Rivets are fasteners used to join two or more parts together, typically made of metal. They are indispensable across various industries. Today, following DEK’s lead, let’s learn about the types of rivets and their uses, enabling you to select the most suitable rivets for your projects!

Types of Rivets and Their Uses

Solid Rivets

Solid rivets are the strongest and most reliable fasteners used in joint connections. They are typically cylindrical and consist of a head and a shaft. The head comes in various shapes such as round, flat, oval, and cone-shaped, to accommodate different applications. Solid rivets are usually made of steel, aluminum, or copper. Installation requires a rivet setter tool to apply external force.

These rivets exhibit excellent characteristics such as high strength, strong corrosion resistance, and durability. As a result, they are commonly used in industries such as automotive, aerospace, electronics, marine, and machinery manufacturing.

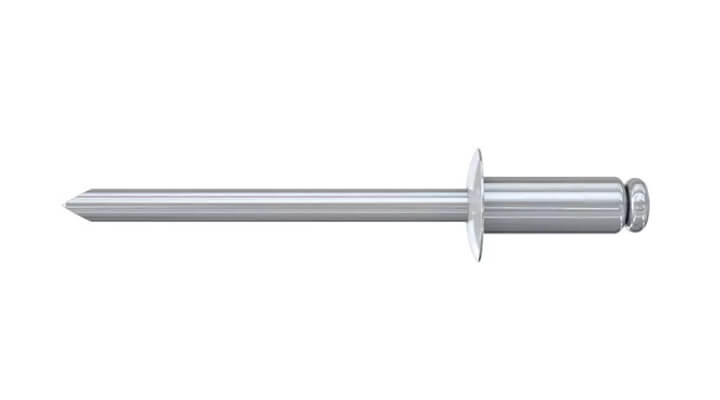

Blind/Pop Rivets

Blind rivets, suitable for single-sided riveting, are mainly composed of a nail, a sleeve, a locking ring, and a cap.

Among them, the open-type flat round head blind rivet is the most widely used, while the countersunk blind rivet is suitable for applications requiring smooth riveting surfaces. The sealed blind rivet is suitable for applications requiring high loads and certain sealing properties. They are widely used in industries such as construction, automotive, shipbuilding, aviation, and machinery.

Drive Rivets

Drive rivets, typically consisting of a shaft and a cylindrical head, are installed by placing them into a hole and then hammering the protruding portion to complete the riveting fastening.

These rivets exhibit good tensile and shear performance, have a simple structure, and are easy to install quickly. They are commonly used in commercial sheet metal applications.

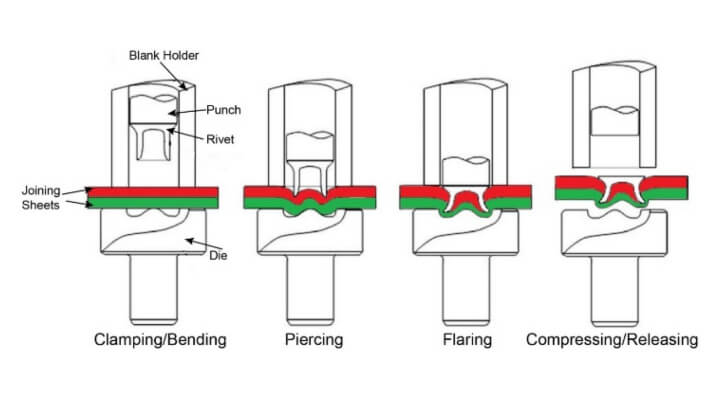

Self-Piercing Rivets

Self-piercing rivets, typically semi-hollow, are usually made of alloy steel. They do not require pre-drilling or punching before use. The shape of the tail allows the rivet to easily pierce the material to be riveted.

These rivets can form a stable connection and have high tensile and shear strength. They are widely used in industries requiring fast and efficient connections, such as automotive and aerospace.

Tubular Rivets

Tubular rivets are metal products consisting of a head, a shaft, and a partially hollow tube. Typically, one end has a head, while the other side is hollow. They are used for connections by piercing the component through the hollow end, often cold-forming the hollow end into a field head.

Due to the requirement for extensive cold-forming, choosing a highly ductile, low-strength metal is crucial. These rivets are commonly used in commercial applications and the electrical equipment industry.

Flush Rivets

Flush rivets, also known as countersunk rivets, typically consist of a slightly concave or flat head and a shaft. They are best used on exterior surfaces and are commonly employed in applications requiring connections to be flush, aesthetically pleasing, and less susceptible to damage, such as in the aerospace and construction industries.

Split Rivets

Split rivets, also known as bifurcated rivets, are lightweight rivets consisting of a forked shaft and a head. The shaft is divided into two separate legs, with sharp ends that facilitate piercing materials. They are preferred fasteners for connecting soft materials such as plastics and leather, making them suitable for household repairs but not ideal for critical applications.

Conclusion

Through the learning about the types and applications of rivets above, you should have a clear understanding of the rivets you need. If you still have doubts about which type of rivet is suitable for your project, DEK’s professional team is always ready to answer your questions. You can contact us by sending an email to our mailbox: quote@dekmake.com. We will be dedicated to serving you.

FAQs

The biggest difference between semi-hollow rivets and tubular rivets?

The shaft retention depth of semi-hollow rivets is kept less than 112% of the shaft diameter, while the shaft hole depth of tubular rivets is at least 112% of the shaft diameter.

Which material is most suitable for making rivets?

Generally, rivets are typically made from high-strength metal materials such as steel, stainless steel, aluminum alloys, etc. These materials have excellent strength and corrosion resistance, meeting various application requirements.

Which type of rivet is the most widely used?

The most widely used type of rivet is the blind rivet (POP rivet). This type of rivet is easy to use, requiring no specialized equipment, and can quickly and effectively join two or more workpieces together.