Aerospace CNC machining plays an important role in creating high-accuracy components that meet the standards of the aerospace industry. From aircraft engines to landing gear, CNC technology secures validity, exactness, and excellent quality in every part.

By using a mixture of complex milling, turning, and finishing operations, one can achieve a wide range of consistent performances under extreme conditions. This blog explains to you about the key materials, machining processes, and surface finishes used in aerospace CNC manufacturing.

What is Aerospace CNC Machining?

Aerospace CNC machining is a subtractive operation. Material is removed from a block with the aid of computer-controlled tools. The method results in parts with tight limits and repeatable quality. CNC machines control speed, feed, and tool paths.

This level of control reduces human error and facilitates the production of complex shapes beyond the reach of machining capabilities. In aerospace, every part is needed to maintain the highest standards.

Benefits of Using CNC Machining for Aerospace Parts

CNC machining is also called the rock of aerospace manufacturing. Manual or traditional methods, CNC machining ensures that elements meet accurate criteria for aircraft performance and safety.

Exceptional Precision and Accuracy

Aerospace components must perfectly fit into complex systems like engines, turbines, landing gears, etc. CNC machining provides micrometer precision for any assembly, where each part must maintain expected tolerances during mass production.

This precision reduces the incidence of errors and ensures reliable operation of parts, even in high-stress situations.

Compatibility with Advanced Materials

Aerospace manufacturing will generally deal with materials like titanium, Inconel, and aluminum alloys considered strong and lightweight.

Good CNC machines are capable of cutting these very tough materials. It allows for superior surface finish and cutting performance without damaging material integrity.

Enhanced Production Efficiency

Automated programming and multi-axis capability are some ways CNC machining will reduce production time. Aerospace parts that once could require numerous setups can now be completed from start to finish in one fell swoop.

This incorporates the capability for manufacturers to meet tight deadlines while ensuring their products remain.

Repeatability and Quality Control

All these aerospace components must indeed replicate in every measure, like shape, size, and performance. CNC machining dominates this repeatability by performing the same programmed procedures in thousands of cycles.

This cancels out the chance of human error and supports the most demanding aerospace quality measures, such as AS9100 and ISO 9001.

Cost-Effectiveness in High-Precision Manufacturing

CNC machines are an upfront investment. Payback over time is considerable. Lessens waste and rework and shortens production cycles. All lead to reduced costs for aerospace applications, where superlative quality is always expected.

Versatility in Design and Customization

CNC machining allows engineers to manufacture complex geometries, intricate channels, and lightweight structures that were impossible to manufacture manually. This freedom furthers the development of new-age aerospace designs aimed at optimum performance and weight-fuel consumption.

Materials Used in Aerospace Machining

Aluminum and Aluminum Alloys

Aluminum is lightweight and good for machining. Most of the time, 6061, 2024, or 7075 would be selected. While 7075 provides high strength for primary structures, 6061 is easier to mill and cheaper. Aluminum finds uses in fuselage panels, brackets, and housings.

Aluminum is easy to machine using standard end mills. When CNC milling aluminum, pay attention to chip evacuation and tool coating to prevent clog-ups.

Titanium and Titanium Alloys

Titanium gives you one of the best lightweight strength ratios, along with corrosion resistance. Some applications include engine casings, landing gear parts, and airframe fittings. Titanium grades work-harden and get hot easily.

Slow down the spindle speed, use rigid tooling, and make coolant a priority. When turning titanium, use sharp inserts with controlled feed rates.

Inconel Superalloys

Inconel is used for extreme heat and stress. Turbine and exhaust components locate it. Oxidation is resisted at these high temperatures.

It is gummy and work-hardens, requiring heavy-duty machines, rigid fixturing, and carbide or ceramic tools. Longer machining cycles must be expected with Inconel.

Carbon Steel

Carbon steel integrates toughness and wear resistance. It is used with structural fittings and components with high loads. Heat treatment will follow the machining process to obtain the required hardness.

It is all about tools and controlling chips. It puts on those coatings that resist wear when milling or turning steel.

Brass

Brass is easy to machine and retains tight tolerances. It is often used for connectors, hydraulic fittings, and precision bushings. It finds its application in avionics, owing to its good finish and conductivity.

Bronze

Bronze is used to manufacture bearings and wear surfaces. It displays good friction properties and lasts well in sliding applications. When machining bronze, chip management is important to prevent surface damage.

Copper

Copper has good thermal and electrical conductivity. Use copper for heat exchangers, busbars, and thermal management components. Its softness may result in chips building up on the cutting edge, so always work with sharp cutters.

Stainless Steel

Stainless steel is corrosion-resistant, yet strong. For numerous aerospace parts, 17-4 or 15-5PH is used. Maintain coolant and suitable speeds to avoid work hardening.

Engineering Plastics

Polymers such as PEEK, Ultem, and PTFE can serve as an insulator, light support bracket or seal. They are easy to CNC but require careful feeds to avoid melting. Plastics allow you to go lighter and offer electrical isolation.

Machining Processes for CNC Aerospace

CNC Milling

Milling is a material-removing process using rotating cutter tools. It accommodates all complex geometries, contours, pockets, and flanges. Multi-axis milling decreases setups and improves surface finish.

When milling in aerospace, go with the DFM rules. Keep wall thickness constant and do not use thin features that are unsupported. This avoids warping of parts and is favorable for machining.

CNC Turning

Turning is the best alternative for cylindrical parts. You would make use of shafts, pins, or threaded components. Swiss-type lathes generate long, slender parts with excellent concentricity on turning operations.

Control the tool nose radius and feeds to achieve surface finish targets. Independently, turning goes with secondary milling for complex parts.

CNC Drilling

Drilling is used to make precise holes for fasteners and assemblies. One must control for runout and straightness of the hole. Pecking drill for a deep hole and coolant for the chips.

Drilled holes usually undergo some reaming or honing to get the required tolerance. This ensures the proper fit for the fastener and assemblies.

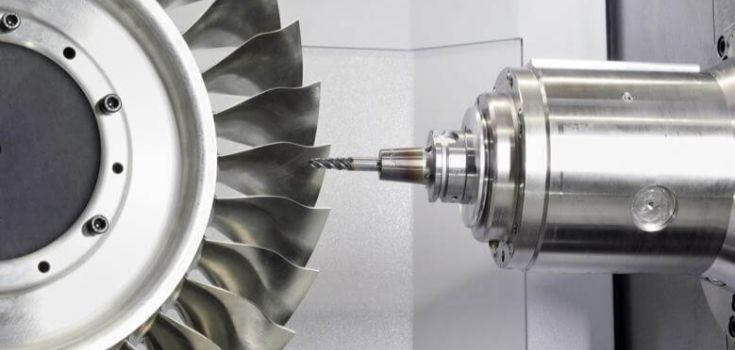

5-Axis CNC Machining

The 5-axis permits access to the parts from many angles. One can finish a complex part in a single setup. This functionality helps to minimize human handling.

Use 5-axis for impellers, aerospace brackets, and complex airframe parts. It saves time and increases dimensional accuracy.

Wire EDM Machining

Wire EDM cuts conductive materials using controlled electrical discharges. It is used for tight slots, internal features, and parts hard to mill. EDM provides you with almost mirror-edge quality. The wire EDM is the best for hardened steels, inconels, and complicated profiles.

Important Aerospace Machining Certifications

AS9100 Certification

AS9100 specializes in excellence systems for aerospace. If your supplier has AS9100, it means that they have documentation for traceability, control, and continuous improvement. It is smart to pick AS9100 for parts that are critical for flight.

ITAR

ITAR forbids the export of defense-related components. If your part is under the rules set forth by ITAR, you must follow very strict handling and shipping regulations. It is recommended to vet the ITAR compliance status of your focused partner before awarding them the contract.

FAI

First Article Inspection (FAI) allows you to prove that your first produced part meets all specifications. You use FAI to validate your processes before engaging in any sort of serious-volume run.

The FAI documents dimensions, materials, and processes, thus confirming that you can prevent any nasty surprises from occurring.

Standard Surface Finishes for CNC-Machined Aircraft Parts

Anodizing

Anodizing will provide corrosion resistance and color to aluminum parts. Type II anodizing provides a cosmetic finish. Type III anodizing provides a hard, wear-resistant coating. The selection of anodizing type depends on the environment and wear parameters.

It also enhances the attachment of subsequent surface coatings, including painting and gluing, thus ensuring the durability of overall coatings.

Passivation

A passivation process removes surface iron and enhances corrosion resistance on stainless steel. Parts facing harsh environments or fluids should be passivated. It ensures a clean surface, free from impurities, suitable for aerospace assemblies.

Polishing

Polishing decreases surface roughness and can increase the aerodynamic effect. Polish for visible surfaces or parts in need of a smooth transition for fluid flow. It also increases the reflectivity of a surface and reduces the probability of weak cracking of critical parts.

Powder Coating

Powder coating is used for strong protection and coloration. It keeps chips and UV rays out. It is fine to apply to external panels or interior fixings. Once applied, it provides an even finish that will not be affected by vibrations and temperature changes during flight.

Painting

Aerospace paints provide corrosion protection and identification. Use aerospace-grade paints tested for flammability, bonding, and environmental exposure. They also allow for marking and branding while maintaining aerodynamic smoothness.

Hard Coating

Hard coatings increase surface wear resistance. Use them on sliding or contact surfaces. Hard anodizing is common for aluminum parts. Such coatings also reduce friction, extending component service life under stress.

Electroplating

Electroplating deposits thin metal layers for conductivity or corrosion resistance. Use nickel or gold plating for electrical contacts and shielding. It enhances solderability and improves electrical performance in sensitive avionics.

Thermal Spray Coating

Thermal spray applies ceramic or metal layers for high-temperature protection. It is common in engine and exhaust components to resist heat and erosion. It also restores dimensions and extends the operational life of important components.

Applications of Aerospace CNC Machining

CNC machine tools can be considered to play a very important role and impart quality and reliability to the critical components. This system operates in the different stages of production-from prototyping through final production. It receives from each stage one part at a time. Also, ensuring that each one meets the exacting performance standards.

Rapid Prototyping

Engineers use CNC machining to produce accurate prototypes that help test fit, form, and function in advance of mass production. With working prototypes, errors are avoided and development time is reduced.

Aviation Components

CNC machining takes place for parts such as aircraft engines, landing gear, brackets, and control systems, where accuracy and durability are paramount. Small quantities with high precision are put to work under aviation needs via CNC machining.

Space Exploration

For spacecraft and satellite production, CNC machining offers lightweight but sturdy parts capable of surviving extreme temperatures and pressures. Such parts are made from materials like titanium and Inconel, which have strength and stability.

How Important is Precision When CNC Machining Aerospace Parts?

In aerospace, accuracy is above everything. Any slight margin of error introduces the possibility of complications during assembly or an influence on flight dynamics. The more closely the tolerances are, the better the benefit of vibration damping and fuel efficiency.

Once tolerances are maintained, there is a decrease in rework and scrap. This means saving costs and protecting schedules. All critical dimensions should be verified using calibrated CMMs and appropriate inspection plans.

Conclusion

CNC machining for the aerospace industry yields dependable parts from advanced materials. The processes range from milling to turning to wire EDM, each ensuring a tight control over requirements.

DEK delivers high-value aerospace manufacturing and provides expert DFM feedback. For exacting CNC machining delivered with traceable quality and practical DFM support on your next project, contact us.