom aluminum heat sinks ensure that cooling solutions are optimized for the specific device, improving reliability, lifespan, and performance in various industries.

What are the Advantages of Custom Aluminum Heat Sink Manufacturing?

Custom aluminum heat sink manufacturing offers numerous advantages by providing tailored cooling solutions that perfectly fit the unique needs of different electronic devices and industrial applications. Aluminum’s excellent thermal conductivity, combined with custom designs, ensures efficient heat dissipation, helping prevent overheating and extending the life of components. The flexibility in manufacturing methods allows for complex shapes and precise dimensions, resulting in optimized performance and better integration into devices. Additionally, custom heat sinks can include surface treatments that improve durability and corrosion resistance, making them suitable for a wide range of environments.

- Superior thermal conductivity

- Lightweight material

- Precise, custom fit

- Complex shape capability

- Enhanced cooling efficiency

- Improved device reliability

- Corrosion-resistant surface options

- Flexible production volumes

- Faster prototype development

- Cost-effective manufacturing

When Do You Need Custom Aluminum Heat Sink Manufacturing?

You need custom aluminum heat sink manufacturing when commercial cooling solutions don’t meet the specific requirements of your electronic devices or machinery. Standard heat sinks often come in fixed sizes and shapes, which may not fit perfectly or provide enough cooling for your unique application. Custom heat sinks are designed to match the exact dimensions, shape, and thermal demands of your product, ensuring optimal heat dissipation. This is especially important in high-performance electronics, such as computers, LED lighting, automotive components, or industrial equipment, where overheating can cause malfunction, reduce efficiency, or shorten lifespan.

Additionally, custom aluminum heat sinks become essential when your project requires special features or materials that standard options can’t provide. For example, if your device operates in harsh environments, you might need surface treatments to protect against corrosion or specific alloys for better durability. Custom manufacturing also allows for more precise control over thermal performance, enabling you to incorporate design elements like fins, grooves, or channels that maximize airflow and heat transfer. Overall, choosing custom aluminum heat sinks helps improve reliability, maintain performance, and extend the life of your equipment in demanding conditions.