High Volume CNC Machining Service

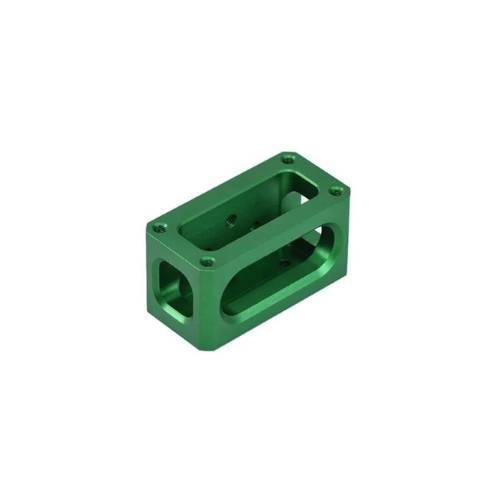

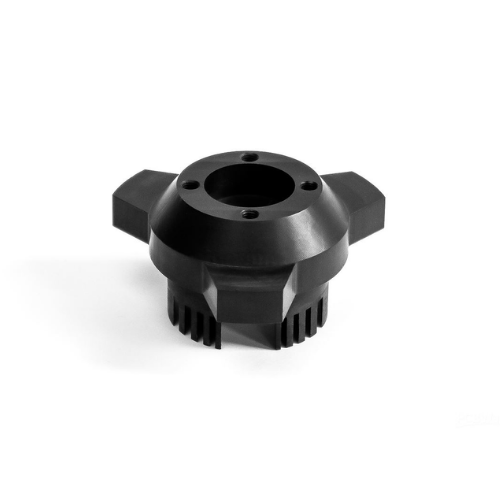

High volume CNC machining caters to your large-scale component production. At DEK, we offer high-quality, precise parts that meet your specific project requirements using a variety of materials.

With our high volume CNC machining process, you can receive several batches of components quickly and cost-effectively. Whether you have specific material, finishing, or design requirements or you need guidance to make a selection, we are here to help. Contact us today.

introduction

High Volume CNC Machining: Precise, Scalable, and Efficient

When you require precise high-volume production with fast turnaround time, quality delivery, and cost effectiveness, DEK is your go-to partner.

With our state-of-the-art technological facilities and machines, readily available materials, coupled with our team of experts, we are sure to deliver right on time without compromising quality. Whether you need a thousand components or several thousand, we are sure to deliver.

Our top-notch high volume CNC machining enables us to serve across several industries while also ensuring customer satisfaction.

- Fast delivery

- Un équipement de pointe

- ±0.005mm tight tolerances

- Highly scalable solutions

- Cost effectiveness

- Creation of complex geometries

High Volume CNC Machining Materials

EDM par immersion

DEK provides first-class Sinker EDM services and is committed to providing customers with high-quality machined […]

High Volume CNC Machining Matériaux

Métaux

Plastiques

Aluminium

Aluminum is lightweight, corrosion-resistant, and highly machinable. It is perfect for parts that demand strength without much weight. Beyond that, it offers excellent thermal and electrical conductivity.

At DEK, we machine high volumes of aluminum material for aerospace, automotive, and electronics industries. With our advanced multi-axis CNC systems, we maintain tight tolerances and high surface finishes, ensuring consistent quality from the first part to the last.

Alliages

AL6060, AL6061, AL6063, AL6082, AL7050 etc.

Laiton

Brass is a yellowish copper-zinc alloy that is known for its corrosion resistance, excellent thermal and electrical conductivity, high machinability, and attractive surface finish.

With DEK's high volume CNC machining services, we machine different alloys of brass, like 260, C360, C230, etc., to create electrical, plumbing, and automotive components like custom fittings, connectors, and fluid control parts in high volumes. Our team ensures a perfect balance of efficiency, detailing, and precision to meet strict industry requirements.

Alliages

C360, C260, Cz121

Cuivre

Copper is a reddish metal known for its outstanding thermal and electrical conductivity, malleability, ductility, corrosion resistance, and visual appeal. It also requires a low-maintenance structure and has a long lifespan.

At DEK, we machine power electronics and energy systems components like copper terminals, bus bars, heat sinks, and connectors. Our high-speed CNC machines ensure tight tolerances, high precision, and smooth finishes, which are essential for electrical performance and heat transfer.

Alliages

Copper C101, Copper C110

Acier inoxydable

Stainless steel offers excellent durability, corrosion resistance, and strength, making it ideal for harsh or sterile environments. It also offers longevity, low maintenance, and aesthetic appeal.

We machine stainless steel materials, like 304, 304L, 316, etc., at DEK for medical devices, food processing equipment, construction, manufacturing, aerospace, oil and gas, and marine parts. Our precision machining and strict quality checks guarantee long-lasting parts with accurate detailing across high-volume runs.

Alliages

Stainless Steel 301, 303, 321, 304, 304L, 316, 316L, etc.

Titane

Titanium is strong, lightweight, corrosion-resistant, and heat-resistant. It is durable, non-magnetic, and biocompatible, making it ideal for extreme environments and suitable for applications where environmental conditions matter.

We offer high volume CNC machining service for high-grade titanium parts for aerospace, medical, and high-performance automotive applications. At DEK, we apply special tooling and strategies to handle this demanding material, delivering parts with excellent structural integrity, precision tolerances, and fine detail, even at high volumes.

Alliages

Titanium Grade 1, Grade 2, Grade 5

Tungstène

Tungsten is a very dense metal offering features like high melting point, resistance to wear, good heat conductivity, durability, and resistance to deformation, making it suitable for military grade applications.

At DEK, we machine all types of tungsten into heat-resistant components, aerospace, industrial and manufacturing parts, and heavy-duty components. You benefit from tight tolerances and precision, high-quality and durable parts, even with this hard-to-machine material. Perfect for missile and rocket components, furnace parts, ballistic penetrators, etc.

Alliages

Tungsten Steel YG15, YL50, YT15, YW1, etc.

Zinc

Zinc is affordable, corrosion-resistant, has good electrical conductivity, and is easy to machine with good dimensional stability. It is also commonly used as an alloy agent in metal production.

At DEK, we machine zinc material for automotive accessories, consumer hardware, and lock systems. Our CNC processes produce clean, accurate geometries quickly and efficiently, making zinc a solid choice for mass production. We ensure dimensional consistency, smooth finishes, and an efficient high-volume fabrication process.

Alliage

Zamak 3

ABS

ABS is impact-resistant, lightweight, durable, easy to process, and offers good dimensional stability, making it popular for functional parts. It is a versatile material, making it suitable for different applications.

We machine different types of ABS at DEK to manufacture consumer goods, medical devices, automotive interior parts, and industrial products like covers, panels, household appliances, and electronic housings. Our precision methods help achieve clean edges and smooth finishes on every part, even in large volumes.

Acrylic/PMMA

Acrylic is a clear plastic that’s easy to machine and polish, with excellent optical clarity. It has versatile applications, resistance to chemicals and UV, is transparent, and is available in a wide range of colours.

We machine acrylic material used in retail, medical, automotive, and electrical industries for display covers, signage, light guides, optical lenses, dental prosthetics, and instrument panels. Our finishing process ensures crystal-clear edges with precision, high quality, and perfect transparency on every component.

Delrin

Delrin has unique properties like high stiffness, excellent wear resistance, good dimensional stability, chemical resistance, and low friction, which make it perfect for high-precision moving parts.

At DEK, we machine Delrin to create medical devices, automation equipment, robotics, and electrical components. Perfect for fasteners, gears, bearings, rollers, etc. We also focus on tight tolerances and repeatability, high quality, and precision to ensure flawless operation in every part while also producing large volumes.

Notes

Delrin 150, Delrin AF, Delrin (30% Glass Filled)

Nylon

Nylon is a strong, wear-resistant plastic used in dynamic, load-bearing parts. It is versatile, flexible, durable, resistant to chemicals and abrasion, and also offers a low coefficient of friction.

We use nylon at DEK to produce automotive, aerospace, and machinery components like gears, spacers, brackets, plug housing, and other wear-resistant components. Our temperature-controlled processes help minimise warping and maintain accuracy throughout our high-volume production.

Notes

Nylon 6, Nylon 66

PEEK

PEEK is a high-performance thermoplastic known for its resistance to chemicals, heat, and wear. It also offers other properties like low moisture absorption, biocompatibility, ease of machining, etc.

At DEK, we machine PEEK into parts for aerospace, medical, electrical, automotive, and oil & gas industries. Our CNC expertise helps preserve PEEK’s properties while achieving precision across complex geometries and high volumes. Perfect for producing connectors, bearings, bushings, medical implants, etc.

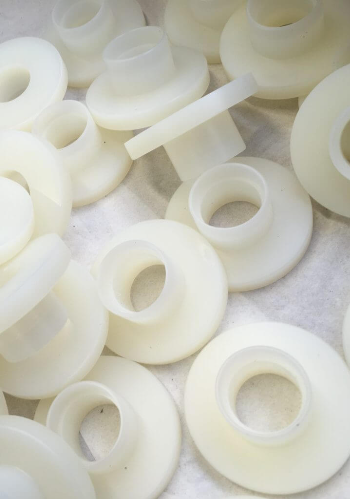

PP

Polypropylene is lightweight, chemical-resistant, and often used in clean or sterile environments. It is used in CNC machining due to its durability, chemical resistance, fatigue resistance, machinability, etc.

At DEK, we machine PP into components used in healthcare, packaging, automotive, and research industries. These include lab trays, enclosures, construction materials, stationery items, medical containers, etc. Our high-volume workflows ensure clean, burr-free parts with excellent chemical resistance.

Notes

PP Homopolyme, PP+GF(30%)

PTFE

PTFE is non-stick, chemically inert, and has very low friction, and it is ideal for sealing and fluid applications. It has excellent temperature and chemical resistance and low moisture absorption properties.

We machine PTFE material at DEK for chemical processing, food-grade systems, and pharmaceutical, manufacturing, and electronics components. Our machines handle this soft material carefully to avoid deformation and achieve leak-proof precision. Commonly used for non-stick cookware coatings, seals, and gaskets in industrial applications, etc.

Instantané & Citations précises

Nous n'utilisons pas d'outils de devis automatisés en ligne, car ils sont très imprécis. Les plateformes de devis en ligne reposent uniquement sur des calculs basés sur des montants de coupe et des coefficients fixes, et ne tiennent pas compte des nuances de traitement réelles, comme la déformation du matériau après le traitement thermique, les exigences de tolérance strictes, le meulage après le traitement thermique, etc. Par conséquent, les calculs de prix automatisés peuvent entraîner des inexactitudes et, en fin de compte, augmenter vos coûts.

Mais chez DEK, vous pouvez être tranquille !

Nos devis sont à la fois rentables et précis, car nous disposons d'une équipe d'ingénieurs mécaniciens professionnels qui examinent méticuleusement chaque dessin. Ces ingénieurs ont plus de 10 ans d'expérience et possèdent une grande expertise en matière de programmation, de fonctionnement des machines, de post-traitement, de propriétés des matériaux, etc. Nous vous garantissons des devis précis dans un délai de 6 heures.

Nos avantages

2300+ ingénieurs Aimer travailler avec nous

Certified Quality Assurance

We don’t just claim quality, we prove it. DEK operates under strict certified quality standards, including ISO 9001 and other industry-specific certifications. Every high volume CNC machining project is backed by rigorous inspections, statistical process controls, and full traceability.

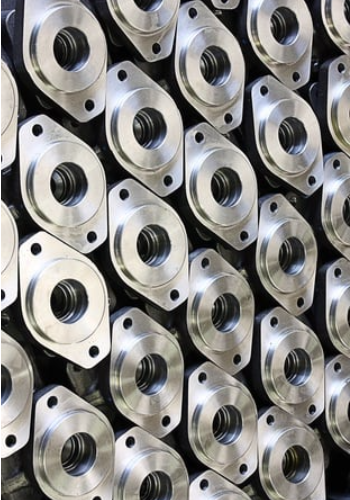

Scalable Production

DEK’s facilities are built for large-scale production. Whether you need 10,000 parts this month or 100,000 next quarter, we scale your production quickly and efficiently. Our automated processes, high-capacity machinery, and streamlined workflows ensure we maintain lead times without sacrificing quality.

Géométries complexes

With DEK’s advanced multi-axis CNC capabilities, we can machine even the most intricate geometries without compromising on speed or quality. You can bring us your most challenging part designs, and we’ll execute them with confidence. No design is too complex.

Global Reliable Logistics

No matter where you are, DEK delivers. We serve customers in over 50 countries with reliable shipping options and international logistics partners. You can count on the timely, safe delivery of your machined parts. Whether it’s a one-time batch or ongoing mass production, our global supply chain remains smooth and uninterrupted.

Prix compétitifs

High volume CNC machining with DEK gives you more value per part. Our efficient operations, automation, and bulk material sourcing allow us to offer highly competitive prices without cutting corners. You benefit from reduced per-unit costs while maintaining top-tier quality.

Délais courts

At DEK, speed doesn’t come at the expense of quality. Our optimised workflows and modern CNC systems enable us to deliver large production runs faster than many competitors. From the moment you place your order to the final shipment, we ensure your project stays on schedule.

Notre Processus de commande

Envoyer l'appel d'offres

Envoyer l'appel d'offres avec les dessins 2D/3D et les exigences détaillées par courrier électronique ou par formulaire en ligne.

Revue et citation

Notre équipe d'ingénieurs examinera soigneusement chaque dessin et fournira un devis précis dans les 6 heures.

Confirmer la commande

Confirmez le devis, les détails et le calendrier de livraison, puis signez le contrat.

Production

Organiser le processus de production, lancer la programmation et l'usinage.

Contrôle de la qualité

Contrôle strict de la qualité pendant la production et l'inspection finale.

Emballage et expédition

Emballez les pièces, apposez les étiquettes d'identification des pièces et commencez l'expédition.

Envoyer l'appel d'offres 222

Revue et citation

Confirmer la commande

Production

QC

Livraison

FAQ

High Volume CNC Machining FAQ sur l'achat

Obtenir un devis précis Pour vos prochains projets

Que votre projet soit simple ou compliqué, qu'il s'agisse de métal ou de plastique, vous obtiendrez un devis précis dans les 6 heures.

Obtenir un devis aujourd'huiComprendre High Volume CNC Machining

What is High Volume CNC Machining?

High volume CNC machining is a manufacturing process used to produce large quantities of parts, often in the thousands, with high precision and consistency. It uses computer-controlled equipment to automate the cutting, drilling, and milling of raw materials into finished components.

This approach is ideal when you need consistent, repeatable parts over long production runs. If you're manufacturing consumer products, automotive parts, or industrial equipment, high volume CNC machining helps you meet demand efficiently. It’s a cost-effective option when economies of scale matter, as the per-unit cost drops significantly as the volume increases.

What are the Advantages of High Volume CNC Machining?

High volume CNC machining offers an efficient, cost-saving solution for producing consistent parts in large quantities. This method is best when you're producing at high scale and want precision, speed, and cost efficiency combined.

- Lower cost per unit

- Consistent quality and repeatability

- Vitesse de production élevée

- Efficient use of materials

- Ideal for mass production

- Streamlined quality control processes

- Supports both simple and complex part designs

When Do You Need High Volume CNC Machining?

You need high volume CNC machining when your production requires a large number of identical parts with strict consistency. It’s ideal for the mass production of components used in industries like automotive, aerospace, and consumer electronics.

If you're scaling up a product for market release or need ongoing supply for an established product, high volume CNC machining ensures fast, repeatable results. This service is also useful when minimising per-part cost is a priority, especially in long-term manufacturing. It helps maintain quality, speeds up delivery, and supports long production cycles without interruptions.