Usinage CNC 4 axes Service

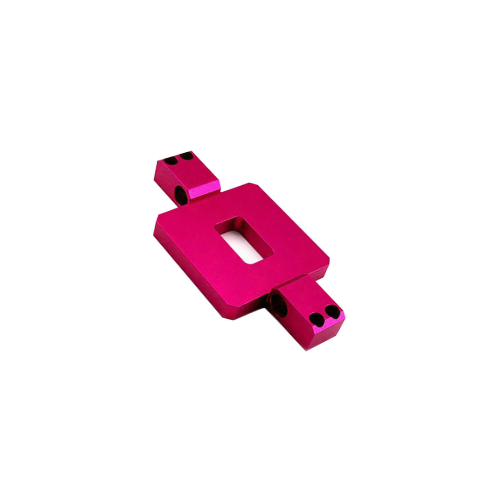

4-axis CNC machining caters to all your highly precise and durable components. This advanced manufacturing technique allows you to get parts with tight tolerances and complex geometries.

DEK offers you the most effective 4-axis CNC machining services, paying attention to your unique requirements and specifications. We are globally recognized for our sophisticated CNC machining technique. We don’t just guarantee you quality, durability, and tight precision, but you can rest assured that you will get your parts swiftly.

introduction

4-Axis CNC Machining Service - Highly Precise, Accurate, and Effective Service

No matter how complex your component design is, our highly precise and effective 4-axis CNC machining service enables us to achieve it. We are dedicated to understanding your unique requirements and delivering beyond your expectations.

At DEK, we appreciate all customers, so no matter what quantity you want, whether a few pieces or hundreds to thousands of units, we are here to help. Our state-of-the-art 4-axis CNC technological facilities, team of professionals, and quality materials allow us to deliver projects swiftly and cost-effectively.

- Custom finishes and surface treatment

- Worldwide delivery

- Tight tolerances of +\-0.005mm

- ISO 9001:2015, ISO 13485, and AS9100D certified

- Cost-effective service

- Fast turnaround time within 4 to 7 days.

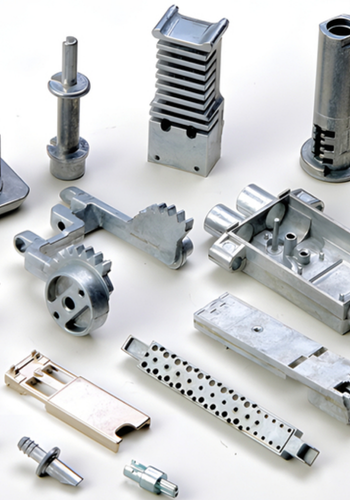

Material Choices for 4-axis CNC Machining

Métaux

Plastiques

Aluminium

Aluminum is a lightweight metal known for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It’s widely used in industries requiring durable yet low-density components.

You can rely on DEK to machine aluminum with high precision and clean finishes, making it suitable for projects where strength, weight, and appearance matter. We use our advanced 4-axis CNC machining service to maintain tight tolerances and consistent quality across parts. These parts include aerospace brackets, automotive engine housing, medical device casing, etc.

Alliage

Aluminum 2017A, 2024, 5052, 5083, 6060

Laiton

Brass is an alloy of copper and zinc, known for its corrosion resistance, electrical conductivity, and excellent machinability. Its bright gold-like appearance also makes it popular for aesthetic components in technical and decorative applications.

We machine brass at DEK with outstanding dimensional accuracy and smooth surface finishes. Our 4-axis capabilities allow precise shaping and hole alignment, especially for complex features. You’ll benefit from burr-free, polished parts that meet tight tolerances and quality standards for industrial-grade performance and visual appeal.

Alliage

Laiton 260, C360, Cz121

Cuivre

Copper is a soft yet durable metal known for its high electrical and thermal conductivity. It is often used in components requiring strong heat or electricity transfer, and it’s easy to machine with proper techniques.

At DEK, we machine copper with precision to achieve smooth, accurate surfaces and optimal tolerances. Our 4-axis CNC machining service ensures even complex parts are manufactured without distortion. We use copper in manufacturing components like electrical connector terminals, medical imaging system contacts, PCB heat spreaders, etc.

Alliage

Copper C101 and C110

Acier inoxydable

Stainless steel is a corrosion-resistant alloy known for its durability, strength, and hygienic properties. It is widely used across industries due to its resistance to oxidation, wear, and extreme conditions.

Using 4-axis CNC machining, DEK produces stainless steel parts with exceptional accuracy and surface quality. We ensure reliable finishes, sharp edges, and exact tolerances for parts that must perform under high stress or environmental exposure. You can expect robust, long-lasting components built with clean, efficient machining.

Alliage

Stainless Steel 301, 303, 321, 304, 304L

Titane

Titanium is a high-performance metal with an excellent strength-to-weight ratio, corrosion resistance, and biocompatibility. It's used in industries that demand lightweight yet strong and durable components under extreme conditions.

DEK machines titanium with advanced techniques to maintain dimensional integrity and achieve tight tolerances. Our 4-axis machining system handles complex shapes and contours smoothly. You'll receive parts that are strong, consistent, and finished with precision, ideal for high-performance applications that cannot compromise on quality.

Alliage

Titanium Grade 1, 2, and 5

Acier à outils

Tool steel is a hard, wear-resistant alloy used for components requiring excellent strength, toughness, and durability. It’s known for holding shape under pressure and resisting deformation even during intense use.

We machine tool steel with specialized tooling and precise 4-axis setups. Our process delivers tough components with reliable shapes, uniform tolerances, and high-quality surface finishes. You’ll benefit from parts that maintain their mechanical properties even in the most demanding manufacturing or tooling environments.

Alliage

Tool Steel A2, A3, D2, H13, O1

Zinc

Zinc is a corrosion-resistant metal that offers good strength, excellent castability, and dimensional stability. It’s often used for lightweight parts where toughness and formability are key.

DEK uses 4-axis CNC machining service to process zinc with care, ensuring sharp features and well-defined geometries. We optimize speed and quality, producing parts with clean finishes. You’ll get well-machined, cost-effective zinc components like aerospace sensor mounts, medical device casings, automotive carburetor parts, etc, that meet precise standards across your project requirements.

Alliage

Zamak 3

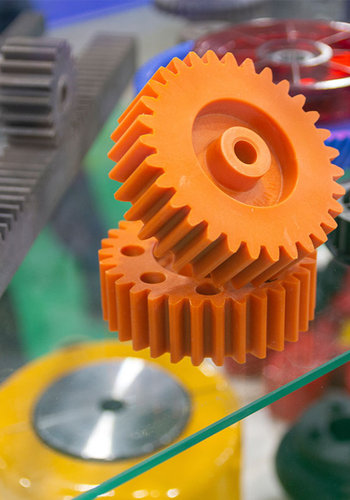

ABS

ABS is a lightweight thermoplastic known for its toughness, impact resistance, and ease of machining. It offers good dimensional stability, making it suitable for parts that need strength, surface quality, and moderate heat resistance.

At DEK, we use ABS to produce parts that require strong durability and accurate dimensions. Our 4-axis CNC machining service ensures precise contours, sharp edges, and consistent detailing even in complex designs. ABS machines cleanly, and we optimize feeds and tooling to minimize material stress. You’ll get smooth, professional finishes ready for functional and aesthetic applications. Whether for prototypes or low-volume production, you benefit from dependable machining quality and part consistency.

Nylon

Nylon or PA is a durable engineering plastic valued for its excellent mechanical properties, high wear resistance, and low friction. It is ideal for producing lightweight parts that must endure heavy loads or constant movement.

We machine Nylon at DEK using 4-axis setups that guarantee reliable precision in complex geometries. The material’s low friction is preserved by our tooling choices, giving you accurate parts like gear housing, medical device handles, bearing sleeves, etc. You can expect high-quality surface finishes with uniform dimensions across many batches.

Notes

Nylon 6, Nylon 6 (30% Glass Filled), Nylon 6/6 (30% Glass Filled), Nylon 6 Flame Retardant

PC

PC is a transparent thermoplastic with high impact resistance, toughness, and excellent dimensional stability. It withstands heat and mechanical stress, making it suitable for demanding applications requiring clarity or durability.

DEK machines PC with precision, ensuring tight tolerances and clean surfaces on all components. Our 4-axis equipment handles complex shapes, angled cuts, and undercuts with excellent repeatability. We optimize parameters to prevent cracking and preserve the integrity of each part. The result is durable, high-clarity parts that meet rigorous performance standards. You benefit from professional, clear finishes and accurate shaping suitable for both functional and visual applications.

PEEK

PEEK is a high-performance plastic with excellent chemical resistance, thermal stability, and mechanical strength. It maintains integrity in extreme environments and is often used in high-precision or high-stress conditions.

At DEK, we use advanced 4-axis CNC machining services to shape PEEK accurately and safely. Our experienced team controls speeds and feeds to avoid deformation, ensuring consistent dimensional quality across each piece. PEEK components, including spinal implants, pump wear rings, aerospace connectors, etc., come out clean, precisely machined, and ready for use in demanding industries. You’ll benefit from repeatable accuracy, exceptional surface quality, and reliable mechanical properties, which are all essential for parts that can’t fail under pressure.

POM

POM (Delrin) is a strong, low-friction plastic with high stiffness and wear resistance. It’s ideal for precision parts where dimensional accuracy and sliding properties are essential, especially in mechanical systems.

At DEK, we use 4-axis CNC machining to produce POM parts with detailed accuracy and uniform finishes. Our process handles the material’s hardness well, resulting in consistent tolerances and smooth sliding surfaces. We focus on eliminating burrs and maintaining clean cuts across all features. Your parts come out crisp, strong, and ready for direct use in structural or mechanical assemblies, where both form and function matter.

Notes

Delrin 150, Delrin AF (13% PTFE Filled), Delrin (30% Glass Filled)

PP

PP is a flexible, lightweight plastic with good chemical resistance and fatigue durability. It’s used for components that require toughness, elasticity, and low cost, particularly in environments where moisture or chemicals are present.

DEK machines PP with care using 4-axis setups that reduce material stress and ensure smooth surfaces. Despite its flexibility, we maintain consistent geometries and wall thicknesses in each part. Our techniques prevent warping or distortion, resulting in clean, functional components. You’ll get high-quality parts with excellent strength-to-weight ratios and surface finishes.

Notes

Homopolymère de PP, PP+GF(30%)

PTFE

PTFE is a slippery, chemically resistant plastic with extremely low friction and excellent thermal stability. It's often chosen for parts that need to withstand aggressive environments or continuous motion.

DEK uses advanced 4-axis CNC machining service to cut PTFE with care, achieving smooth, burr-free edges and detailed geometries. Our team controls every step to avoid material swelling or deformation. The result is precise, high-performance parts that resist heat, chemicals, and wear. You get ultra-smooth components that maintain tight tolerances, even on intricate shapes. Whether you need prototypes or production runs, your PTFE parts, like aerospace sealing rings, valve seats, insulating bushings, etc, come out functional and consistent every time.

Polyvalent Options de finition de surface

Sablage de perles

We can effectively remove rust, paint, scale, and other contaminants from various surfaces using bead […]

Polissage

We enhance the visual appeal of components by providing a smooth and reflective finish with […]

Électropolissage

Electropolishing enhances the corrosion resistance of metal by removing impurities and creating a clean, passive […]

Instantané & Citations précises

Nous n'utilisons pas d'outils de devis automatisés en ligne, car ils sont très imprécis. Les plateformes de devis en ligne reposent uniquement sur des calculs basés sur des montants de coupe et des coefficients fixes, et ne tiennent pas compte des nuances de traitement réelles, comme la déformation du matériau après le traitement thermique, les exigences de tolérance strictes, le meulage après le traitement thermique, etc. Par conséquent, les calculs de prix automatisés peuvent entraîner des inexactitudes et, en fin de compte, augmenter vos coûts.

Mais chez DEK, vous pouvez être tranquille !

Nos devis sont à la fois rentables et précis, car nous disposons d'une équipe d'ingénieurs mécaniciens professionnels qui examinent méticuleusement chaque dessin. Ces ingénieurs ont plus de 10 ans d'expérience et possèdent une grande expertise en matière de programmation, de fonctionnement des machines, de post-traitement, de propriétés des matériaux, etc. Nous vous garantissons des devis précis dans un délai de 6 heures.

Nos avantages

2300+ ingénieurs Aimer travailler avec nous

Géométries complexes

With DEK’s advanced 4-axis CNC machining, we create complex parts that are difficult with traditional methods. Our machines rotate and cut on multiple axes, allowing you to achieve intricate designs in a single setup. This saves time, improves consistency, and supports even the most demanding geometries.

Haute précision

We consistently deliver parts with tight tolerances and clean finishes. You can trust our team to meet your exact specifications every time. Whether it’s functional performance or aesthetic quality, our precision machining ensures every part fits and works perfectly in your final assembly or system.

Rapport coût-efficacité

Our efficient 4-axis CNC machining setup reduces material waste and shortens production time. DEK helps you keep costs down while still delivering high-quality results. Our streamlined workflow and expert machinists ensure you get the best value for your investment, whether it’s a single part or bulk production.

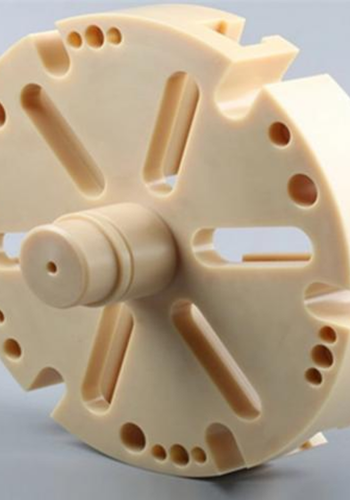

Polyvalence des matériaux

DEK works with a wide range of metals and plastics in 4-axis CNC machining, giving you full freedom in design and performance needs. Whether your part requires strength, heat resistance, or lightness, we can recommend the ideal material. We help match the right material to your specific project for reliable and lasting performance.

Délai d'exécution rapide

Time is often critical, and we make sure you never wait too long. DEK’s 4-axis CNC machining is built for speed and precision, helping you meet tight deadlines. Our team works efficiently to deliver your parts quickly and accurately. You’ll receive your components fast and right the first time.

Assurance qualité

We never compromise on quality. Every part produced by DEK undergoes strict inspection and quality control processes. From material selection to final delivery, we ensure accuracy, consistency, and reliability throughout. You get dependable results that meet your standards and exceed expectations.

Notre Processus de commande

Envoyer l'appel d'offres

Envoyer l'appel d'offres avec les dessins 2D/3D et les exigences détaillées par courrier électronique ou par formulaire en ligne.

Revue et citation

Notre équipe d'ingénieurs examinera soigneusement chaque dessin et fournira un devis précis dans les 6 heures.

Confirmer la commande

Confirmez le devis, les détails et le calendrier de livraison, puis signez le contrat.

Production

Organiser le processus de production, lancer la programmation et l'usinage.

Contrôle de la qualité

Contrôle strict de la qualité pendant la production et l'inspection finale.

Emballage et expédition

Emballez les pièces, apposez les étiquettes d'identification des pièces et commencez l'expédition.

Envoyer l'appel d'offres 222

Revue et citation

Confirmer la commande

Production

QC

Livraison

FAQ

Usinage CNC 4 axes FAQ sur l'achat

Obtenir un devis précis Pour vos prochains projets

Que votre projet soit simple ou compliqué, qu'il s'agisse de métal ou de plastique, vous obtiendrez un devis précis dans les 6 heures.

Obtenir un devis aujourd'huiSavoir Usinage CNC 4 axes

What is 4-axis CNC Machining?

4-axis CNC machining is a type of computer-controlled manufacturing process where a cutting tool moves along four different axes to shape materials like metal or plastic into precise components.

The three primary axes are X, Y, and Z, which cover left-right, forward-backward, and up-down movements. The fourth axis, typically called the A axis, allows rotation around one of the three linear axes, which is usually the X-axis.

This additional movement enables the machine to perform more complex cuts and work on multiple sides of a part without repositioning it manually. As a result, you can achieve greater accuracy and consistency across all features of a component. It’s especially useful for parts with curved or cylindrical shapes, angled features, or operations on multiple faces.

What are the Advantages of 4-axis CNC machining?

4-axis CNC machining provides an ideal balance between complexity and efficiency. It allows you to produce highly detailed and accurate parts while reducing manual setups and improving lead times.

Here are some advantages of 4-axis CNC machining:

- Cuts multiple faces at once

- Reduces setup time

- Improves dimensional accuracy

- Enables complex part shapes

- Allows tight tolerance control

- Speeds up the production cycle

When Do You Need 4-axis CNC Machining Service?

You need a 4-axis CNC machining service when your part designs involve multiple sides, curved surfaces, or features that would be difficult to reach using only three axes.

It’s especially beneficial when you want to reduce part repositioning or avoid errors from multiple setups. If you’re creating parts with angled features, spiral patterns, or cylindrical holes not aligned with the main axis, the fourth axis becomes essential.

It’s also a great choice when you're working on parts that require high accuracy and consistent results in medium to high production runs. When time, precision, and complexity all matter to your project, turning to 4-axis CNC machining helps you hit all your quality and performance goals.