With the development of production, gears operation more and more attention by people, there are many types of it. You still can not find the right gear and trouble? This article is for you to solve the problems.

What are gears?

Gears are cylindrical, circular or cone-shaped toothed mechanisms. The teeth are carved in the material at equal distances. Gear teeth are also known as cogs and gears as cogged wheels or toothed wheels. There are many ways used for the production of gears, such as blanking, forging, powder metallurgy, extrusion, casting, and machining. They are usually attached to machines by means of a shaft. A pair of gears are meshed together through teeth to increase the movement and force in the mechanism.

Most Common Types of Gears

There are many types of gears that differ in shapes, sizes (radius), and the number and arrangement of teeth. The type of gears that are most commonly used include,

- Spur gears

- Helical gears (and screw gears)

- Double helical gears (and herringbone gears)

- Rack and pinion

- Bevel gears

- (straight, Zerol, spiral, Hypoid, crown, and Miter bevel gears)

- Worm gears

- Internal gears

Spur gears

Spur gears have straight teeth with a cylindrical or circular body. They are one of the most efficient types and are very simple to construct. Teeth straight to the shaft axis are carved in the gear body, and hence, they are a part of the parallel shaft gear group. They can manage significant loads with a high velocity and higher accuracy rate as compared to other types of gears.

Spur gears do not generate axial (thrust load) on the shaft and are noisy while performing accelerated operations. In a mashing pair of gears, the smaller one is called pinion, and the larger one is called gear. Machines have spur gears attached in mashing pairs with internal gears, gear racks, and even spur gear.

The most commonly used gear amongst all is spur gear. These are widely used in industries such as beverage, food, and automotive industries. They are also significant in small machines (clocks, household machines like clothes drying machines, washing machines) and large machines (in power plants, pumps, farms, trains, product handling machinery, and planetary gear sets with internal gears).

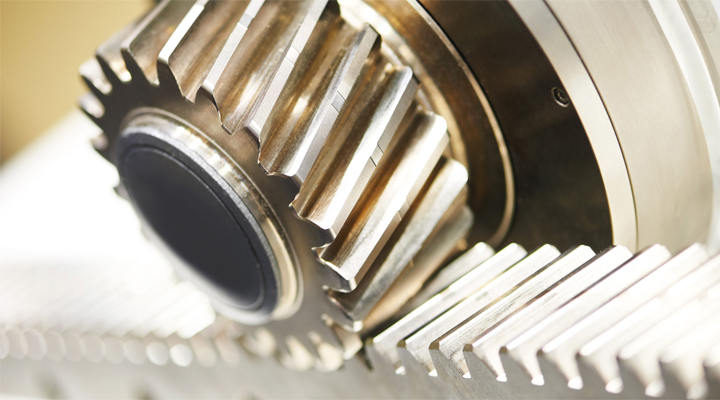

Helical gears

Helical gears are cylindrical gears and are used with straight shafts. They are different from spur gears as the teeth are twisted and angled. Helical gears are capable of handling more load than spur gears as the curved arrangement of teeth causes the connection of two teeth of each gear at a time during application. It also becomes a reason behind the lesser noise during high-speed and heavy load operations.

It is mandatory to use thrust bearings with helical gears because they generate thrust (axial direction) load. The teeth of helical gears are of two types, right hand and left hand twisted teeth. So you have to use one helical gear with the left hand and the other with right hand winded teeth to make a mashing pair.

Helical gears are used in heavy industries such as power plants, beverages, mining, cement, food, and forests. They have excellent tolerance of heavier loads and are thus, used in hefty material handling and transferring machines, generators, and pumps. Due to their super quiet nature than spur gears, they are also used in transmission systems in automobiles.

Screw Gears

Screw gears are a type of single helical gears. In contrast to helical gears, they are used for non-intersecting and non-parallel configurations. Screw gears use a mashing pair of the same hand toothed helical gears and not left and right toothed helical gears. They cannot ideally perform a high energy and high-speed operation because of their lower load handling and lower efficiency. They need lubrication when working and are also known as crossed helical gears.

Screw gears are also used for parallel as well as skewed offset shafts depending on the direction of the teeth of mating gears.

Double helical gears

Besides a single helix, helical gears also come as double helical gears. In double helical gear, there are two rows of angled teeth similar to each other but opposite in direction. In simple words, two rows of winded (twisted) teeth that look like a mirror image of one another are cut on a single gear. The two rows are separated by each other with a gap in between. Using a mashing pair of double helical gears can quickly eliminate thrust load.

Double helical are more durable, stronger, and operate more smoothly than single ones. To use double-helical gears in machines like generators, pumps, mining, construction, marine, transmission systems in gas turbines and fans is very common.

Herringbone gears

Herringbone gear is a variation of double helical gears. The slight difference between herringbone and double helical gear is the gap between the two mirrored rows of teeth. There is no space between the two rows of teeth, and they are joined, forming a “V” shape like a herringbone pattern.

They are smaller in size than double helical and not frequently used because of their higher cost and complicated production compared to other gears. The use of herringbone gears is common in heavy industries like mining, marine, ships, and steam turbines.

Rack and Pinion

Rack and pinion is a mashing pair of gear racks with either a helical gear or a spur gear, known as pinion. A gear rack is a flat rod having a straight tooth line, and the teeth carved in the bar are of identical shape and size at equal spaces. It can bear heavy loads, and the design and manufacture of the gear rack are pretty simple and easy.

When the gear rack has a mating pair with the spur gear, it has straight and parallel teeth, and the rotation motion will convert into linear motion. And when the mating pair is between the gear rack and the helical gear, the teeth are also helical, i.e. angled and then the linear motion will convert into rotation motion.

Rack and pinion are used in many types of machinery such as material transferring equipment, trains and railways, weighing scales, and rack and pinion steering systems of automobiles.

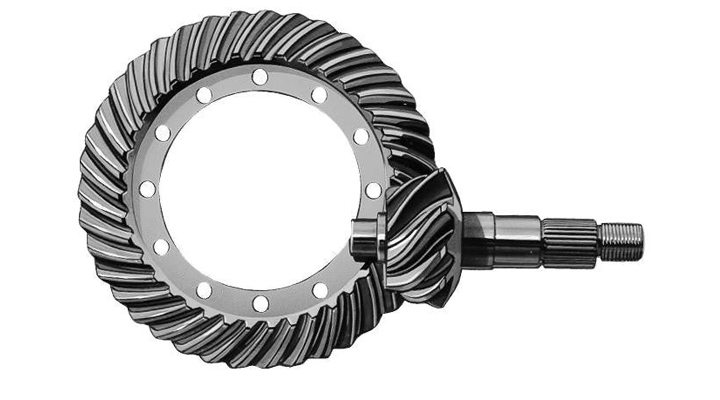

Bevel gears

In bevel gears, the teeth are on the conical pitch surface. Bevel gears are commonly used to transfer force and motion between two intersecting shafts (at 90o angle). It ideally manages 90o shaft configuration but can also handle greater or smaller arrangements. There is no such frequent use of bevel gears because of their high manufacturing cost and complex production.

Bevel gears are used in automobiles, pumps, trains and railways, power plants, product handling equipment, and aircraft. On the basis of the teeth shapes and arrangement, the cone-shaped bevel gears are mainly of three types.

Straight bevel gears

The most commonly used bevel gears are straight bevel gears of all types. The teeth are placed in a parallel pattern on the conical gear in this type. They are simple and easy to manufacture, but due to their straight teeth, they produce a large amount of noise and are all less efficient than spiral gears. Same as the spur gears, they do not make thrust load in the axial direction.

Zerol Bevel gears

It is the second type of bevel gear, and they are the ones with zero twisting angle. This type of bevel gear is somewhat like a spiral as well as a straight bevel gear. In Zerol bevel gears, the teeth are not angled but curved like spiral gears that means the curve teeth are straight in positioning. They can perform the same applications as straight bevel gears but are more durable and less noisy than them. The Zerol gear comes in both right hand and left hand twisted teeth, but they can spin in both directions.

Spiral bevel gears

The characters of spiral bevel gears are much like helical gears. In these gears, the teeth on the conical pitch surface are curved and thus produce thrust load in the axial direction. The teeth of spiral bevel gears contact more smoothly, helping them in lessening the noise, vibration, and stress on the teeth. They can perform operations that need higher accuracy and high speed. Same as helical gears, they come in right-hand spiral and left-hand spiral teeth and are costly and difficult to manufacture but are more durable than straight bevel gears.

More Types of Bevel Gears

Apart from the three main types mentioned above, bevel gears have many variations. Some of them are Hypoid, crown, and Miter gears.

Hypoid gears

Hypoid gears are a variety of spiral bevel gears, but unlike them, they work on non-intersecting and non-parallel shafts. The teeth are twisted and angled just like spiral bevel gears. The use of bearings is a must in the mashing pair of Hypoid gears because the placement of the gear and pinion is not on the same level. The production of Hypoid gears is pricier and more complicated as compared to spiral bevel gears. These gears are not used very frequently because of their high prices.

They are used in cement, food, mining, and beverage industries, but the main application of Hypoid gears are in the automobiles industries. They are also used in power plants, conveyors, material transfer systems, and mixers.

Crown Gears

Crown gears are another variation of bevel gears in which the pitch surface is plane, and the body is cylindrical instead of conical. The name crown is because of its crown-like structure. The gear teeth are placed at 90o to the gear face making it look like a crown. They are also known as “face gears”. The mashing pair of crown gears depends on the designs of their teeth, and they can pair with spur gears and other types of bevel gears. The usage of crown gears in machines for reducing noise and vibration is widespread.

Miter Gears

The Miter gears have a shaft angle of 90o whereas, angular Miter gears can have any shaft angle except the right angle. The Miter gears are mainly used in machines to shift the transmitting direction of force while keeping the speed constant. With the use of a mashing pair of two Miter gears with the same numbers and shape of teeth, the speed ratio becomes 1:1. The Miter gears produce thrust load (axial load), which is why thrust bearings are always used with a mashing pair of Miter gears to reduce thrust load.

Worm gears

The worm gear transfers force and motion at right angles between non-intersecting and non-parallel shafts. It is a mashing pair of a worm and worm wheel, where the worm is a screw-like shaft, and the worm wheel is a cylindrical gear. They are superior in operating smoothly and quietly, but they are not as excellent when it comes to efficiency as other gear types.

The manufacture of the hourglass worm gear is more complicated. The sliding of worm and worm gear surfaces causes friction, which makes lubrication necessary during the application. If the worm has a small lead angle, it is impossible for the worm wheel to turn the worm, which is called the self-locking characteristic.

The most common use of worm gears is in systems that need the self-locking feature. They are also used in steering systems of automobiles, material transferring equipment, elevators, and lifts.

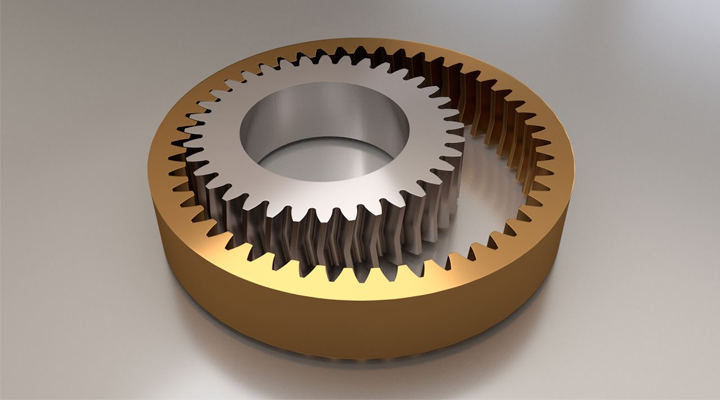

Internal gears

Internal gears are cylindrical or conical gears in which teeth are present on the inside of the gear body. They make a mashing pair with external gears, and the number of teeth is different in both gears due to the difference in sizes. The difference in the number of teeth is finite because of trimming issues, trochoid interference, and involute interference.

Most of the time, spur gears are used as external gears to pair with internal gears. Unlike the mesh of external gears, the meshing pair of external and internal gear spins in the same direction. Pinion cutters are used for shaping and manufacturing internal gears.

The main reason for manufacturing internal gears is to use them in shaft couplings and planetary gearbox operations.

Conclusion

Gears are an essential part of the machinery and are crafted with utmost care and precision. The right gears must be chosen to ensure the efficient functioning of the machine and ideal outcomes. Choose the one you feel fits the best, or connect to us to know more about gears and the right choice for you!