Superalloys CNC Machining Service

Superalloys CNC machining produces strong, accurate parts from tough metals, offering cutting, drilling, shaping, and finishing for aerospace, energy, and medical industry needs.

DEK specializes in machining complex superalloy components with tight tolerances. With expertise that ensures reliable performance, even for the most demanding applications in high-stress environments. DEK stands out by using advanced machinery and experienced professionals to work with tough materials, delivering higher precision, quicker production, and reliable quality for the aerospace, energy, and medical industries.

introduction

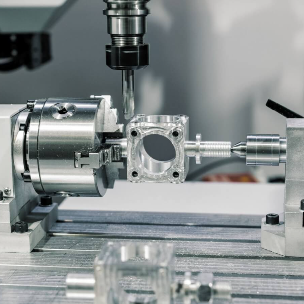

Superalloys CNC Machining Designed for Extreme Precision

DEK provides engineered CNC solutions for complex superalloy parts, combining advanced machinery and expert techniques to deliver precise, durable components for demanding industries.

We specialize in CNC machining services for superalloys that demand the highest levels of precision and reliability. Using state-of-the-art 4-axis and 5-axis CNC machines, we expertly handle complex geometries and tight tolerances that superalloys require. Our advanced tooling, combined with optimized cutting, ensures minimal tool wear and reliable surface finishes. From prototype development to full-scale production, DEK delivers consistent quality parts designed to perform in extreme conditions.

With DEK’s expertise and equipment, clients benefit from enhanced part durability, reduced lead times, and scalable production options.

- Advanced CNC machines

- High-precision tooling

- Tight tolerance control

- In-process quality checks

- Complex geometry support

- Scalable production runs

Matériaux for Superalloys CNC Machining

Hastelloy

Hastelloy is a corrosion-resistant superalloy ideal for harsh chemical and marine environments. Known for its strength and durability under extreme heat and pressure, it performs exceptionally in chemical plants, aerospace systems, and marine hardware.

DEK’s superalloys CNC machining services offer precision manufacturing of Hastelloy alloys such as C-22, C-276, and X. We deliver components with clean edges, tight tolerances, and high repeatability. Hastelloy is perfect for parts exposed to oxidizers, strong acids, and aggressive fluids.

Alliages

Hastelloy C-22, C-276, X, B, G-30

Inconel

Inconel is a nickel-based superalloy designed for high-temperature and high-stress applications. It excels in environments with extreme heat, oxidation, or corrosive elements and is commonly used in jet engines, exhaust systems, and reactors.

Our superalloys CNC machining services specialize in Inconel alloys such as 625, 718, and 600, producing highly accurate parts with excellent finishes. Inconel maintains strength at elevated temperatures and resists scaling and cracking, making it essential for mission-critical components in aerospace and energy.

Alliage

Inconel 718, 625, 600, etc.

Monel

Monel is a high-strength, nickel-copper alloy with outstanding resistance to seawater, acids, and alkalis. It is widely used in marine engineering, chemical processing, and oil production systems.

DEK machines Monel alloys like 400, K-500, and 404, delivering consistent quality with tight tolerances and smooth finishes. This alloy performs reliably under high pressure and thermal stress. Monel is the material of choice for manufacturing valves, pumps, shafts, and heat exchangers that require superior corrosion resistance and durability.

Alliages

Monel 400, K-500, 404, R-405, 401

Instantané & Citations précises

Nous n'utilisons pas d'outils de devis automatisés en ligne, car ils sont très imprécis. Les plateformes de devis en ligne reposent uniquement sur des calculs basés sur des montants de coupe et des coefficients fixes, et ne tiennent pas compte des nuances de traitement réelles, comme la déformation du matériau après le traitement thermique, les exigences de tolérance strictes, le meulage après le traitement thermique, etc. Par conséquent, les calculs de prix automatisés peuvent entraîner des inexactitudes et, en fin de compte, augmenter vos coûts.

Mais chez DEK, vous pouvez être tranquille !

Nos devis sont à la fois rentables et précis, car nous disposons d'une équipe d'ingénieurs mécaniciens professionnels qui examinent méticuleusement chaque dessin. Ces ingénieurs ont plus de 10 ans d'expérience et possèdent une grande expertise en matière de programmation, de fonctionnement des machines, de post-traitement, de propriétés des matériaux, etc. Nous vous garantissons des devis précis dans un délai de 6 heures.

Nos avantages

2300+ ingénieurs Aimer travailler avec nous

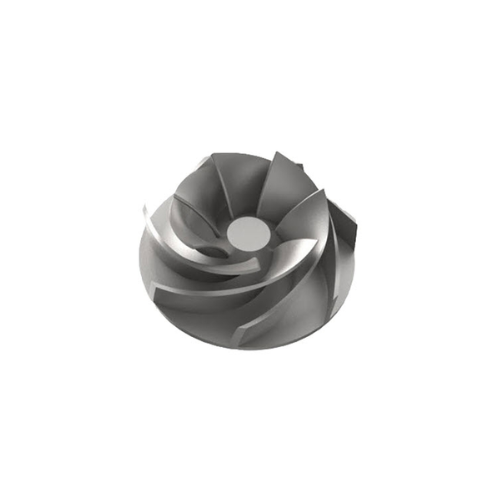

Complex Geometry Support

DEK uses multi-axis milling, Swiss turning, wire EDM, and grinding to manufacture intricate superalloy parts. This allows us to achieve complex features, tight angles, and fine details with consistent precision. Our machining capabilities make it possible to turn highly technical designs into fully functional, production-ready components.

Advanced Material Capability

Our CNC systems are optimized for machining hard-to-cut superalloys like Inconel, Hastelloy, and Monel. DEK has extensive experience working with these materials, which are known for their toughness and heat resistance. We maintain cutting performance and part integrity, even when dealing with the most challenging superalloys.

Ultra-High Precision

DEK delivers exceptional accuracy with tolerances as tight as ±0.005 mm for superalloy components. Our advanced CNC systems and skilled technicians ensure every detail meets exact specifications. This level of precision is essential for critical applications in aerospace, energy, and medical sectors.

Versatile Surface Finishes

DEK offers a variety of surface treatments for superalloy parts, including polishing, passivation, powder coating, and more. These finishes enhance corrosion resistance, reduce friction, and improve part appearance. Whether for performance or aesthetics, we tailor each finish to your specific material and application needs.

Flexible Order Volumes

DEK supports both low- and high-volume production for superalloy components, perfect for custom prototypes or full-scale manufacturing. We have no minimum order quantity (MOQ) requirements, making it easy for clients to scale up or down based on their project needs, while still receiving the same level of precision and service.

Normes de qualité certifiées

DEK operates under ISO 9001:2015, ISO 13485, and AS9100D certifications, ensuring every superalloy part meets the highest international quality standards. We follow strict processes and documentation protocols, making our services ideal for industries like aerospace and medical where compliance and traceability are critical.

Notre Processus de commande

Envoyer l'appel d'offres

Envoyer l'appel d'offres avec les dessins 2D/3D et les exigences détaillées par courrier électronique ou par formulaire en ligne.

Revue et citation

Notre équipe d'ingénieurs examinera soigneusement chaque dessin et fournira un devis précis dans les 6 heures.

Confirmer la commande

Confirmez le devis, les détails et le calendrier de livraison, puis signez le contrat.

Production

Organiser le processus de production, lancer la programmation et l'usinage.

Contrôle de la qualité

Contrôle strict de la qualité pendant la production et l'inspection finale.

Emballage et expédition

Emballez les pièces, apposez les étiquettes d'identification des pièces et commencez l'expédition.

Envoyer l'appel d'offres 222

Revue et citation

Confirmer la commande

Production

QC

Livraison

FAQ

Superalloys CNC Machining FAQ sur l'achat

Obtenir un devis précis Pour vos prochains projets

Que votre projet soit simple ou compliqué, qu'il s'agisse de métal ou de plastique, vous obtiendrez un devis précis dans les 6 heures.

Obtenir un devis aujourd'huiAbout Superalloys CNC Machining

What are Superalloys CNC Machining?

Superalloys CNC machining involves the precision manufacturing of components made from high-performance metal alloys designed to withstand extreme environments. These alloys, such as Inconel, Hastelloy, Waspaloy, and other nickel, cobalt, or iron-based materials, are commonly used in industries like aerospace, energy, and medical due to their exceptional strength, corrosion resistance, and heat tolerance. CNC (Computer Numerical Control) machines are essential for shaping these hard materials into complex parts with tight tolerances and high accuracy.

Because superalloys are difficult to machine using standard tools and methods, specialized CNC machining services are required. These services use advanced equipment, high-performance cutting tools, optimized parameters, and skilled technicians to ensure quality and efficiency. Whether for prototyping or full-scale production, superalloys CNC machining ensures that parts meet the highest standards of durability and precision in demanding applications.

What are the Advantages of Superalloys CNC Machining?

Superalloys CNC machining offers a range of advantages that make it a top choice for manufacturing high-performance components. These services ensure reliable, high-quality components made from tough materials.

- Exceptional durability

- Résistance aux hautes températures

- Corrosion protection

- Precision tolerances

- Complex part capability

- Consistent quality

- Superior surface finish

- Long service life

- Polyvalence des matériaux

- Prototype to production support

When Do You Need Superalloys CNC Machining?

Superalloys CNC machining is not just about handling tough materials; it's also essential when your project demands advanced manufacturing capabilities. These services are ideal for producing highly complex parts with intricate features, undercuts, or multi-axis contours that standard machining may struggle to achieve. With the use of 4-axis and 5-axis CNC machines, superalloy parts can be manufactured to exact specifications, even when dealing with challenging designs or tight space constraints.

Another key reason to choose superalloys CNC machining is when product performance and reliability are non-negotiable. These services ensure consistency across production runs, with strict quality control measures such as in-process monitoring, inspections, and material traceability. Whether for critical prototypes or high-volume runs, superalloy CNC machining guarantees not just part accuracy but also performance stability in real-world operating conditions.