Crankshafts are manufactured by casting modified cast iron and use in marine, stationary, locomotive, and tractor engines. It is made by heating the steel block until the red hot then formed into the shape by extreme pressure. Cast iron crankshafts are cheaper and less time-consuming for the manufacturer as compare to those made from forged steel.

In this article, we will thoroughly discuss the functions, types, and parts of the crankshaft. The working principle and applications are also discussed in this article. Complete detail of DEK manufactured crankshaft is also mentioned at the end of the article.

What is Crankshaft?

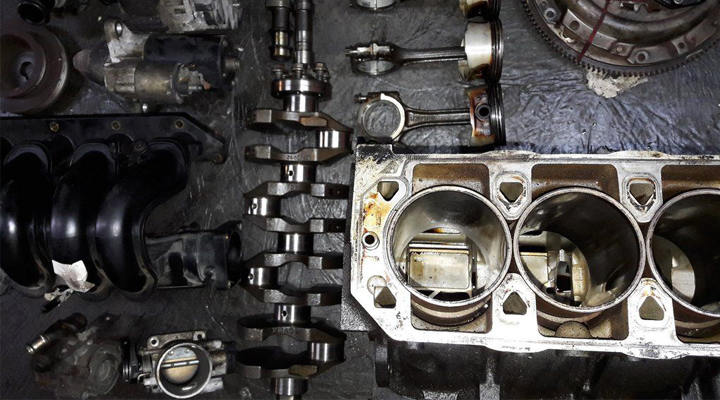

The crankshaft is the most important part of the internal combustion engine and faces a very high load during the use of the engine. Its function is to transform linear motion into rotational motion. Or you can say it is the mechanical part that performs reciprocating motion into rotational motion. The selection of the material and manufacturing depend upon the type of the engine and the design and the geometry of the crankshaft. To ensure long operational life it is necessary to use high-strength material.

What is the function of the Crankshaft?

The crankshaft is important to provide a smooth drive to the vast motors with multi-cylinders. While inspecting the crankshaft, you can discover the rod bearing is almost balanced. At this place, the balance of the shaft changes the responding movement into the rotating motion of the crankshaft. The shaft is bored with the minute holes to feed the shaft with the oil to keep the activities smooth. This mechanical part is consisting of some counterweight that helps the framework to adjust and control the heaviness of the connecting rod.

It also guarantees to adjust the power while rotating the moving part. The crankshaft is structure according to each motor. Its design is based on the number of the cylinders in motor and its size. In the ignition cycle, the crank throws fill in a lever arm that pulls and pushes the cylinders. This helps the rotational movement of the motor. When the crankshaft completes its rotation, which restores the piston to the highest point of the cylinders. To maintain the weight and balance to reduce the vibration in the motor, the crankshaft needs a pure smooth design. Such vibrations can be lethal and extremely unsafe.

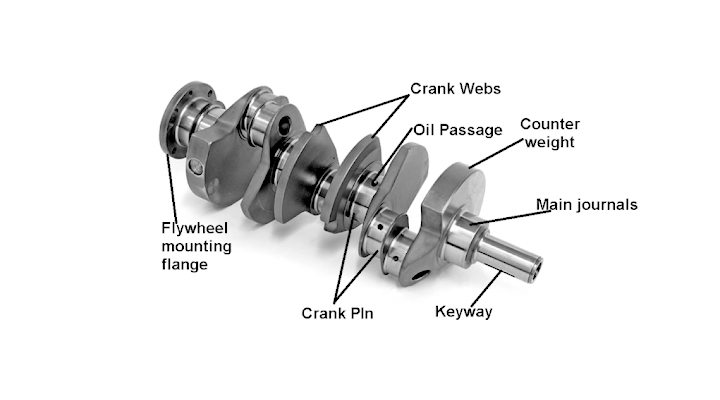

What are the parts of a Crankshaft?

Crankpin

The crankpin is the mechanical part of the engine by which connecting road attached itself with the crankshaft very firmly. To give the rotating force to the large part of the connecting rod its shape is cylindrical. Crankpin is also known as the connecting rod journals.

Main Journals

These are attached to the engine blocks. The main journal bearing holds the crankshaft and specifies the axis of the rotation of the shaft. These bearings differ from engine to engine, depend upon the force given by the engine. This bearing is like plain bearings and journal bearings.

Crank Web

This is the most important part of the crankshaft. Crank web connects the crankshaft to the main journals.

Counterweight

This is the weight that applies the opposite force that helps the crankshaft in balance and stability. These are mounted on the crank web. The reason for placing the counterweight in the crankshaft is, they can eliminate the reaction caused by the rotation motion. It also makes the engine run easily and helpful in increasing the RPM rate.

Types of Crankshafts

The crankshaft can be forged from the steel bar through roll forging or cast in ductile steel. Today more and more manufacturers favor forged crankshafts due to their lighter weight, better inherent dampening, and more compact dimensions. Below mentioned are the two types of crankshafts.

Monolith

Monolith is made from the one-piece this is the reason it was called a monolith. Monolith crankshafts are very popular and are used in multi-cylinder engines.

Assembled

Assembled type crankshaft is made from separate elements, which is mainly used in motorcycles. Assembled crankshafts are also used in large and small engines.

Types of Crankshafts in Marine engine

Fully Built

As the name suggests these kinds of shafts are built parts by part. In a fully built shaft, various components are fitted together after separate fabrication. This consists of forging separate crank web, crankpins, and main journals.

This process is easy in sense of joining small parts to create a bigger shaft. In this way, handling pieces are easier. Fully built shafts are heavier as they are made from extra metal to bear the shrink forces. This leads to making the shaft difficult to make and heavier. These shafts are not used anymore.

Semi Built Shaft

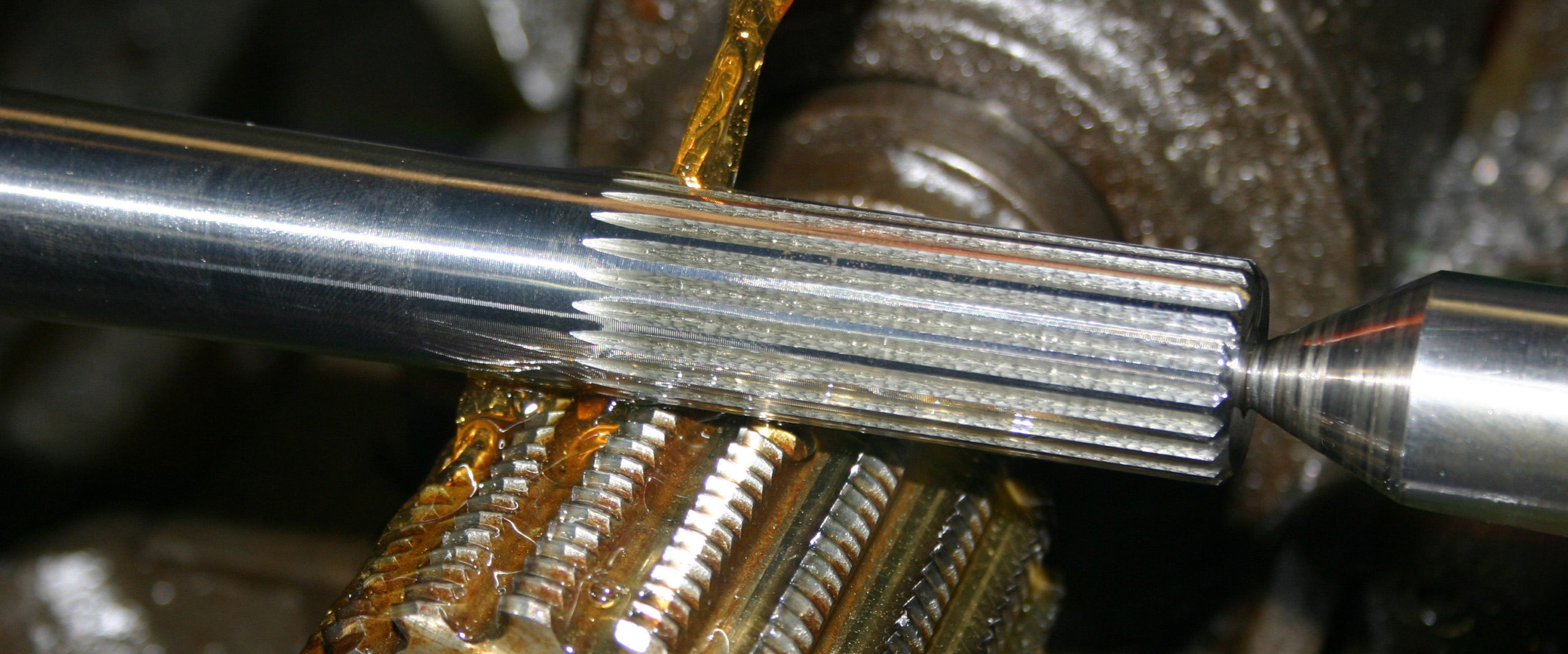

They are not made from assembling many parts like a fully built shaft. In this shaft, the fully built crank web is forged and shrunk fit to bearing generals. So, the crankpin and crank web material is the same and they are machined together to give a smooth surface finish. Nowadays, mostly large diesel engines used in ship’s main engines are created from this kind of process. This process helps us get grain structure all over the crank web and avoid heat damage to the holes of the crank while putting journals into it.

Welded Crankshaft

In this type of shaft making, all parts are assembled through welding. So, the one half is welded to the other half. The same is used to join journals to the crank web. Very few shafts are made through this process but they are quite well and lasted very long intervals as compared to other types. This process of making the shafts are too costly and now the manufacturer stopped making shafts using this process.

Single Solid Piece

These shafts are forged or cast as a single piece. Single solid piece shafts are used in small, medium, and high-speed engines. It is created in more than one part and bolted together with bolts on the integral flanges. This is designed in a way to withstand the firing and cyclic stresses. The crankshaft is stressed due to misalignment, axial vibration, and torsion vibration of the main bearing.

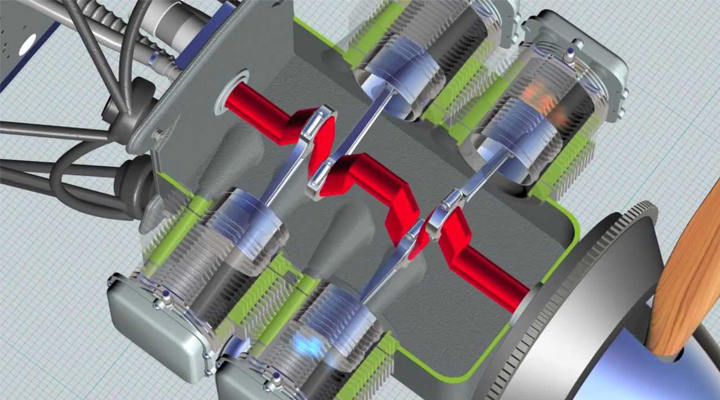

How does Crankshaft work?

Fundamentally, the crankshaft performs a simple task. It translates the linear motion of the piston into rotational motion. Although the principle is simple we have to look closely to see how it works. The crankshaft moves in an upward and downward direction in cylinders. It regulates the motion of the piston. Two components of the engine camshaft and crankshaft are synchronized to regulate the piston movement properly.

The movement of the crankshaft rotates the camshaft that controls the operations of the intake and exhaust valves. This lets the air flow in the engine cylinders which helps in an explosion inside the engine cylinders. This explosion puts pressure on the piston and delivers energy to the flywheel.

Where is Crankshaft used?

The crankshaft is mainly used for the linear reciprocating motion of the piston into the rotating motion. This helps your car to move. If you know how the engines work, it reciprocates as the fuel burns and gases are emitted. Its functions include keeping the piston from crashing into the cylinder head and from falling out at the bottom of the bores. A multi-cylinder engine ensures the piston reaches the top at the appropriate time. It also helps in preserving basic engine balance by crank angular displacement for an appropriate interval of time.

The other functions of the crankshaft are to transmit power to the other engine systems like the oil pump, air conditioning compressor, valve timing, and alternator.

Can you offer customized Crankshaft?

If you are a manufacturer who is looking for a crankshaft with paramount quality that lasts long and provides beyond measurable ROI, DEK should be your first choice. Our crankshaft is trusted by the top manufacturers around the globe. We make a top-notch customized on-demand crankshaft that increases the engine capability and your brand value in the market. We are experienced in custom manufacturing and crafting machines that provide the finest operational reliability.

We at DEK offer our service to a wide range of clientele spread worldwide with the utmost build quality and bespoke service. Our quality is what makes us unique in the industry.

Conclusion

In the above section, we have thoroughly discussed the crankshaft functions, parts, types, usability, and working pattern. This article gives an overall idea about each function of the crankshaft along with the types of engines you can use crankshaft in. You can now decide on the best practice and crankshaft type that you can employ in your manufacturing.

Place your order right now to get your order at your business address. You can always contact our engineers for technical support or if you have any queries about the product.