CNC machining as a manufacturing procedure helps improve component precision, work efficiency, speed, etc. However, it comes in many versions, including 4-axis CNC machining vs 5-axis CNC machining. Deciding on which to use depends on some factors and their benefits.

In this guide, we will explore the two types, the pros and cons of each of them, when to use each, how to select the most suitable, and lots more.

What is 4-Axis CNC Machining?

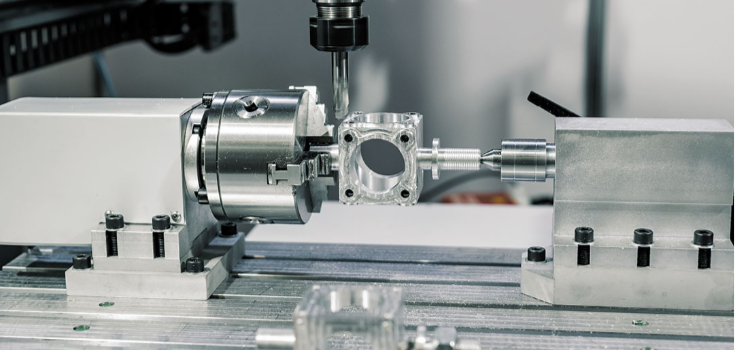

This is a machining process that involves using a 4-axis machine to cut out material until a desired shape or design is formed.

Usually, it has 3 main axes together with an additional axis known as the A axis, which allows for proper rotational movement without any manual repositioning.

Unlike the 3-axis CNC machine that typically has X, Y, and Z axes, the A axis in 4-axis CNC makes it suitable for engraving and machining involving the vertical axis and on all four sides.

This process also allows for more accuracy and precision while minimizing costs and errors. Whether you are involved in milling activities consisting of hole drilling or cutting out, 4-axis CNC machines are more suitable.

Pros and Cons of 4-Axis CNC Machining

Pros

- Suitable for more intricate designs, shapes, and angles that 3-axis machines cannot handle.

- Helps increase efficiency since it doesn’t need manual repositioning.

- Allows for continuous operation, thereby improving work speed.

- Can be used for high-volume production.

- Suitable for several material types and sizes.

- Great work, precision, and accuracy.

Cons

- Requires a high cost of investment and setup.

- Relatively slower in operations compared to 5-axis

- Not suitable for machining large materials.

When Should You Use 4-Axis CNC Machining?

You should use 4-axis CNC machining when:

- Working on operations relating to curved surfaces and angles involving one axis.

- Machining parts that require higher tolerance and precision that cannot be handled by 3-axis machines.

- You want to generate high output or production volume.

- Working on parts with several sides and features

What is 5-Axis CNC Machining?

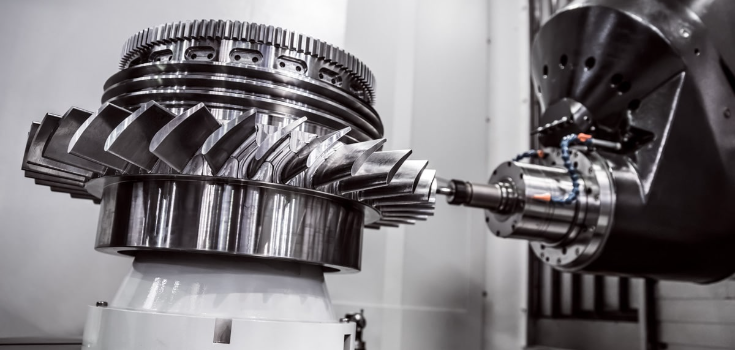

Just like the 4-axis CNC machine has an additional axis, 5-axis CNC machining involves two extra axes, which could be two out of the three A, B, or C axes. These 2 additional axes are also responsible for the rotational activities of the machine.

5-axis CNC machining allows for a more complex production process involving more geometries and angles, tolerance, and precision.

3+2-Axis CNC Machining

This is a type of 5-axis CNC machining, also known as positional 5-axis machining. In this type, the cutting equipment maintains a definite angle while the spindle moves around the two additional axes.

This way, the cutting tool is not always perpendicular to the part. Similarly, there is an indexed 3+2 machining form that allows the angle of the cutting tool to be changed manually during operations. It also has 2 rotational axes that work individually.

Simultaneous 5-Axis CNC Machining

Also known as continuous 5-axis machining. In this machining type, the cutting tool remains perpendicular to the part, allowing the machine to reach more intricate areas while providing quality surface finishes.

This method is slow compared to 3+2 axis machining; however, it can produce more complex curved designs and shapes

Pros and Cons of 5-Axis CNC Machining

Pros

- Can work on more complex geometries and angles.

- Operates at a higher speed in one setup.

- Adequate for higher precision and quality machining.

- Suitable for complex material while also working with less time.

- Can efficiently work on a contoured surface.

- Reduces tool wear out as much as possible.

Cons

- Require more purchase, set up, and maintenance costs

- Requires extra guidance and training to use.

- Might need more programming training due to the extra 2 axes present.

When to Choose 5-Axis CNC Machining?

You should use 5-axis CNC machining when:

- Machining involves higher production outputs.

- Working on more complex geometries, shapes, or designs.

- Higher precision is needed, for example, in the medical and aerospace sectors.

- Machining a workpiece with several sides and features on each of them.

What are the Differences Between 4-axis CNC Machining vs 5-axis CNC Machining?

Here are the differences between the 4-axis and 5-axis CNC machining you should know.

Difference in Axes

4-axis CNC machines have only one additional A axis, while 5-axis machines have two, which could be either of the A, B, or C axes.

Rotation in Axes

The 4-axis allows rotation only on the A axis, while the 5-axis allows rotation on two axes, either of the A, B, or C axes. This characteristic makes the 5-axis much more flexible in terms of the movement of the cutting tool.

Accuracy and Precision

While the CNC machining process is known for its accuracy and precision, 3-axis CNC machining might offer you less accuracy since it involves constant repositioning of the material.

4-axis and 5-axis machining, on the other hand, offers more precision since there is no manual repositioning.

This helps avoid deviations while also creating several designs on a material with just a single setup. However, the 5-axis provides more accuracy and precision compared to 4-axis CNC machining.

Lead Time

With 5-axis machining, less time is needed to complete operations, and so higher output can be generated while also improving efficiency. This is possible because of the multiple-cutting abilities that make machining much easier.

Flexibility

In terms of flexibility, 4-axis CNC machines usually have an additional axis on the X-axis. However, the 5-axis machines could have their extra axis on the XY and Z axes.

Cost

Generally, the 5-axis machines are much more expensive than the 4-axis. This is due to their advanced features and capabilities, enabling them to handle higher volume production, complex designs and so on.

Table Explaining the Differences Between 4 axis and 5 Axis CNC Machining

| Features | 4 Axis CNC Machining | 5 Axis CNC Machining |

| Flexibility | The additional A axis usually rotates around the X axis, which makes movement limited to a single direction. | The 2 additional axes rotate on the XY and Z axes; two out of the three. This allows for more rotation so that the material can be worked on from many sides. |

| Number of Axes | Has the basic XY and Z axes, together with the A axis. | It has the XYZ axes together with an extra 2 axes, which can be two out of the AB and C axes. |

| Volume of Production | Could handle high production but not as high as 5-axis | Can handle much higher volume production. |

| Cost | Relatively cheaper than 5-axis | Quite expensive compared to 4-axis machines |

| Application | Suitable for operations involving several sides, angles, and holes. | Best for advanced 3D machining requiring more accuracy. |

Applications of 4-axis CNC Machining vs 5-axis CNC Machining

4-axis and 5-axis CNC machining is valuable in different industries. Here are some applications to note.

4 Axis CNC Machining

Automotive: They are used in manufacturing engine parts. Also, they are important in creating automobile body components.

Aerospace: Their precision level is vital in producing turbines and airframe parts.

Oil and Gas: Used in creating quality components that can resist harsh conditions.

Electronics: Valuable in manufacturing casings and circuit boards, which require precision.

5 Axis CNC Machining

Medical: Essential in producing complex-shaped medical equipment, like knee replacement

Energy: Used in producing turbine components, which require a high precision level.

Automotive: Used in creating custom components and engine parts.

Aerospace: Necessary for producing complex aero-engine component designs.

How to Choose Between 4-axis CNC Machining vs 5-axis CNC Machining

Budget

Since 5-axis machining offers more advanced operations with high efficiency and precision, they are generally more expensive. However, if you are on a fair budget, then 4-axis machining would be suitable as it still offers many valuable features at a moderate cost.

Volume of Production

5-axis CNC machines are mostly suitable for a large-volume manufacturing process. If your production level is low or moderate, you can consider 4 axes.

Part Shape and Complexity

If you are working on a simple or moderately complex part, a 4-axis machine is suitable. However, if you’re working on a highly complex curve, shapes, geometries, or parts with tight tolerances, consider using 5-axis machining.

Application

Your choice also depends on the industry in which the output will be used. Aerospace and medical components usually require high precision and quality, which can most time only be achieved with 5-axis CNC machining.

Time Factor

While 5-axis CNC machines require more time to set up, their production speed is high. For the 4-axis, setting up is simple and fast, but production takes more time.

Conclusion

While the 5-axis offers higher precision, production volume, and efficiency, 4-axis machining is suitable if you’re working on a basic to moderate part and on a fair budget.

Whether you need a quality and top-notch CNC machining service or you need help deciding between 4-axis and 5-axis machining, DEK’s group of experts is always available. Our CNC machine workshop has several advanced technological machines that suit your project needs, so contact us now.